</SPAN><TABLE BORDER=0 ALIGN=CENTER WIDTH=85%><TR><TD CLASS=$row_color>

lonepigeon wrote:<HR></TD></TR><TR><TD CLASS=$row_color>

The brass catch I used to have (can't find it now) looked like the one Kenny posted. I could swear it had a little hole in the center already - which is why I never questioned the little hole before.

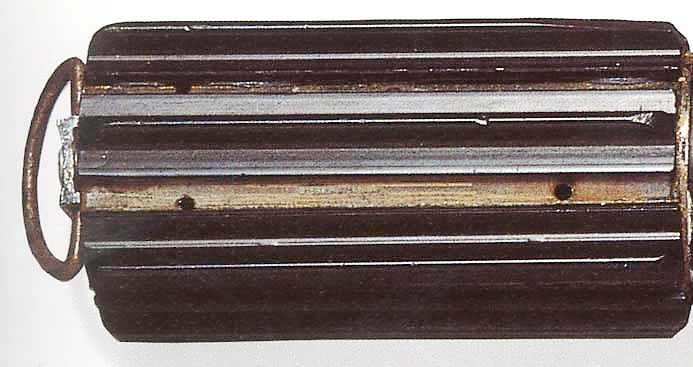

I see nothing showing the rear (grip area) is a larger diameter than the "clamp" or front part.

DS- I think you're seeing a highlight off that cut groove or something, plus there's a fair size gap between the grips and "clamp".

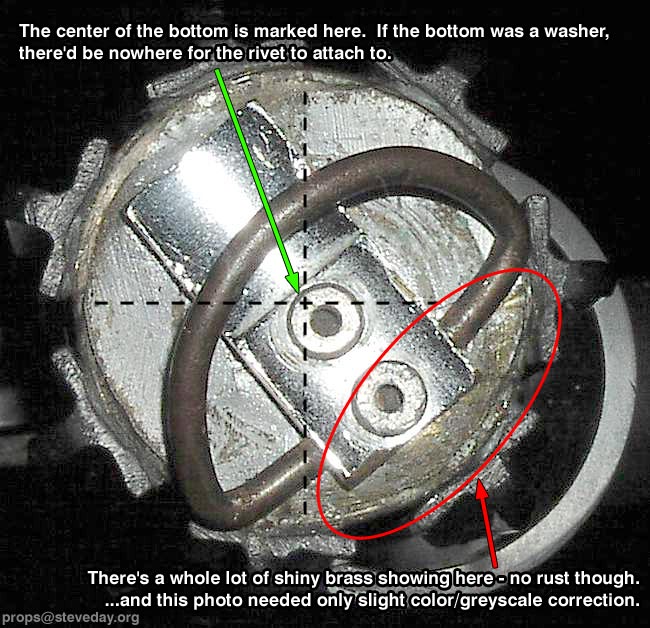

The bottom piece, Graflex or not, had a bottom to begin with because the metal circle is riveted to something- pressing it down in the center.

It still looks like a Graflex bottom to me. I doubt the difference between 20 year old aluminum "conduit" and a 20 year old plated flash tube would even be that noticable (half covered with grips and lots of grime on the rest). Since the top half is a bit shiner I think it's common to at first think the bottom is a different material, but I see no proof that it is.

Where's the proof for the bottom cap being brass? The one photo? The color is hardly correct on it and other areas look rusty in the same pic- It can't go both ways, brass doesn't rust.

To clarify - IF the bottom piece was a washer the center hole was not used. It just would have been a handy metal circle. They would have drilled two new holes.

I tend to lean towards sheet metal, but I did find a pretty thin metal washer I had laying around in my parts box for several years as a possible part for this saber. It seems like it would work pretty well too.

</TD></TR><TR><TD><HR></TD></TR></TABLE><SPAN CLASS=$row_color>

Well, the proof of the pie is in the eating...

The One photo? ...well, I'd rather trust a clear, well focused and well lit single photo than a dozen obliquely angled blurred ones of the same area. If you prefer to squint and see clouds that look like elephants, that's entirely up to you.

No, brass doesn't rust, which is why we can't see any on the bottom plate. There is rust on the D-ring though, as I mentioned earlier, but that's a seperate component.

Chris, do you have any proof that supports your theory of the bottom being a steel washer?

mmmm .... Pie!

Steve

.jpg)