lucavigg

New Member

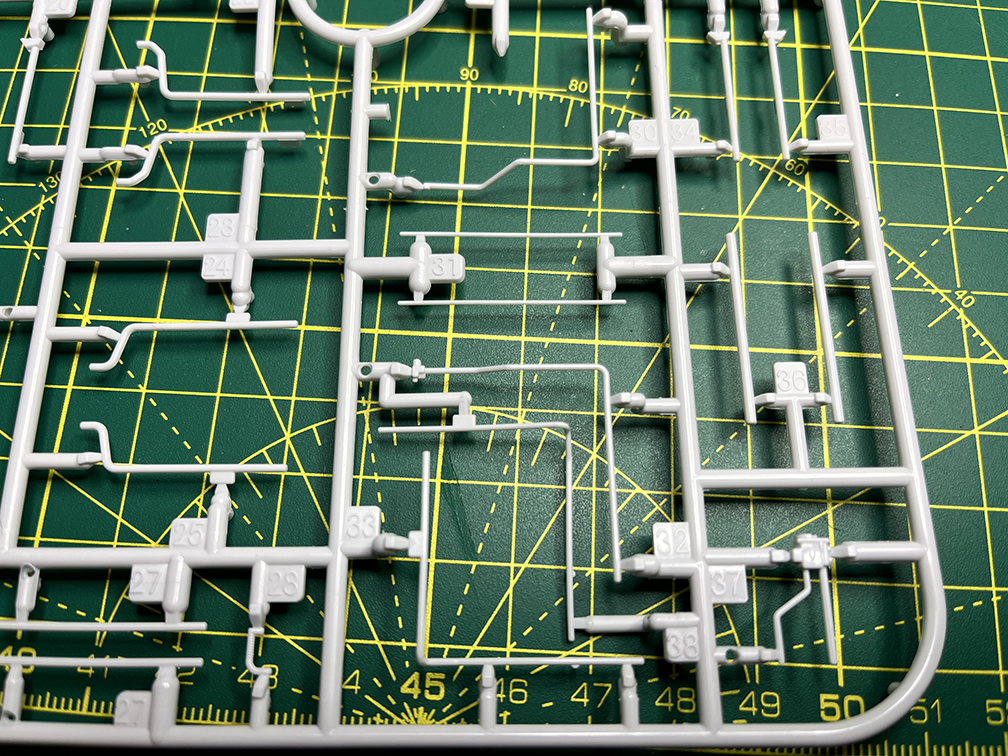

My son got me the Bandai 1/72 Y Wing for Christmas and I've just started identifying and cutting out parts. Does anyone have any suggestions for handling the very tiny parts on Sprue C? So far I've had to repair two parts that snapped while removing them from the sprue.

Sprue cutters tend to move the thick mount so much that the part distorts and scalpel is difficult to use without applying too much pressure. Next attempt would be a small saw blade to cut through and relieve some of the tension before cutting the other supports.

Hope everyone has a great New Year.

Sprue cutters tend to move the thick mount so much that the part distorts and scalpel is difficult to use without applying too much pressure. Next attempt would be a small saw blade to cut through and relieve some of the tension before cutting the other supports.

Hope everyone has a great New Year.