Thanks Bondservnt, and thank for the tip regarding the molding process!

Could you make the support shell from plaster strips?

Here's a new update!

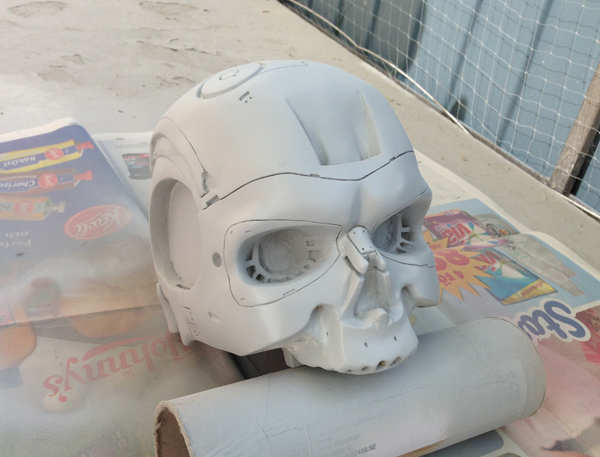

I decided I wasn't happy with my endoskull's face, I wanted it more "flat" like the real endoskull is.

I have been thinking about doing it for quite some time but because of the wire mesh inside of the skull this would be kind of hard.

Well today I went berzerk:

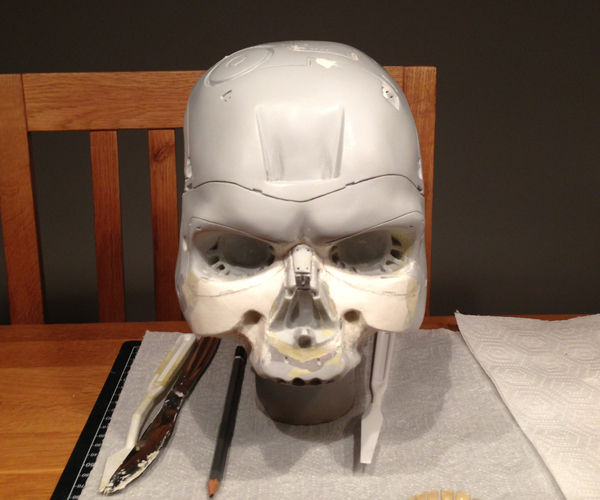

Step one, guide lines:

Step two, face off! I needed a beer for this step, I didn't want to crack anything else than the face:

Step three, reposition the nose and "gums":

Step four, add new clay to keep things in place:

Here you can actually see how far back I moved the face. This is much more accurate.

The remaining cheeks will be sanded down, and resurfaced.