robn1

Master Member

I've been using this paint pot from Harbor Freight for casting

Paint Pressure Tank - 2-1/2 Gallon

The poor design of the clamps made it difficult to seal it air tight. I had to tighten the bolts with a wrench, which caused severe damage to the lid.

The clamps and bolts are cast metal which eventually became deformed, they no longer turn without a wrench. The thought of using it any more is just too scary.

While searching the web for info on this pot I found this horror story. The guy made an unsafe modification to the lid, and was operating at 90psi! but it still gave me the willies.Catastrophic pressure pot failure...my wife almost became a widow! - International Association of Penturners

My search also turned up this post, which got me thinking about the Grizzly pot.

Resin Addict Forum ? View topic - CA Technologies - Pressure Pot : A Review

H6329 2-1/2 gal. Paint Tank w/ Gauges

So I got one last week.

It needs the same mods as the HF pot to get it ready for casting, plus a couple more. First I removed the siphon tube with a torch and pliers.

The Grizzly pot also has a paint mixer installed in the lid, which I also removed.

This unfortunately left a huge hole through the lid.

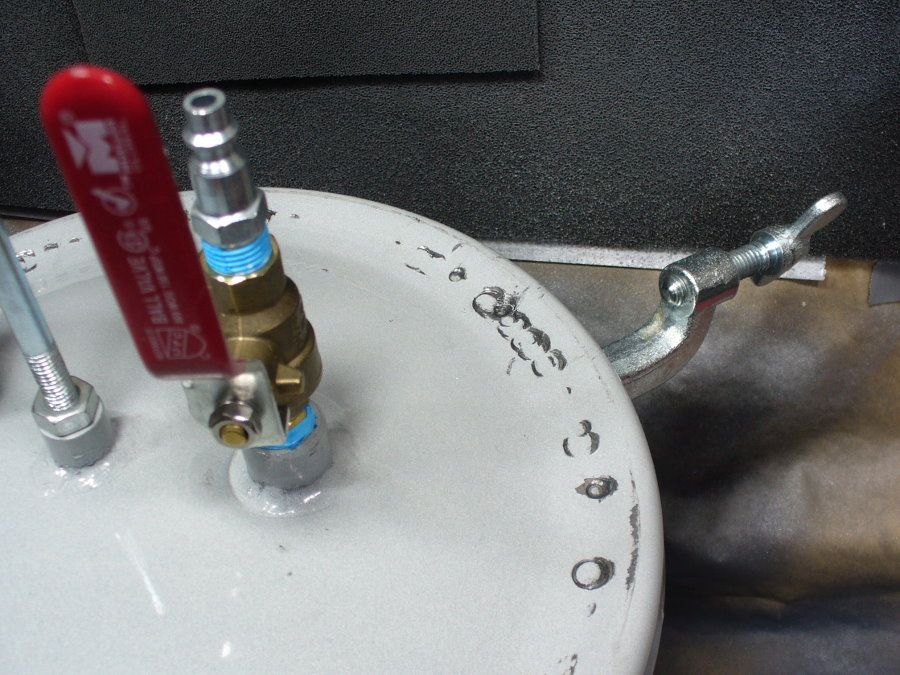

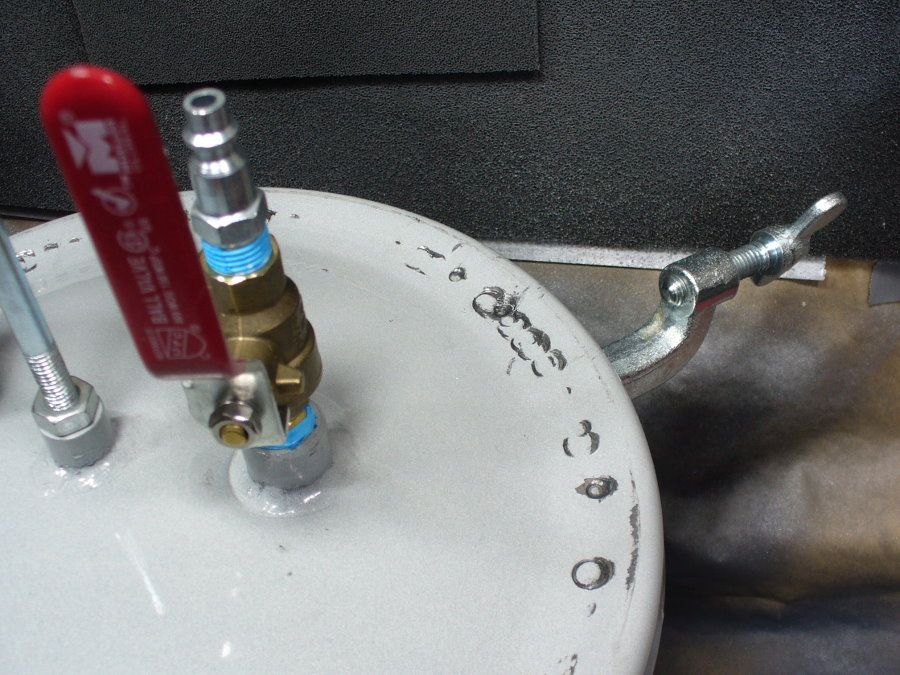

I got a 5/8 bolt, washers and nut to seal it.

I removed the mixer fitting and reattached it with silicone gasket compound.

I applied the gasket to the bolt threads, and to the back of the washers.

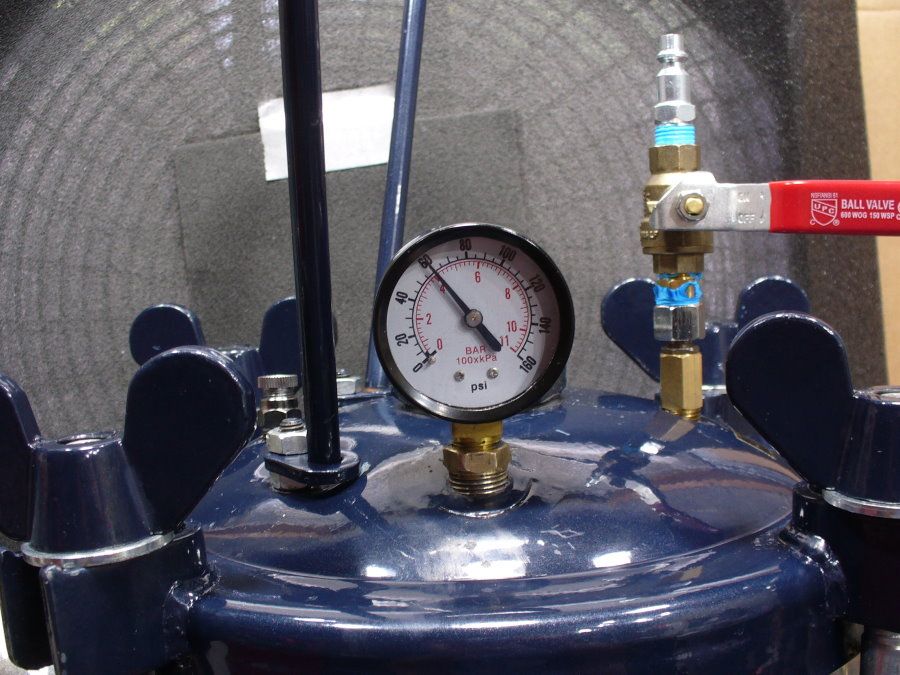

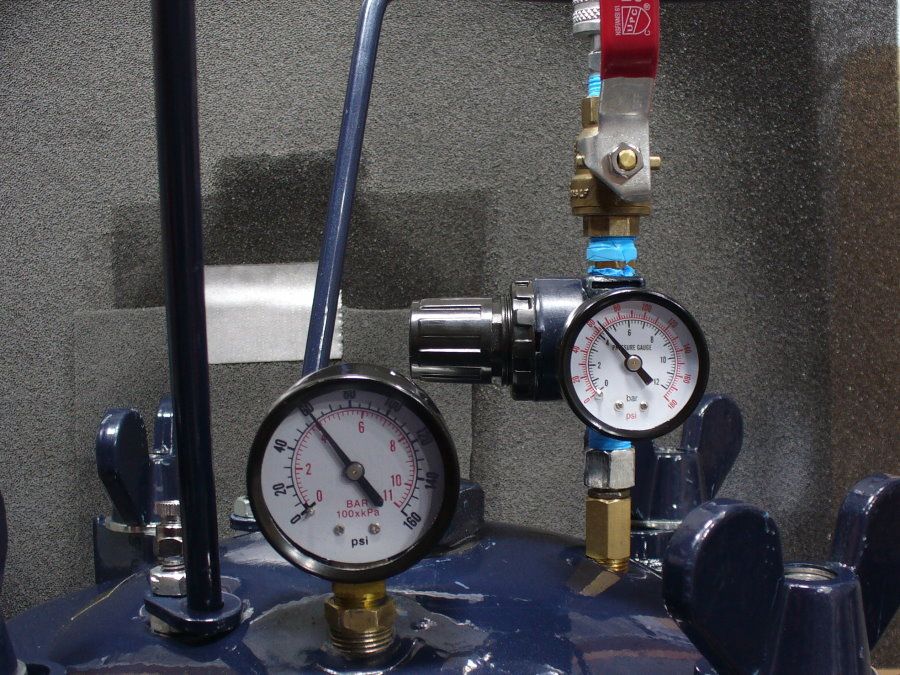

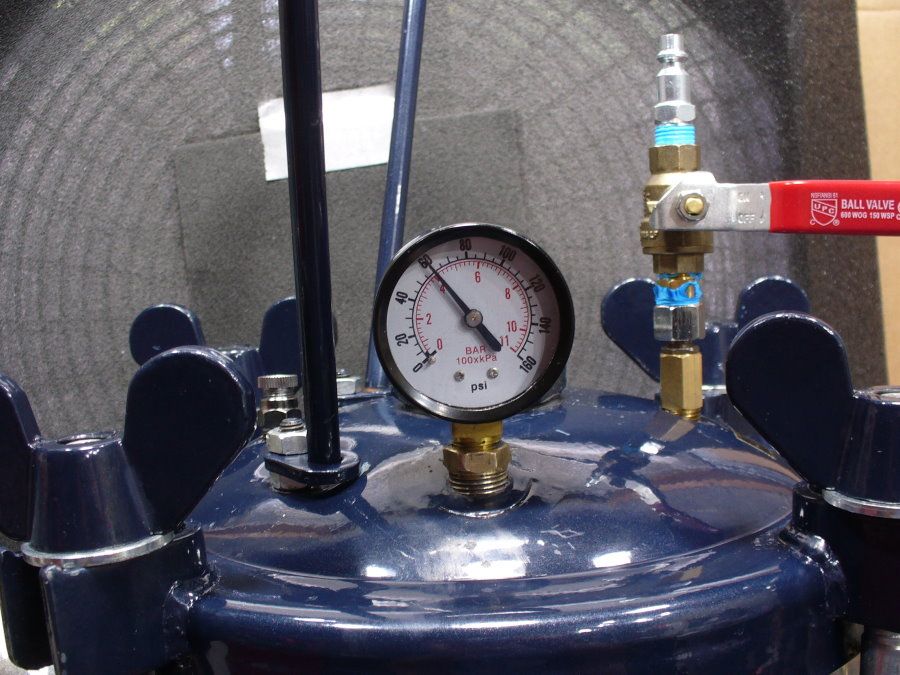

Here it is with a gauge and ball valve attached. I used a valve from the plumbing dept., it feels more substantial than the air tool valves.

The Grizzly clamps are much better than the HF. They won't damage the lid, and the large wing nuts can be tightened by hand.

I tested it out at my usual 60psi, but it had a slow leak. It lost 15psi over three hours.

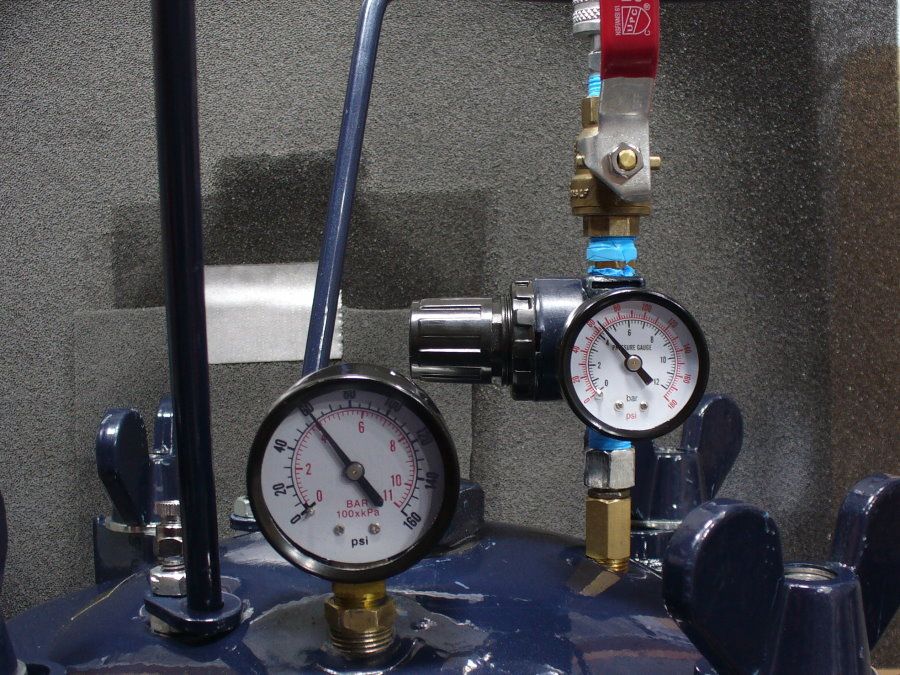

So I added the regulator that came with it. By setting the regulator to my desired pressure, I can leave the air supply attached and it keeps it topped off.

If I bleed pressure from the safety valve, it will go back to 60psi once the valve closes. After three hours it was still right where I left it.

This pot is much more heavy duty than the HF, the lid alone weighs as much as the whole HF! I now have a great pressure casting rig, for about $170 total for the pot and extra parts. Not too bad

Paint Pressure Tank - 2-1/2 Gallon

The poor design of the clamps made it difficult to seal it air tight. I had to tighten the bolts with a wrench, which caused severe damage to the lid.

The clamps and bolts are cast metal which eventually became deformed, they no longer turn without a wrench. The thought of using it any more is just too scary.

While searching the web for info on this pot I found this horror story. The guy made an unsafe modification to the lid, and was operating at 90psi! but it still gave me the willies.Catastrophic pressure pot failure...my wife almost became a widow! - International Association of Penturners

My search also turned up this post, which got me thinking about the Grizzly pot.

Resin Addict Forum ? View topic - CA Technologies - Pressure Pot : A Review

H6329 2-1/2 gal. Paint Tank w/ Gauges

So I got one last week.

It needs the same mods as the HF pot to get it ready for casting, plus a couple more. First I removed the siphon tube with a torch and pliers.

The Grizzly pot also has a paint mixer installed in the lid, which I also removed.

This unfortunately left a huge hole through the lid.

I got a 5/8 bolt, washers and nut to seal it.

I removed the mixer fitting and reattached it with silicone gasket compound.

I applied the gasket to the bolt threads, and to the back of the washers.

Here it is with a gauge and ball valve attached. I used a valve from the plumbing dept., it feels more substantial than the air tool valves.

The Grizzly clamps are much better than the HF. They won't damage the lid, and the large wing nuts can be tightened by hand.

I tested it out at my usual 60psi, but it had a slow leak. It lost 15psi over three hours.

So I added the regulator that came with it. By setting the regulator to my desired pressure, I can leave the air supply attached and it keeps it topped off.

If I bleed pressure from the safety valve, it will go back to 60psi once the valve closes. After three hours it was still right where I left it.

This pot is much more heavy duty than the HF, the lid alone weighs as much as the whole HF! I now have a great pressure casting rig, for about $170 total for the pot and extra parts. Not too bad