You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finished The Eighth Passenger

- Thread starter daredevil665

- Start date

-

- Tags

- alien

daredevil665

Sr Member

Re: The Eighth Passenger

Hello to all, To this mold not use silicone rubber. Use only fiberglass,because there are no undercuts. I plasticized with spray the separation area in MDF. So the wax for the posting will not be absorbed by the MDF. The black curve drawn on MDF,represents the limit of the lip which contains the keys coupling between the two shells of the mold. It is about 5 cm from the model. The keys are between them about 10 cm. The keys are made of stucco glass. I wanted to ask two pieces of information to those in the know:

Are sufficient 5 cm (2 inches) of lip coupling?

Sufficient number of keys stored in the picture?

If you notice anything that might be wrong or not work,I'd be glad to hear it.

Thank you in advance.

See you soon.

Hello to all, To this mold not use silicone rubber. Use only fiberglass,because there are no undercuts. I plasticized with spray the separation area in MDF. So the wax for the posting will not be absorbed by the MDF. The black curve drawn on MDF,represents the limit of the lip which contains the keys coupling between the two shells of the mold. It is about 5 cm from the model. The keys are between them about 10 cm. The keys are made of stucco glass. I wanted to ask two pieces of information to those in the know:

Are sufficient 5 cm (2 inches) of lip coupling?

Sufficient number of keys stored in the picture?

If you notice anything that might be wrong or not work,I'd be glad to hear it.

Thank you in advance.

See you soon.

daredevil665

Sr Member

Re: The Eighth Passenger

Hello to all,

Here are the two half-shells made of fiberglass. I had never worked with fiberglass and now I can say I do not like, and I can realize the hard work that awaits me, if I want to do all the molds. However the result is satisfactory. To know how much gypsum and how much water will be used to get the printout, I combined the two half-shells with volumes polystyrene and I filled water that I later weighed. Knowing that one kg of gypsum is combined with 250 g of water and that the mixture occupies a volume of 0.6 liters, I know how much gypsum and how much water is used. The total volume is 29 liters, thus serving about 48 kg of gypsum and 12 lt of water. A small problem I found when I filled with water, was the infiltration of water into the coupling area. To avoid this problem, I thought to seal with wax.

the polyvinol

the wax

the gel-coats

the shells

Hello to all,

Here are the two half-shells made of fiberglass. I had never worked with fiberglass and now I can say I do not like, and I can realize the hard work that awaits me, if I want to do all the molds. However the result is satisfactory. To know how much gypsum and how much water will be used to get the printout, I combined the two half-shells with volumes polystyrene and I filled water that I later weighed. Knowing that one kg of gypsum is combined with 250 g of water and that the mixture occupies a volume of 0.6 liters, I know how much gypsum and how much water is used. The total volume is 29 liters, thus serving about 48 kg of gypsum and 12 lt of water. A small problem I found when I filled with water, was the infiltration of water into the coupling area. To avoid this problem, I thought to seal with wax.

the polyvinol

the wax

the gel-coats

the shells

daredevil665

Sr Member

Re: The Eighth Passenger

Thanks Leigh,

here's the casting. The area is already very precise and clean, but I will have to remove the burrs in the middle and on the edges of the base. Some areas seem to have bent, but in reality are only spots derived from the mold, maybe it is just a little wax residue. Then I will have to polish the area useful and paste a wooden support to protect the edges of the base while dragging on the thermoforming machine.

It was tough because I was alone to carry out maneuvers. They were required 48 kg of plaster and 13.5 of water, distributed in three buckets from the weight of 20.5 kg each, to mix in a short time 2-3 minutes each, in order to have a three buckets with the same viscosity. I failed to fully dissolve all lumps of chalk. Perhaps it would be better to make a bucket at a time, ensuring better mixing. However when no bubbles or surface areas mealy.

This synthetic gypsum acquire its maximum mechanical characteristics (hardness> 300 Brinell) in 8 hours in the oven at 40 °, but in my case within 3 - 4 days at room temperature. However, it is already very hard and allows free sanding knead the sandpaper.

Post back to the mold completed.

Greetings

These could be silicone residues, however, they are the alien skin residue moulting.

Nice job! Neat & tidy :thumbsup

Thanks Leigh,

here's the casting. The area is already very precise and clean, but I will have to remove the burrs in the middle and on the edges of the base. Some areas seem to have bent, but in reality are only spots derived from the mold, maybe it is just a little wax residue. Then I will have to polish the area useful and paste a wooden support to protect the edges of the base while dragging on the thermoforming machine.

It was tough because I was alone to carry out maneuvers. They were required 48 kg of plaster and 13.5 of water, distributed in three buckets from the weight of 20.5 kg each, to mix in a short time 2-3 minutes each, in order to have a three buckets with the same viscosity. I failed to fully dissolve all lumps of chalk. Perhaps it would be better to make a bucket at a time, ensuring better mixing. However when no bubbles or surface areas mealy.

This synthetic gypsum acquire its maximum mechanical characteristics (hardness> 300 Brinell) in 8 hours in the oven at 40 °, but in my case within 3 - 4 days at room temperature. However, it is already very hard and allows free sanding knead the sandpaper.

Post back to the mold completed.

Greetings

These could be silicone residues, however, they are the alien skin residue moulting.

BatFastard

New Member

Re: The Eighth Passenger

I am totally Blown Away by your skills! Seriously, I can't believe how quickly you do this either!

I am totally Blown Away by your skills! Seriously, I can't believe how quickly you do this either!

daredevil665

Sr Member

Re: The Eighth Passenger

Thanks BatFastard,

I try, but I'm afraid it will be hard to complete the work.

However, here is the finished mold and polished. The polishing is not only necessary for a better finish of the molded part, but also to improve the extraction of the piece, because it glides better with less friction. And in this case it is necessary that slides better, because there are some undercuts.

I used an abrasive paste for car body with cloth and "gravy elbow" (way of saying fatigue)

This evening I deliver it to the supplier of thermoformed and hope that it works well.

Another point that I can recommend to those who want to do the same thing, is to keep a thickness less than that given by me, that is 25mm, because my mold weighs almost 50 kg. Should be more than enough 15mm, provided that it is ribbed like mine. You should get a mold from 30 kg.

I return to post as soon as I got the first mold.

See you soon

I am totally Blown Away by your skills! Seriously, I can't believe how quickly you do this either!

Thanks BatFastard,

I try, but I'm afraid it will be hard to complete the work.

However, here is the finished mold and polished. The polishing is not only necessary for a better finish of the molded part, but also to improve the extraction of the piece, because it glides better with less friction. And in this case it is necessary that slides better, because there are some undercuts.

I used an abrasive paste for car body with cloth and "gravy elbow" (way of saying fatigue)

This evening I deliver it to the supplier of thermoformed and hope that it works well.

Another point that I can recommend to those who want to do the same thing, is to keep a thickness less than that given by me, that is 25mm, because my mold weighs almost 50 kg. Should be more than enough 15mm, provided that it is ribbed like mine. You should get a mold from 30 kg.

I return to post as soon as I got the first mold.

See you soon

Last edited:

daredevil665

Sr Member

Re: The Eighth Passenger

Hello Leigh,

I'm waiting for the thermoformed piece. The supplier is overworked. Perhaps he will be able to give it to me next week and post the photos here. When I have the dome,I can finish the head according to the contours of the dome.

Meanwhile,I have covered other parts of the body with plastic resin two-component "DURALOID COATPLAST",to protect the polystyrene from fiberglass.

Thanks for your participation and best regards

Any progress on this?

Hello Leigh,

I'm waiting for the thermoformed piece. The supplier is overworked. Perhaps he will be able to give it to me next week and post the photos here. When I have the dome,I can finish the head according to the contours of the dome.

Meanwhile,I have covered other parts of the body with plastic resin two-component "DURALOID COATPLAST",to protect the polystyrene from fiberglass.

Thanks for your participation and best regards

Catzenjaeger

New Member

Re: The Eighth Passenger

OMG what a cool Projekt. Exellent .The 3D model and bluprints Looks also cool? How have you scale it perfect to 1:1?

OMG what a cool Projekt. Exellent .The 3D model and bluprints Looks also cool? How have you scale it perfect to 1:1?

daredevil665

Sr Member

Re: The Eighth Passenger

Thank you, With a projector.

OMG what a cool Projekt. Exellent .The 3D model and bluprints Looks also cool? How have you scale it perfect to 1:1?

Thank you, With a projector.

Catzenjaeger

New Member

Re: The Eighth Passenger

More plz

More plz

daredevil665

Sr Member

Re: The Eighth Passenger

Hello everyone,here are the molded parts, finally! However, the mold is cracked,although I can retrieve it with putty. Probably it was filled with polyurethane in the inland areas, between the ribs,and would resist better. Soon I'll put pictures of the dome trimmed on the head. I hope that the contour of the dome is not too different from that of the head.

Hello everyone,here are the molded parts, finally! However, the mold is cracked,although I can retrieve it with putty. Probably it was filled with polyurethane in the inland areas, between the ribs,and would resist better. Soon I'll put pictures of the dome trimmed on the head. I hope that the contour of the dome is not too different from that of the head.

daredevil665

Sr Member

Re: The Eighth Passenger

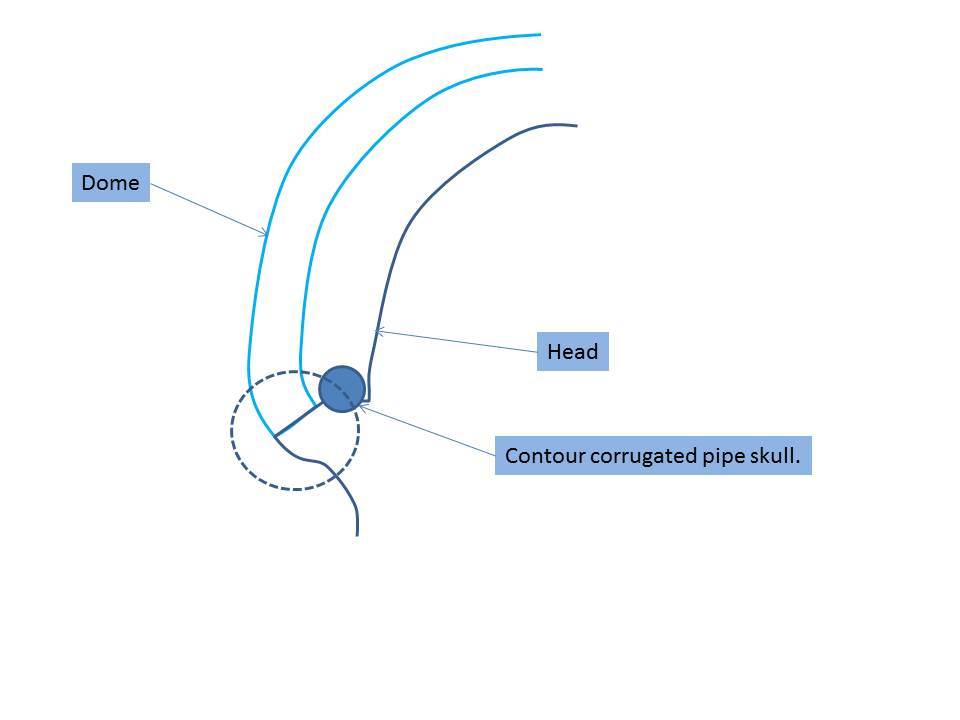

hello everyone, I'm very happy because,having taken the pieces separately,although there I trusted, I would never have expected this precision. After trimmed the dome, the contours of the head and the dome are practically identical. Now I can finally finish the head and round the contour of the head to recover that part of the radius that was not possible to get to mold,because it would be too undercut.

hello everyone, I'm very happy because,having taken the pieces separately,although there I trusted, I would never have expected this precision. After trimmed the dome, the contours of the head and the dome are practically identical. Now I can finally finish the head and round the contour of the head to recover that part of the radius that was not possible to get to mold,because it would be too undercut.

Re: The Eighth Passenger

This is Awesome!!!

How did the Vacuum forming process go? Did it all form around your mould easily?? Did it need any persuasion???

Since our moulds are very similar in design & you've been able to get on with yours, I've been looking forward to this update

This is Awesome!!!

How did the Vacuum forming process go? Did it all form around your mould easily?? Did it need any persuasion???

Since our moulds are very similar in design & you've been able to get on with yours, I've been looking forward to this update

daredevil665

Sr Member

Re: The Eighth Passenger

Hello Leigh,

Premise that this piece that Giger designed, is tremendous. :wacko

I think to make the original, have troubled a lot, that, in fact, in the scenes of the film and in the various images, it is always a bit 'ramshackle. For other people who have replicated the head of ALIEN, hiding the outline behind the tube, rather than above as in the original. In this way they avoid all the difficulties of the undercut of the dome.

For the vacuum, I brought the mold at a company that makes thermoformed. The material for the sheet to be thermoformed, I used the PETG, which is resistant to normal cans of acrylic paint and alcohol, which I use to airbrush and paint to clean up any mistakes. The slab of origin has a thickness of 5 mm to obtain a thickness of 3mm printed. The size of the sheets is 1.5 x 1 m.

The mold came out well, without fatigue or persuasion, but I think the die maker could pull more on the boundary, practicing more suction holes. I have to ask for confirmation of this question and then I will make you know.

However I think it is impossible, with a normal thermoforming, get the piece as in the original, with so much undercut. I think that the piece does not come out from the mold and you should cut without removing it from the mold. Leaving a deep groove in the mold, on the contour of the cut, so that the plastic does not reach that depth and it can be cut without damaging the mold. But this is just my idea never proven. So I chose a compromise between putting the dome in front of the tube, as in the original, but to limit the undercut, dividing it between the head and the dome.

The plaster mold is cracked in several places, probably because it was too hard. Fortunately he not scored too dome. The mold will be adjusted with filler, but I intend to do it again with a special resin charged aluminum, which probably allows casting in a mold made of fiberglass (Iam informing). This casting resin should have an exothermic peak of max 50 °, a processing time of between 2.5 and 3 hours, and a time of demoulding of 20-24 hours. This resin is made for thermoforming, because, unlike the plaster has superior mechanical characteristics and a lower cost than machined from solid metal.

For these reasons, I believe that your mold fiberglass can not resist the pressure, vacuum and temperature of the thermo-formed (130 °). I think you should follow my concept. You should build two half-shells on your mold, for casting in a resin and obtain the same form of your mold. But I think the critical point is that you also reduce undercuts, dividing them in half between the head and the dome. So change the molds of the head. Moreover, having to manually trim thermoformed, it is impossible to have a sharp coincidence of contours and will always require a minimum grouting.

You could try to make a plaster casting standard, which costs very little. This way you may see if the thermoformed out of the mold. But you still have to do at least two half-shells made of fiberglass.

It is a complicated big job! Why did a monster so complicated ?! :wacko

This is Awesome!!!

How did the Vacuum forming process go? Did it all form around your mould easily?? Did it need any persuasion???

Since our moulds are very similar in design & you've been able to get on with yours, I've been looking forward to this update

Hello Leigh,

Premise that this piece that Giger designed, is tremendous. :wacko

I think to make the original, have troubled a lot, that, in fact, in the scenes of the film and in the various images, it is always a bit 'ramshackle. For other people who have replicated the head of ALIEN, hiding the outline behind the tube, rather than above as in the original. In this way they avoid all the difficulties of the undercut of the dome.

For the vacuum, I brought the mold at a company that makes thermoformed. The material for the sheet to be thermoformed, I used the PETG, which is resistant to normal cans of acrylic paint and alcohol, which I use to airbrush and paint to clean up any mistakes. The slab of origin has a thickness of 5 mm to obtain a thickness of 3mm printed. The size of the sheets is 1.5 x 1 m.

The mold came out well, without fatigue or persuasion, but I think the die maker could pull more on the boundary, practicing more suction holes. I have to ask for confirmation of this question and then I will make you know.

However I think it is impossible, with a normal thermoforming, get the piece as in the original, with so much undercut. I think that the piece does not come out from the mold and you should cut without removing it from the mold. Leaving a deep groove in the mold, on the contour of the cut, so that the plastic does not reach that depth and it can be cut without damaging the mold. But this is just my idea never proven. So I chose a compromise between putting the dome in front of the tube, as in the original, but to limit the undercut, dividing it between the head and the dome.

The plaster mold is cracked in several places, probably because it was too hard. Fortunately he not scored too dome. The mold will be adjusted with filler, but I intend to do it again with a special resin charged aluminum, which probably allows casting in a mold made of fiberglass (Iam informing). This casting resin should have an exothermic peak of max 50 °, a processing time of between 2.5 and 3 hours, and a time of demoulding of 20-24 hours. This resin is made for thermoforming, because, unlike the plaster has superior mechanical characteristics and a lower cost than machined from solid metal.

For these reasons, I believe that your mold fiberglass can not resist the pressure, vacuum and temperature of the thermo-formed (130 °). I think you should follow my concept. You should build two half-shells on your mold, for casting in a resin and obtain the same form of your mold. But I think the critical point is that you also reduce undercuts, dividing them in half between the head and the dome. So change the molds of the head. Moreover, having to manually trim thermoformed, it is impossible to have a sharp coincidence of contours and will always require a minimum grouting.

You could try to make a plaster casting standard, which costs very little. This way you may see if the thermoformed out of the mold. But you still have to do at least two half-shells made of fiberglass.

It is a complicated big job! Why did a monster so complicated ?! :wacko

Last edited:

daredevil665

Sr Member

Re: The Eighth Passenger

Meanwhile I answer that, I have confirmed that the resin molds charged aluminum, can be cast in molds made of fiberglass.

The resin is MC 1164 / W 340, which you can find here:

http://www.cristex.co.uk/products/tooling-system-resin

This is Awesome!!!

How did the Vacuum forming process go? Did it all form around your mould easily?? Did it need any persuasion???

Since our moulds are very similar in design & you've been able to get on with yours, I've been looking forward to this update

Meanwhile I answer that, I have confirmed that the resin molds charged aluminum, can be cast in molds made of fiberglass.

The resin is MC 1164 / W 340, which you can find here:

http://www.cristex.co.uk/products/tooling-system-resin

Last edited:

daredevil665

Sr Member

Re: The Eighth Passenger

...I forgot, another tip if you do a plaster mold, is to fill the cavity between the ribs with polyurethane foam at least 90kg / m3 density. This could help to support the collapsing vacuum producing cracks.

In my case, it would take about 28 liter volume of the mold, which is equivalent to 6 cans MC 1164 + 6 cans of hardener W 340, for a total of 174 €. For the synthetic gypsum spent € 150. So, for just 24 € difference, I could make the mold resin that would not be cracked, but I thought it was not compatible with the fiberglass.

...I forgot, another tip if you do a plaster mold, is to fill the cavity between the ribs with polyurethane foam at least 90kg / m3 density. This could help to support the collapsing vacuum producing cracks.

In my case, it would take about 28 liter volume of the mold, which is equivalent to 6 cans MC 1164 + 6 cans of hardener W 340, for a total of 174 €. For the synthetic gypsum spent € 150. So, for just 24 € difference, I could make the mold resin that would not be cracked, but I thought it was not compatible with the fiberglass.

Last edited:

Similar threads

- Replies

- 0

- Views

- 400

- Replies

- 6

- Views

- 864

- Replies

- 19

- Views

- 1,387