You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:1 Millennium Falcon Cockpit Replica - Group Build

- Thread starter SteveStarkiller

- Start date

There's no such thing much bigger than the laser cutter...er, wait...you said BIGGER:eek

BIGGER!

The Emperor himself is personally overseeing the final stages of the construction?...

The Emperor is coming here? We shall double our efforts..."

Sorry, T. No info until we know more.

Last edited by a moderator:

I hope it lasts! Geez... the pressure!!! I think you guys/gals will be very happy. If not, I'll be sent to the spice mines of Kessel and smashed into who-knows-what!

Hi Gang,

Time to get this holiday weekend into high gear! Enjoy!

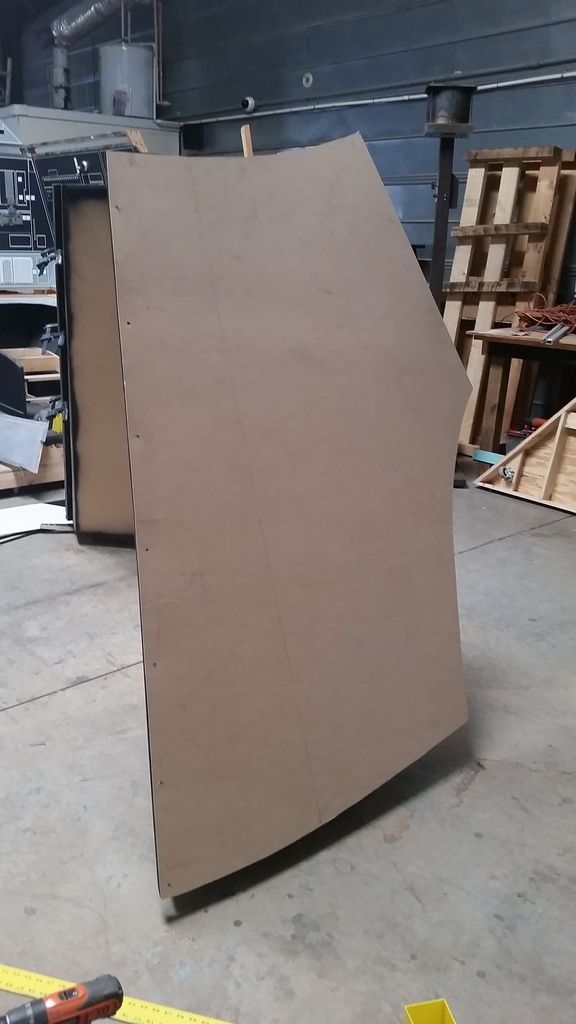

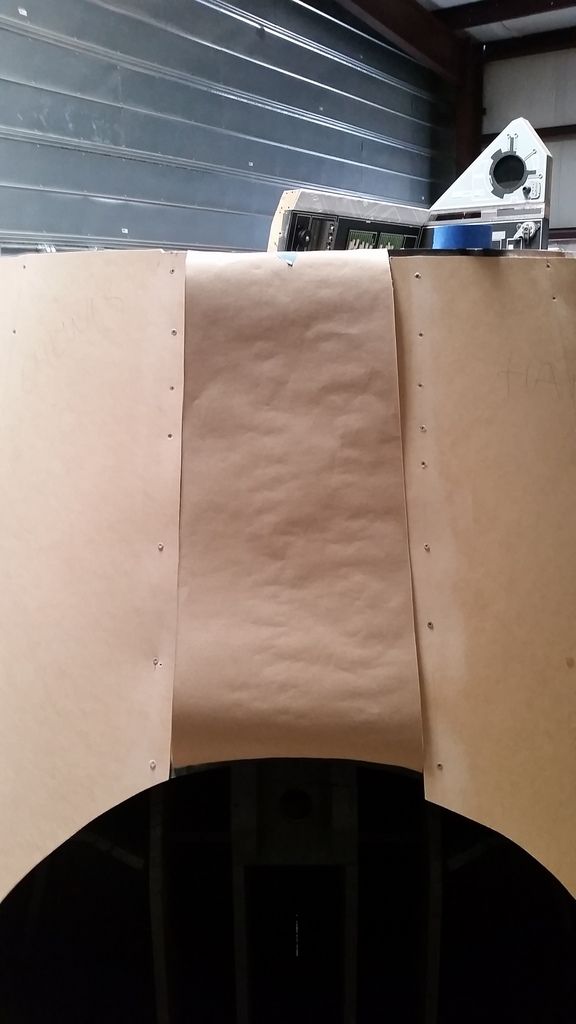

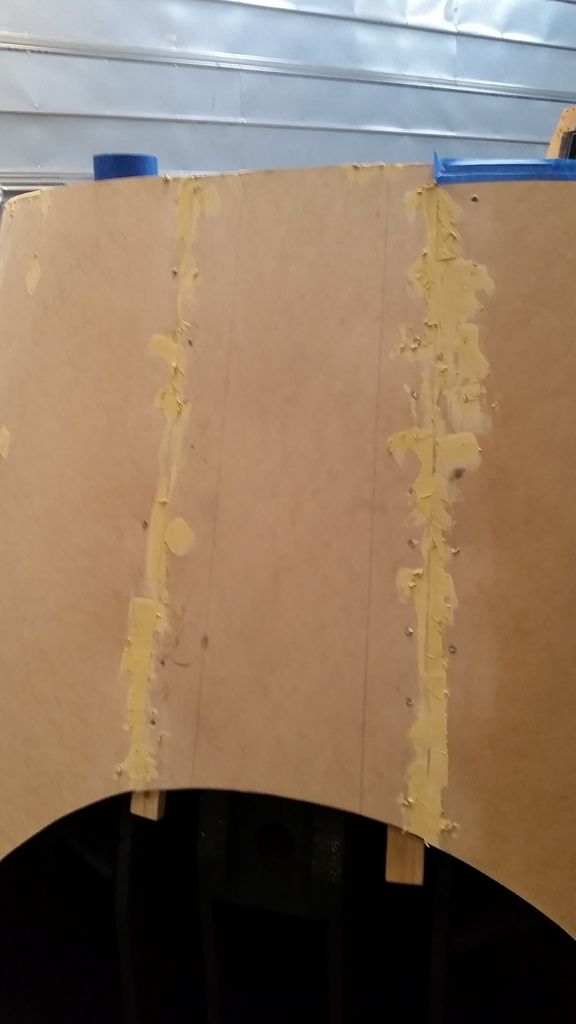

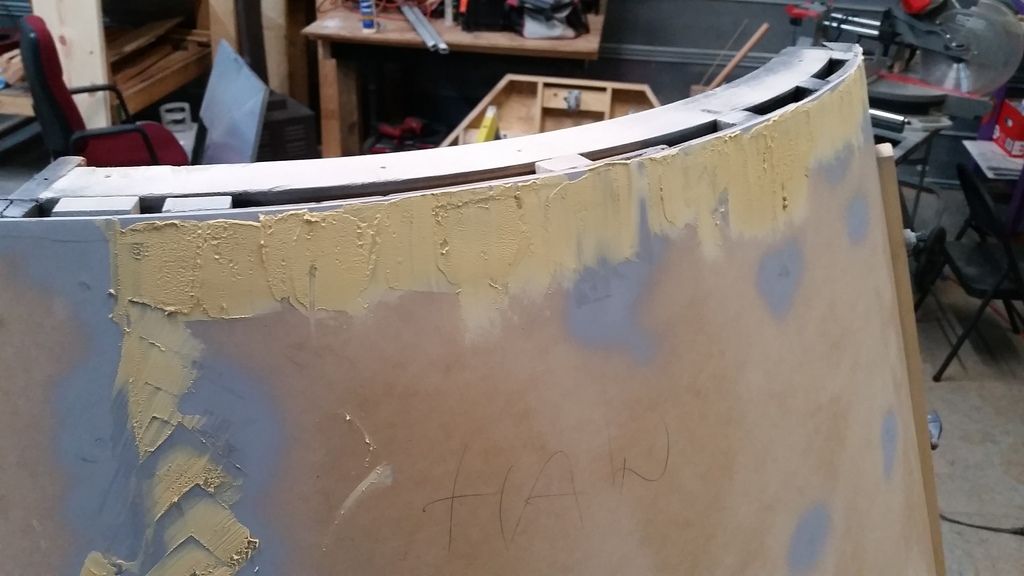

Started the day with adhering the two lower nose skins

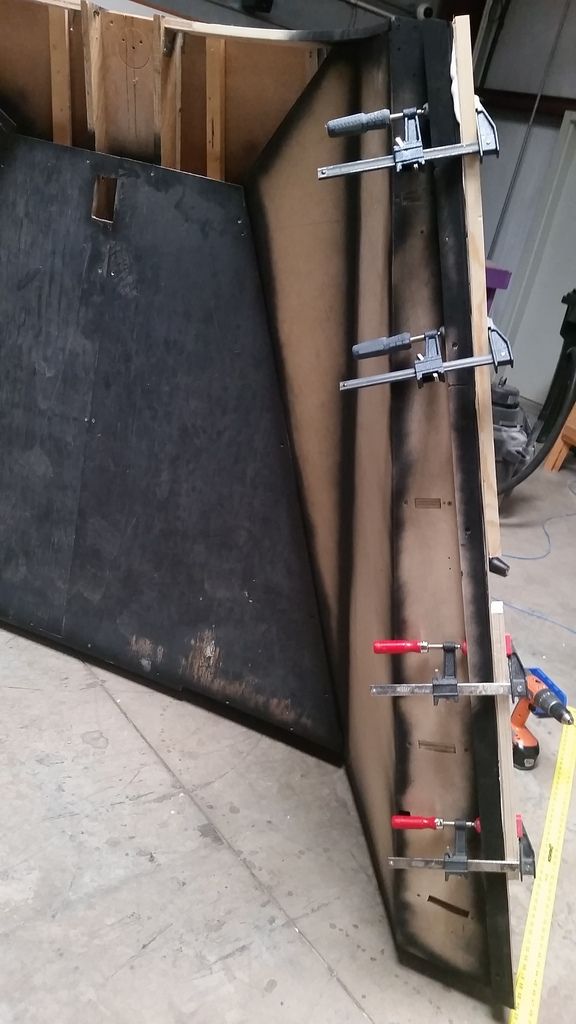

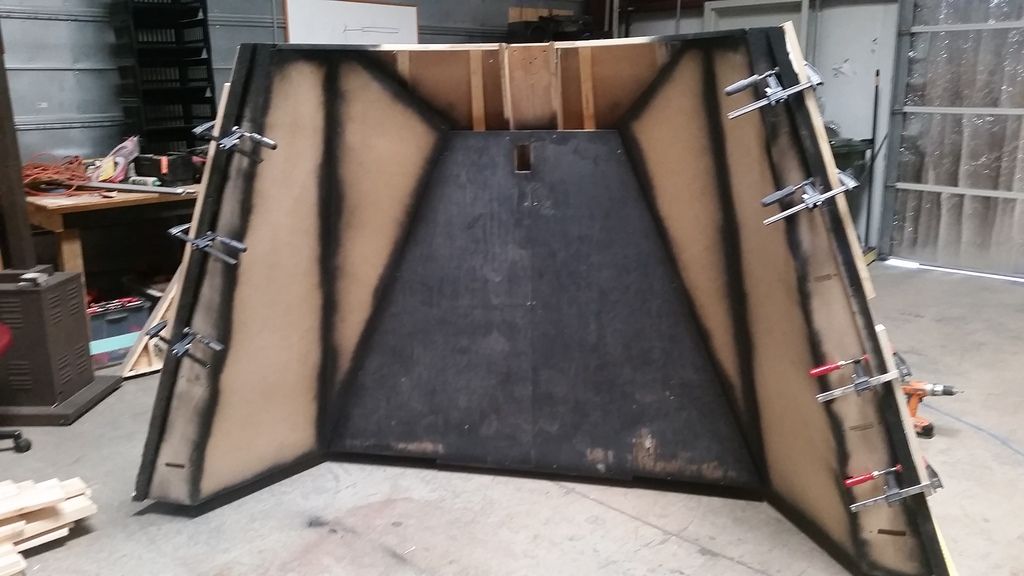

Lots of adhesive on the ends required a little extra clamping together!

Lots of sanding ahead

And filling!

Gotta fill that gap in the middle

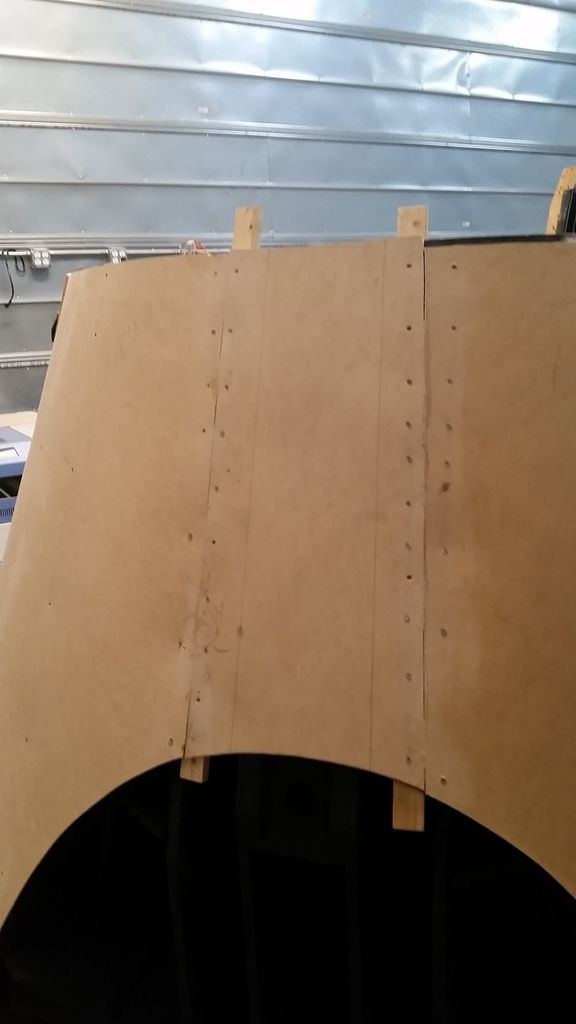

Paper template

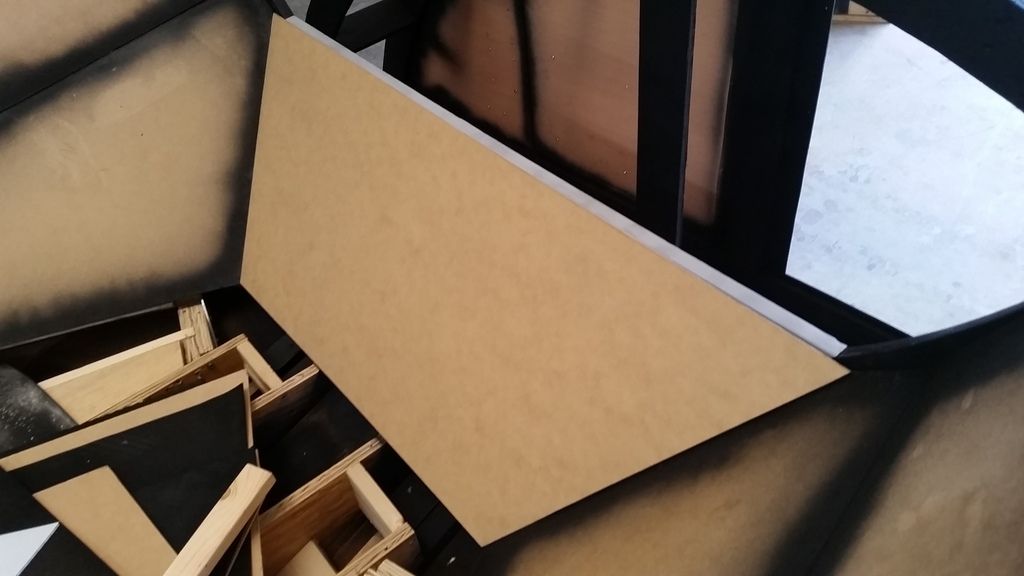

MDF

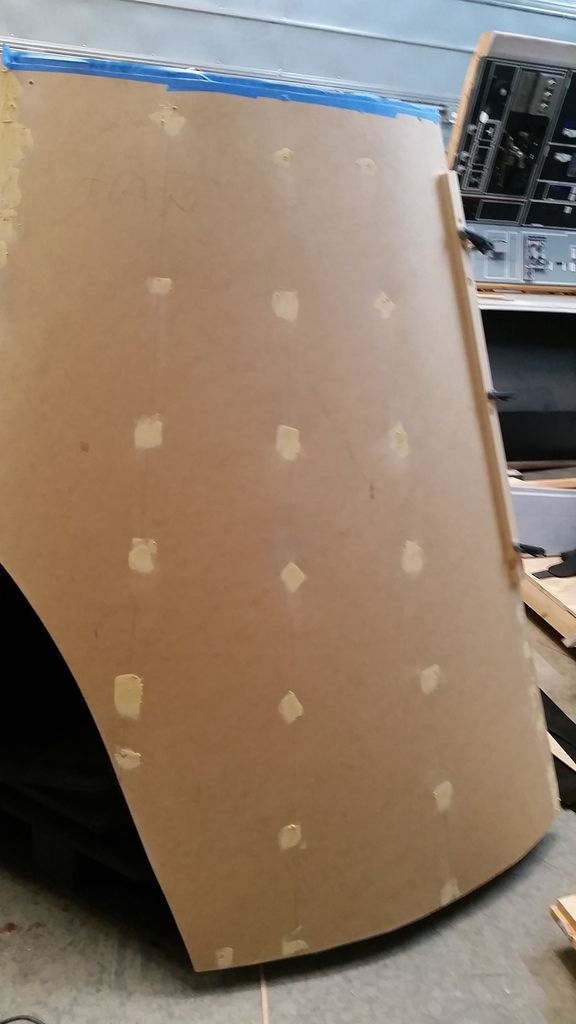

Filled!

Add filler to counter sink screws

YUCK

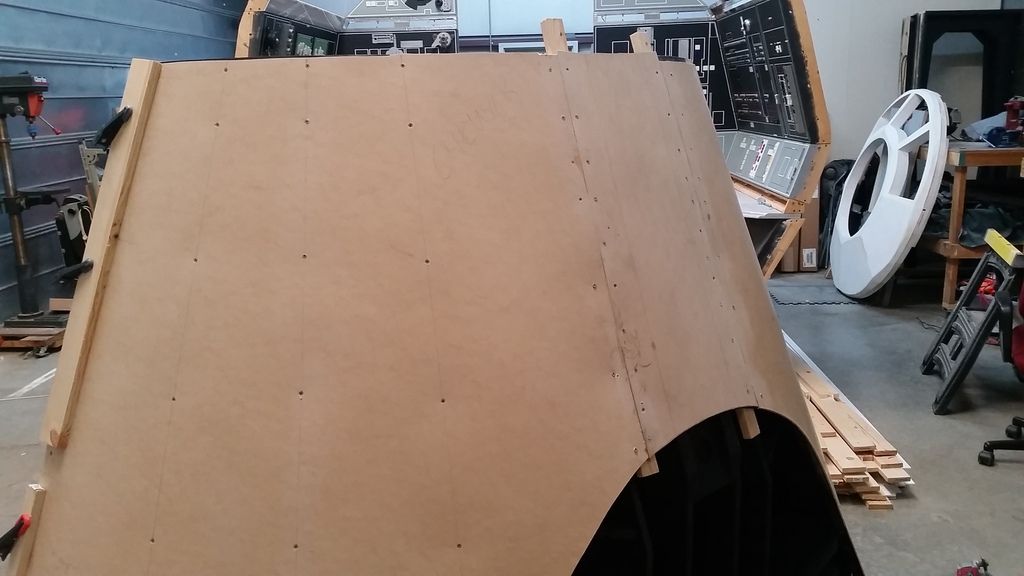

Time to fill that large gap... taped the area, xacto knife to follow shape and adhered tape to MDF

Cut basic shape on the bandsaw

Adhere into place!

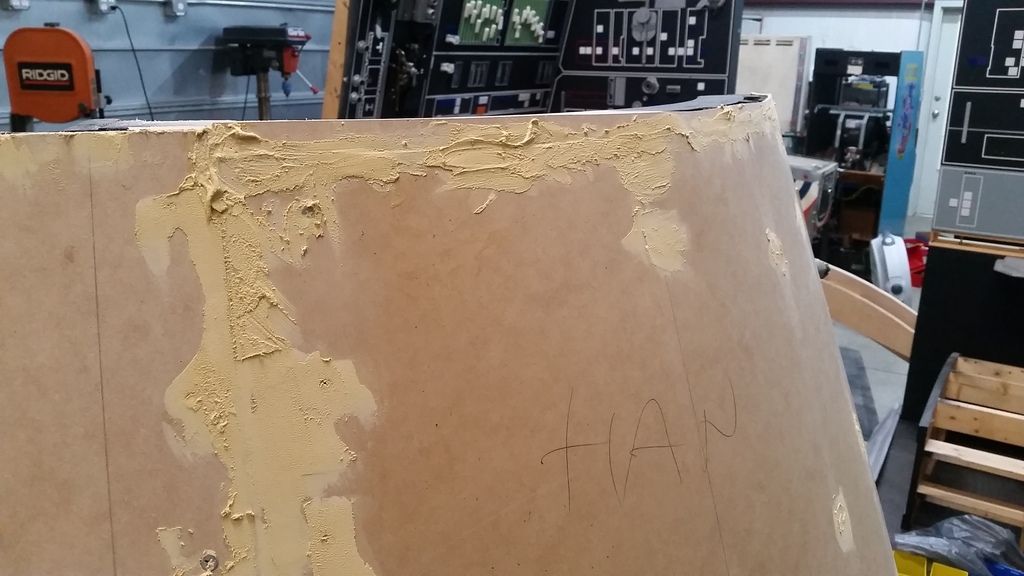

Add filler

First pass with sander and add more filler

It's going to be a good weekend!

Stay tuned for more!

Time to get this holiday weekend into high gear! Enjoy!

Started the day with adhering the two lower nose skins

Lots of adhesive on the ends required a little extra clamping together!

Lots of sanding ahead

And filling!

Gotta fill that gap in the middle

Paper template

MDF

Filled!

Add filler to counter sink screws

YUCK

Time to fill that large gap... taped the area, xacto knife to follow shape and adhered tape to MDF

Cut basic shape on the bandsaw

Adhere into place!

Add filler

First pass with sander and add more filler

It's going to be a good weekend!

Stay tuned for more!

<Rubs hands together gleefully>

Friendly flyer

Well-Known Member

I've been away from the forum all summer holiday, and this thread is still amazing! The skin looks fantastic already!

Good luck getting the laser cutter up and running!

Good luck getting the laser cutter up and running!

Roughneckone

Sr Member

I'm staying tuned to this channel all weekend..............

Roughneckone:cool

Roughneckone:cool

Hi Gang,

We just received hint of some GREAT news! No... the laser cutter is still down. This is MUCH BIGGER than the laser cutter! I'm going to have switch into triple supercharger overdrive!!!!

Hi Sofa King,

Nice Pics!

Sorry if my last post was a little over-zealous..but this is a very cool build.

I know you guys a relying on several volunteers scattered around the country-some of you guys are utilizing local maker-spaces etc.

Regarding laser cutters, I am in the market for finding another reliable (not too expensive) Laser cutting service.

Including one that can do fairly large pieces.

Have you come across any Laser Cutting Services you can recommend?

We have several Maker-Spaces that have cropped up here in the DC area, including the TechSHop.

Some, with very nice facilities, alas, all have only 90 day and yearly subscription plans,.

My schedule is such that Ineed the type of payment plan where one can simply by "hours" on a Card and spend them as needed.

...but none of the local Maker-Spaces have adopted they type of payment program.

Also I will send you a PM, Of a good service with a beautiful 3DP machine.

It has a 36" inch (3-foot! ) x 36" grow bed in the X & Y and 30" inches in the Z axis!

I have had some fun growing some HUGE parts! Their rates are good and this is much nicer quality and fidelity than most Desk-top 3D printers available out there.

keep up the good work

Last edited by a moderator:

Hi Gang,

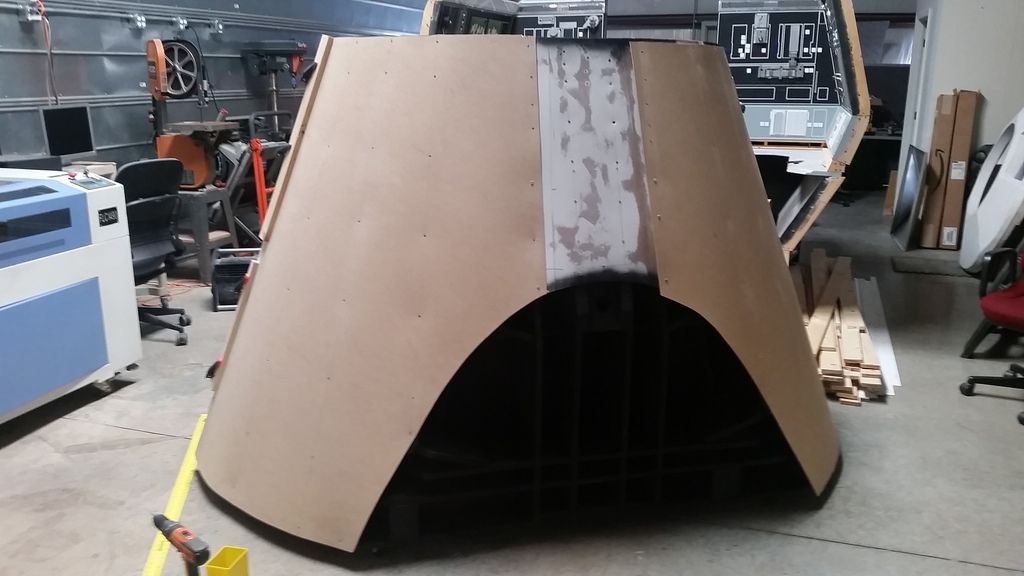

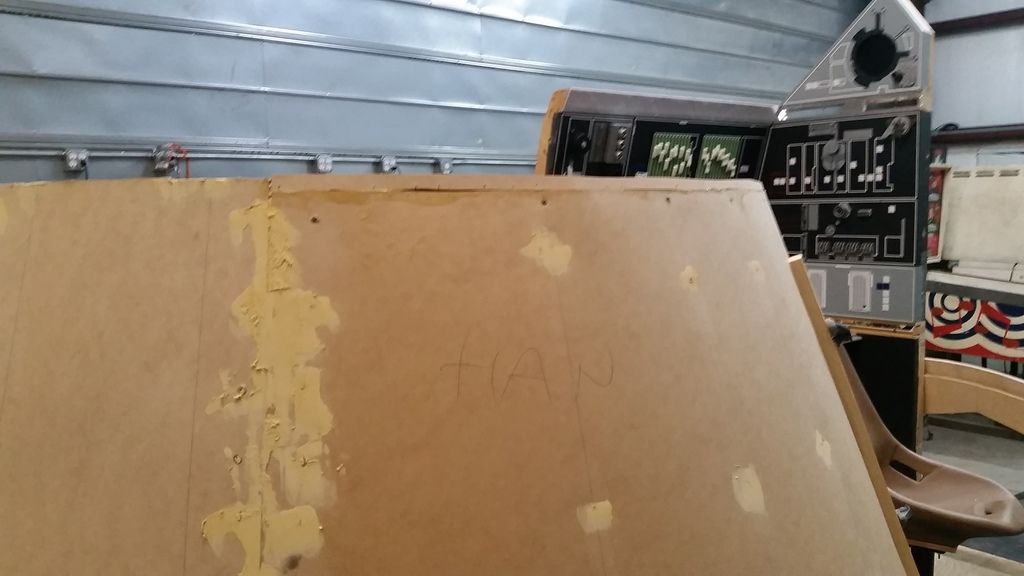

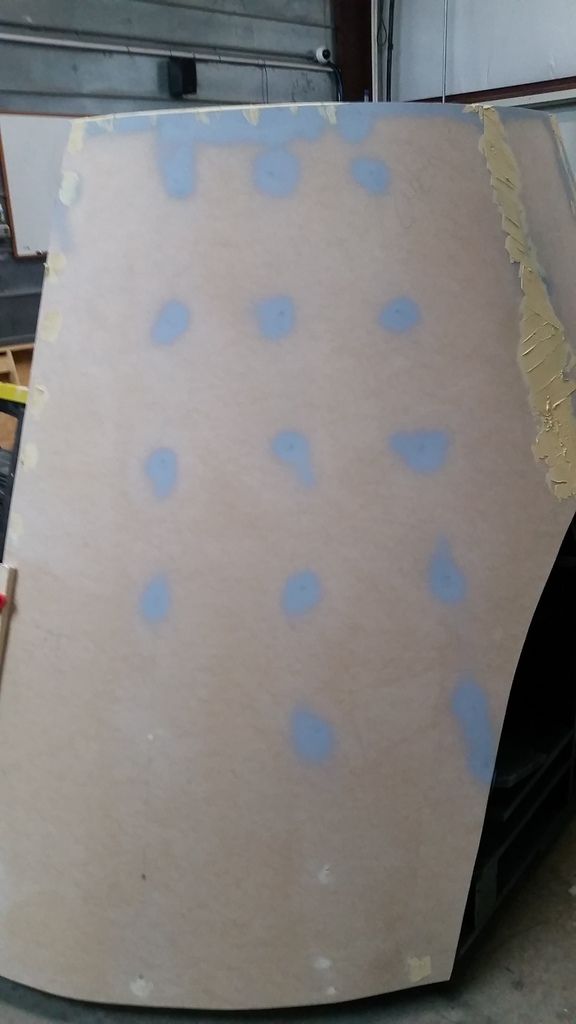

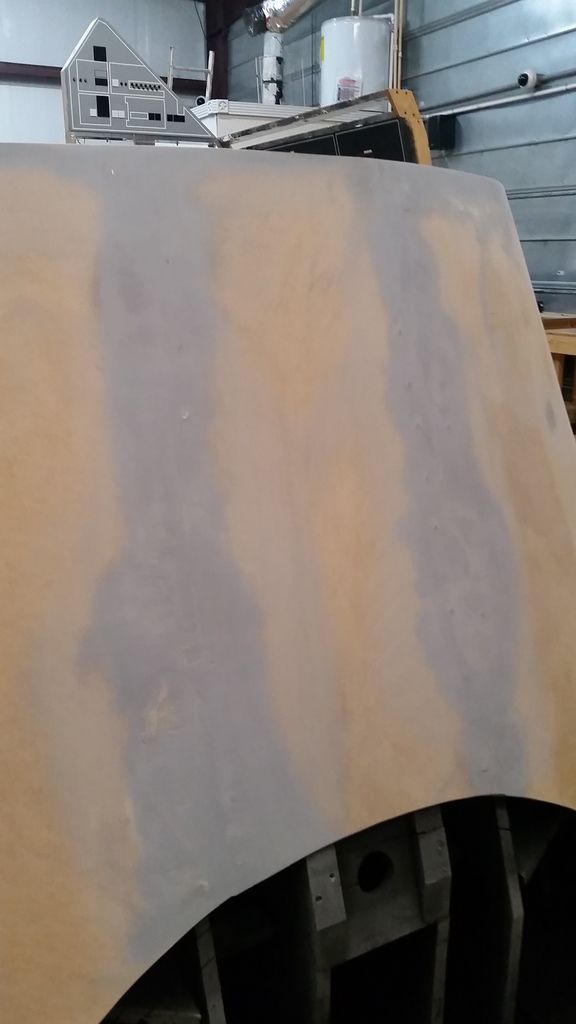

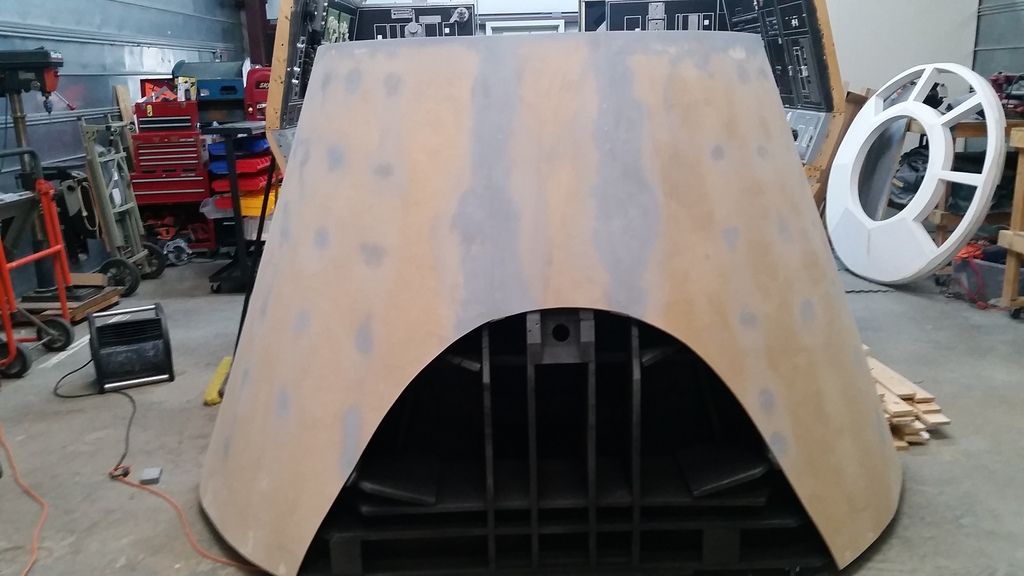

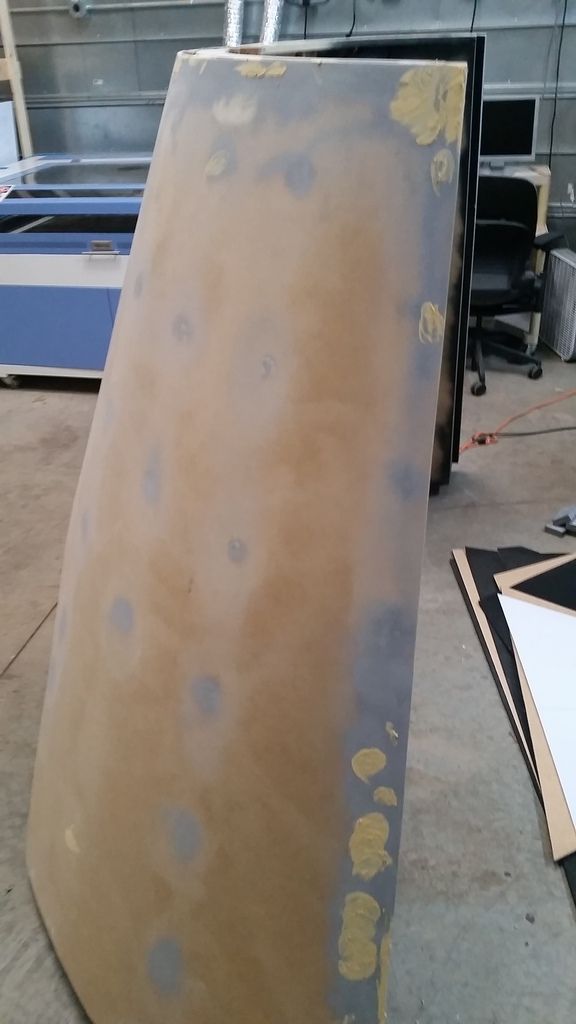

Lets get to this update! As always... I never EVER get farther than I would expect especially over a long holiday weekend. BUT, forward progress was made and I'm pretty happy... Most of the weekend was spent on the front nose cleaning up the edges, the skin and other various areas trying to get a nice clean surface. Lots and lots of sanding followed by some new forward progress!

This area under the front window is finally smoothing out!

I love the primer/filler!

Time for another walk around... EWE

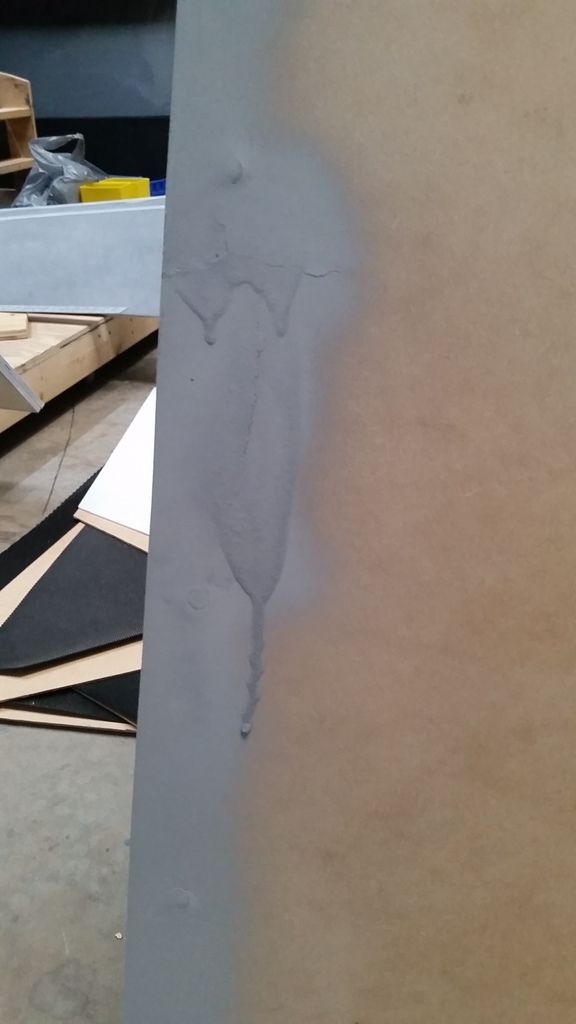

Whoops... more filler!

Yup... More Filler

And More

And... yup! More filler!

I then added more black to the edges and exposed wood

I like the black paint. It hides the look of the natural wood and pushes it back into the shadows

The casters help me move the nose around the shop

Prepping the door frame to finally be fit into position with a new/mod'd base and smoother edges

This base will be mod'd to simply fit into place between the cockpit platform and the corridor platform

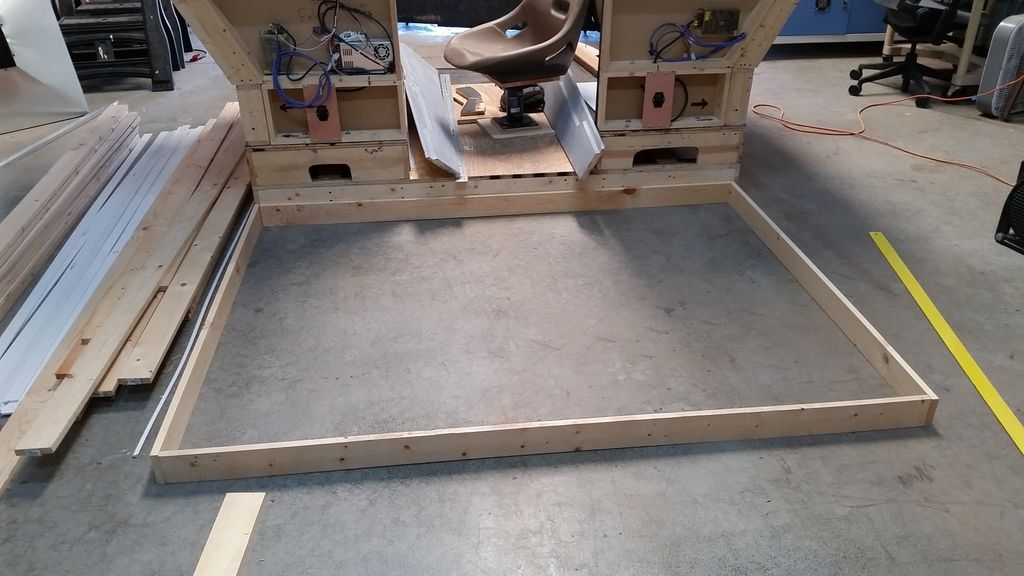

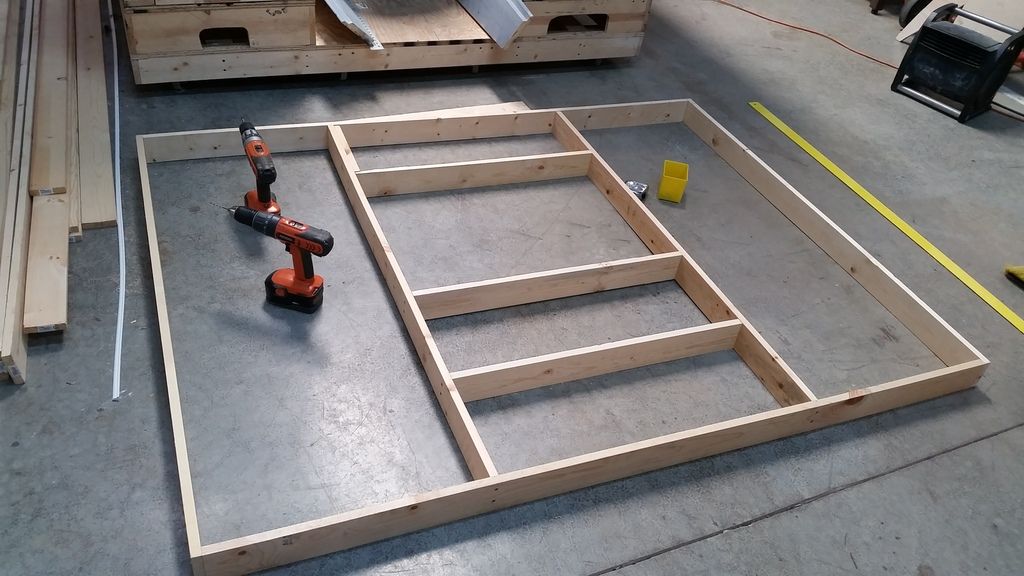

Speaking of which... The new corridor platform takes shape

There is SO MUCH going on with the floor/corridor layout so I have to plan this out (which consumed a lot of time)

We have a surface!

If you remember I added an interior panel just under the window. This required a horizontal brace to keep the panel from sagging

The panel wont be permanently adhered, it will simply rest in place to allow for access into the nose frame. The best part, I get to add some greeblies of my own design!

The panel will be mounted to the angled surface. I think I need more bracing / support

Primed and filled

Still more to do but I really like how this is turning out! Things are fitting into place!

And then finally... I cut these two little platforms...

Which mount to the bottom of the cockpit entrance wall. Like the nose, I'm painting the entire frame(s) black to hide the natural wood look

These "little" platforms give the walls some much needed rigidity and keep the bottoms of the walls flexing when mounted into place to the corridor frame

And they stay up by themselves

The Volvo panels wont be started for quite some time. It's a step by step process as so many other elements of the build affect another... We'll get there!

And this is where we are... I'm considering painting the existing panel(s) edges black to match the nose but I'm not sure if that's a good idea?

I don't have to say that there is SO much more coming... BUT

More to Follow!

Lets get to this update! As always... I never EVER get farther than I would expect especially over a long holiday weekend. BUT, forward progress was made and I'm pretty happy... Most of the weekend was spent on the front nose cleaning up the edges, the skin and other various areas trying to get a nice clean surface. Lots and lots of sanding followed by some new forward progress!

This area under the front window is finally smoothing out!

I love the primer/filler!

Time for another walk around... EWE

Whoops... more filler!

Yup... More Filler

And More

And... yup! More filler!

I then added more black to the edges and exposed wood

I like the black paint. It hides the look of the natural wood and pushes it back into the shadows

The casters help me move the nose around the shop

Prepping the door frame to finally be fit into position with a new/mod'd base and smoother edges

This base will be mod'd to simply fit into place between the cockpit platform and the corridor platform

Speaking of which... The new corridor platform takes shape

There is SO MUCH going on with the floor/corridor layout so I have to plan this out (which consumed a lot of time)

We have a surface!

If you remember I added an interior panel just under the window. This required a horizontal brace to keep the panel from sagging

The panel wont be permanently adhered, it will simply rest in place to allow for access into the nose frame. The best part, I get to add some greeblies of my own design!

The panel will be mounted to the angled surface. I think I need more bracing / support

Primed and filled

Still more to do but I really like how this is turning out! Things are fitting into place!

And then finally... I cut these two little platforms...

Which mount to the bottom of the cockpit entrance wall. Like the nose, I'm painting the entire frame(s) black to hide the natural wood look

These "little" platforms give the walls some much needed rigidity and keep the bottoms of the walls flexing when mounted into place to the corridor frame

And they stay up by themselves

The Volvo panels wont be started for quite some time. It's a step by step process as so many other elements of the build affect another... We'll get there!

And this is where we are... I'm considering painting the existing panel(s) edges black to match the nose but I'm not sure if that's a good idea?

I don't have to say that there is SO much more coming... BUT

More to Follow!

Last edited:

Great update -hope you enjoyed the weekend.

Hi Sofa King,

Nice Pics!

Sorry if my last post was a little over-zealous..but this is a very cool build.

I know you guys a relying on several volunteers scattered around the country-some of you guys are utilizing local maker-spaces etc.

Regarding laser cutters, I am in the market for finding another reliable (not too expensive) Laser cutting service.

Including one that can do fairly large pieces.

Have you come across any Laser Cutting Services you can recommend?

We have several Maker-Spaces that have cropped up here in the DC area, including the TechSHop.

Some, with very nice facilities, alas, all have only 90 day and yearly subscription plans,.

My schedule is such that Ineed the type of payment plan where one can simply by "hours" on a Card and spend them as needed.

...but none of the local Maker-Spaces have adopted they type of payment program.

Also I will send you a PM, Of a good service with a beautiful 3DP machine.

It has a 36" inch (3-foot! ) x 36" grow bed in the X & Y and 30" inches in the Z axis!

I have had some fun growing some HUGE parts! Their rates are good and this is much nicer quality and fidelity than most Desk-top 3D printers available out there.

keep up the good work

Hi GG,

Thanks so much!

Unfortunately I dont know or use any Laser Cutter service here in HSV. I was a member of lab that had a laser cutter before jumping in and buying my own. Like you, I was forced to get a monthly membership but I also had access to a CNC so everything did balance out. I would consider checking out the TechShop and see if their setup justifies the membership. If you have a LOT of cutting required it might be worth the membership for a few months?

Looking forward to seeing the 3DP!

- - - Updated - - -

Great update -hope you enjoyed the weekend.

Thank you, my friend! It was a busy and exhausting weekend! Fun, but busy! I am wiped out! Hope you had a relaxing holiday weekend!

Last edited by a moderator:

Whoa!

The last few Pics really drive home how big this thing is.

Any Idea of the weight?

...in case I want to order one... I want to have an idea of the shipping cost

Thanks Sofa King,

As a matter of fact I had a tour of the Tech Shop a while back. Very nice "toys" -everything the budding young mad scientist could want.

The injection molding equipment was particularly interesting as I've been learning/doing more work of that nature with gigs from toy and model manufacturers.

I think there will be some big strides with injection molding for DIY types including "desk-top injection molding -pairing along with the advances & price drops in desktop 3D Printing.

There's another MakerSpace that is opening soon closer to me, they are a smaller operation but I may end up working with them lending some of my experience with 3D/CAD, and CNC and 3D printing its in conjunction with a local "Art Space"

Nice Work!..weekend well spent

The last few Pics really drive home how big this thing is.

Any Idea of the weight?

...in case I want to order one... I want to have an idea of the shipping cost

Thanks Sofa King,

As a matter of fact I had a tour of the Tech Shop a while back. Very nice "toys" -everything the budding young mad scientist could want.

The injection molding equipment was particularly interesting as I've been learning/doing more work of that nature with gigs from toy and model manufacturers.

I think there will be some big strides with injection molding for DIY types including "desk-top injection molding -pairing along with the advances & price drops in desktop 3D Printing.

There's another MakerSpace that is opening soon closer to me, they are a smaller operation but I may end up working with them lending some of my experience with 3D/CAD, and CNC and 3D printing its in conjunction with a local "Art Space"

Nice Work!..weekend well spent

Last edited by a moderator:

You may have been asked this before, but which brand name of filler works best for you, being an expert in filler that you surely are by now?...or are they all pretty equal?

Hey T,

I use several brands of filler for specific tasks. The most common for all the wood is the Elmers Wood Filler in the tubs. Elmers has both Interior and Exterior grade fillers. I use the same filler for the greeblies made from MDF but if there is acrylic I'll use Bondo Spot and Glazing Putty.

Its funny you ask this because I was poking around the filler section of the Home Improvement store over the weekend and stumbled upon the DAP's Plastic Wood Filler. This is stuff is pretty good and hardens almost instantly - sandable within 10-15min depending on how thick it's applied. I just hope its flexible enough for the nose!

I hope this helps?

Whoa!

The last few Pics really drive home how big this thing is.

Any Idea of the weight?

...in case I want to order one... I want to have an idea of the shipping cost

Thanks Sofa King,

As a matter of fact I had a tour of the Tech Shop a while back. Very nice "toys" -everything the budding young mad scientist could want.

The injection molding equipment was particularly interesting as I've been learning/doing more work of that nature with gigs from toy and model manufacturers.

I think there will be some big strides with injection molding for DIY types including "desk-top injection molding -pairing along with the advances & price drops in desktop 3D Printing.

There's another MakerSpace that is opening soon closer to me, they are a smaller operation but I may end up working with them lending some of my experience with 3D/CAD, and CNC and 3D printing its in conjunction with a local "Art Space"

Nice Work!..weekend well spent

OH YES! She's not a little desktop laser cutter! We lucked out finding it and made to make a last minute trip to Atlanta. Despite her being down for a little over a month, it was well worth it. We'll get her fixed soon enough.

Makers Spaces are popping up all over. I would DEF get involved and see what you can contribute! I think you'll have fun!

Last edited by a moderator:

Filler is your friend Sofa! Yeah, not fun sanding it and discovering that you need to apply more of it:confused Oh well, that's the life of an Artist. Keep on building, it's always looking great!

Hey J,

The Filler Co. LOVE ME! I don't think I've ever applied filler, sanded and primed and have it NOT require a second coat. The things we do for our craft, right? But it's all part of the journey.

Similar threads

- Replies

- 2

- Views

- 862

- Replies

- 6

- Views

- 623

- Replies

- 8

- Views

- 554

- Replies

- 8

- Views

- 933

- Replies

- 4

- Views

- 2,325