Inspired by the amazing Lunar Module Eagle build by Crackerjazz here on RPF, I decided to design and construct a 1/10 scale Apollo 13 CSM/LEM stack together with a display stand. The end goal is that the model with be on display and used as a lecture prop in a series of space lectures in the UK, the first of which will take place at the end of Oct 2015. You may have noticed that the deadline has already passed. I actually started this project 6 months ago and it has been pretty intense at times, especially as the deadline loomed ever nearer. As such, I have not had time to start a thread until now.

So, this is a retrospective thread and will catch up with the present time quite quickly. The model is presently at a stage one of completion, meaning it looks finished but lacks fine detail and work will continue to add details in the coming months.

My thanks to Crackerjazz for sharing links, info and tips at the start of my build some 6 months ago. I don't know if I'll ever be able to replicate the incredible detail in his model but I may get there one day.

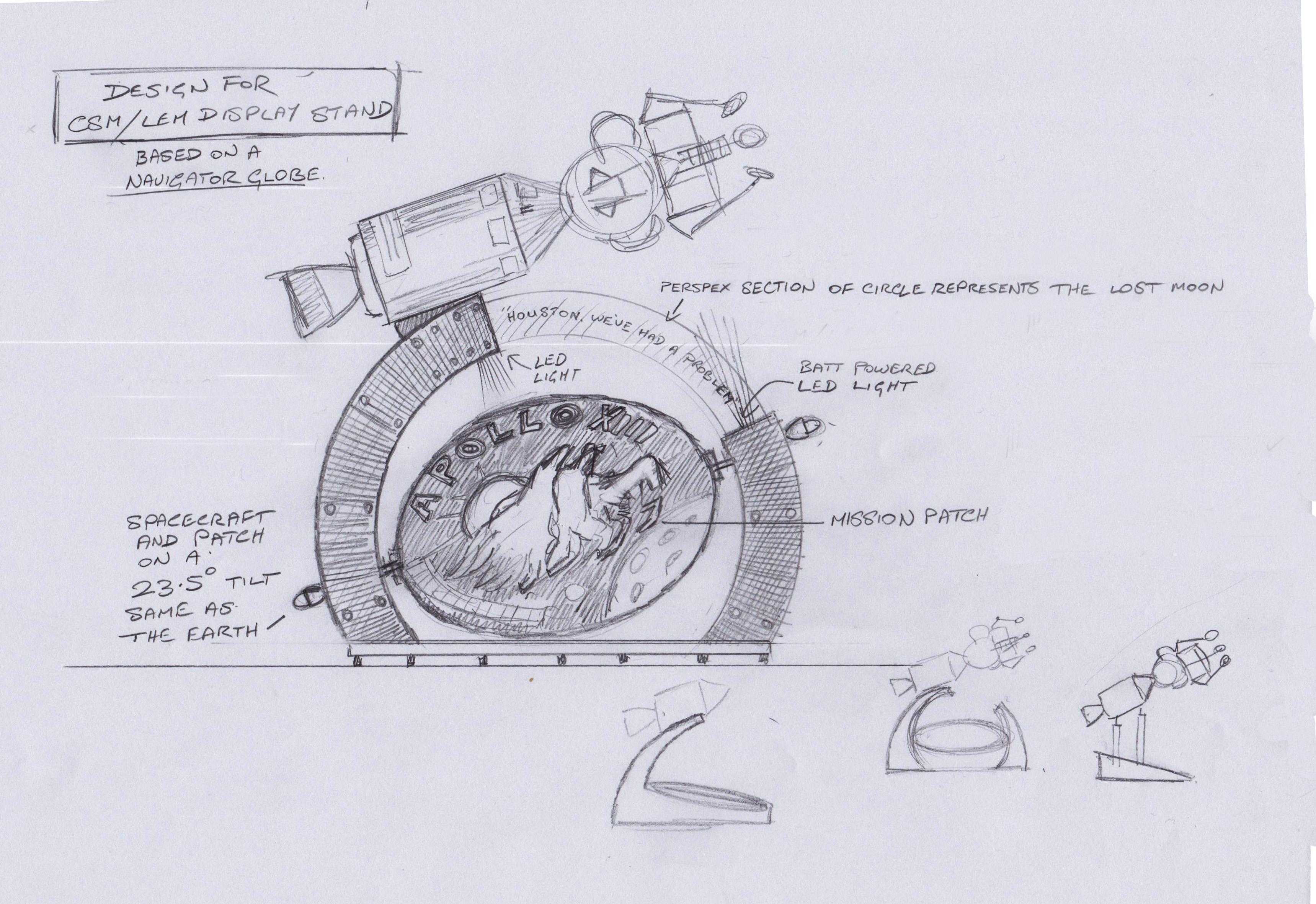

Here's a rough sketch of my design on the back of an envelope

So, this is a retrospective thread and will catch up with the present time quite quickly. The model is presently at a stage one of completion, meaning it looks finished but lacks fine detail and work will continue to add details in the coming months.

My thanks to Crackerjazz for sharing links, info and tips at the start of my build some 6 months ago. I don't know if I'll ever be able to replicate the incredible detail in his model but I may get there one day.

Here's a rough sketch of my design on the back of an envelope

Attachments

Last edited: