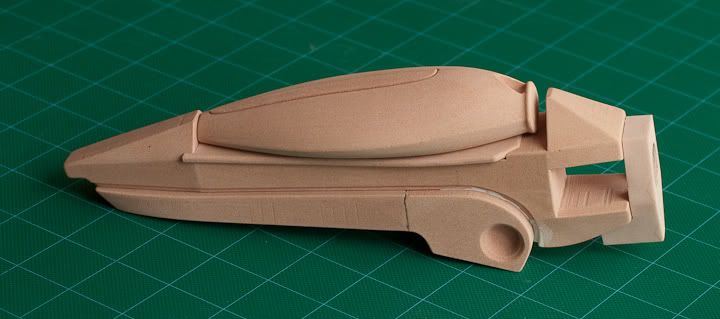

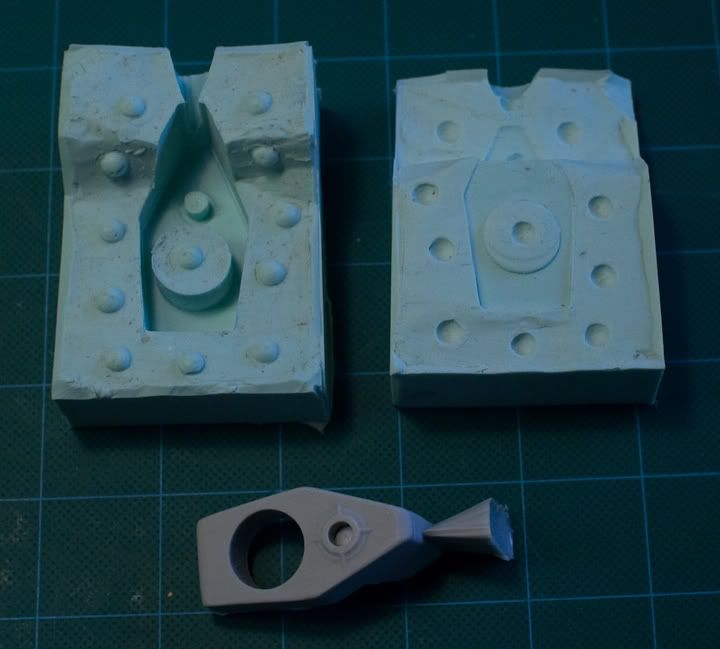

Well if one phaser project on the workbench is good, two must be better, right? Actually, my TOS Phaser Project is one hold for a few days until I can get some of the dimensions confirmed. In the meantime, I've started modeling up the Kelvin Phaser from J.J. Abram's 2009 Star Trek. I know it was never seen on screen, but it's such a cool design I just had to take a crack at it. One of the coolest things is the rough, almost crude look to the cast metal surfaces. That'll be fun to duplicate (easier than making the surfaces perfect, that's for sure!).

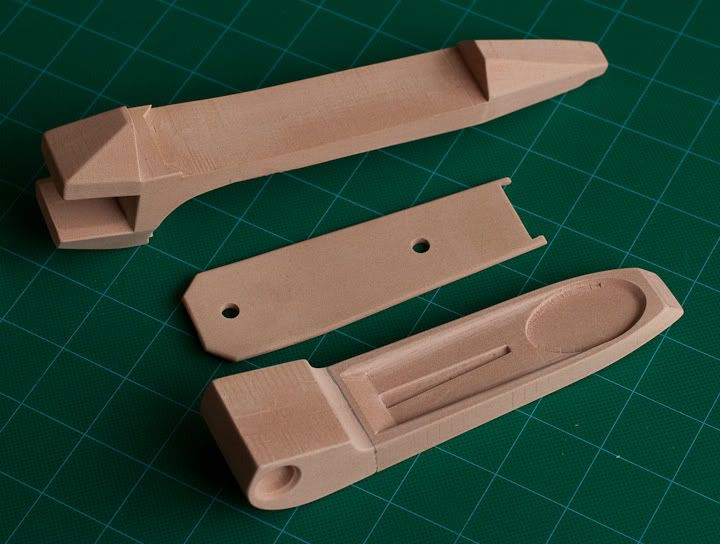

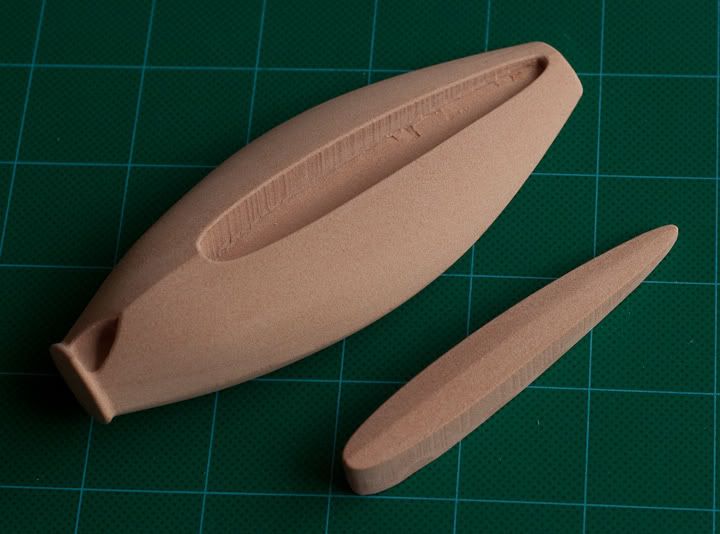

Working from auction photos of the prop, I've first drawn it in 2D and then used those drawings to build a virtual 3D Cg model in Rhino. This will then be used to mill out the patterns on the CNC.

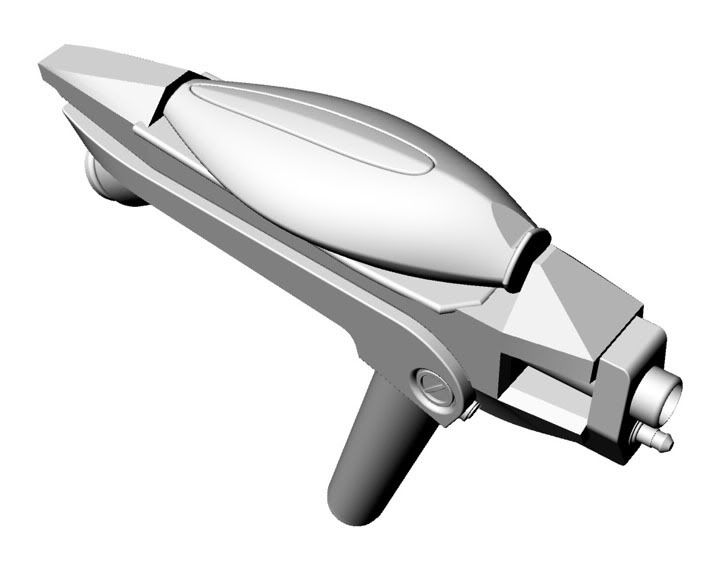

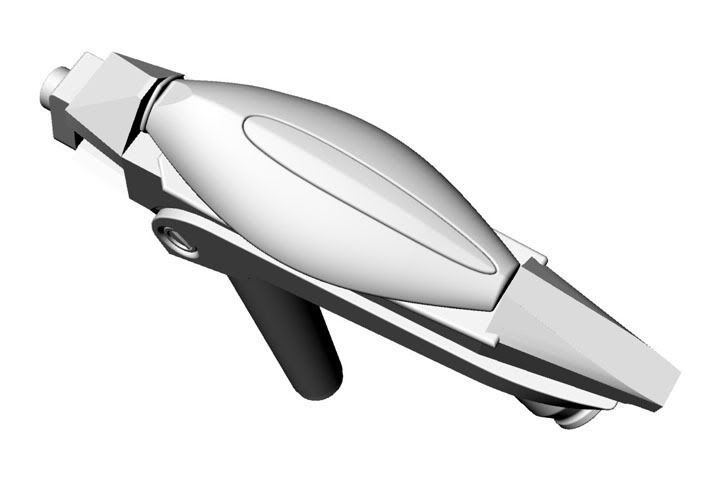

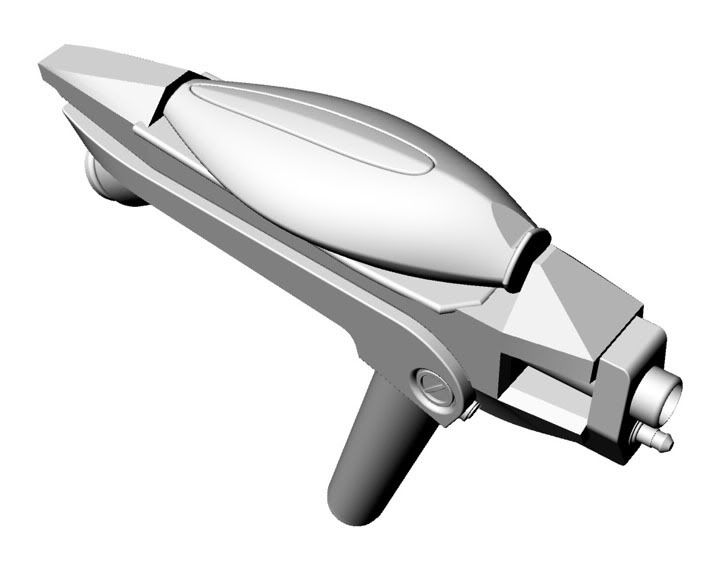

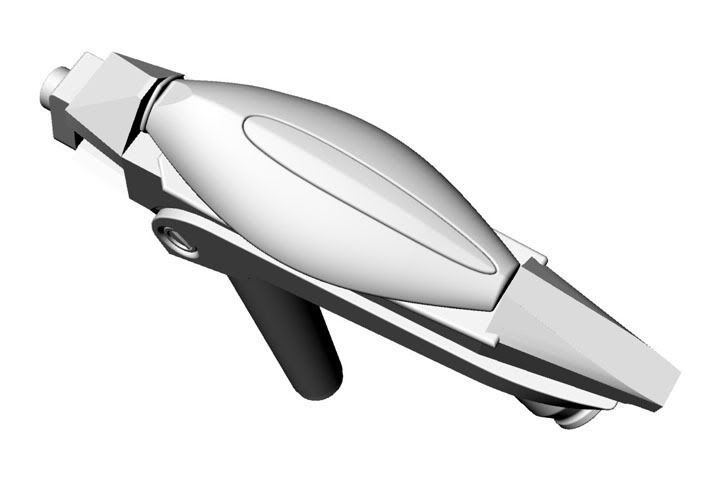

Here are some work-in-progress renderings of the Rhino model. There are still a few details to finish.

Working from auction photos of the prop, I've first drawn it in 2D and then used those drawings to build a virtual 3D Cg model in Rhino. This will then be used to mill out the patterns on the CNC.

Here are some work-in-progress renderings of the Rhino model. There are still a few details to finish.