You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blade Runner 2049 props and replicas

- Thread starter Mr Webber

- Start date

The clip is not removable. Once we are done 'collating', I should be able to reproduce these fairly accurately with laser cut acrylics and engraved metalgraph laminate for the corner tabs and aluminium sections. Hopefully find somewhere to cut 1mm aluminium sheet to size for the plates.

Obviously, these dims would need to be scaled up

.View attachment 798865

Looking forward to the interest thread :thumbsup

Unforgiven

Active Member

That sublime moment when a thriving research thread becomes an active project...

Last edited:

Unforgiven

Active Member

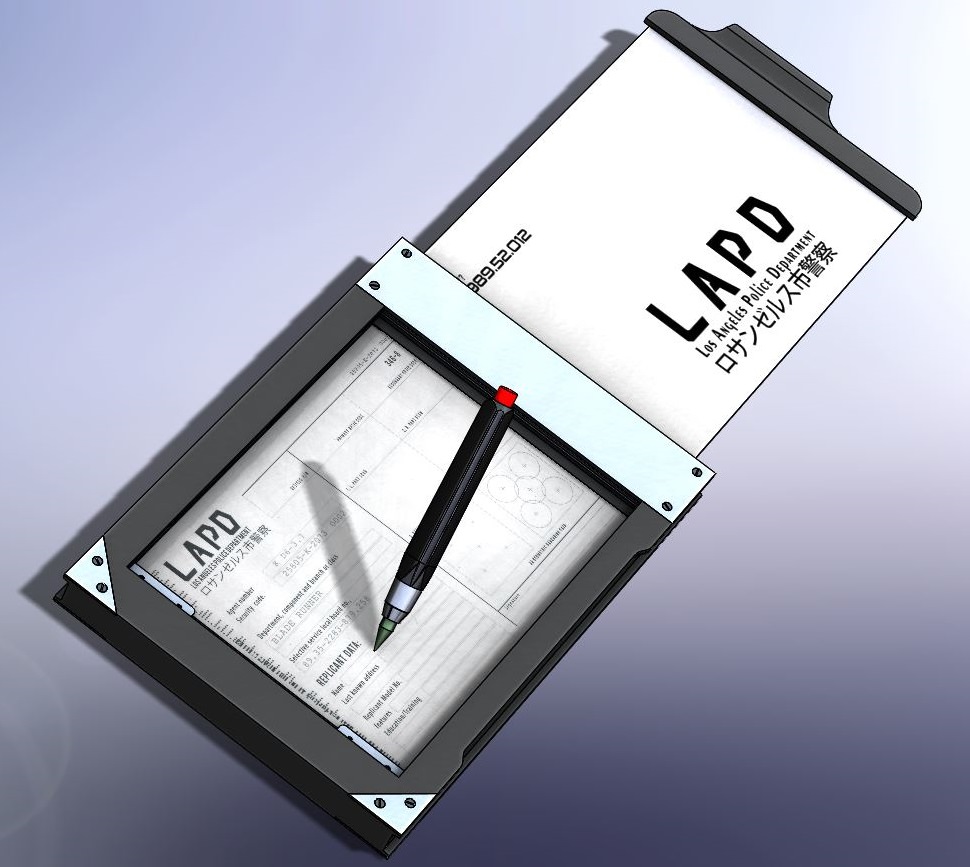

Work in progress... Still need to add the inlaid number 3 and slap the Kanji onto the cross bar (which needs to be a bit narrower).

Last edited by a moderator:

Unforgiven

Active Member

I’m flattered that you asked if it was real - my CAD software thanks you!

I tried to get all the details as close to the screen-used prop as possible, but to verify the accuracy of the geometry, components, and proportions, I’d still need to get my hands on an original, and searching for these is coming up bupkes...

In any event, my plan is to either 3D print or CNC machine the frame & grip, and laser cut, water jet, or CNC machine the aluminum parts, whichever is cheaper. I’ll start getting quotes next week - just for myself, not a run, but I will ask to have the parts quoted in different quantities, because you never know.

Sent from my iPhone using Tapatalk

I tried to get all the details as close to the screen-used prop as possible, but to verify the accuracy of the geometry, components, and proportions, I’d still need to get my hands on an original, and searching for these is coming up bupkes...

In any event, my plan is to either 3D print or CNC machine the frame & grip, and laser cut, water jet, or CNC machine the aluminum parts, whichever is cheaper. I’ll start getting quotes next week - just for myself, not a run, but I will ask to have the parts quoted in different quantities, because you never know.

Sent from my iPhone using Tapatalk

Unforgiven

Active Member

Best if you ask the guys here who modeled the blaster and sculpted the badge - they own the master patterns, but I can tell you now that it would be extremely expensive, given the machine time and intricate features. The plate holders are very simple geometries in comparison, so that’s the only reason I’m even considering it.

For the badge, casting and forging are the best bet - that’s how real ones are made.

Sent from my iPhone using Tapatalk

For the badge, casting and forging are the best bet - that’s how real ones are made.

Very nice. I tried the picture frame route, but couldn't make it work. While your at it... Would you ask about CNCing a metal Blade Runner badge? ...and maybe a Blaster?

Sent from my iPhone using Tapatalk

Just to chime in on the discussion. I could CNC a metal badge... for about $300 each. They can be cast in metal, but with the detail on mine, I would have to spin cast it, and I'm not set up to do that at this time.

-GG

-GG

Unforgiven

Active Member

Updated CAD model:

* reduced screw size from M2 to M1.6

* added number 3 inlay

* reduced crossbar width

* added Kanji to crossbar

In order to make the model accurate and get parts quoted, I need to confirm the accuracy of component dimensions and proportions from an actual 13x18 Mentor plate holder, which, to the best of my knowledge, nobody has been able to score so far. For now, however, I'd appreciate help from people who've already purchased Mentor plate holders of various formats with getting the following features and areas right, since none of the reference photographs I've been able to find reveal these features:

Even if your Mentor plate is undersized (6x9 or9x12), taking photos of these areas from several angles and with rulers to set the scale would be very instructive. Please PM me to discuss. Thanks!

* reduced screw size from M2 to M1.6

* added number 3 inlay

* reduced crossbar width

* added Kanji to crossbar

In order to make the model accurate and get parts quoted, I need to confirm the accuracy of component dimensions and proportions from an actual 13x18 Mentor plate holder, which, to the best of my knowledge, nobody has been able to score so far. For now, however, I'd appreciate help from people who've already purchased Mentor plate holders of various formats with getting the following features and areas right, since none of the reference photographs I've been able to find reveal these features:

Even if your Mentor plate is undersized (6x9 or9x12), taking photos of these areas from several angles and with rulers to set the scale would be very instructive. Please PM me to discuss. Thanks!

[I will try and take some pics tomorrow.

QUOTE=Unforgiven;4421118]Updated CAD model:

* reduced screw size from M2 to M1.6

* added number 3 inlay

* reduced crossbar width

* added Kanji to crossbar

https://i.imgur.com/rlUCjAt.jpg

In order to make the model accurate and get parts quoted, I need to confirm the accuracy of component dimensions and proportions from an actual 13x18 Mentor plate holder, which, to the best of my knowledge, nobody has been able to score so far. For now, however, I'd appreciate help from people who've already purchased Mentor plate holders of various formats with getting the following features and areas right, since none of the reference photographs I've been able to find reveal these features:

https://i.imgur.com/gaxVFQv.jpg

https://i.imgur.com/xvnalSV.jpg

https://i.imgur.com/XQKOcgq.jpg

Even if your Mentor plate is undersized (6x9 or9x12), taking photos of these areas from several angles and with rulers to set the scale would be very instructive. Please PM me to discuss. Thanks![/QUOTE]

QUOTE=Unforgiven;4421118]Updated CAD model:

* reduced screw size from M2 to M1.6

* added number 3 inlay

* reduced crossbar width

* added Kanji to crossbar

https://i.imgur.com/rlUCjAt.jpg

In order to make the model accurate and get parts quoted, I need to confirm the accuracy of component dimensions and proportions from an actual 13x18 Mentor plate holder, which, to the best of my knowledge, nobody has been able to score so far. For now, however, I'd appreciate help from people who've already purchased Mentor plate holders of various formats with getting the following features and areas right, since none of the reference photographs I've been able to find reveal these features:

https://i.imgur.com/gaxVFQv.jpg

https://i.imgur.com/xvnalSV.jpg

https://i.imgur.com/XQKOcgq.jpg

Even if your Mentor plate is undersized (6x9 or9x12), taking photos of these areas from several angles and with rulers to set the scale would be very instructive. Please PM me to discuss. Thanks![/QUOTE]

Unforgiven

Active Member

WAIT, WHAT???

Will he make more? Possible run?

Does he have access to any other 2049 prop references?

PMed you!

Sent from my iPhone using Tapatalk

Will he make more? Possible run?

Does he have access to any other 2049 prop references?

PMed you!

New addition to the collection: Rachel's Data Card from the Tyrell Archives, created by the guy who made the originals for the movie. Beautiful prop

http://i65.tinypic.com/wt8u2d.jpg

Sent from my iPhone using Tapatalk

Stefan Jones

Sr Member

Similar threads

- Replies

- 16

- Views

- 1,003