trymypatience

Active Member

Any update on this? Would love to see how a 3d printed terminator comes out.

Any update on this? Would love to see how a 3d printed terminator comes out.

Thanks!WOW! That came up really nice.

Thanks!

@Pumpkinhead, great reference shots...thank you!! Do you know what version/model is skull is?

That's an M1 skull

1. Hollow out the skull as much as possible and make it a "shell" so I can put stuff inside

2. Remove the neural net processor port hole/door

3. Remove the eyes and model them separately

4. Completely remove the left/right side greeblies and print those separately

5. Add hinge points for the lower jaw to connect to the skull

6. Come up with a way for all the pieces to "click" into place like a puzzle.

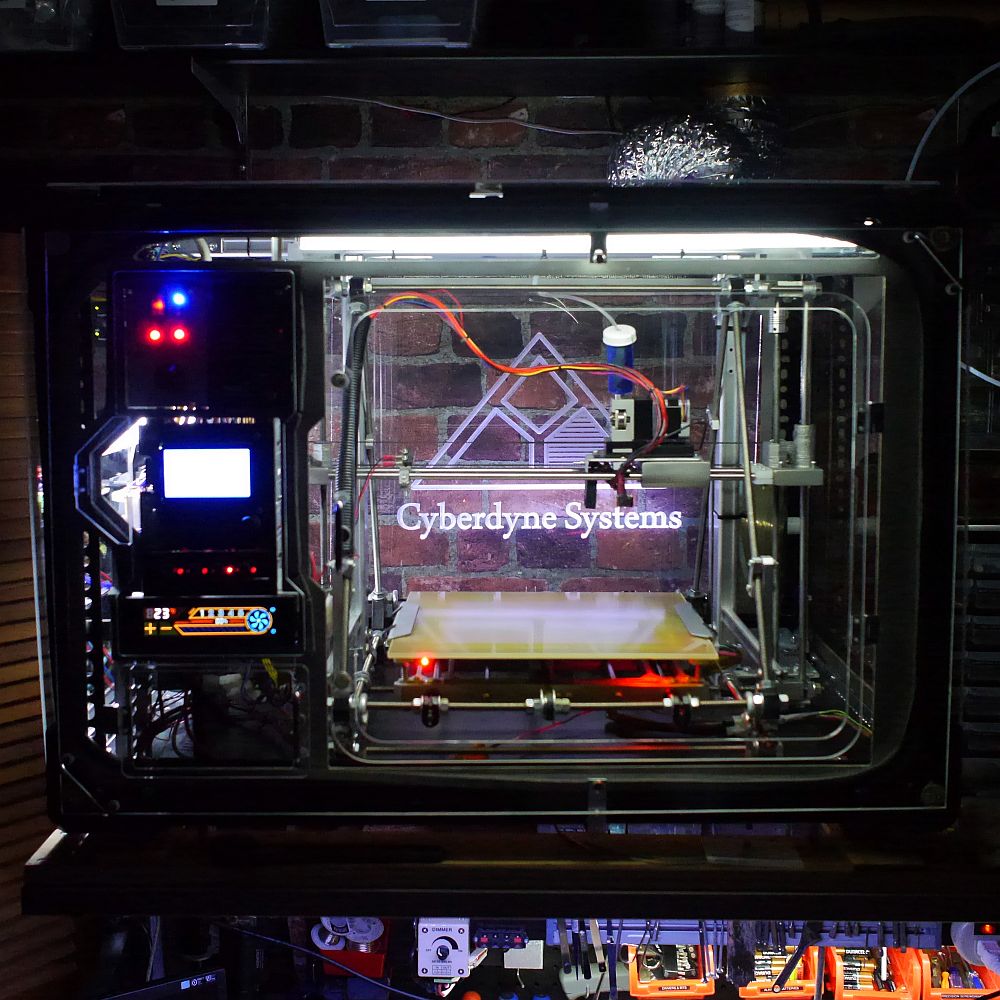

images....

Printing just this half of the skull took about 32 hours at 0.2mm layers to capture as much detail as possible (using translucent "natural" PLA):

Still lots of Bondo and sanding work to smooth it out and hit all the fine details.

Looks cool! Any reason you didn't use ABS and try solvent smoothing?