You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Men in Black MIB Pulsar project

- Thread starter Zombie Killer

- Start date

Re: MIB Pulsar project

Thats some good timing Pat, just got done cleaning up after working on 3 projects and this was one. FINALLY got the broken grip back on and strengthened. I used TC1630 yesterday to get the grip held in psoition and today got it stregthened with epoxy resin and glass. I have about 7 layers of glass. I will probably give both sides another 5 or more in the grip area to make sure it doesn't come off again. It lined up nice!

Broken one is on the bottom half in the first pic. Second pic show the 2 halves together and how they lined up.

Thats some good timing Pat, just got done cleaning up after working on 3 projects and this was one. FINALLY got the broken grip back on and strengthened. I used TC1630 yesterday to get the grip held in psoition and today got it stregthened with epoxy resin and glass. I have about 7 layers of glass. I will probably give both sides another 5 or more in the grip area to make sure it doesn't come off again. It lined up nice!

Broken one is on the bottom half in the first pic. Second pic show the 2 halves together and how they lined up.

Last edited:

Rusty85

Sr Member

Re: MIB Pulsar project

Looks great Glenn! I just got a PS3 and was considering buying the Bluray to get some good screen caps to see if there was anything useful for reference. How are you going to go about doing the top chamber that's supposed to be clear with the alien inside? I remember that the rings that hold the clear tube in place were misaligned.

Looks great Glenn! I just got a PS3 and was considering buying the Bluray to get some good screen caps to see if there was anything useful for reference. How are you going to go about doing the top chamber that's supposed to be clear with the alien inside? I remember that the rings that hold the clear tube in place were misaligned.

Re: MIB Pulsar project

Blue ray is great. I got alot of shots from it. When i build mine i will be using as many real parts as possible. For the top i am getting clear acrylic and will machine some aluminum rings to go around them. I want to see about sculpting the creature inside and put liquid in too. I may even do that top part that goes along the top of the barrel part in machined aluminum with the slots cut. I am going all out on this guy. I will probably cut it all the way down to just the shell halves and machine all the side parts like the revolver looking parts, that hammer looking thing in front of it. Also planning on using real break cable covering near the tube you speak of. Trying to find some correct looking drawer slides for the pump grip to slide on too. I have to get those top teardrop looking parts made in aluminum because these are pretty much useless. Also need to clean out the barrel side vents to fit stainless conduit like the original. I am going for the gusto on my personal build. Still need to ID a bunch o stuff.

Blue ray is great. I got alot of shots from it. When i build mine i will be using as many real parts as possible. For the top i am getting clear acrylic and will machine some aluminum rings to go around them. I want to see about sculpting the creature inside and put liquid in too. I may even do that top part that goes along the top of the barrel part in machined aluminum with the slots cut. I am going all out on this guy. I will probably cut it all the way down to just the shell halves and machine all the side parts like the revolver looking parts, that hammer looking thing in front of it. Also planning on using real break cable covering near the tube you speak of. Trying to find some correct looking drawer slides for the pump grip to slide on too. I have to get those top teardrop looking parts made in aluminum because these are pretty much useless. Also need to clean out the barrel side vents to fit stainless conduit like the original. I am going for the gusto on my personal build. Still need to ID a bunch o stuff.

gbound

New Member

Re: MIB Pulsar project

Hi, just want to say that´s amazing work with te pulsar and I want to ask you if you still have the tri-barrel, because I want build one, but I´m struggling to get the right size with the photos from other threads, like this one http://www.therpf.com/f9/men-black-tri-barrel-project-updated-4-a-58496/, I want to make it in metal, machine some parts like the barrels and the main body in metal casting or something like that, I want to do almost everything myself, like this things I made in the past.

Any suggestions are welcome.

greetings from Mexico

Hi, just want to say that´s amazing work with te pulsar and I want to ask you if you still have the tri-barrel, because I want build one, but I´m struggling to get the right size with the photos from other threads, like this one http://www.therpf.com/f9/men-black-tri-barrel-project-updated-4-a-58496/, I want to make it in metal, machine some parts like the barrels and the main body in metal casting or something like that, I want to do almost everything myself, like this things I made in the past.

Any suggestions are welcome.

greetings from Mexico

Re: MIB Pulsar project

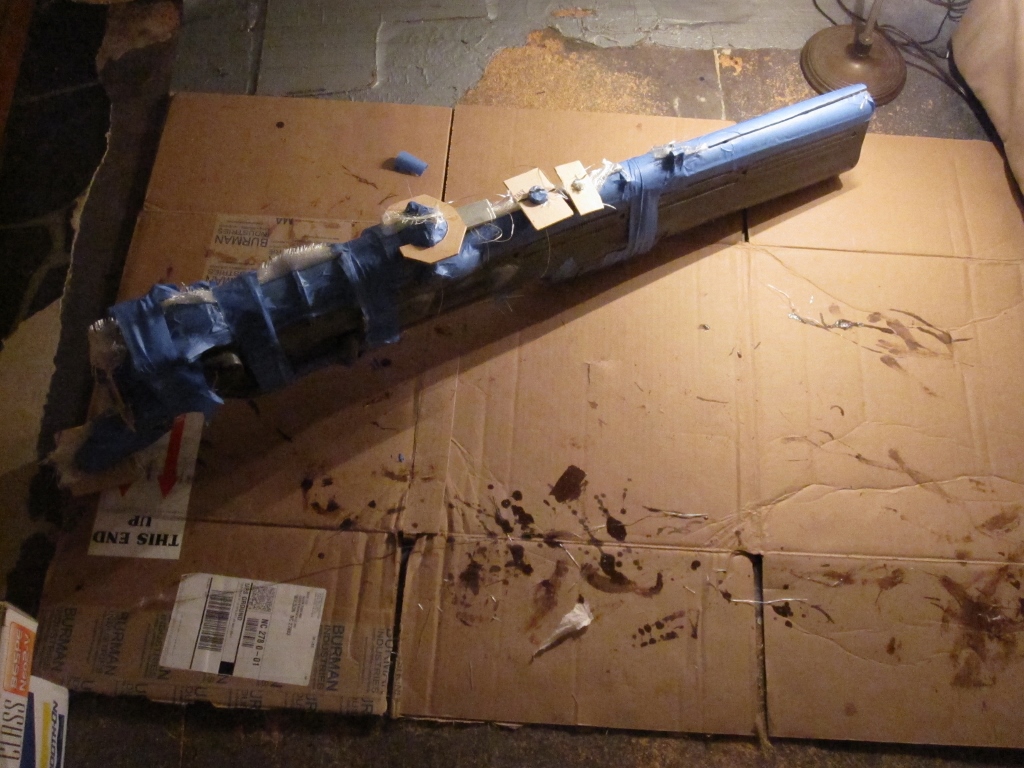

A little update. Finally got around to working on this thing again. She is back together. Bit of a mess but I guess i'll see what I have tomorrow when it all cures. I taped the edges up and laid 2 layers of glass and resin to the edges of both halves for a total of 4. Then I stuck them together , reattached my locating jigs and taped it up. I think the halves are lined up but will not know for sure until it dries. I did not glue the front barrel area yet. The front is twisted and I need to untwist it and glue that after the rear is cured. I'll have to trim away all the edges after it cures too.

Couple pics....

A little update. Finally got around to working on this thing again. She is back together. Bit of a mess but I guess i'll see what I have tomorrow when it all cures. I taped the edges up and laid 2 layers of glass and resin to the edges of both halves for a total of 4. Then I stuck them together , reattached my locating jigs and taped it up. I think the halves are lined up but will not know for sure until it dries. I did not glue the front barrel area yet. The front is twisted and I need to untwist it and glue that after the rear is cured. I'll have to trim away all the edges after it cures too.

Couple pics....

Last edited:

Re: MIB Pulsar project

A little bit of a mixed bag but not too bad. The grip and receiver area lined up nice. Only issue is the bottom, from the front of the magwell forward. One side is about 1/16" lower. It's not really an assembly issue , the casting is just curved more on one half than the other. Still bugged me so I cut the bottom open again and I will realign it and re epoxy it. Now that the top half is together it will not be a big deal. Will do that next.

Top section and grip looks OK

Here the rings are lined up but they don't look it because they were sanded when the halves were assembled crooked.

You can just see where the flat area just ahead of the magwell is not lined up.

Recut the bottom, ready to be realigned.

I probably shouldn't do this but I wanted to make sure my grip repair would hold up. Looks like a winner. I can hold it up one handed by the grip. Yay! All I need is a cup of coffee and I am ready to glass again!

A little bit of a mixed bag but not too bad. The grip and receiver area lined up nice. Only issue is the bottom, from the front of the magwell forward. One side is about 1/16" lower. It's not really an assembly issue , the casting is just curved more on one half than the other. Still bugged me so I cut the bottom open again and I will realign it and re epoxy it. Now that the top half is together it will not be a big deal. Will do that next.

Top section and grip looks OK

Here the rings are lined up but they don't look it because they were sanded when the halves were assembled crooked.

You can just see where the flat area just ahead of the magwell is not lined up.

Recut the bottom, ready to be realigned.

I probably shouldn't do this but I wanted to make sure my grip repair would hold up. Looks like a winner. I can hold it up one handed by the grip. Yay! All I need is a cup of coffee and I am ready to glass again!

Last edited:

Re: MIB Pulsar project

Thx MxlPlx!

A little more, when the gun that was molded was made they did not glue the halves together correctly at the pump grip and barrel area. one side sat about 1/16" too low. On top of that when they molded that gun they did not mold it right down the middle, it is off to one side. I needed to cut that section off the one half and reattach it to the correct half in the right position then glue the 2 halves again . This way I could correct the lower piece and still preserve the original middle "joint" In these pics I have relined up the bottom, cut the piece off one side of the grip and reattached to the proper side and epoxied it again. I will have to do this same thing with the bottom of the barrel because it has the same issue. Tomorrow I will tackle correcting the barrel.

Thx MxlPlx!

A little more, when the gun that was molded was made they did not glue the halves together correctly at the pump grip and barrel area. one side sat about 1/16" too low. On top of that when they molded that gun they did not mold it right down the middle, it is off to one side. I needed to cut that section off the one half and reattach it to the correct half in the right position then glue the 2 halves again . This way I could correct the lower piece and still preserve the original middle "joint" In these pics I have relined up the bottom, cut the piece off one side of the grip and reattached to the proper side and epoxied it again. I will have to do this same thing with the bottom of the barrel because it has the same issue. Tomorrow I will tackle correcting the barrel.

Last edited:

Re: MIB Pulsar project

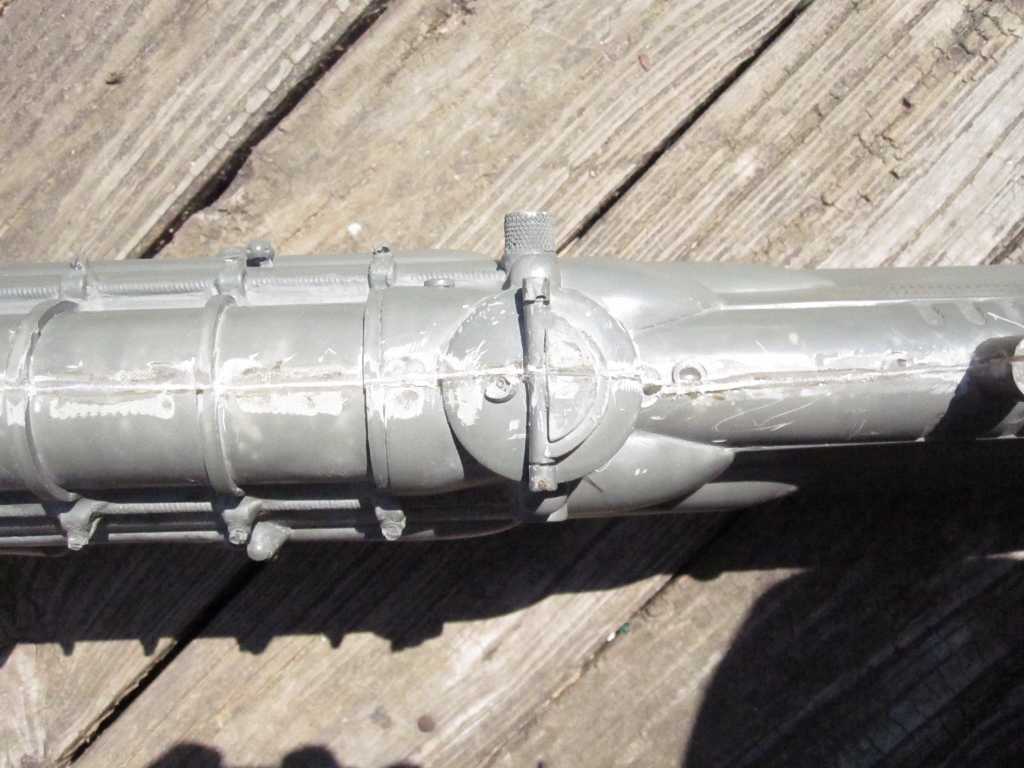

After pulling off all the tape and doing a bit a cleaning everything lined up really nice.

I epoxied the piece back on the correct side so now the grip is split down the middle again.

I'll need to do the same to the barrel.

The only part I need to fix is the rear receiver part. It's a bit warped too . It's why it doesn't line up right. I'll do it after the barrel .

Next thing was to straighten the barrel. Everything forward of the front sight was curved to the right, had droop and it was twisted. First I straightened one side. then the other. Here you can see I moved it over 1/4" which in the end was still not enough...... I used a heat gun and heated it up until it was a bit pliable.

Still warped to the right.

So after moving the barrel yet another 1/4" at least, jacking it up about 3/8 and untwisting the barrel most of the way shes really straight. Just had a pinch in the sides just behind the sight. I ended up recuting that area and unpinching it. I want to make a new top shroud out of aluminum so I really need this thing to be straight.

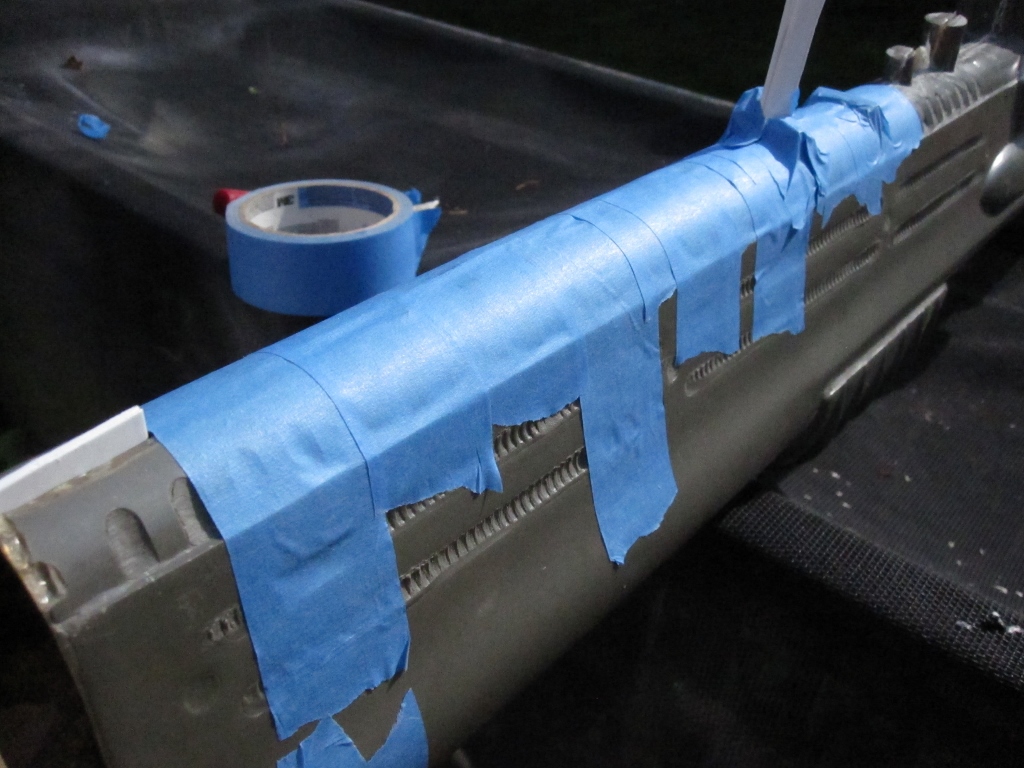

Once I was sure the top was straight I taped it up and glassed it. I put around 6 layers of glass. It was fun trying to do this part.....

And so the top is reattached and super straight. Next i'll takle the bottom of the barrel. I need to do a little more untwisting and reshaping at the bottom so the sides meet straighter than they were. On the gun that was molded the bottom did not line up and i do want to fix that. Then i'll fix the rear receiver area and rebuild the grip then the cleanup comes along with replacing all the screws with real ones. It's been alot of work but I am very happy with progress so far.

After pulling off all the tape and doing a bit a cleaning everything lined up really nice.

I epoxied the piece back on the correct side so now the grip is split down the middle again.

I'll need to do the same to the barrel.

The only part I need to fix is the rear receiver part. It's a bit warped too . It's why it doesn't line up right. I'll do it after the barrel .

Next thing was to straighten the barrel. Everything forward of the front sight was curved to the right, had droop and it was twisted. First I straightened one side. then the other. Here you can see I moved it over 1/4" which in the end was still not enough...... I used a heat gun and heated it up until it was a bit pliable.

Still warped to the right.

So after moving the barrel yet another 1/4" at least, jacking it up about 3/8 and untwisting the barrel most of the way shes really straight. Just had a pinch in the sides just behind the sight. I ended up recuting that area and unpinching it. I want to make a new top shroud out of aluminum so I really need this thing to be straight.

Once I was sure the top was straight I taped it up and glassed it. I put around 6 layers of glass. It was fun trying to do this part.....

And so the top is reattached and super straight. Next i'll takle the bottom of the barrel. I need to do a little more untwisting and reshaping at the bottom so the sides meet straighter than they were. On the gun that was molded the bottom did not line up and i do want to fix that. Then i'll fix the rear receiver area and rebuild the grip then the cleanup comes along with replacing all the screws with real ones. It's been alot of work but I am very happy with progress so far.

Last edited:

Re: MIB Pulsar project

Thank you Pat and snooks. Not much new to show. I have to do some heat gun adjusting to the barrel to get the bottom lined up with the endcap. Before that I have to reattach the barrel piece I cut off the other side. I got it all taped up this evening and it's ready to be epoxied. If I can get up early tomorrow morning I will glass it in. Then I can adjust the barrel and epoxy it together. Then I will glue the end cap halves and put a sleeve in it so it fits into barrel end. I want to make it so the end cap is removable and is held in with the screws on the sides of the barrel.

Thank you Pat and snooks. Not much new to show. I have to do some heat gun adjusting to the barrel to get the bottom lined up with the endcap. Before that I have to reattach the barrel piece I cut off the other side. I got it all taped up this evening and it's ready to be epoxied. If I can get up early tomorrow morning I will glass it in. Then I can adjust the barrel and epoxy it together. Then I will glue the end cap halves and put a sleeve in it so it fits into barrel end. I want to make it so the end cap is removable and is held in with the screws on the sides of the barrel.

Last edited:

gyoung2993

Sr Member

Re: MIB Pulsar project

Oh my Glen, didn't know , that you were taking on such a mindblowing project, that thing was a disaster of a casting, kudos man, you have really tackled this beast.....you have put in many, many hours , to get where you are at now,.....all I can say is congrats on your impossible status at where you are now....dang....you have done a great job so far....really interested as to see how this is going to turn out....this was sorta like how my terminator endoarm kit was, I had to supply so many hand made parts out of so many materials in order for my resin kit to take shape and hold, its half and half....lol...but it turned out so perfect comparing to what mess I started with...almost threw it away, and then I just got determined to do it, its a pain of a job I know, but as your results are showing , this will really turn out better than you would ever hope for , I am seeing a major improvement with your determination, congrats bro.....Guy

Oh my Glen, didn't know , that you were taking on such a mindblowing project, that thing was a disaster of a casting, kudos man, you have really tackled this beast.....you have put in many, many hours , to get where you are at now,.....all I can say is congrats on your impossible status at where you are now....dang....you have done a great job so far....really interested as to see how this is going to turn out....this was sorta like how my terminator endoarm kit was, I had to supply so many hand made parts out of so many materials in order for my resin kit to take shape and hold, its half and half....lol...but it turned out so perfect comparing to what mess I started with...almost threw it away, and then I just got determined to do it, its a pain of a job I know, but as your results are showing , this will really turn out better than you would ever hope for , I am seeing a major improvement with your determination, congrats bro.....Guy

Re: MIB Pulsar project

Pat , I sure hope so!

Thanks Guy, yes it's a bit of work but it's OK, it's a worthy piece.

I was able to get the piece back on the barrel. I may leave it split down the middle and put something on the inside for the screws to go into and also hold the halves together. This way I can get a good looking seam.

Pat , I sure hope so!

Thanks Guy, yes it's a bit of work but it's OK, it's a worthy piece.

I was able to get the piece back on the barrel. I may leave it split down the middle and put something on the inside for the screws to go into and also hold the halves together. This way I can get a good looking seam.

Last edited:

gyoung2993

Sr Member

Re: MIB Pulsar project

I know its a heck of a chore, but this hard work will turn this thing into a beauty...looking forward to your updates and will be watching this with great interest.....

I know its a heck of a chore, but this hard work will turn this thing into a beauty...looking forward to your updates and will be watching this with great interest.....

Similar threads

- Replies

- 21

- Views

- 1,079

- Replies

- 4

- Views

- 928