Mark2000

Active Member

It's been about three years since I purchased this kit. After several false starts I've finally committed to finishing it. The world being what it is at the moment I certainly need the distraction.

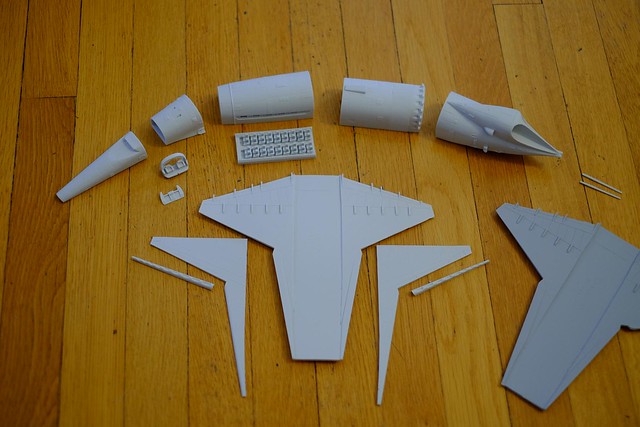

This is a really great kit. It's 18" long, packed full of detail, is a breeze to light, and has a full, incredibly accurate interior. I have a second wing base because the first had vane missing. Starship Modeller was really good about quickly sending me a replacement. Since this is a resin garage kit not everything fits together perfectly. The fuselage parts are a little wonky on the ends and the wing intakes dont fit the wing at all. The panel lines don't even line up. I'll have to putty redraw them.

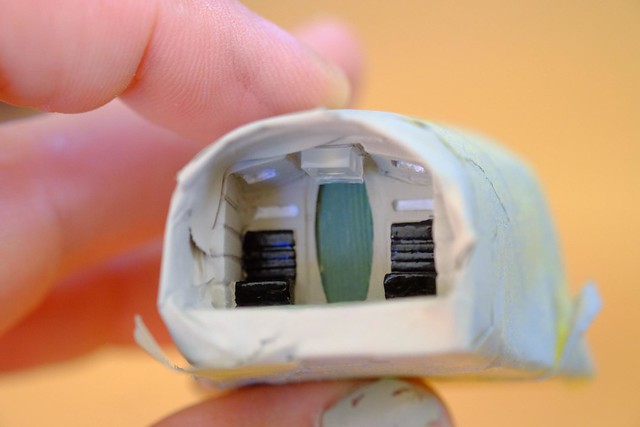

I painted and wired up the interiors. Four square LEDs in the cabin, one in the cockpit. I'll be running them to a 5v power supply through a 15ohm resistor.

This is a really great kit. It's 18" long, packed full of detail, is a breeze to light, and has a full, incredibly accurate interior. I have a second wing base because the first had vane missing. Starship Modeller was really good about quickly sending me a replacement. Since this is a resin garage kit not everything fits together perfectly. The fuselage parts are a little wonky on the ends and the wing intakes dont fit the wing at all. The panel lines don't even line up. I'll have to putty redraw them.

I painted and wired up the interiors. Four square LEDs in the cabin, one in the cockpit. I'll be running them to a 5v power supply through a 15ohm resistor.