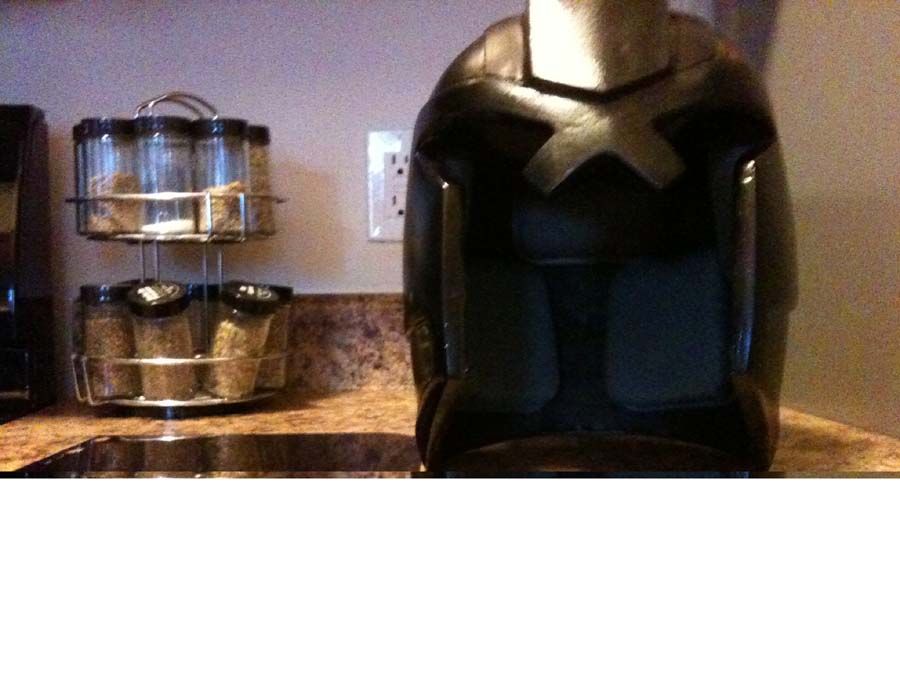

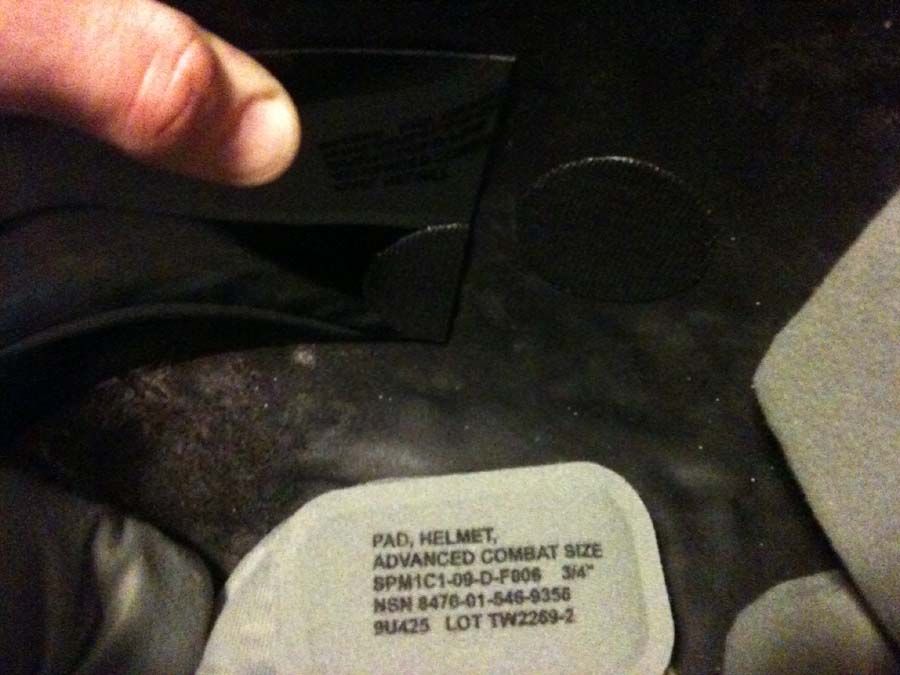

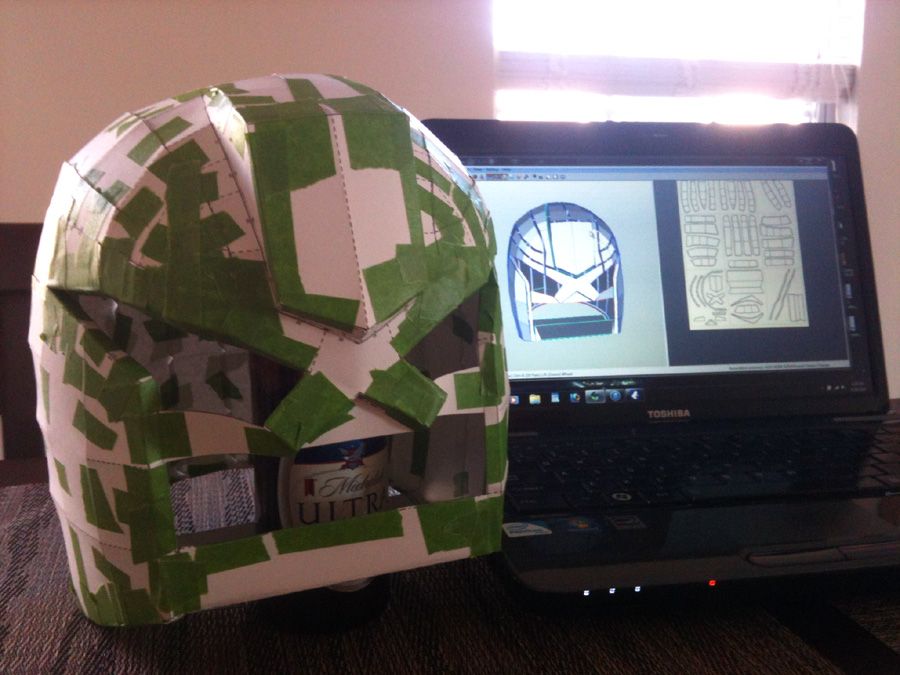

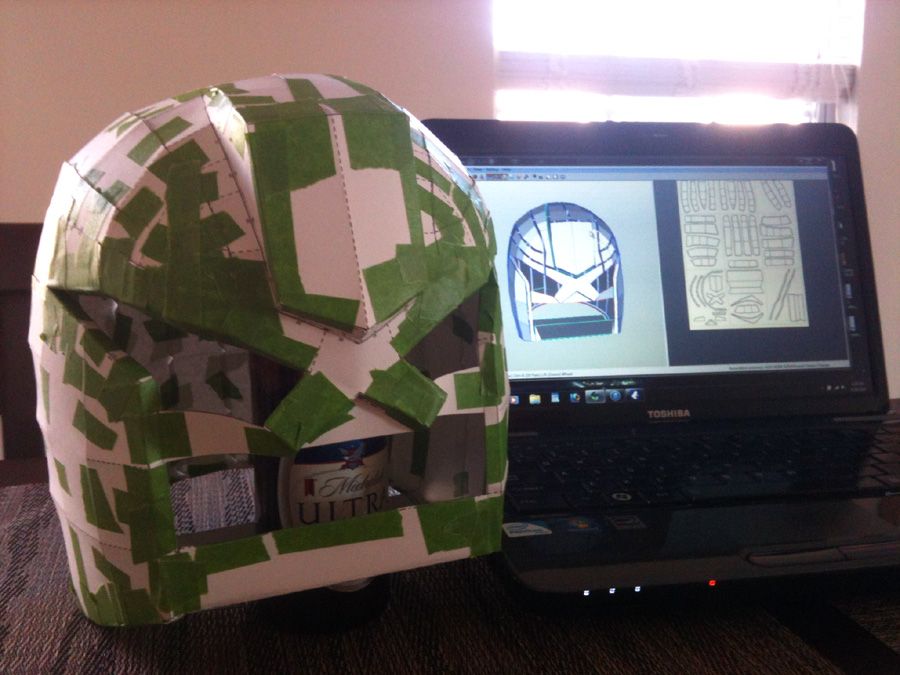

I've never attempted anything like this before, this is all a first for me! Been lurking for a bit, but having been inspired by some of the sweet lids and homemade armors, I'm building a Dredd helmet from the Blaxmyth pep file. Seeing as I didn't have a clue on what I was doing, I printed out and assembled an A4 sized (and then scaled to fit) copy, which is a fit without any padding but will eventually be cut and extended. I printed out the proper Letter sized version and did not do any scaling, cut and assembled, and it seems to be great!

Assembly, yes I used tape, I was impatient and did not want to wait to source proper glue. After assembly I did brush the pep with a Elmers glue mixture (just a little water) to harden it up a tad. This is probably unnecessary and did cause some edges to come up on the tape.

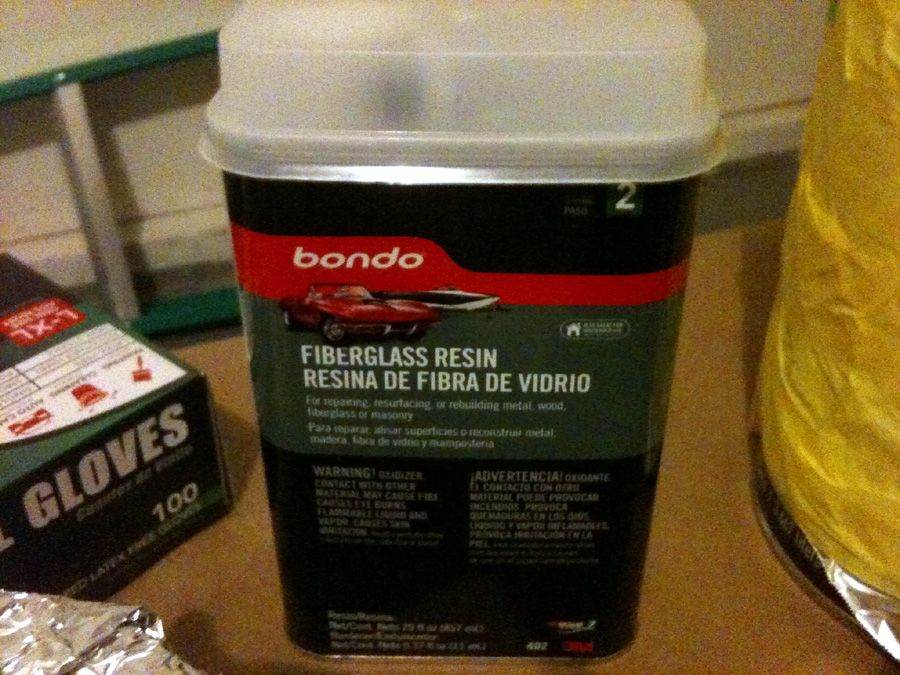

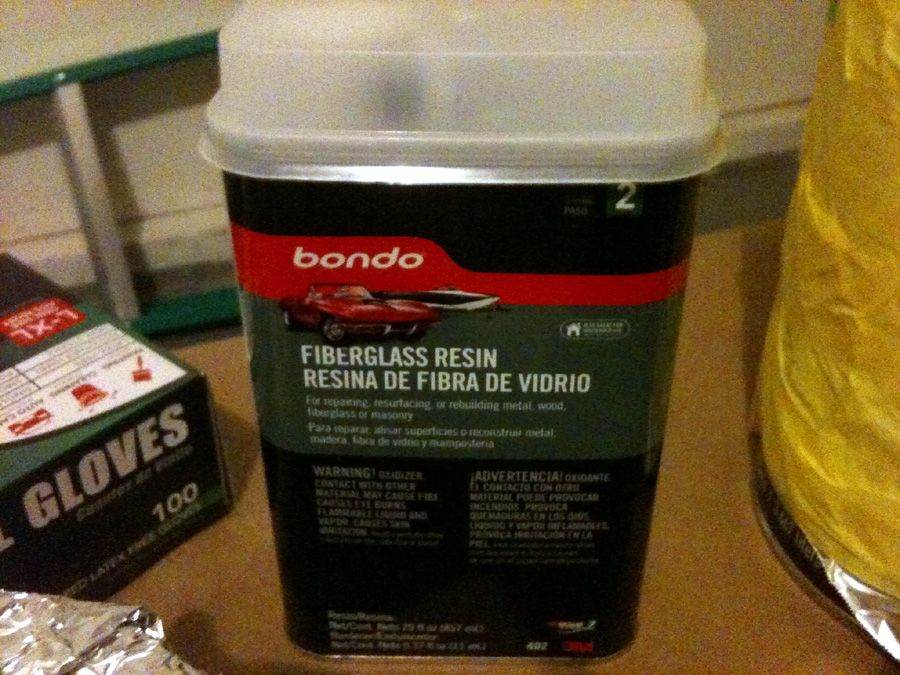

Had time to hit Walmart on my way home from work, grabbed some resin.

Workstation (my garage, door open for fumes)

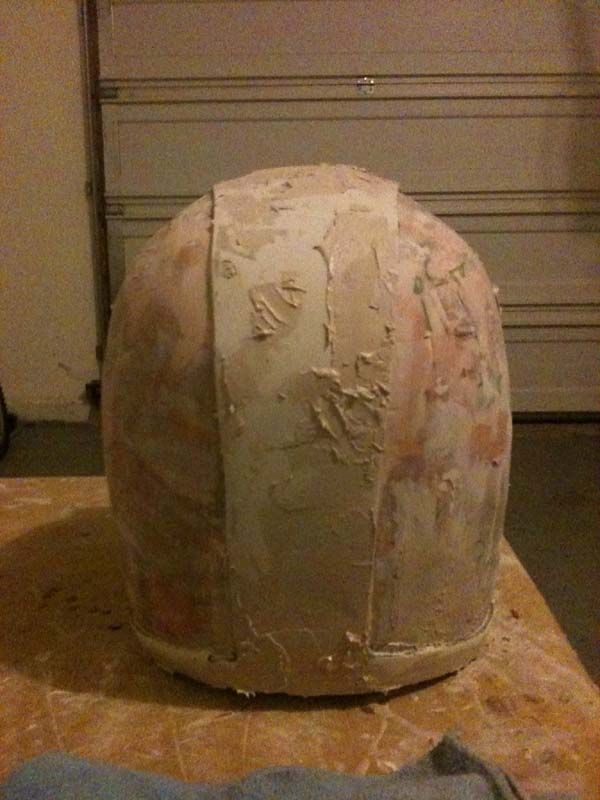

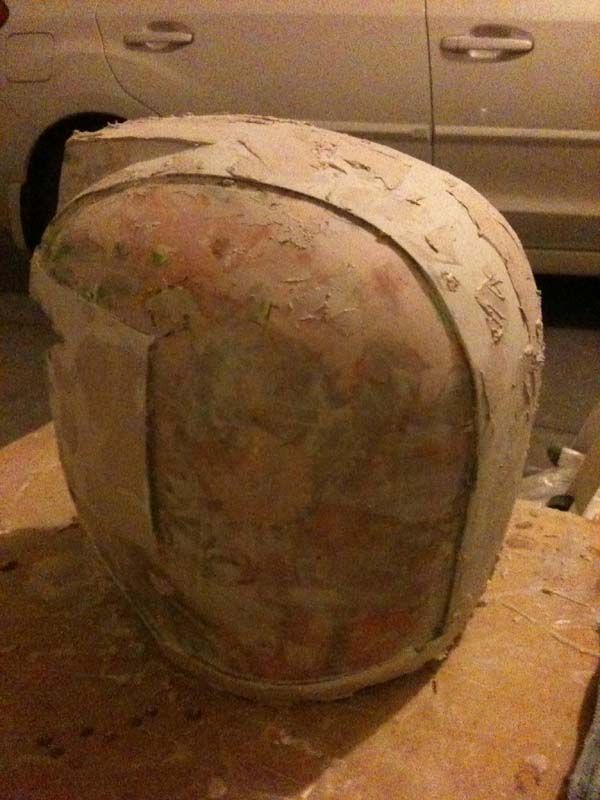

After my first coat of resin, I'm pretty pleased with the shape thus far. 1 more coat tonight on the outside, then I'll hit the inside and lay some fiberglass sheeting for strength. Bondo soon enough!

I have ordered a cheapo ($50 shipped) leather jacket off of fleabay and have an older Swat/tactical vest that will be perfect (I think anyway) to affix panels to for armor. I have foam sheets that I plan to seal and paint, I might need to get another type of foam but these were free so they get first crack. Also I am bidding on a Nerf Retaliator on Ebay as well, if it falls thru another trip to Walmart will be in order.

Tips or comments are welcome, I am a total newbie here. Cheers! :cool

Assembly, yes I used tape, I was impatient and did not want to wait to source proper glue. After assembly I did brush the pep with a Elmers glue mixture (just a little water) to harden it up a tad. This is probably unnecessary and did cause some edges to come up on the tape.

Had time to hit Walmart on my way home from work, grabbed some resin.

Workstation (my garage, door open for fumes)

After my first coat of resin, I'm pretty pleased with the shape thus far. 1 more coat tonight on the outside, then I'll hit the inside and lay some fiberglass sheeting for strength. Bondo soon enough!

I have ordered a cheapo ($50 shipped) leather jacket off of fleabay and have an older Swat/tactical vest that will be perfect (I think anyway) to affix panels to for armor. I have foam sheets that I plan to seal and paint, I might need to get another type of foam but these were free so they get first crack. Also I am bidding on a Nerf Retaliator on Ebay as well, if it falls thru another trip to Walmart will be in order.

Tips or comments are welcome, I am a total newbie here. Cheers! :cool