Hey guys, you may all know about this already, but I just wanted to share a little information about some new materials that it seems Shapeways is undergoing test with. One is HP Strong and Flexible and the other is Hi Def Acrylate.

They currently are both on maker materials and only avaiable to designers but I suspect if tests go well they will be openly available soon. I ordered a part in both and I can see advantages (and disadvantages) to both of these materials.

First the Acrylate.

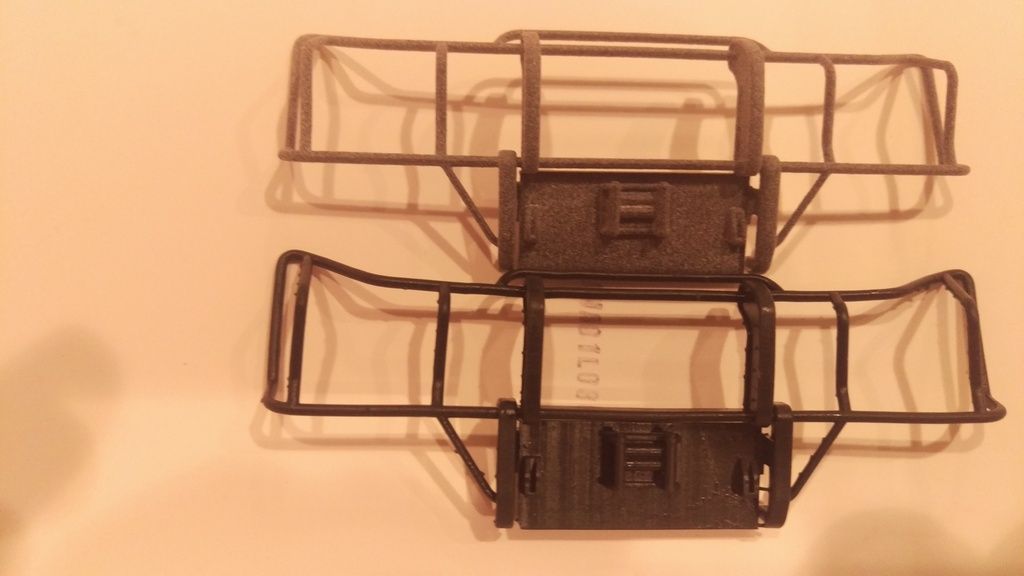

I really like this material on first observation. I haven't painted it or tried to clean up the support "stubs" yet, but my first impression is that the print lines are much less noticable than other materials. You can see the little nips where the support material was removed. I'll have to carefully go in with a file and see how hard to remove it is. Here are a few pics of my Hummer Bumper. (sorry the pics suck, I will try to get better ones soon.

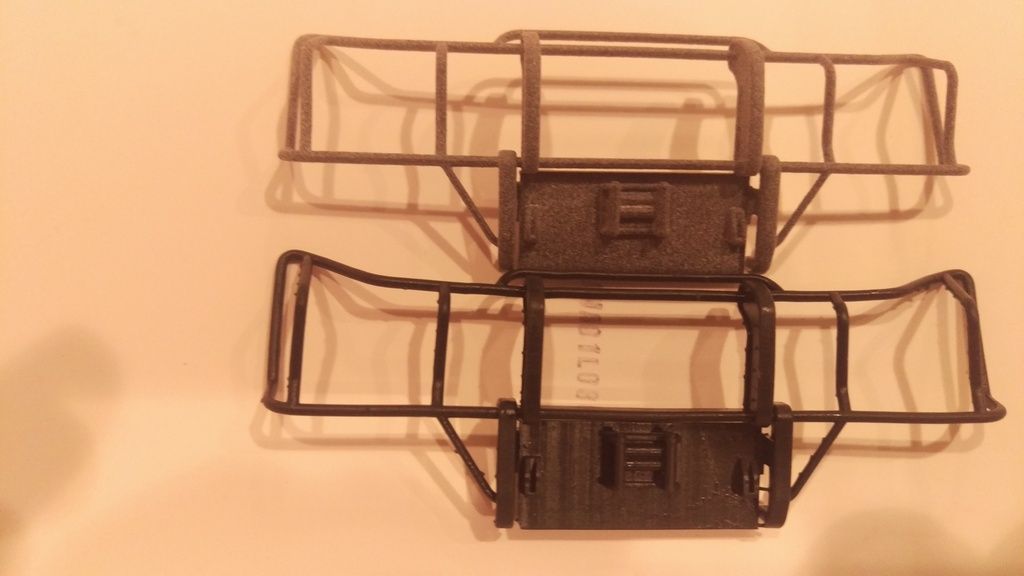

Then the HP Strong and Flex. This is a grainy material but I don't think it's as grainy as the regular Strong and Flex. I will do some priming and sanding on this to see how well it takes handling. But it seems like it's going to be easier to get smoother results with this material. Again, bad pics. sorry,

I just wanted to let you guys know to be on the look out for designers being able to offer these materials soon. I don't know yet if they will necessarily be game changers, but they do seem to be heading the way of cheaper and better model prints. I'll post up more information if anyone is interested.

Thanks,

Bill

They currently are both on maker materials and only avaiable to designers but I suspect if tests go well they will be openly available soon. I ordered a part in both and I can see advantages (and disadvantages) to both of these materials.

First the Acrylate.

I really like this material on first observation. I haven't painted it or tried to clean up the support "stubs" yet, but my first impression is that the print lines are much less noticable than other materials. You can see the little nips where the support material was removed. I'll have to carefully go in with a file and see how hard to remove it is. Here are a few pics of my Hummer Bumper. (sorry the pics suck, I will try to get better ones soon.

Then the HP Strong and Flex. This is a grainy material but I don't think it's as grainy as the regular Strong and Flex. I will do some priming and sanding on this to see how well it takes handling. But it seems like it's going to be easier to get smoother results with this material. Again, bad pics. sorry,

I just wanted to let you guys know to be on the look out for designers being able to offer these materials soon. I don't know yet if they will necessarily be game changers, but they do seem to be heading the way of cheaper and better model prints. I'll post up more information if anyone is interested.

Thanks,

Bill