That is awesome! It's such an ambitious project... looking good!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:1 Stargate Life Size Replica! - "Too big?" Throwback to July 2022

- Thread starter Sendel

- Start date

Me want pictures!

AnubisGuard

Master Member

This is mind-blowing. I've always wished I could have a life-sized gate, somehow. Respect for being able to do it.

One thing I'm wondering and didn't see the info (apologies if I missed it) – is this based off tbe molds for the SGC/movie gate, or off of the smaller static gate that was used for location shoots?

One thing I'm wondering and didn't see the info (apologies if I missed it) – is this based off tbe molds for the SGC/movie gate, or off of the smaller static gate that was used for location shoots?

Sendel

Active Member

Thanks all of you ! We'll provide more pictures as soon as we'll be able to do it. Actually I can already share a few of them (see below) but you won't see a lot more than what you've already seen.

Good question. It's made from an original segment of the SGC gate used in SG-1 for 10 years (the first one after the main chevron) that we molded.

I don't think the gate used for location shoots was smaller. It would have needed to re-make all the pieces to gain around 1.5m only ? I really don't see any purpose for this. This gate when auctioned was described as measuring 22ft in diameter which is the same than the SGC one.

One thing I'm wondering and didn't see the info (apologies if I missed it) – is this based off tbe molds for the SGC/movie gate, or off of the smaller static gate that was used for location shoots?

Good question. It's made from an original segment of the SGC gate used in SG-1 for 10 years (the first one after the main chevron) that we molded.

I don't think the gate used for location shoots was smaller. It would have needed to re-make all the pieces to gain around 1.5m only ? I really don't see any purpose for this. This gate when auctioned was described as measuring 22ft in diameter which is the same than the SGC one.

Sendel

Active Member

Amazing! Any idea if you guys will be adding sound and effects?

Funny that you asked. Please have a look at the following video which is also showing the end of the first part of this project.

We did it !!! We built a freaking Stargate !

And to be clear : The SGA model of the gate as shown may never exist again as we really want to make a SG-1 on the base we have. So more work, more awesome things to see/learn/make !

I'll be back to the RPF in a few days to explain why it was really complicated to make this happen.

simon830

Active Member

Incredible! Is it not possible to intertwine when going to events having SGA or SG1 gates?Funny that you asked. Please have a look at the following video which is also showing the end of the first part of this project.The sound IS edited here but I had to due to everyone talking in the exhibition. It was exactly the same on site with the DHD buttons sound added too !

We did it !!! We built a freaking Stargate !

I can't wait to show you more pictures of it and explain all the technical details. For now enjoy the video !

And to be clear : The SGA model of the gate as shown may never exist again as we really want to make a SG-1 on the base we have. So more work, more awesome things to see/learn/make !

I'll be back to the RPF in a few days to explain why it was really complicated to make this happen.But before I have some social medias to hit with that.

So incredible. Great work.

Sendel

Active Member

Thanks everyone !

simon830 Do you mean being able to switch between the SGA and SG1 version ? It would be quite difficult as the SG1 needs it's spinning ring and the SGA needs it's complicated LED system... and there is the question of the paint. The SGA is mostly silver and the SG1 mostly black. :/ The best thing would be to have enough money to make both using the same panels. The SGA version wouldn't be as accurate as the SG1 one then but it's not that much a problem as we've seen there that no-one would notice anything.

simon830 Do you mean being able to switch between the SGA and SG1 version ? It would be quite difficult as the SG1 needs it's spinning ring and the SGA needs it's complicated LED system... and there is the question of the paint. The SGA is mostly silver and the SG1 mostly black. :/ The best thing would be to have enough money to make both using the same panels. The SGA version wouldn't be as accurate as the SG1 one then but it's not that much a problem as we've seen there that no-one would notice anything.

simon830

Active Member

No I meant as in going from 1 place to the other cause you needa disassemble it to travel right?Thanks everyone !

simon830 Do you mean being able to switch between the SGA and SG1 version ? It would be quite difficult as the SG1 needs it's spinning ring and the SGA needs it's complicated LED system... and there is the question of the paint. The SGA is mostly silver and the SG1 mostly black. :/ The best thing would be to have enough money to make both using the same panels. The SGA version wouldn't be as accurate as the SG1 one then but it's not that much a problem as we've seen there that no-one would notice anything.

Sendel

Active Member

No I meant as in going from 1 place to the other cause you needa disassemble it to travel right?

We will definitely work on making it more easily disassembled, so yeah the goal is to travel with it and then assemble it in convention or other locations where it would be needed. The idea would be to build the stone base of the outworld SG from SG1 and under it have a system to lift the gate without needing a crane.

Storm

Active Member

If you are interrested by some parts of the Stargate, some of them that the association have make and are not used will be for sell here

Les Enfants de Mac Gyver / Children of Mac Gyver

Les Enfants de Mac Gyver / Children of Mac Gyver

Sendel

Active Member

Hey guys, we're back ! And this time we're trying to make this gate stand on its own and MAKE IT SPIN !!!!!!

We're streaming the process on twitch everyday between 10 and 12h / 14 and 18h or more UTC+1.

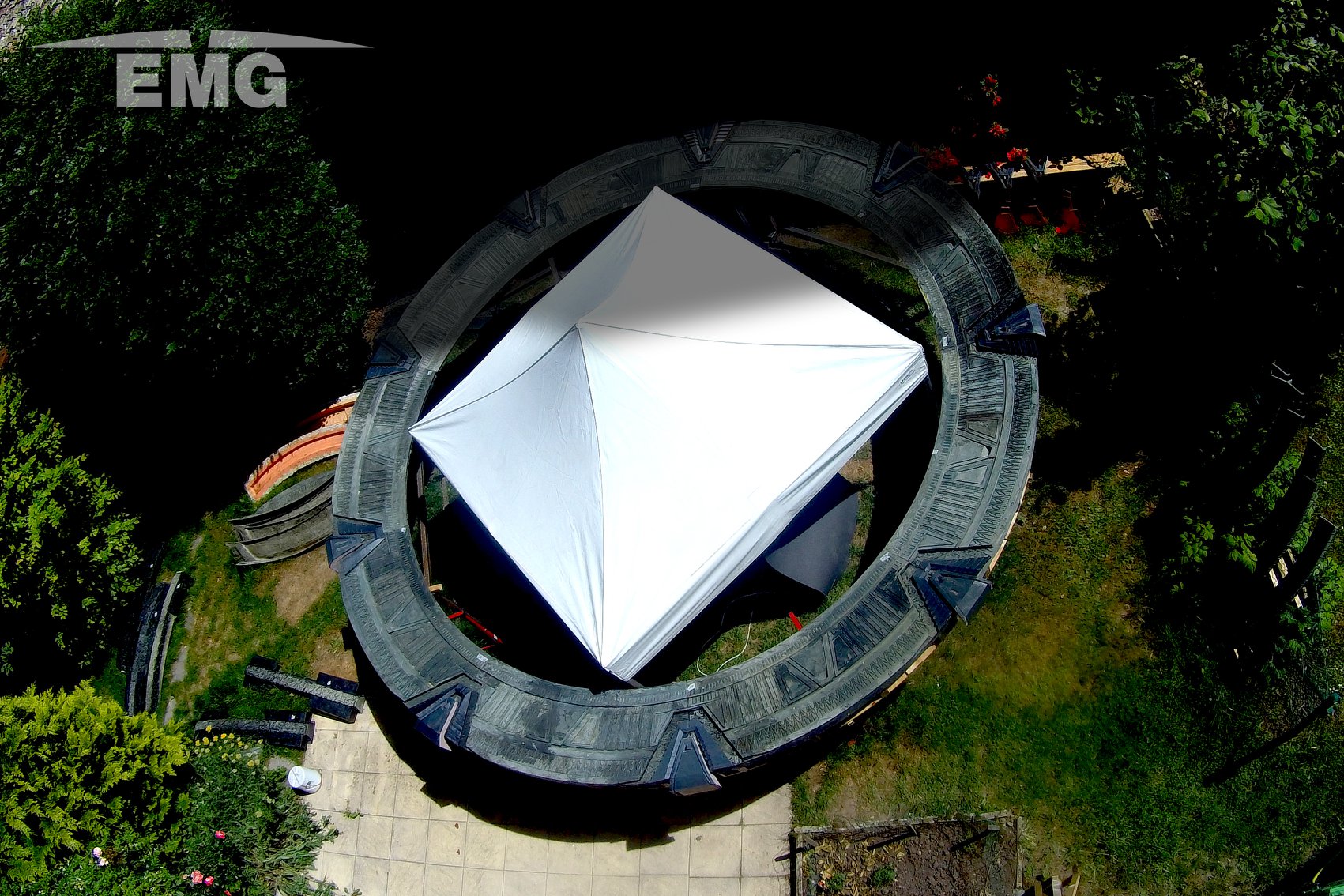

So, as you know this project has always been about a SG-1 Gate replica. The gate quit London a few weeks ago and is now back to Geneva thanks to our good friend Reis :

It's now back in the garden, we now have to remove part of the paint, create the spinning mecanism, correctly align the panels, fix the chevrons for an easy assembling / disassembling process (with magnets), fix the final lights...

First days were used to prepare a space we could use as a workshop in the house and the reassemble our original section of the stargate.

We're not quite sure we did it exactly right, it's 3cm thinner than expected. We tried different angles, this one seem right for the panels but not for the chevrons. Mysteries...

No chevron, I know, we had a small accident with the original one. Woops.

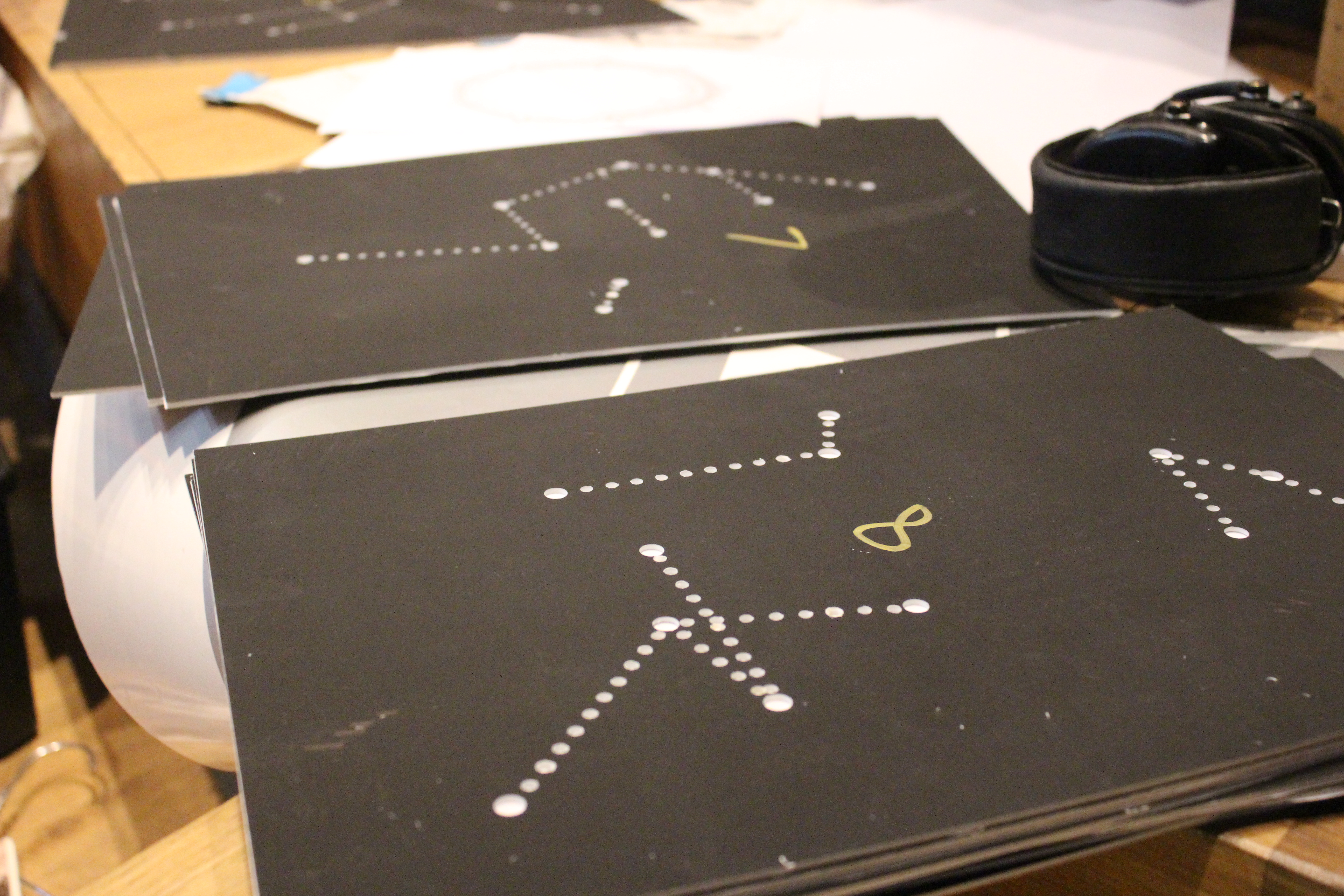

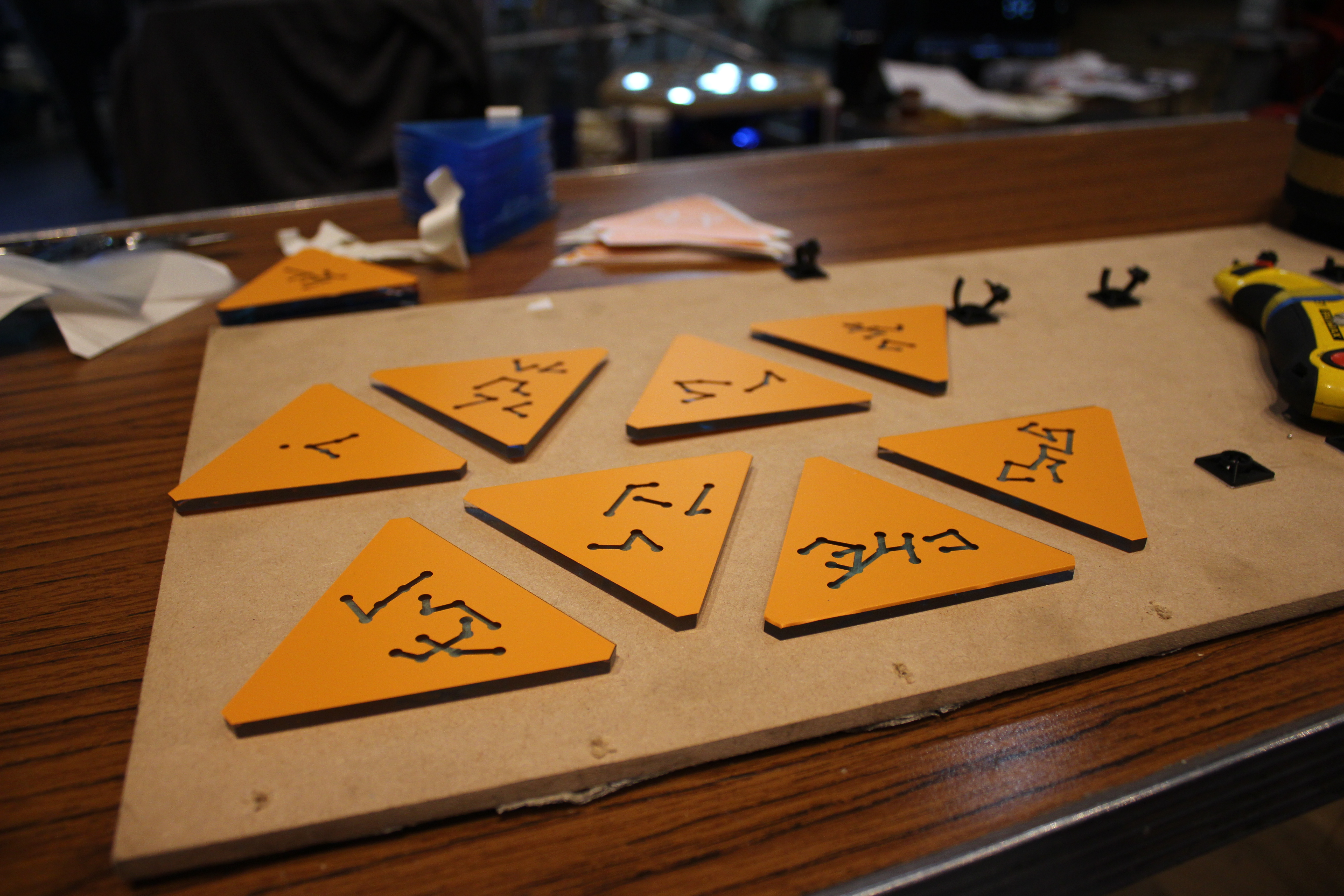

Then back to the glyphtrack :

As we don't have a giant CNC we made the lines ourselves, it took 3 days.

It seems like it's the right scale!

I'll post more really soon as we're working everyday on it.

Come and say hi on twitch if you can.

And never hesitate to ask questions of course.

We're streaming the process on twitch everyday between 10 and 12h / 14 and 18h or more UTC+1.

So, as you know this project has always been about a SG-1 Gate replica. The gate quit London a few weeks ago and is now back to Geneva thanks to our good friend Reis :

It's now back in the garden, we now have to remove part of the paint, create the spinning mecanism, correctly align the panels, fix the chevrons for an easy assembling / disassembling process (with magnets), fix the final lights...

First days were used to prepare a space we could use as a workshop in the house and the reassemble our original section of the stargate.

We're not quite sure we did it exactly right, it's 3cm thinner than expected. We tried different angles, this one seem right for the panels but not for the chevrons. Mysteries...

No chevron, I know, we had a small accident with the original one. Woops.

Then back to the glyphtrack :

As we don't have a giant CNC we made the lines ourselves, it took 3 days.

It seems like it's the right scale!

I'll post more really soon as we're working everyday on it.

Come and say hi on twitch if you can.

And never hesitate to ask questions of course.

Sendel

Active Member

Damned, it’s been nearly one year since our last update ???? Ok it was one Covid year, but still…

Anyway, things are not going as we’d love to (of course, for that kind of project it’s expected) but more of that later. I’ll continue where I stopped.

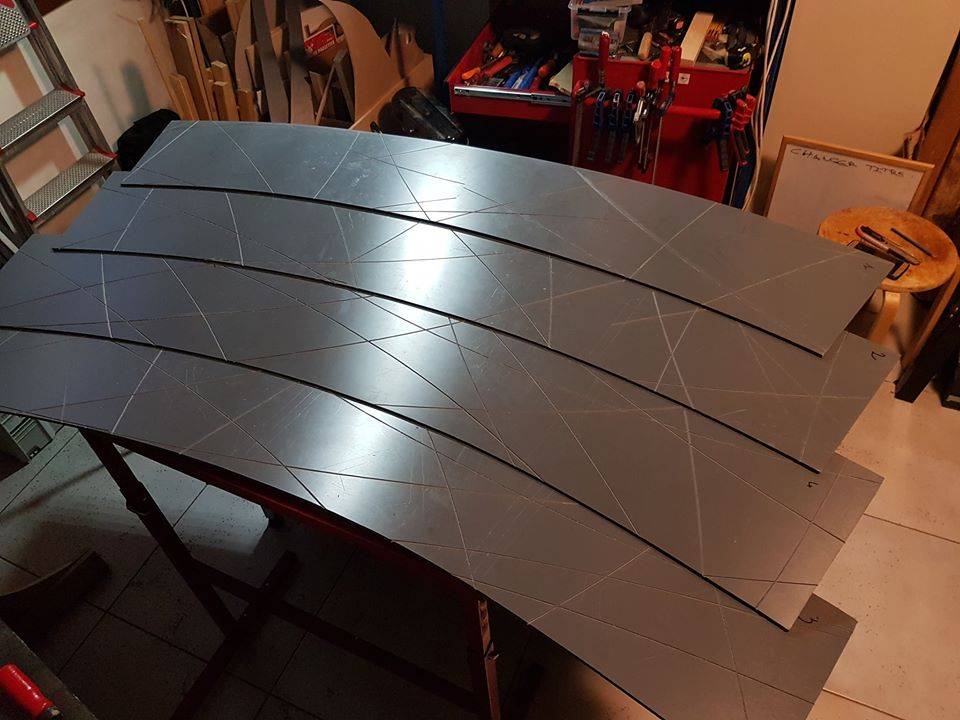

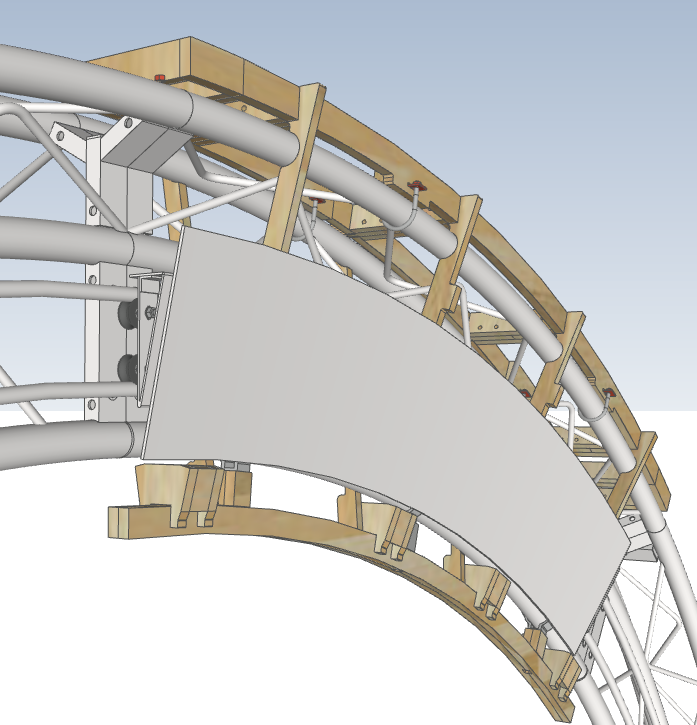

So, we got the SG back from London, we first disassembled all of it to remove the blue atlantis paint, which took us so much time and effort, it was a painful task but we had to. Then we used some boat clear coat on the wood to protect it from the sun and the rain.

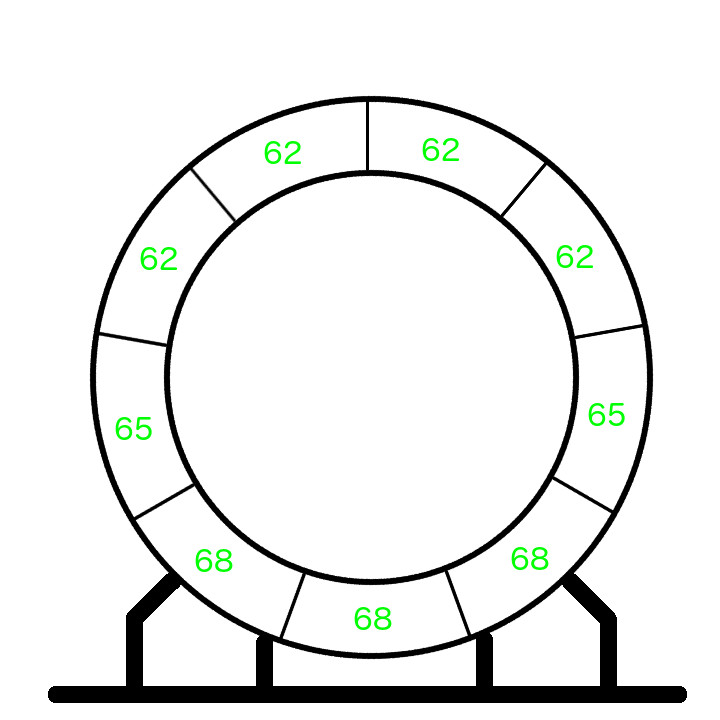

After that we put the wood parts back on the truss structure and we chose to reshuffle the panels to put most of the weight on the lower parts (we hope it will help to avoid too much shaking when the SG spins). As you can see the lower part is now 6kg heavier than then top one.

After that we put the wood parts back on the truss structure and we chose to reshuffle the panels to put most of the weight on the lower parts (we hope it will help to avoid too much shaking when the SG spins). As you can see the lower part is now 6kg heavier than then top one.

That meant we had to fix all the panels again, they were fixed with threaded inserts fixed in the wood so we had to remove these and change their location as the holes in the panels were all a bit shifted now. So we did that for the back panels and before the work session ended we flipped the gate and tried just to place the front panels together just to see how it looked (which is awesome). Then we removed these panels and put them on the floor.

Then… then I have been suffering from intense chronic fatigue for 10 years, which is a b**ch and is becoming worse with time, so I had to just let everything as it was because I just couldn’t work on this alone and my friend Zat couldn’t come back before January this year. Yep, there it is, that’s the main reason for this project taking so long and I hate that because it’s so much fun and it’s just like there is no energy in me. I still hope a doctor will finally find something and cure me, but it didn’t happened yet. Anyway **** happens. Let’s continue.

I let the SG in the garden for nearly one year. Which is bad. I let molds out there and they got... molds in them. Maybe it’s ok and I’ll be able to use them again if needed. We cleaned everything since and there are just spots stuck on it but I feel like they are safe now.

Also the wood took a lot of rain and sun and even with the clear coat it became gray and dry. I think structurally it’s ok, it doesn’t seem too brittle.

Lastly, the resin panels I let outside on the floor (remember it’s a garden so it’s not flat) warped a lot. Now I hope we’ll be able to reshape them with heat but even if it worked a bit on a test piece, I’m not 100% sure we’ll be able to fix them.

Oh yeah and because of the sun there are now some bumps on the wings that we have to fix too.

Now let’s list what we still have to do to finish this gate :

-Repair the broken parts of some panels (broken since London)

-Fix the wings and put them back together with the outer rings (some of he fell since London)

-Reshape the front panels

-Make a third set of ABS glyphs

-Construct the whole rotating system

-Fix the front panels to the wooden structure

-Find a safe and easy way to fix all the chevrons

-Paint everything

-Add the lights

-Develop the moving main chevron

-Construct special pieces to link the truss circle and a truss base for the gate to stand up

-Add a motor and a system to manage it and if possible a fun dialing program for anyone to use

Additionally we would add a video projector for the event horizon and some sound effects, and eventually the stone base, but that’s for later.

That’s a lot of time, effort and money to add to all that I spent already. But we’ll do it, until we don’t, but for now we’ll do it.

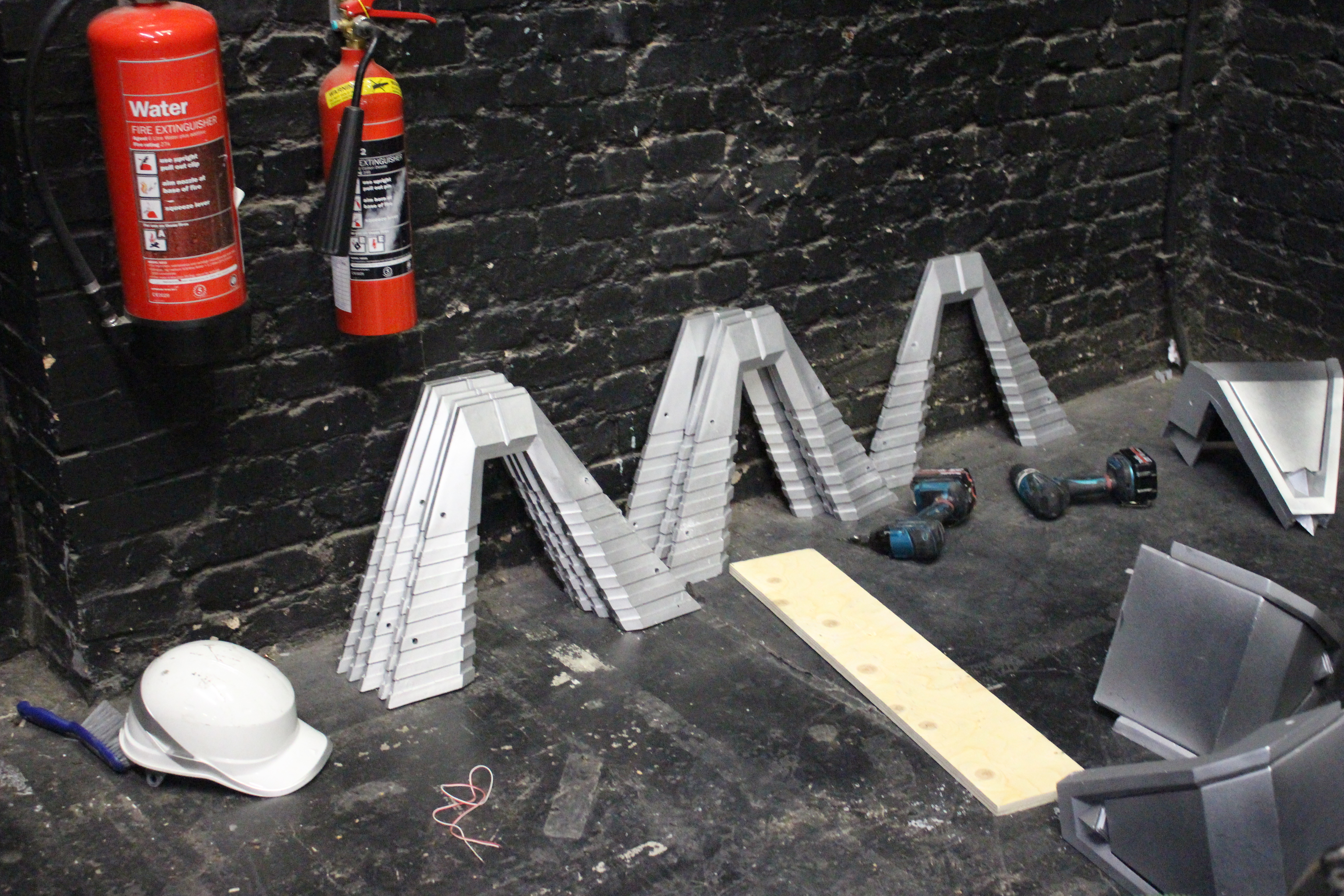

Then comes January. The goal was to reshape and fix the front panels, but when Zat arrived we went on the rotating system and it was going pretty well, so we decided to do that instead.

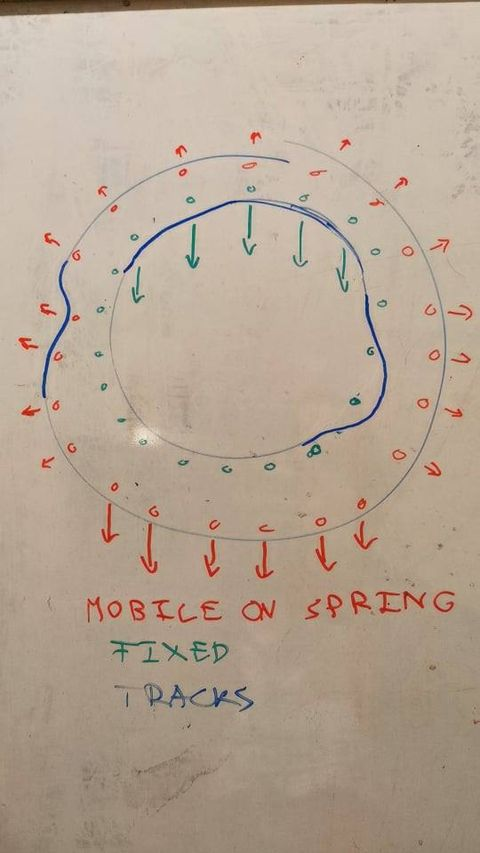

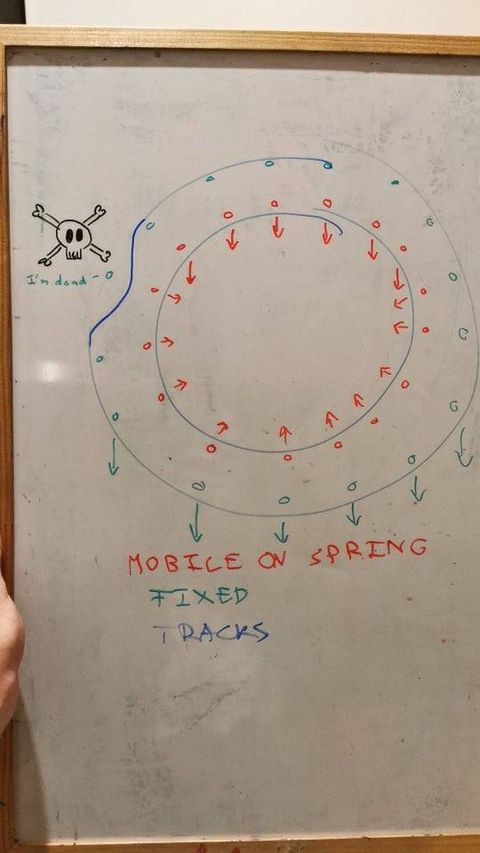

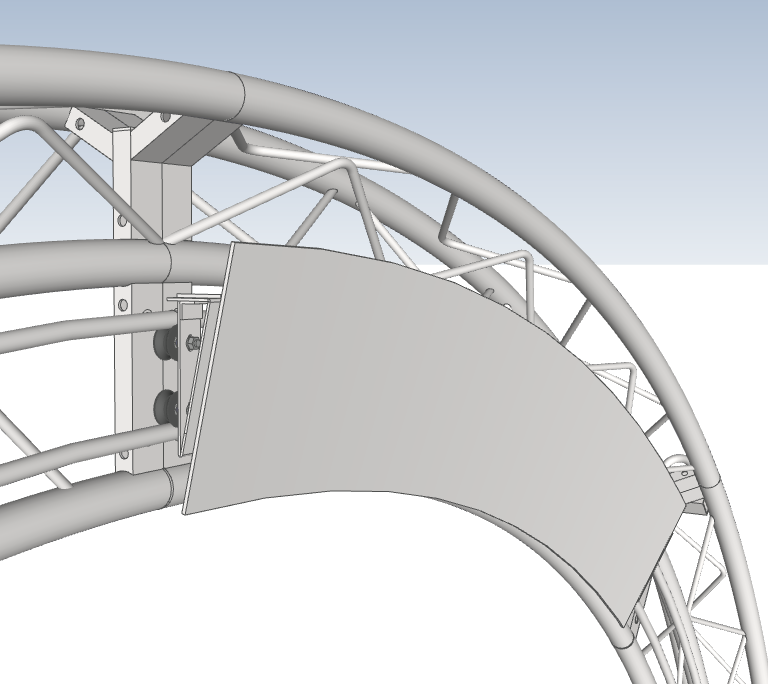

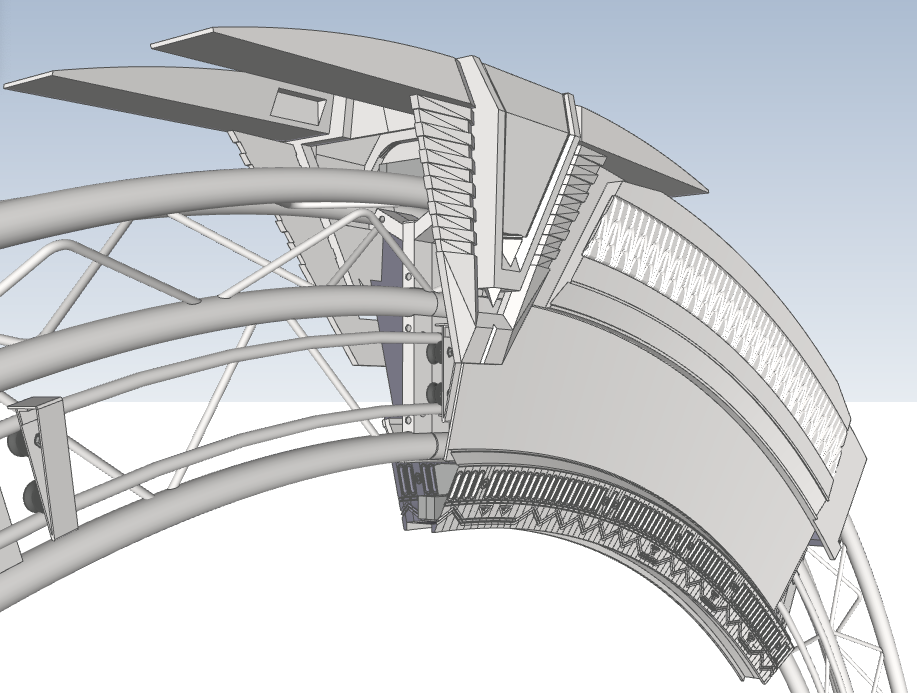

First the design was this one, with springs on each side. But it was complicated to create this kind of piece and above all, it would be a mess to calculate the exact needed strength of the springs to keep the ring centered during the rotation. And if we chose to put the springs only on one side it would create those problems (I love white boards so much). As you can see the forces are not really well distributed and we still have a problem if the track is not a perfect circle.

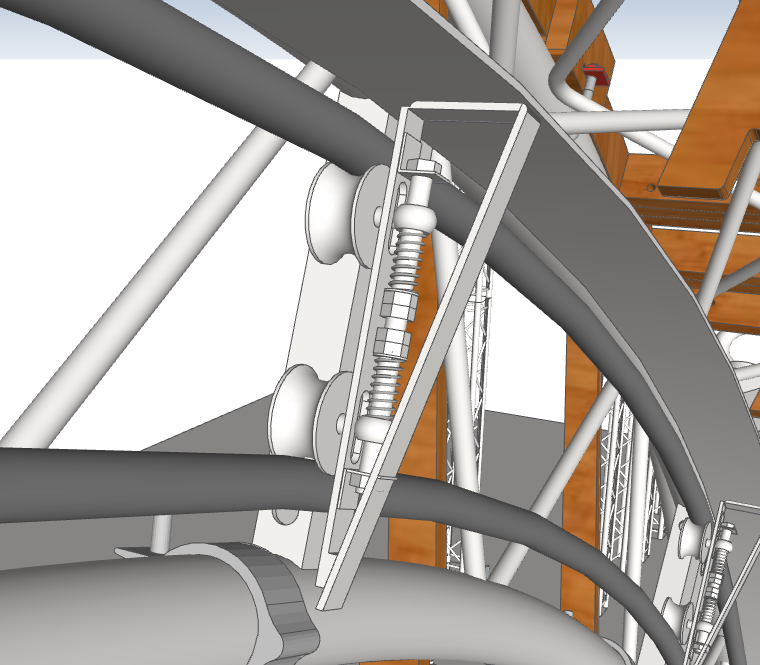

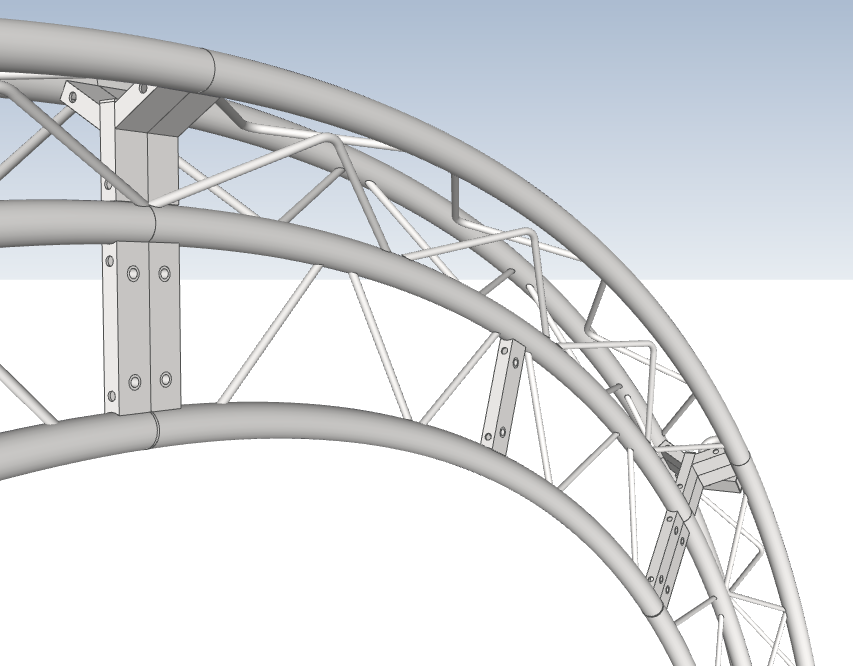

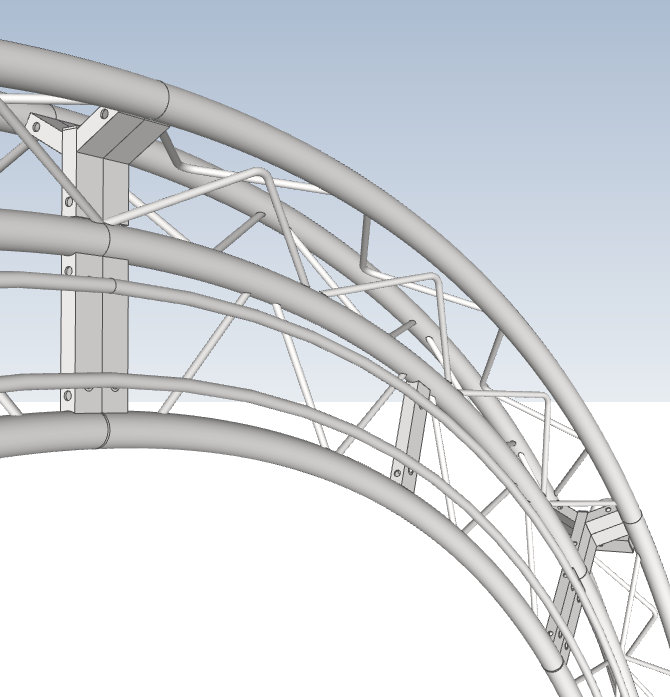

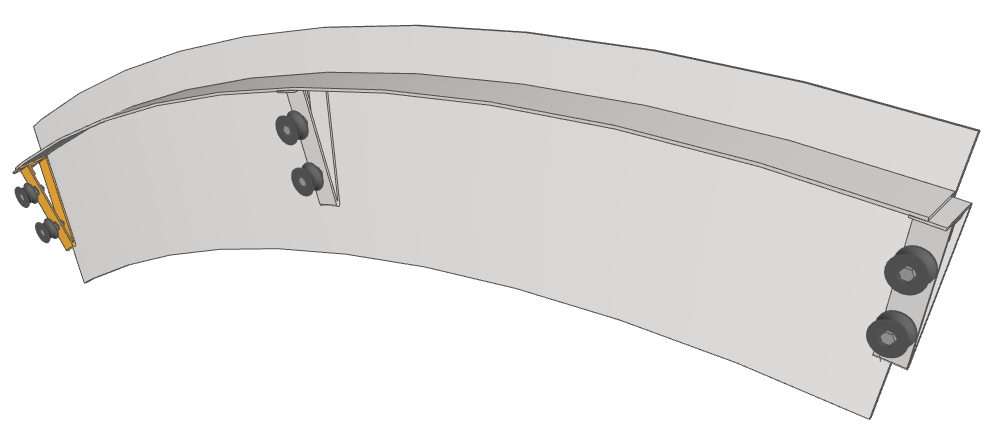

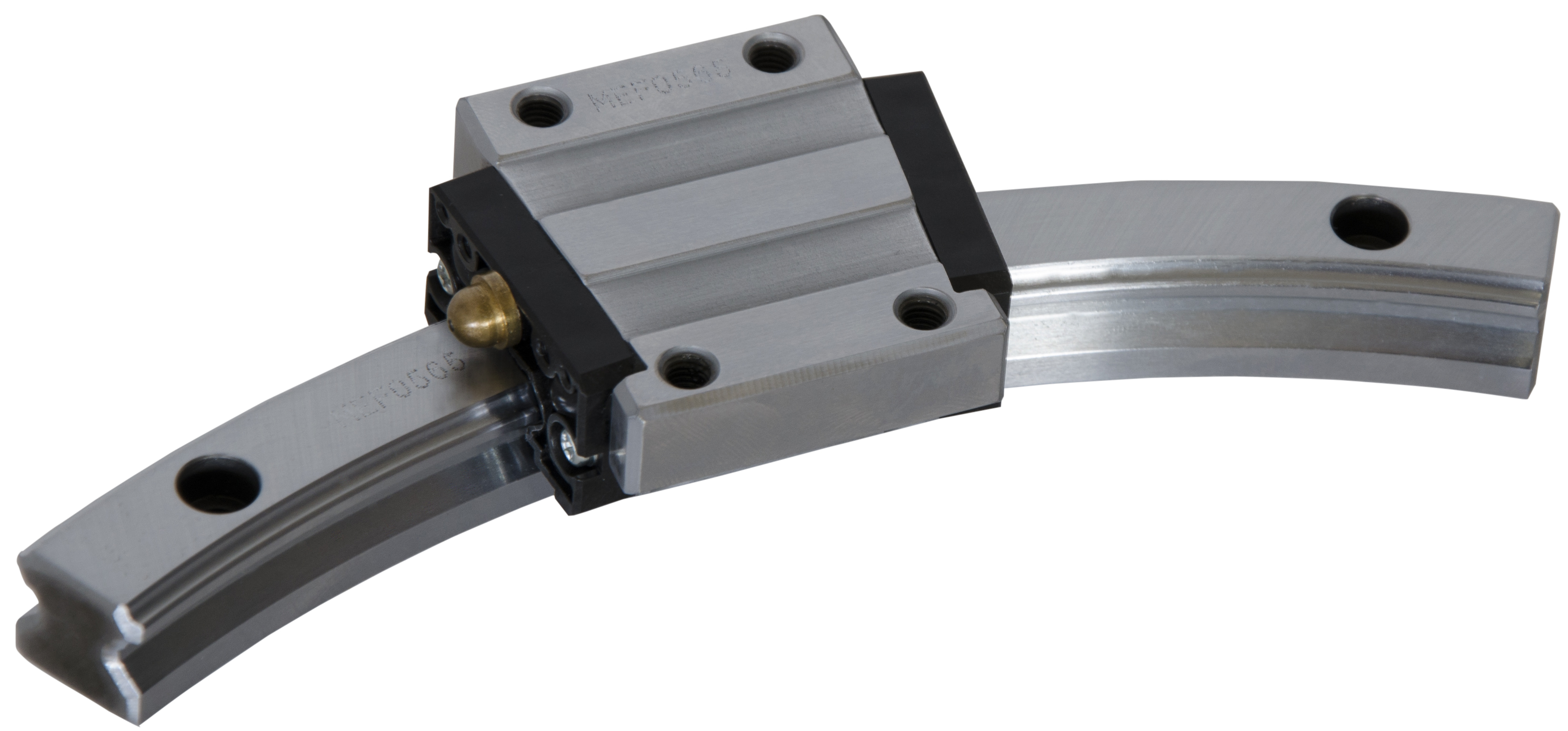

So we went for : Everything has to be perfect and we should be fine. And we designed a new carriage which is actually the same but simpler. Then we made a prototype using aluminium and we fixed three of them on a glyph track section.

Here is how it’s supposed to work : The carriages are fixed to the glyph track (which is made of PVC). There is a flat piece of aluminium going all around, that’s where the moto wheel should push everything with friction (later). The wheels are stuck between two rails which are made of simple curved aluminium tubes fixed to the truss structure. Simple right ? Except it’s not.

We made the holes in the tubes and fixed them all around the structure, then we put the section with the carriages in place and tried to spin it. It literally popped out of the track, pushed by an unknown force... or defect ?

So we took some measurements, the space between our tracks wasn’t so bad, a 2mm error which shouldn’t be that fatal for the rotation. I know we’re not professional mechanicians, but we did our best to be precise… and then I saw it. We based ourselves on the structure because it was made by a professional company in London so we were sure it was precise and we specifically explained them that we’d put tracks there so it had to be flat and constant. Of course it wasn’t and that’s not the first problem we had with this structure. I’ll never work with this company again. So the main problem is that the center tube of the truss structure is actually welded not perfectly horizontally but going down (look closely). The effect is that the squared tubes where we fixed the tracks are also going down at the center of each section son one track is nearly flat and the other is going up and down on 16mm! Of course our wagon is going off tracks.

We then spent the remaining of the work session to try to determine the amount of error of each section and how to level them, but we finally understood it wasn’t possible in these conditions. First working outside under rain / snow and walking in mud is just not possible and second, without a flat floor we can’t take precise measurements to level everything correctly.

That’s where we’re at for now. But we think we found a place to continue the work in better conditions (inside with a concrete floor) and that’s a pretty goof thing!

Now I think if we want to make this work, we’ll have to construct the full rotating system OUTSIDE of the gate structure (perfect space between both track all around, perfect circle, perfect placement of the carriages on the PVC panels…) and THEN fix the tracks to the truss structure. That’s the only way this system can work. OR we could buy an already existing system with specific rails and bearings, but that costs a lot and we'd still have to be super precise.

That’s it for now. I’m sorry it’s not more good news. We don’t know when we’ll be able to move the gate and move forward (mostly because of covid) but we’ll try our best to do it asap and make it spin !

Anyway, things are not going as we’d love to (of course, for that kind of project it’s expected) but more of that later. I’ll continue where I stopped.

So, we got the SG back from London, we first disassembled all of it to remove the blue atlantis paint, which took us so much time and effort, it was a painful task but we had to. Then we used some boat clear coat on the wood to protect it from the sun and the rain.

That meant we had to fix all the panels again, they were fixed with threaded inserts fixed in the wood so we had to remove these and change their location as the holes in the panels were all a bit shifted now. So we did that for the back panels and before the work session ended we flipped the gate and tried just to place the front panels together just to see how it looked (which is awesome). Then we removed these panels and put them on the floor.

Then… then I have been suffering from intense chronic fatigue for 10 years, which is a b**ch and is becoming worse with time, so I had to just let everything as it was because I just couldn’t work on this alone and my friend Zat couldn’t come back before January this year. Yep, there it is, that’s the main reason for this project taking so long and I hate that because it’s so much fun and it’s just like there is no energy in me. I still hope a doctor will finally find something and cure me, but it didn’t happened yet. Anyway **** happens. Let’s continue.

I let the SG in the garden for nearly one year. Which is bad. I let molds out there and they got... molds in them. Maybe it’s ok and I’ll be able to use them again if needed. We cleaned everything since and there are just spots stuck on it but I feel like they are safe now.

Also the wood took a lot of rain and sun and even with the clear coat it became gray and dry. I think structurally it’s ok, it doesn’t seem too brittle.

Lastly, the resin panels I let outside on the floor (remember it’s a garden so it’s not flat) warped a lot. Now I hope we’ll be able to reshape them with heat but even if it worked a bit on a test piece, I’m not 100% sure we’ll be able to fix them.

Oh yeah and because of the sun there are now some bumps on the wings that we have to fix too.

Now let’s list what we still have to do to finish this gate :

-Repair the broken parts of some panels (broken since London)

-Fix the wings and put them back together with the outer rings (some of he fell since London)

-Reshape the front panels

-Make a third set of ABS glyphs

-Construct the whole rotating system

-Fix the front panels to the wooden structure

-Find a safe and easy way to fix all the chevrons

-Paint everything

-Add the lights

-Develop the moving main chevron

-Construct special pieces to link the truss circle and a truss base for the gate to stand up

-Add a motor and a system to manage it and if possible a fun dialing program for anyone to use

Additionally we would add a video projector for the event horizon and some sound effects, and eventually the stone base, but that’s for later.

That’s a lot of time, effort and money to add to all that I spent already. But we’ll do it, until we don’t, but for now we’ll do it.

Then comes January. The goal was to reshape and fix the front panels, but when Zat arrived we went on the rotating system and it was going pretty well, so we decided to do that instead.

First the design was this one, with springs on each side. But it was complicated to create this kind of piece and above all, it would be a mess to calculate the exact needed strength of the springs to keep the ring centered during the rotation. And if we chose to put the springs only on one side it would create those problems (I love white boards so much). As you can see the forces are not really well distributed and we still have a problem if the track is not a perfect circle.

So we went for : Everything has to be perfect and we should be fine. And we designed a new carriage which is actually the same but simpler. Then we made a prototype using aluminium and we fixed three of them on a glyph track section.

Here is how it’s supposed to work : The carriages are fixed to the glyph track (which is made of PVC). There is a flat piece of aluminium going all around, that’s where the moto wheel should push everything with friction (later). The wheels are stuck between two rails which are made of simple curved aluminium tubes fixed to the truss structure. Simple right ? Except it’s not.

We made the holes in the tubes and fixed them all around the structure, then we put the section with the carriages in place and tried to spin it. It literally popped out of the track, pushed by an unknown force... or defect ?

So we took some measurements, the space between our tracks wasn’t so bad, a 2mm error which shouldn’t be that fatal for the rotation. I know we’re not professional mechanicians, but we did our best to be precise… and then I saw it. We based ourselves on the structure because it was made by a professional company in London so we were sure it was precise and we specifically explained them that we’d put tracks there so it had to be flat and constant. Of course it wasn’t and that’s not the first problem we had with this structure. I’ll never work with this company again. So the main problem is that the center tube of the truss structure is actually welded not perfectly horizontally but going down (look closely). The effect is that the squared tubes where we fixed the tracks are also going down at the center of each section son one track is nearly flat and the other is going up and down on 16mm! Of course our wagon is going off tracks.

We then spent the remaining of the work session to try to determine the amount of error of each section and how to level them, but we finally understood it wasn’t possible in these conditions. First working outside under rain / snow and walking in mud is just not possible and second, without a flat floor we can’t take precise measurements to level everything correctly.

That’s where we’re at for now. But we think we found a place to continue the work in better conditions (inside with a concrete floor) and that’s a pretty goof thing!

Now I think if we want to make this work, we’ll have to construct the full rotating system OUTSIDE of the gate structure (perfect space between both track all around, perfect circle, perfect placement of the carriages on the PVC panels…) and THEN fix the tracks to the truss structure. That’s the only way this system can work. OR we could buy an already existing system with specific rails and bearings, but that costs a lot and we'd still have to be super precise.

That’s it for now. I’m sorry it’s not more good news. We don’t know when we’ll be able to move the gate and move forward (mostly because of covid) but we’ll try our best to do it asap and make it spin !

Lt Washburn

Sr Member

That's a shame about the misaligned tube. Is it not possible to cut the welds and shift it into alignment and re-weld?

Sendel

Active Member

That's a good question, and the short answer is no, sadly.

The reasons are :

-It's aluminium and it's pretty hard to weld correctly

-To display it in public areas and allow people to go through it, it has to be safe in reality and on technical paperwork

-We are already fighting the company who made it to give us the needed paperwork that says "yep, this structure allows X kg on it". We asked for it to be capable to stand at least 1T (we have e-mails to prove it), they provided it saying "it's good" and now when we ask for an official statement they just say "lol no, you'd need an engineer to certify it". That's just ********, you can't provide a truss structure and not certify it. It's used all the time in venues and you have to be able to prove all the material is safe all the time or you're just toying with human lives... Anyway we can't modify the structure ourselves or they will never be ok to certify it at the end.

But, as said we should be able to bear with it. The error is not taking too much space, so that part is ok. It's just not right, so we'll find a way to level everything. I just hope the design I chose for the rotation is good enough to avoid the spinning ring to go off track at the end. When I saw the section pop out it made me anxious. The front panels should keep it in place and I may even have a solution to secure it if needed.

We based ourselves on the real design used for the gate rotation, except their wheel were fixed on the structure and the rails on the rotating part. But they were able to make it spin full speed only for the first season... so maybe that was a bad idea to do it that way. We'll see when we'll assemble it again.

The reasons are :

-It's aluminium and it's pretty hard to weld correctly

-To display it in public areas and allow people to go through it, it has to be safe in reality and on technical paperwork

-We are already fighting the company who made it to give us the needed paperwork that says "yep, this structure allows X kg on it". We asked for it to be capable to stand at least 1T (we have e-mails to prove it), they provided it saying "it's good" and now when we ask for an official statement they just say "lol no, you'd need an engineer to certify it". That's just ********, you can't provide a truss structure and not certify it. It's used all the time in venues and you have to be able to prove all the material is safe all the time or you're just toying with human lives... Anyway we can't modify the structure ourselves or they will never be ok to certify it at the end.

But, as said we should be able to bear with it. The error is not taking too much space, so that part is ok. It's just not right, so we'll find a way to level everything. I just hope the design I chose for the rotation is good enough to avoid the spinning ring to go off track at the end. When I saw the section pop out it made me anxious. The front panels should keep it in place and I may even have a solution to secure it if needed.

We based ourselves on the real design used for the gate rotation, except their wheel were fixed on the structure and the rails on the rotating part. But they were able to make it spin full speed only for the first season... so maybe that was a bad idea to do it that way. We'll see when we'll assemble it again.

Similar threads

- Replies

- 0

- Views

- 335

- Replies

- 36

- Views

- 1,804