sandbagger

Master Member

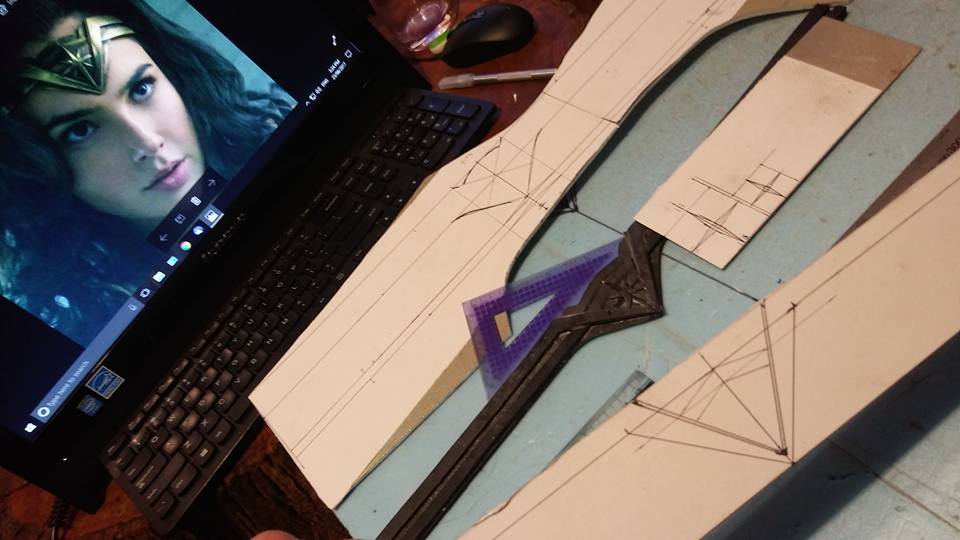

I recently took my wife to see Wonder Woman for her birthday and was thoroughly impressed that DC finally got a movie right.

I thought I'd make my wife a WW headband out of aluminium. I surprised her with it last night and she loves it.

Upon getting this far, I am seriously thinking about doing the rest of the costume for her.

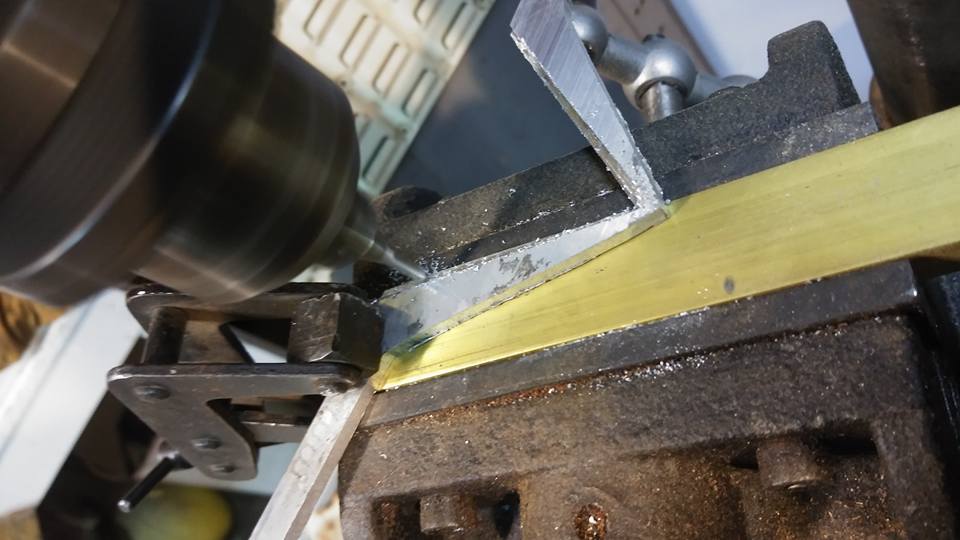

Starting with the head band, I used screenshots from the movie, blown up on screen to a known face height, then used a ruler to scale it all directly onto paper, glued to thick aluminium sheet. The pieces were cut out using a hacksaw and filed and sanded into shape. I used a mill drill to cut a couple of fancy ledges in the centre piece. I will bend it into shape, rivet the larger pieces on then JB-Weld the star on in the centre.

I thought I'd make my wife a WW headband out of aluminium. I surprised her with it last night and she loves it.

Upon getting this far, I am seriously thinking about doing the rest of the costume for her.

Starting with the head band, I used screenshots from the movie, blown up on screen to a known face height, then used a ruler to scale it all directly onto paper, glued to thick aluminium sheet. The pieces were cut out using a hacksaw and filed and sanded into shape. I used a mill drill to cut a couple of fancy ledges in the centre piece. I will bend it into shape, rivet the larger pieces on then JB-Weld the star on in the centre.

Last edited by a moderator: