You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blade Runner Snub Nose Blaster Project

- Thread starter DaveG

- Start date

MrSinistar

Well-Known Member

WOW.

Absolutely LOVE the Ennis House Tile grip. Keep it up!!!

Keep it up!!!

Absolutely LOVE the Ennis House Tile grip.

Daddy Solo

Active Member

Dave - please keep going!!!! don't stop for anything. Every time you post pics of your build/mockup progress, my heart gets a little closer to exploding. Will you be posting a sign up list here, on propsummit, or both? Regardless, your snubby looks incredible & keeps getting better. Put me down for one:love

HeroWorship

Well-Known Member

You've blown past amazing! Great designs man!

3D Printed Parts

Whenever I get s box of parts from the 3D printer it's like Christmas. I'm still blown away by the technology and what it can achieve! The parts still need some sanding and cleanup but the process saves soooooo much time! The first set of parts arrived today. As I unwrapped each part I get more and more excited.

Here's the trigger guard:

Here's the bolt lever. It's about 84% the size of the real lever.

Here are the thumb slides. The Bulldog slide is 1:1 to the real slide (complete with fillester head screw!) The Steyr slide is 84% the size of the real slde. (When I saw these my brain started melting!)

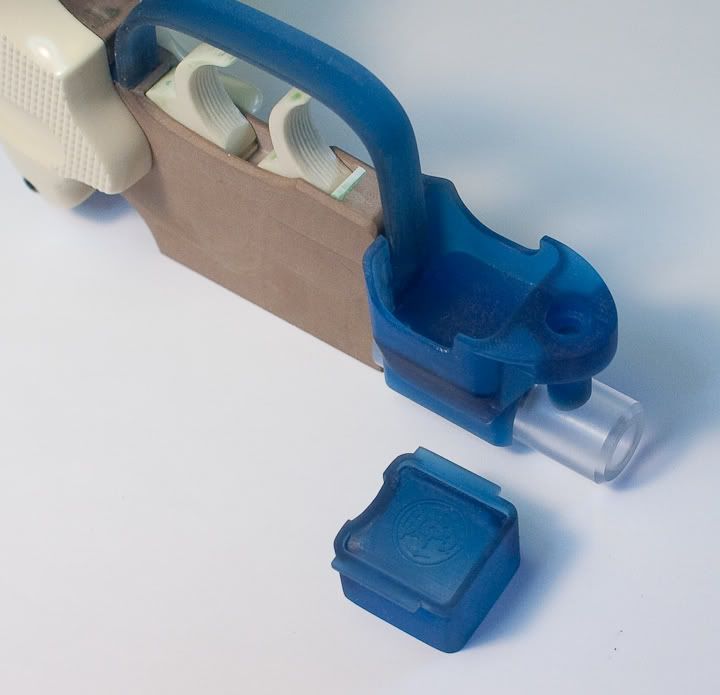

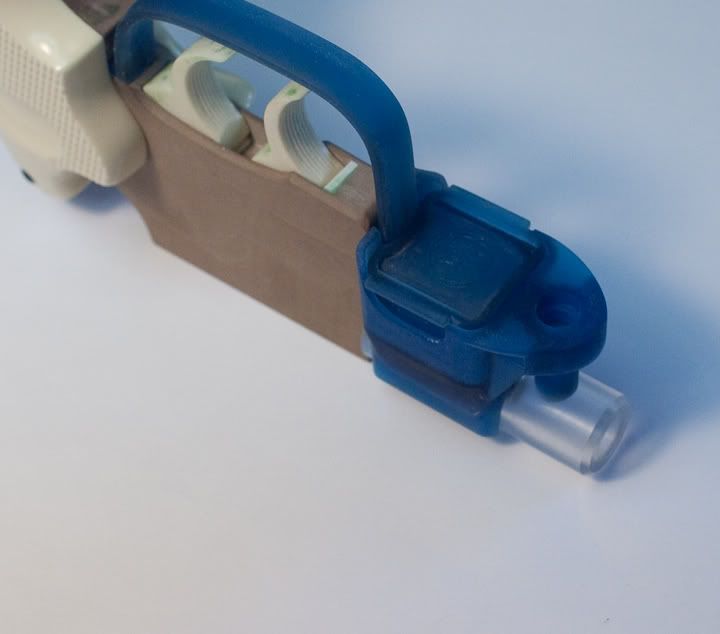

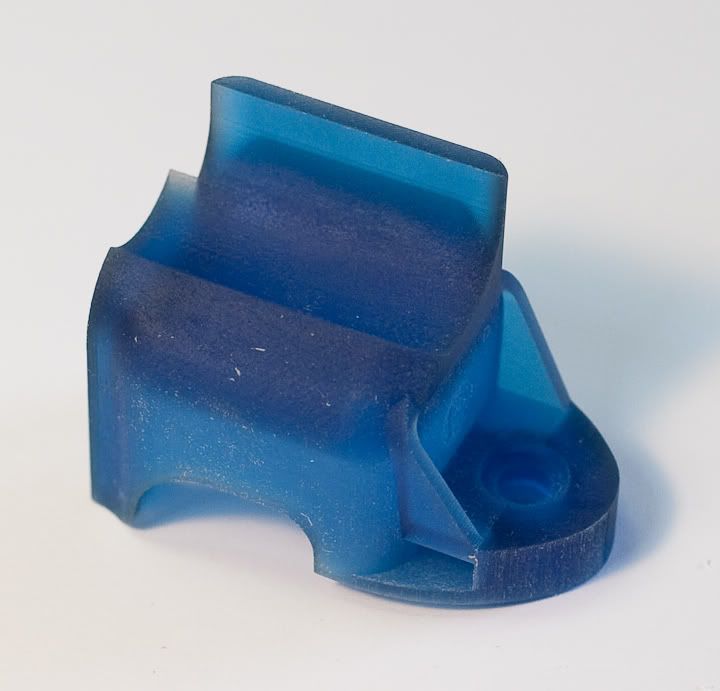

Here's the Clip Housing:

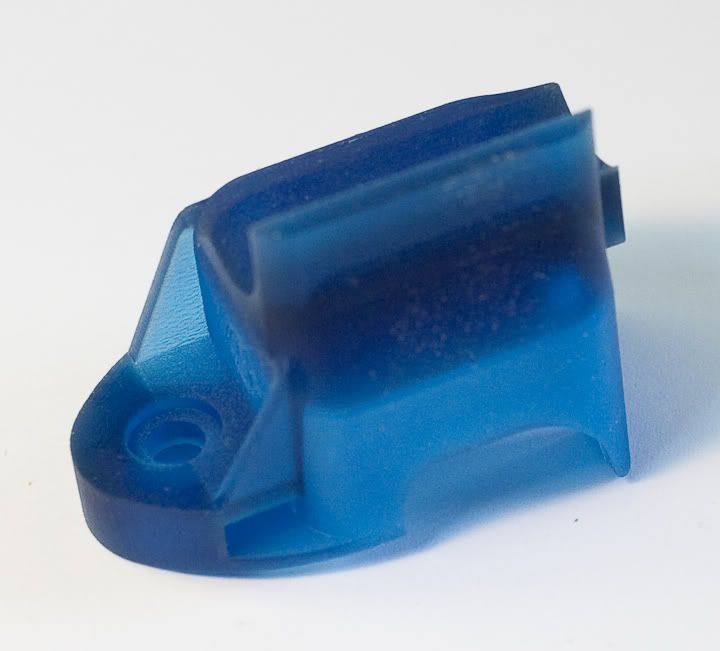

And the removeable clip (it will be held in place with rare earth magnets).

Whenever I get s box of parts from the 3D printer it's like Christmas. I'm still blown away by the technology and what it can achieve! The parts still need some sanding and cleanup but the process saves soooooo much time! The first set of parts arrived today. As I unwrapped each part I get more and more excited.

Here's the trigger guard:

Here's the bolt lever. It's about 84% the size of the real lever.

Here are the thumb slides. The Bulldog slide is 1:1 to the real slide (complete with fillester head screw!) The Steyr slide is 84% the size of the real slde. (When I saw these my brain started melting!)

Here's the Clip Housing:

And the removeable clip (it will be held in place with rare earth magnets).

Last edited:

Darth Brass

Sr Member

Holy MACKEREL that's awesome! I'm definitely interested. So amazing. Such clean lines and clean parts!

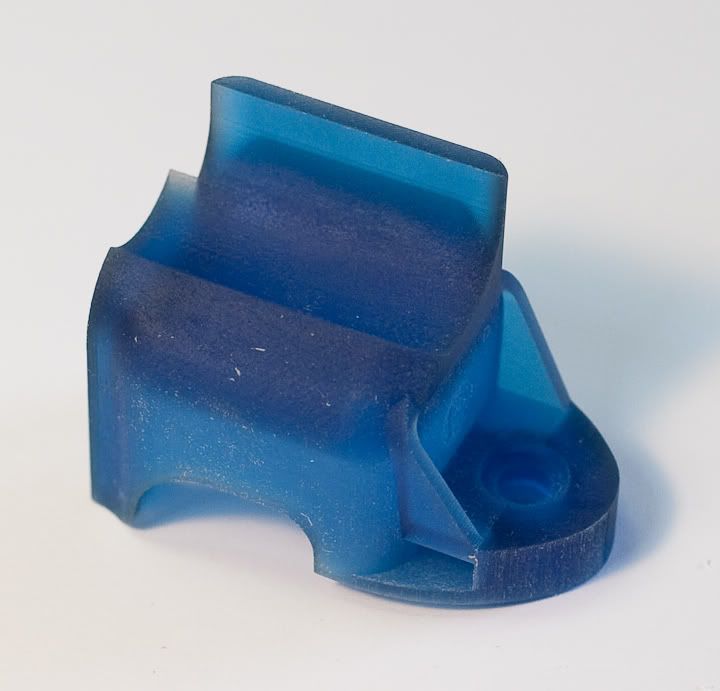

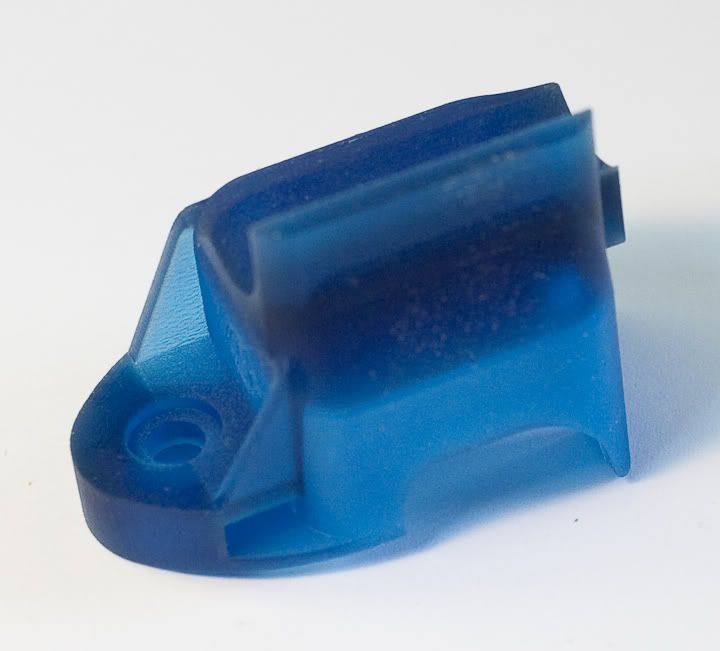

The 3D printed parts are made in .oo3" steps, that's about the thickness of a single sheet of paper. Pretty fine, but the steps do show up, primarily visible on gently curved surfaces. Here's the clip part fist, as it came from the printers, and then after I've cleaned it up with 320, 400 and 600 grit snadpaper.

BEFORE

AFTER

BEFORE

AFTER

HOW on EARTH do you achieve the etched designs in the grips and parts? :confused

The enovation is unbelievable !!!

The appllications of the process are mind boggling !!! :confused love:love

love:love

PLEASE - HOW did you do this? :confused

.... wait I fell out of my chair looking at the DETAIL on these parts ...:eek

Thanks for the pics and the education of the build.

This is AWESOME !!

Gordon

The enovation is unbelievable !!!

The appllications of the process are mind boggling !!! :confused

PLEASE - HOW did you do this? :confused

.... wait I fell out of my chair looking at the DETAIL on these parts ...:eek

Thanks for the pics and the education of the build.

This is AWESOME !!

Gordon

Thanks, Gordon. Actually the engraving is among the easier things to do, but only because I have the right tools. I use a CNC (Computer Numerically Controlled) router that I built for my shop. The engraving design is drawn on the computer using Adobe illustrator. The plain grip castings are set up in a jig on the machine and the router mills the pattern with a pointed bit.

Thanks, Gordon. Actually the engraving is among the easier things to do, but only because I have the right tools. I use a CNC (Computer Numerically Controlled) router that I built for my shop. The engraving design is drawn on the computer using Adobe illustrator. The plain grip castings are set up in a jig on the machine and the router mills the pattern with a pointed bit.

Thanks for taking time with the reply

I am extraordinarily curious about the CNC and the cost of such a set up. :confused

I have used Rhino 3D to build cad models. I have a complete model in an STL format – or can covert to any CAD requirement. I am looking for a shop that can build it, cut it in parts from MDF, metal or equivalent to make the kit for casting. I can build it by hand. But the detail and quality would never reach the level I would like. I have approached a couple of companies online – but the cost is outrageous for the end result. I just had a dream of doing one hundred kits – original design – and see what happens. The only cost effective way is tooling it by hand – but the precision cut would be the dream

The CNC is so fantastic it makes it almost impossible to compete – everything else looks – hand made

The serial numbers, details, and etching make the model come alive! :love

I work for the government and play with props as a hobby and collector. The CNC setup – bits and software – must be a fortune!!! :confused

The CNC process is the next step in prop evolution … heck … I just learned how to make something and cast it. NOW the CNC makes the” light at the end of the tunnel extend OVER the horizon." :cry

AWESOME post and thanks for showing us the magic of the CNC.

That CNC would make anything imaginable!! If you can draw it and build in the 3D world – it can really happen. . . .

The CNC is like what George Lucas did to film …. Then James Cameron with AVATAR …

It sets a whole new standard …:eek

I have attached a couple of Rhino models I built for rendering in 3D ….

I plan to make the Blade Runner pistols in one form or another. I did the concepts in RHINO first to see how they looked. Someday soon – they will be a reality.

Gordon

Gordon,

I've been building models and props for the movies for close to 25 years and only added CNC to my "toolbox" nine months ago. It doesn't really allow you to acheive things that couldn't be done by hand (well, maybe some things) it just does them faster. Keep in mind that for most of the "Golden Age" of movie modelmaking, from the late 70s to the turn of the century, CNC was virtually unheard of in model shops, most everything was done by hand. And 3D printing has really only become cost effective for small projects in the last five years.

Pretty much every part on this project that's been made with the assistance of CNC or 3D printing, could be made by hand, or with other more common tools. CNC just speeds the process up, a lot. Whatever you do, don't let the lack of access to CNC, or it's cost, stop you from finishing your project.

CNC is a huge field. If you want to learn more about it, and what's involved in buying or building a machine you should check out the forums at CNCzone.com.

CNC machinery, software, bits and training are very expensive. That's why the costs are so high to have work cut by a CNC vendor. Commercial machines can cost many 10s of thousands of dollars. Even DIY CNC costs a lot of money, a couple of grand would be the bare minimum to build a small machine. Plus driver electronics, computer software, etc. etc.

But keep plugging away on your car project, don't let the goal of completion disappear over the horizon.

I've been building models and props for the movies for close to 25 years and only added CNC to my "toolbox" nine months ago. It doesn't really allow you to acheive things that couldn't be done by hand (well, maybe some things) it just does them faster. Keep in mind that for most of the "Golden Age" of movie modelmaking, from the late 70s to the turn of the century, CNC was virtually unheard of in model shops, most everything was done by hand. And 3D printing has really only become cost effective for small projects in the last five years.

Pretty much every part on this project that's been made with the assistance of CNC or 3D printing, could be made by hand, or with other more common tools. CNC just speeds the process up, a lot. Whatever you do, don't let the lack of access to CNC, or it's cost, stop you from finishing your project.

CNC is a huge field. If you want to learn more about it, and what's involved in buying or building a machine you should check out the forums at CNCzone.com.

CNC machinery, software, bits and training are very expensive. That's why the costs are so high to have work cut by a CNC vendor. Commercial machines can cost many 10s of thousands of dollars. Even DIY CNC costs a lot of money, a couple of grand would be the bare minimum to build a small machine. Plus driver electronics, computer software, etc. etc.

But keep plugging away on your car project, don't let the goal of completion disappear over the horizon.

Similar threads

- Replies

- 2

- Views

- 644

- Replies

- 1

- Views

- 910

- Replies

- 11

- Views

- 754