SteveNeill

Sr Member

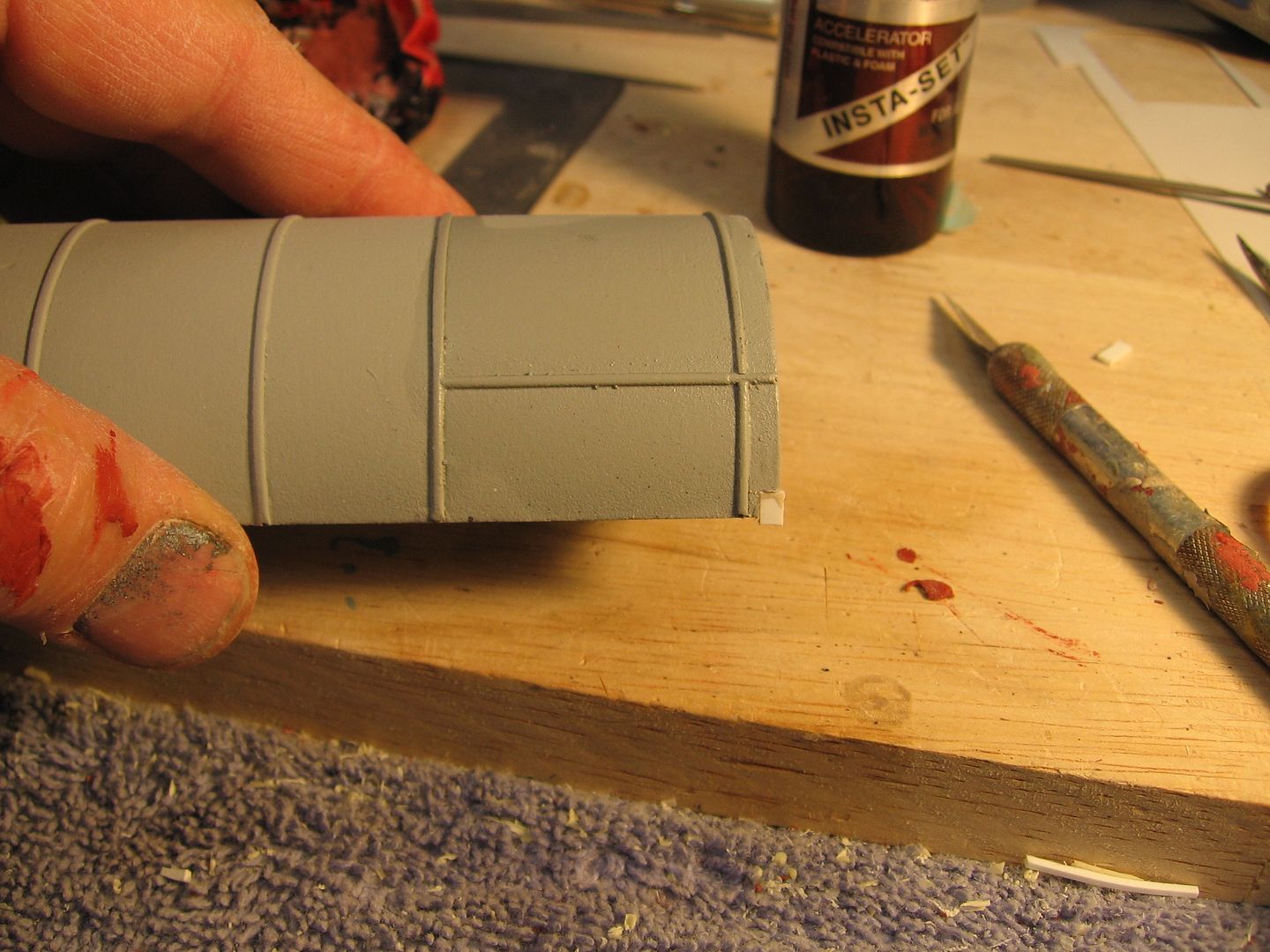

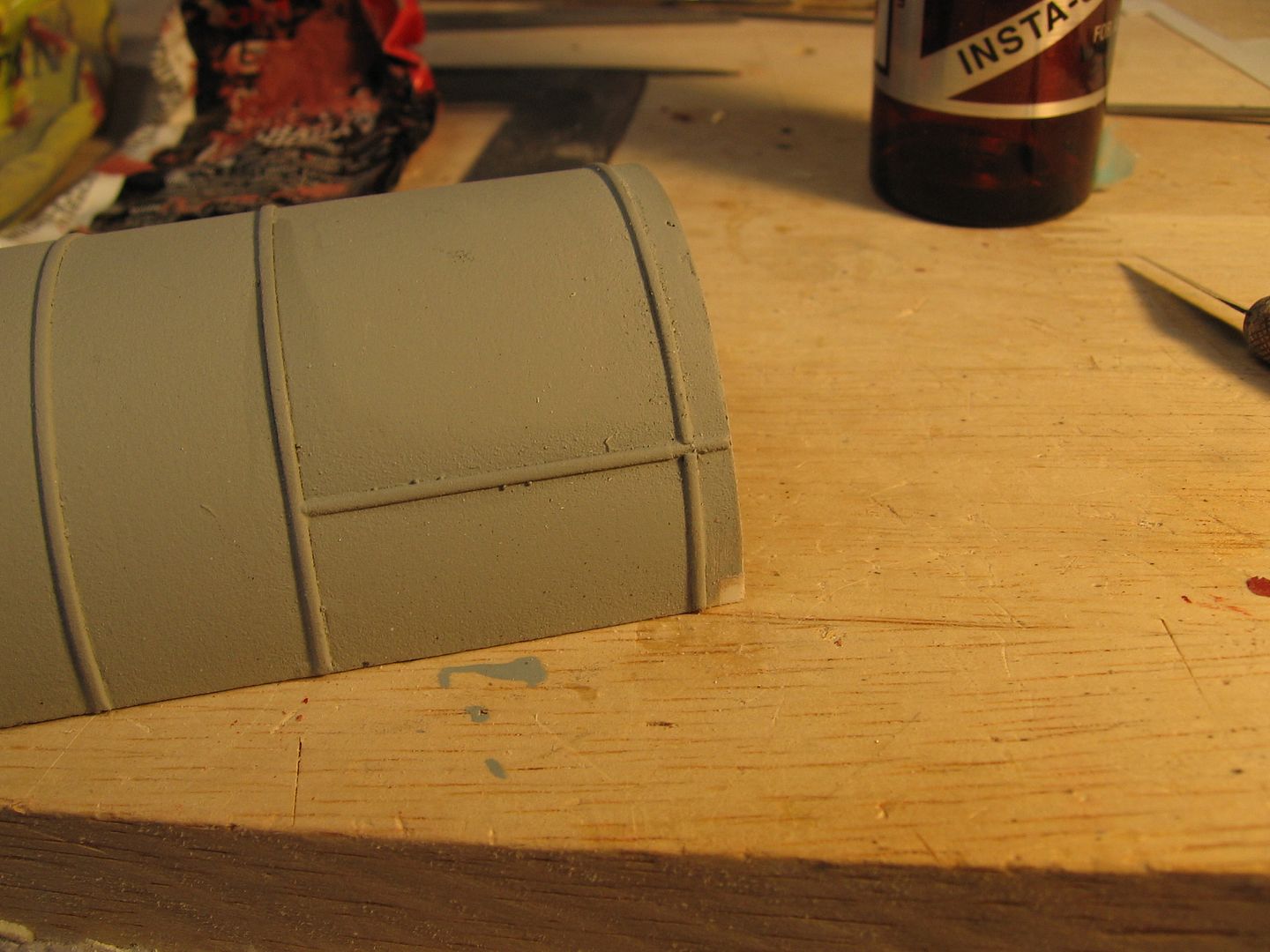

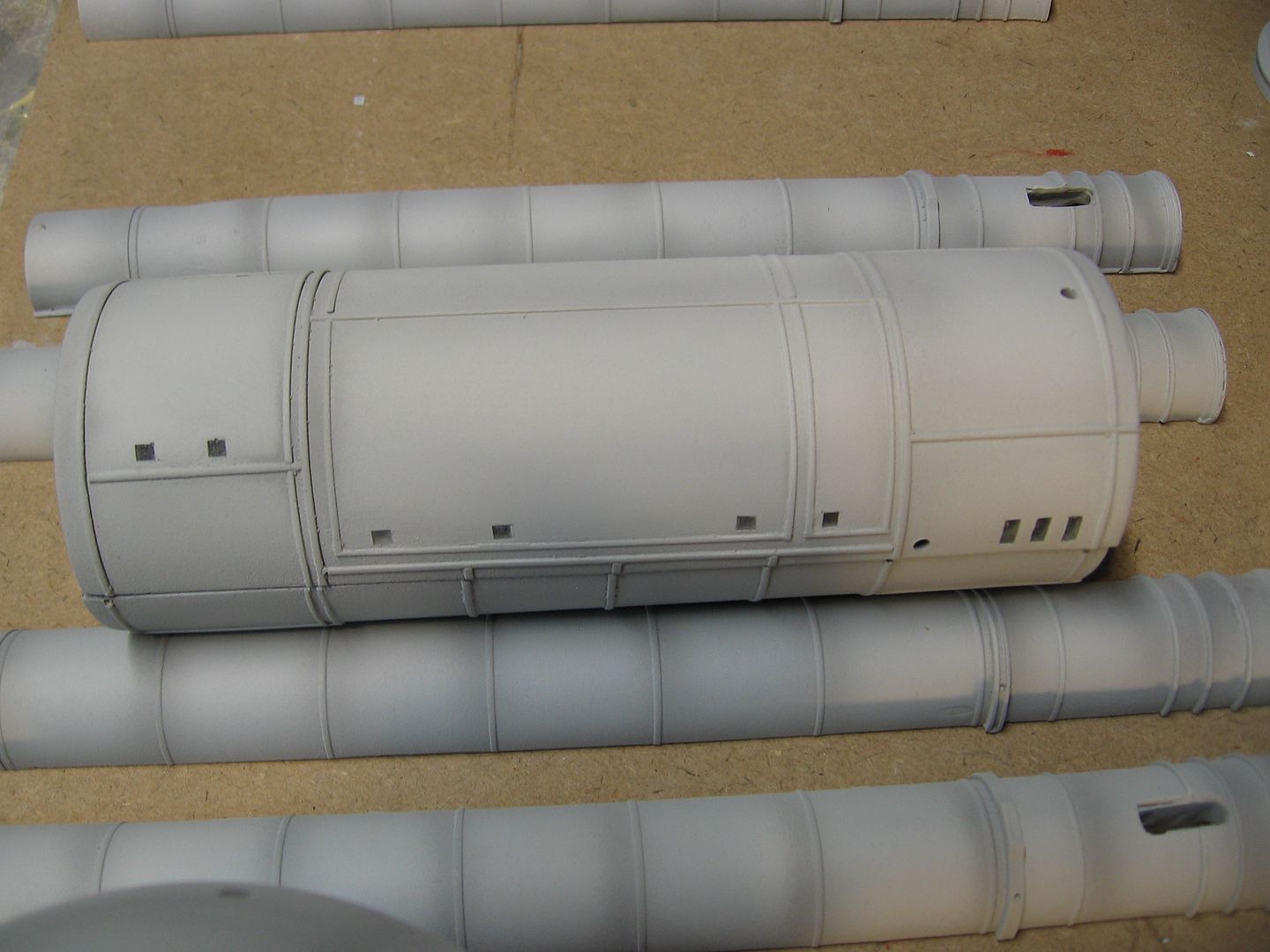

Richard thanks they still could be a bit better and the pictures somewhat hide that. I'm happy with them though. They will do. It would have been better if I would have spent a few days doing them perfect as I could. Then backing the windows with thin styrene and making a new mold. This way I'd have the deep cut windows with a thing back that would file out in a heart beat. But the cost of silicone and time were prohibiting to me.

As for the windows tape and 30 minute epoxy will do the job.

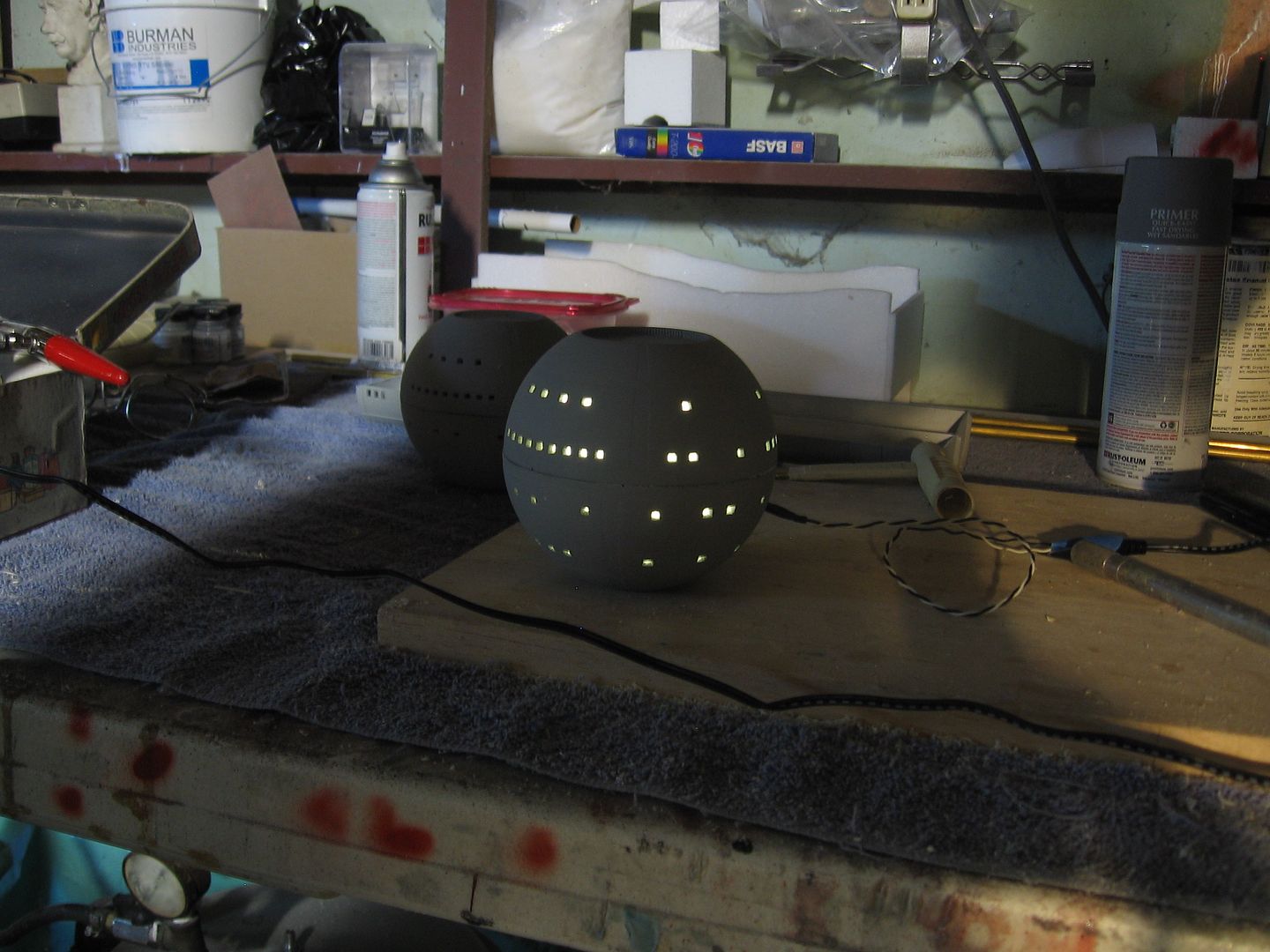

As for the lights Randy's kit include the soft warm white straw hat LEDs, real strobes and NAV lights. I say real as they run off a board that gives them the correct rates and brightness.

Steve

As for the windows tape and 30 minute epoxy will do the job.

As for the lights Randy's kit include the soft warm white straw hat LEDs, real strobes and NAV lights. I say real as they run off a board that gives them the correct rates and brightness.

Steve