The show is up to episode 9 the other night and I've been working on bits and pieces of this since episode one. The daggers themselves are cg about there are several distinct types: medium fat, skinny and kitchen knife style. I wanted to have the thing light up from the inside so the kitchen knife style was beyond my limited electronics abilities. The longer skinny one I've set up but trying to get the workings inside it is too tight of a squeeze at the moment with smaller stronger batteries it could be done but as mentioned my skills are limited. So I've been working on the medium fat one. I made it to be a a square cross section (the skinny one is a triangular cross section).

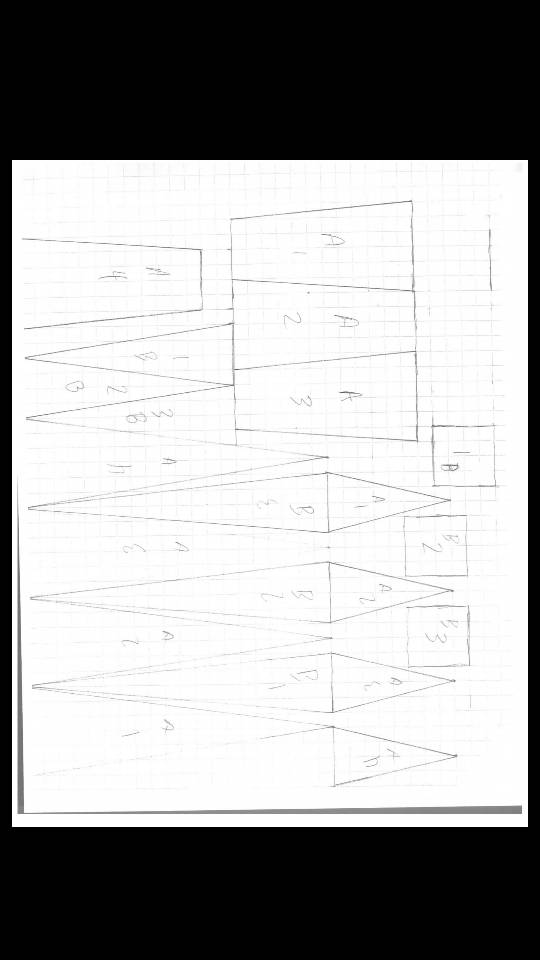

I'm making it out of paper I snagged a sheet of my girlfriend's artist sketch pad drawing paper and used that I put clear packing tape on one side to catch any outside light and put a hot glue layer on the inside to diffuse the light from the inside, as well as to adhere the sides together. I'll put up the graph paper plans A is the fat dagger B the skinny one.

The inner workings consist of a battery pack (6v -from 4 1.5v watch batteries) 8 led panels or strips I cannibalized from night lights (2 strips per nightlight, times 4) a switch also from one of those nightlights and 2 additional LEDs to light up each dagger pointy end.

Here's the video of the set up and the first progress report: https://youtu.be/IZgBGO9V1B4

Sent from my XT1710-02 using Tapatalk

I'm making it out of paper I snagged a sheet of my girlfriend's artist sketch pad drawing paper and used that I put clear packing tape on one side to catch any outside light and put a hot glue layer on the inside to diffuse the light from the inside, as well as to adhere the sides together. I'll put up the graph paper plans A is the fat dagger B the skinny one.

The inner workings consist of a battery pack (6v -from 4 1.5v watch batteries) 8 led panels or strips I cannibalized from night lights (2 strips per nightlight, times 4) a switch also from one of those nightlights and 2 additional LEDs to light up each dagger pointy end.

Here's the video of the set up and the first progress report: https://youtu.be/IZgBGO9V1B4

Sent from my XT1710-02 using Tapatalk