Dalex

Active Member

So, just a quick update...

I still haven't picked up the materials to do the casting. I'm pretty sure I'm still going to be casting this in resin, but in the last while I've been thinking more and more about a better approach to the Key to Time...

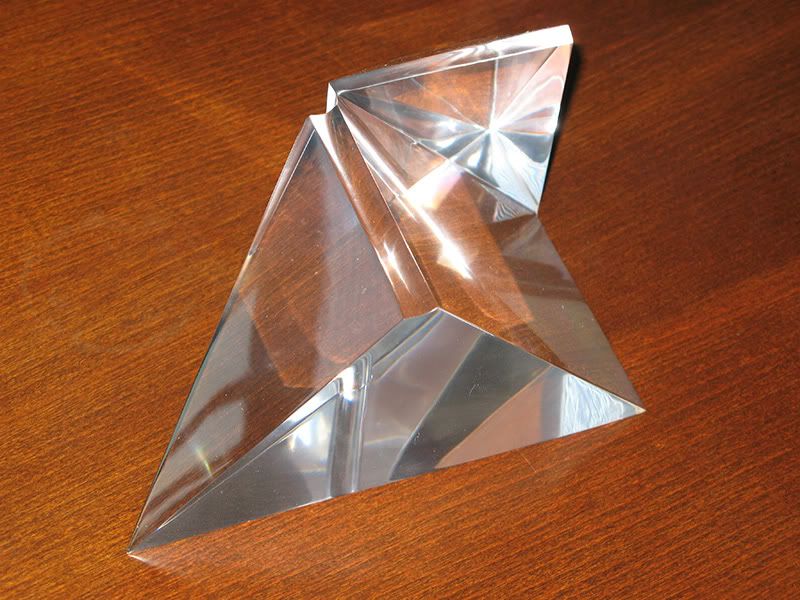

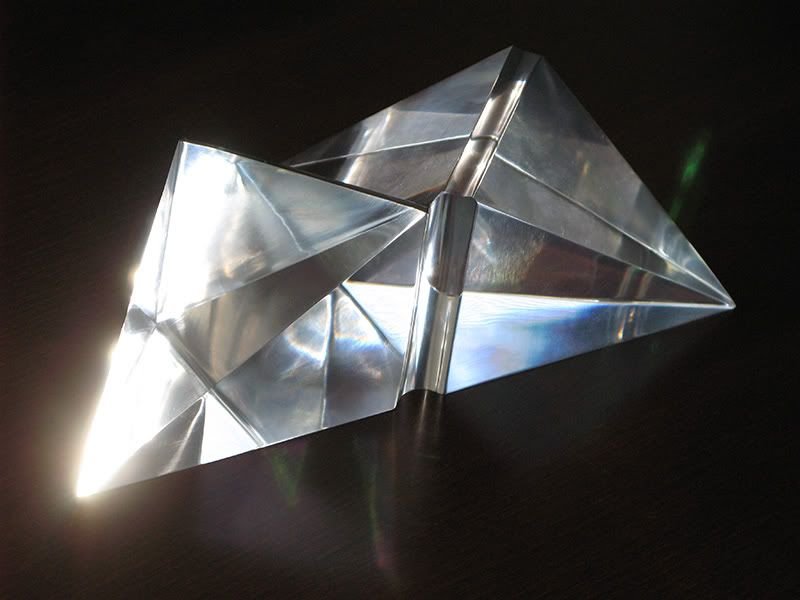

I've started making some inquiries into having the Key to Time professionally produced out of crystal or Lucite. (Lucite is what they use for doing those glass-like awards, and is similar to crystal but lighter and more durable.)

I've got Hydin getting a quote from his source. And I've found a place here in Toronto that looks like they'd be able create all six segments out of Lucite. (And as a bonus, the two people I've spoken to are big Dr. Who fans, so they're eager to see this happen!)

There's one huge catch though -- It's expensive. Like, really expensive. But I'm going to get some official quotes before I dismiss the idea entirely. Just doing a google image search on Lucite and imagining a Key to Time made out of it has me salivating....

I still haven't picked up the materials to do the casting. I'm pretty sure I'm still going to be casting this in resin, but in the last while I've been thinking more and more about a better approach to the Key to Time...

I've started making some inquiries into having the Key to Time professionally produced out of crystal or Lucite. (Lucite is what they use for doing those glass-like awards, and is similar to crystal but lighter and more durable.)

I've got Hydin getting a quote from his source. And I've found a place here in Toronto that looks like they'd be able create all six segments out of Lucite. (And as a bonus, the two people I've spoken to are big Dr. Who fans, so they're eager to see this happen!)

There's one huge catch though -- It's expensive. Like, really expensive. But I'm going to get some official quotes before I dismiss the idea entirely. Just doing a google image search on Lucite and imagining a Key to Time made out of it has me salivating....