SteveNeill

Sr Member

I must be crazy but here I go. I've been a modeler, makeup effects and creature man for many moons now. I've worked on everything from Star Trek the Motion Picture to Ghost Busters. But I always wanted to build the Enterprise and have a big model of her. Since I missed the Custom Replicas model I figured why not build one myself.

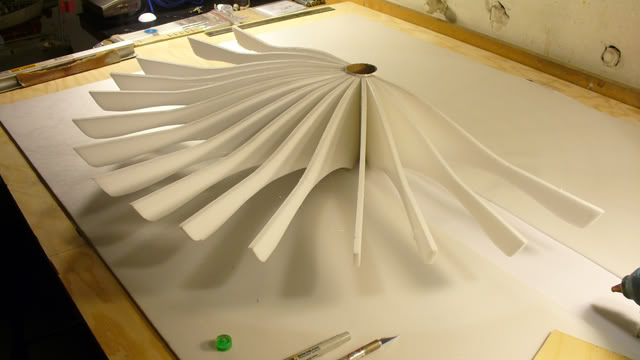

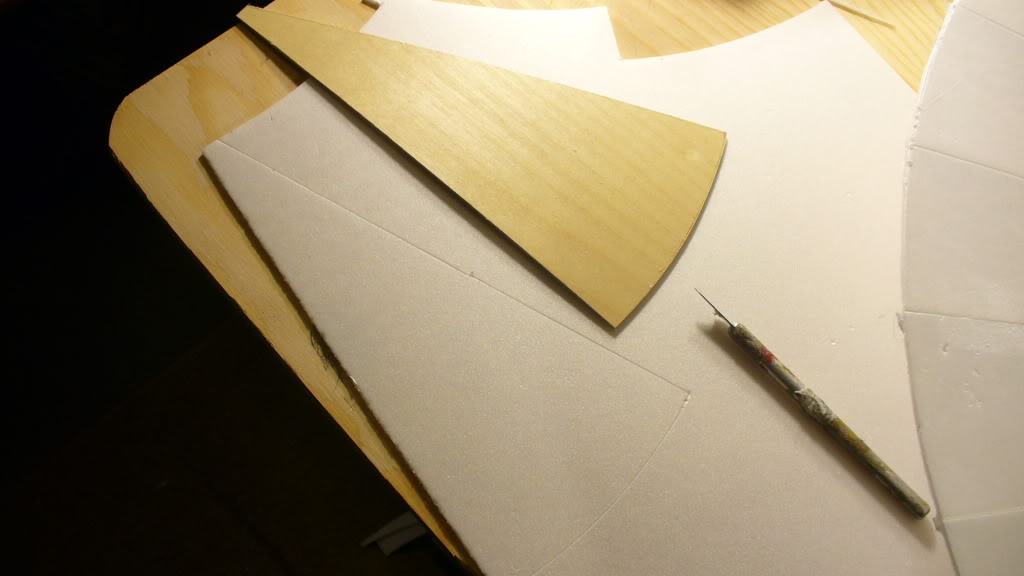

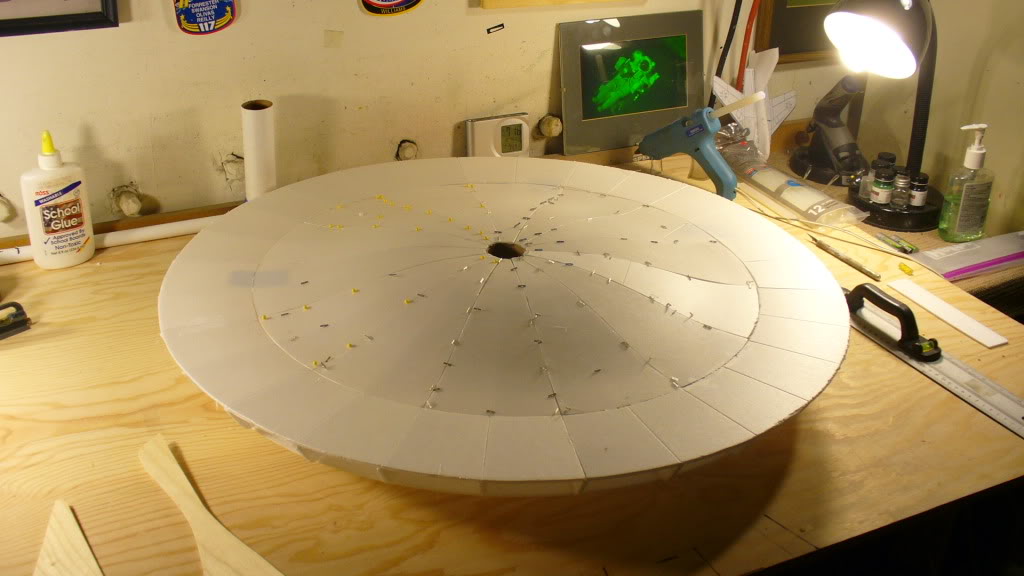

The technique I'm using is nothing new to Radio controlled airplane builders like myself. I'm using Depron foam sheet in various thicknesses and framing up the geometry of all the basic shapes off the scale plans. Make templates and cut bulkheads and frame them up and sheet them. Now I could do foam wire cutting. CNC. Or balsa construction but this foam sheet is very user friendly and not so messy.

Once I have the shapes I glass and epoxy for strength and beating on. All the small details and window reliefs can be added as well as placements for the NAV and other lights that adorn her hull.

Once I have all the masters and the smaller parts mastered then I can mold everything in RTV silicone. GI 1000 is my poison of choice. The mother molds will be epoxy glass. Main hull parts and nacelles will be epoxy glass while the other parts such as the Bridge, impulse engines and other such details will be made out of cast Alumilite.

Lighting will be LED based and small drive motors in the nacelles to get the warp engine effects.

So far I’ve framed up the saucer and I’ve started sheeting it. Here’s some pictures and the constant updates can be found on my Blog.

Also check out my website to learn more about this old guy with a kids passion for all things fun, Star Trek and Sci-Fi. Space, submarines, ships, airplanes, yada, yada, yada.

More to come,

Steve

The technique I'm using is nothing new to Radio controlled airplane builders like myself. I'm using Depron foam sheet in various thicknesses and framing up the geometry of all the basic shapes off the scale plans. Make templates and cut bulkheads and frame them up and sheet them. Now I could do foam wire cutting. CNC. Or balsa construction but this foam sheet is very user friendly and not so messy.

Once I have the shapes I glass and epoxy for strength and beating on. All the small details and window reliefs can be added as well as placements for the NAV and other lights that adorn her hull.

Once I have all the masters and the smaller parts mastered then I can mold everything in RTV silicone. GI 1000 is my poison of choice. The mother molds will be epoxy glass. Main hull parts and nacelles will be epoxy glass while the other parts such as the Bridge, impulse engines and other such details will be made out of cast Alumilite.

Lighting will be LED based and small drive motors in the nacelles to get the warp engine effects.

So far I’ve framed up the saucer and I’ve started sheeting it. Here’s some pictures and the constant updates can be found on my Blog.

Also check out my website to learn more about this old guy with a kids passion for all things fun, Star Trek and Sci-Fi. Space, submarines, ships, airplanes, yada, yada, yada.

More to come,

Steve

Last edited by a moderator: