You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yellowjacket (Ant-Man 2015) Progress.

- Thread starter Creator1326

- Start date

Wearenotlinear

Well-Known Member

awesome.

Creator1326

Well-Known Member

What you see is 75-ish hours of printing. What you don't see (and hear) is the cursing from the few mounds of "spaghetti" that I made. All I can say is that the weak/tiny supports that the slicer Cura makes leave much to be desired. I tried all sorts of tweaks to thicken them up but it was still aggravating. Some of them are so thin I had to use blue tape to reinforce them and super glue them to the blue tape on the print bed. Ugh.

Test assembled outer helmet parts. There are four parts to the gray part.

Inner helmet. This has yellow lenses inside and outside of it.

A slight wiggled support caused some stringiness on one side. Right above the blue tape. Nothing a dremel and epoxy can't fix.

Inner helmet on printer. Look at those stupid weak support Cura produced! I had to tape them to the middle of the chin support so they didn't fall over.

Test assembled outer helmet parts. There are four parts to the gray part.

Inner helmet. This has yellow lenses inside and outside of it.

A slight wiggled support caused some stringiness on one side. Right above the blue tape. Nothing a dremel and epoxy can't fix.

Inner helmet on printer. Look at those stupid weak support Cura produced! I had to tape them to the middle of the chin support so they didn't fall over.

Creator1326

Well-Known Member

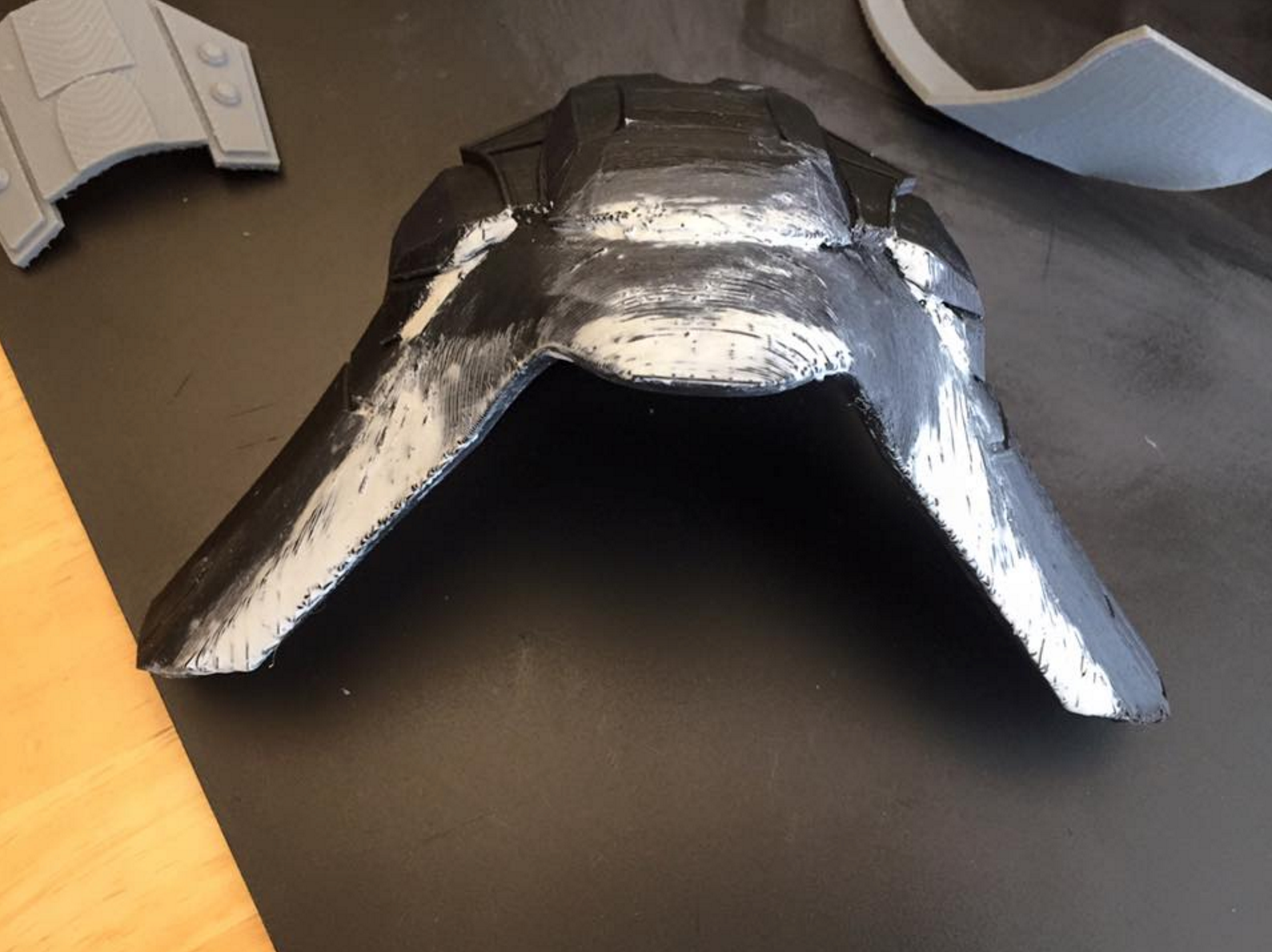

Taping pieces together and test fitting. It's fairly fitted so I had to cut some scoops out of the black bottom piece so my monkey ears would fit lol

The "U" shaped piece is the bottom side of the lower part of the helmet. You can see where I used a hot knife to scoop out some crescent shaped sections so my ears would fit. I could have made the alteration in the model but since it's on the bottom I didn't feel it was necessary.

Patching some rough sport by building it up then I'll coat it and sand it all down and repeat until smooth.

The "U" shaped piece is the bottom side of the lower part of the helmet. You can see where I used a hot knife to scoop out some crescent shaped sections so my ears would fit. I could have made the alteration in the model but since it's on the bottom I didn't feel it was necessary.

Patching some rough sport by building it up then I'll coat it and sand it all down and repeat until smooth.

Last edited by a moderator:

Your helmet looks great. What are you going to use for the transparent/translucent parts?

Creator1326

Well-Known Member

Your helmet looks great. What are you going to use for the transparent/translucent parts?

Runs now I'm looking at 3D printing out the lenses, which I'll build up a base under, and then either vacuum form or just heat form a thin piece of PETG over it and then cut to size. The trick is I have to make the 3D part slightly smaller so the actual part won't be over sized.

Sent from my iPhone using Tapatalk

Creator1326

Well-Known Member

Looking great. I always seem to forget taking into account my ears when making helmets too. Fitted is always a better look though. Good solution to get the extra space.

I'm considering putting a rubber flap on the bottom of the helmet to cover up the ear cutouts. Haven't totally decided though.

Creator1326

Well-Known Member

Resin coating pieces of the helmet with Smooth-On's XTC. YES I know there are cheaper alternatives. I've had this stuff for a while and I'm just trying to use it up.

When resin coating I always keep a few toothpicks handy so I can clean out details. I also don't like foam brushes because they tend to soak up the resin. I use disposable bristle brushes because i can very easily clean out details and back brush the resin as it sets to clean out any resin that may pool. Loving the painters triangles, those babies are handy.

I also use a super sharp chisel to clean off support material and fine tune the fit of some parts. Even though it's 3D printed and it may not have warped sometimes a close shave will fix things because nothing is perfect.

Fixed a support wobble that caused the piece under the white Apoxie sculpt to be offset about 1/16 of an inch. I dremeled off the stringy bits and then filled in with Apoxie. I wish the stuff didn't take 24hrs to dry :-/

When resin coating I always keep a few toothpicks handy so I can clean out details. I also don't like foam brushes because they tend to soak up the resin. I use disposable bristle brushes because i can very easily clean out details and back brush the resin as it sets to clean out any resin that may pool. Loving the painters triangles, those babies are handy.

I also use a super sharp chisel to clean off support material and fine tune the fit of some parts. Even though it's 3D printed and it may not have warped sometimes a close shave will fix things because nothing is perfect.

Fixed a support wobble that caused the piece under the white Apoxie sculpt to be offset about 1/16 of an inch. I dremeled off the stringy bits and then filled in with Apoxie. I wish the stuff didn't take 24hrs to dry :-/

Creator1326

Well-Known Member

Started to paint the inner helmet and mouthpiece and then realized the inner part is missing some textures

So using some 1mm, 2mm (two 1mm pieces) and some 3mm sintra I made the textures for the inner helmet

Heat shaped and super glued in place and clamped for an hour or so. Used a little Apoxie sculpt to cover up the inner edges where you see my hand.

Painted up in gloss black enamel. Still need to weather it some, this was more of a test fitting.

Also working on the chest piece. I think this entire method is just going to be a false start. I think I'm going to just make the entire mold in 3D, print it out as a negative to save some steps including walls and other flat spots and then cast it in silicone.

Last edited:

Have you considered using silicone or puff paint through a silk screen to get your textures? I know that's how they get a lot of texture on fabric for movies. You could design the pattern in photoshop and then have it screen printed. Just a thought! Helmet's looking rad though!

Creator1326

Well-Known Member

Thanks drumguy560. I've considered that but as you know this thing was all CGI and the models and video references show a dimensional thickness to this black part. I think I'm still on the molding bandwagon.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Creator1326

Well-Known Member

I built a Vacuum former with my friend TJ. It's based on the model built by Volpin Props on Instructables. I did the heater box and frame and TJ made the vacuum platen. We used it to make a set of the outer lenses. Still have to do a little shaping on them to fit them to the outer helmet then dye and glue (or screw?) them in. I made them just a little bigger on the edges so I could heat them up and force it into the shape of the helmet edge (in theory).

Creator1326

Well-Known Member

JJ Griffin

Sr Member

Oh baby. This thing is looking incredible

Creator1326

Well-Known Member

Creator1326

Well-Known Member

Creator1326

Well-Known Member

Progress and final black paint. Just need some weathering, yellow accents and grey accents.

Some more flat wiring. The grey square in the middle is where the inner helmet attaches.

The inner helmet with the lenses inserted and masked. They are removable too!

These are the lenses. You can see the LEDs on the top and sides. Edge lighting I think isn't going to work well unless I steam it up lol. I may have to come up with a plan B in the future.

Some more flat wiring. The grey square in the middle is where the inner helmet attaches.

The inner helmet with the lenses inserted and masked. They are removable too!

These are the lenses. You can see the LEDs on the top and sides. Edge lighting I think isn't going to work well unless I steam it up lol. I may have to come up with a plan B in the future.

Last edited by a moderator:

Creator1326

Well-Known Member

Similar threads

- Replies

- 2

- Views

- 819

- Replies

- 16

- Views

- 4,830