Hello all! It’s been a while since I’ve had something worth posting.

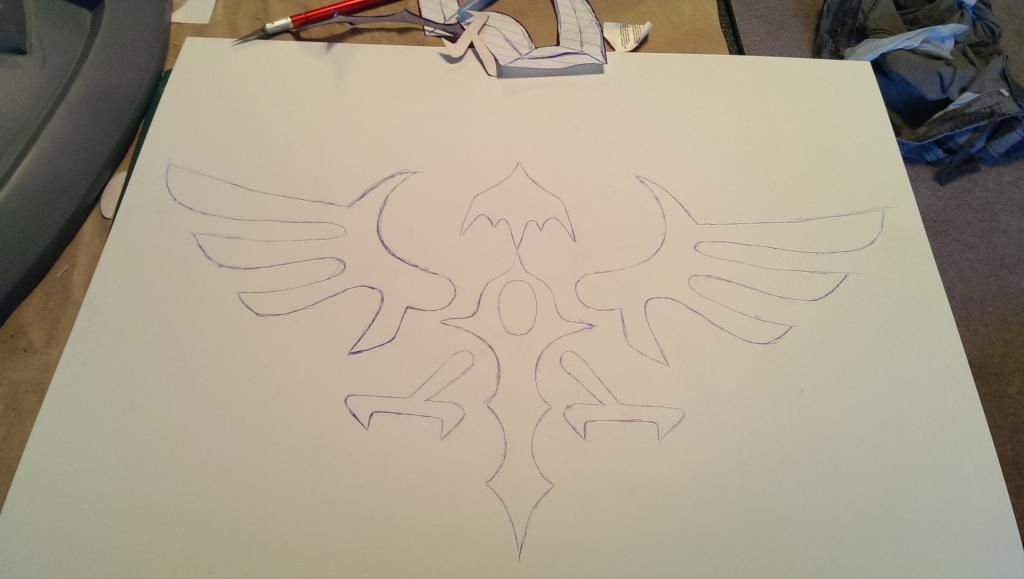

I started working on this shield mid September and now I’m coming to the end of it. It’s isn’t suppose to be 100% game accurate and is more so based on my own interpretation. I hope you like it

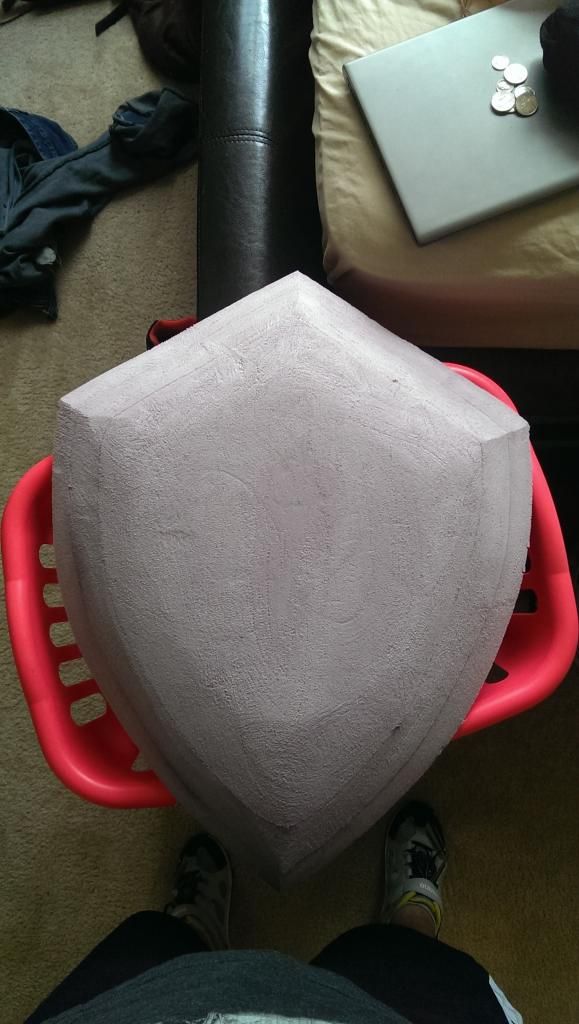

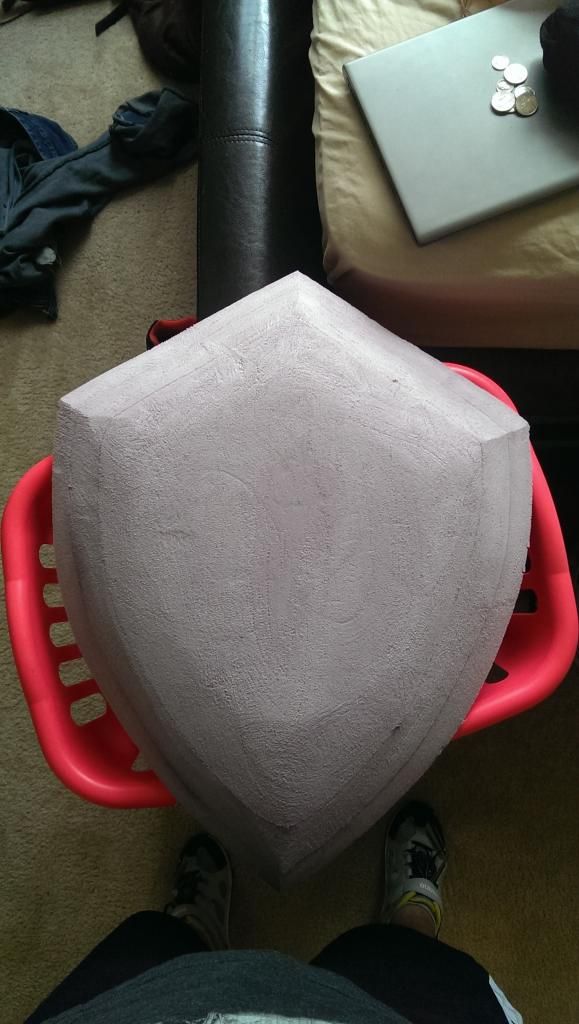

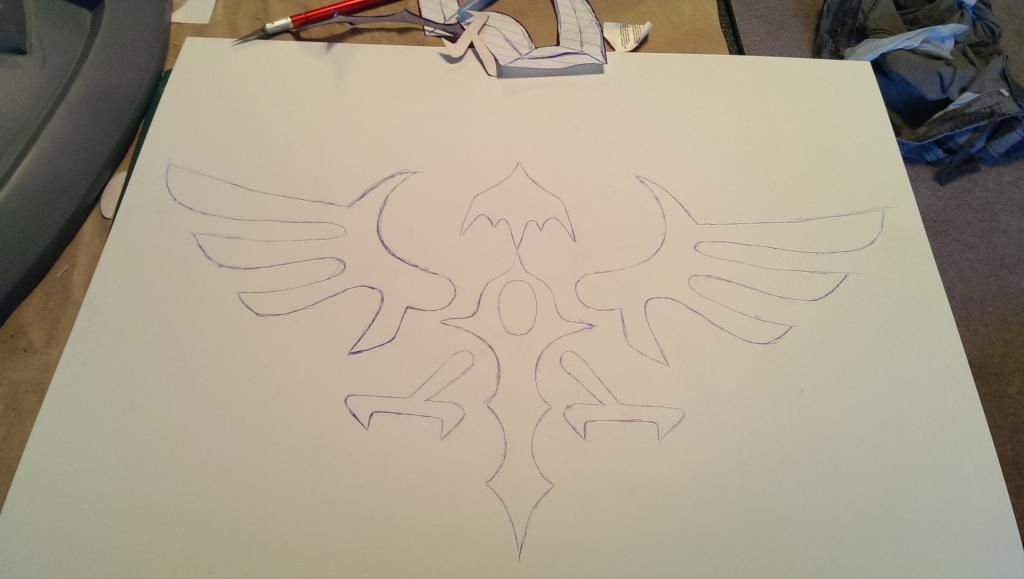

I started out with a bit of foam and carved and shaped it to the basic shape.

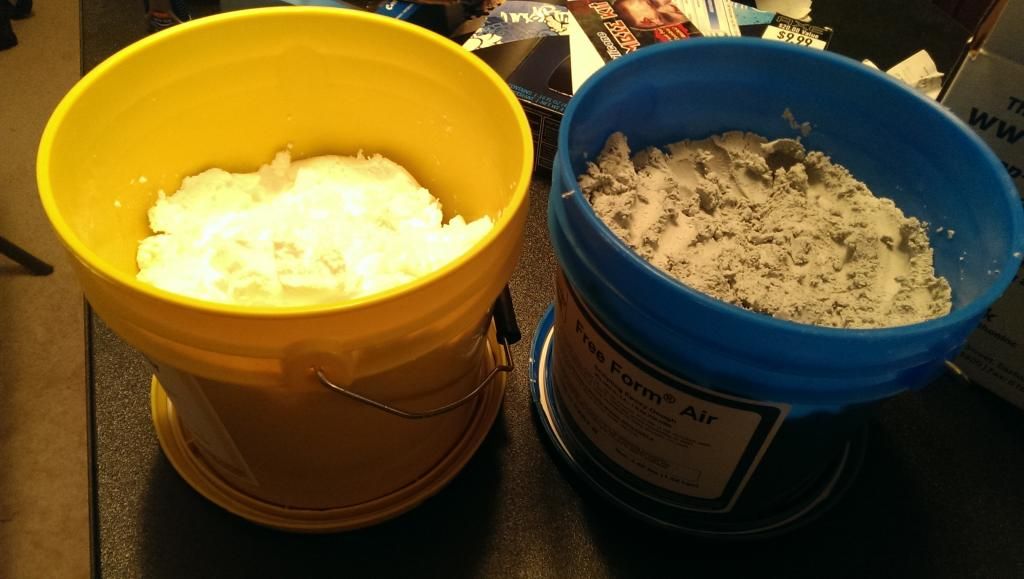

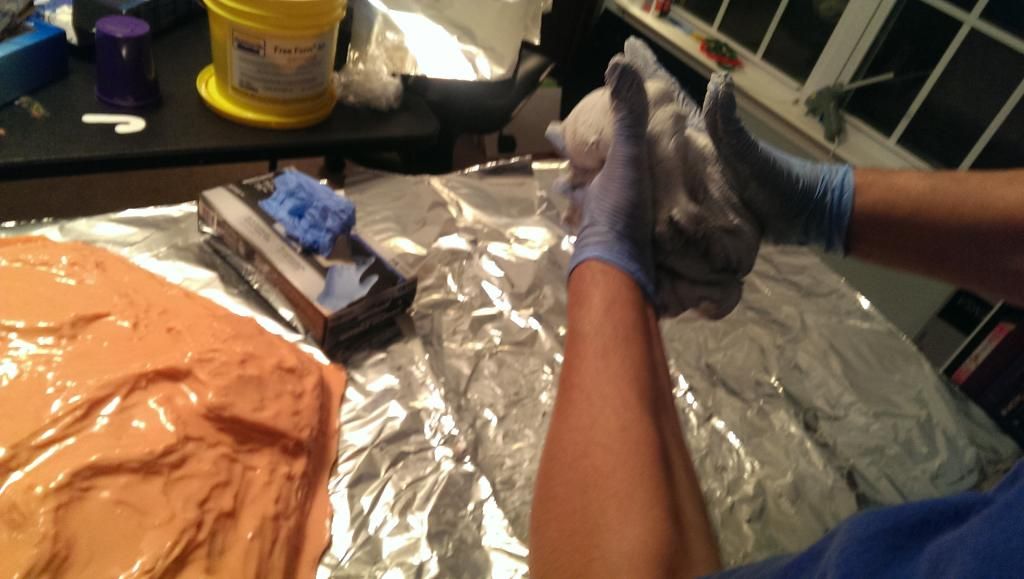

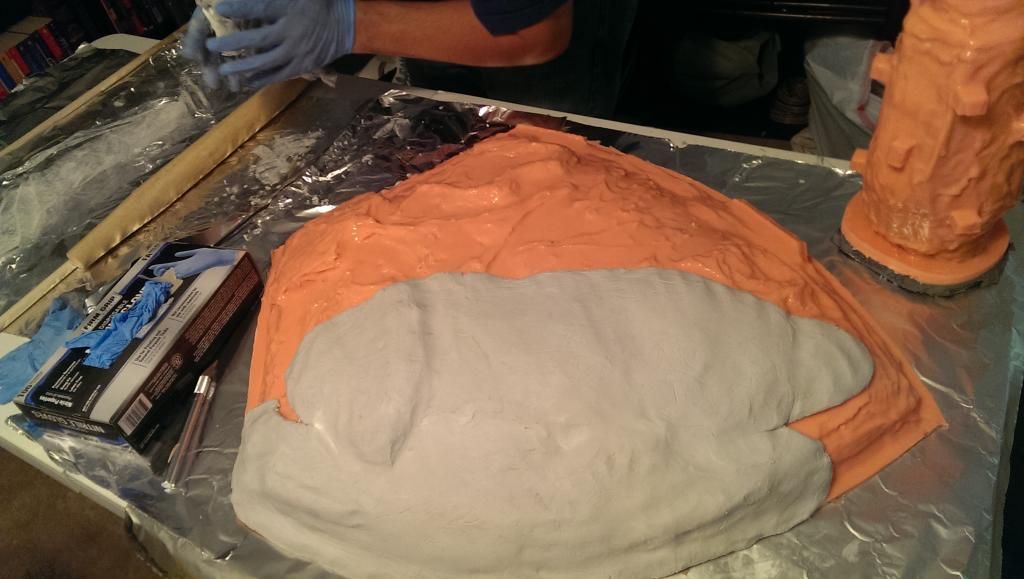

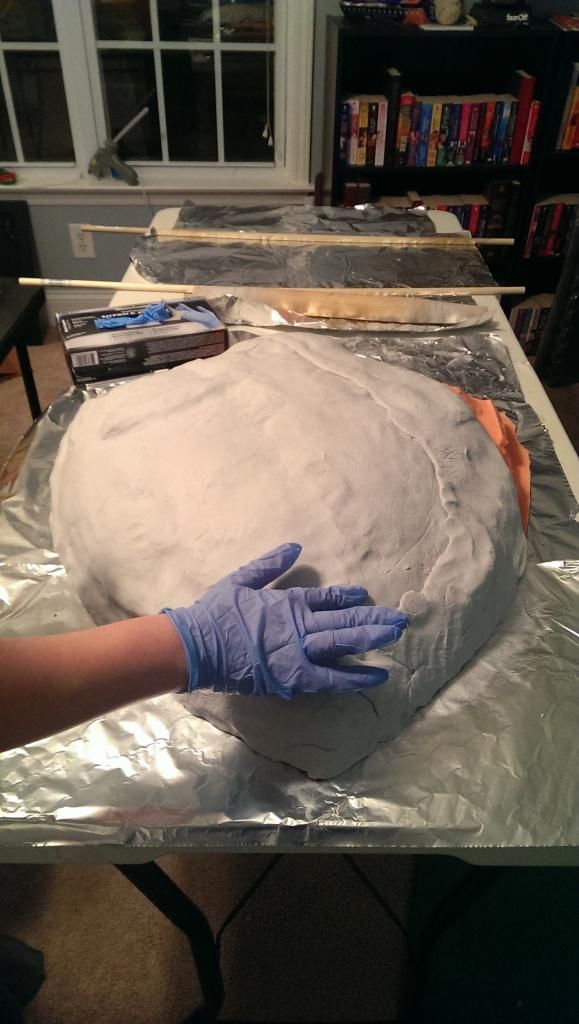

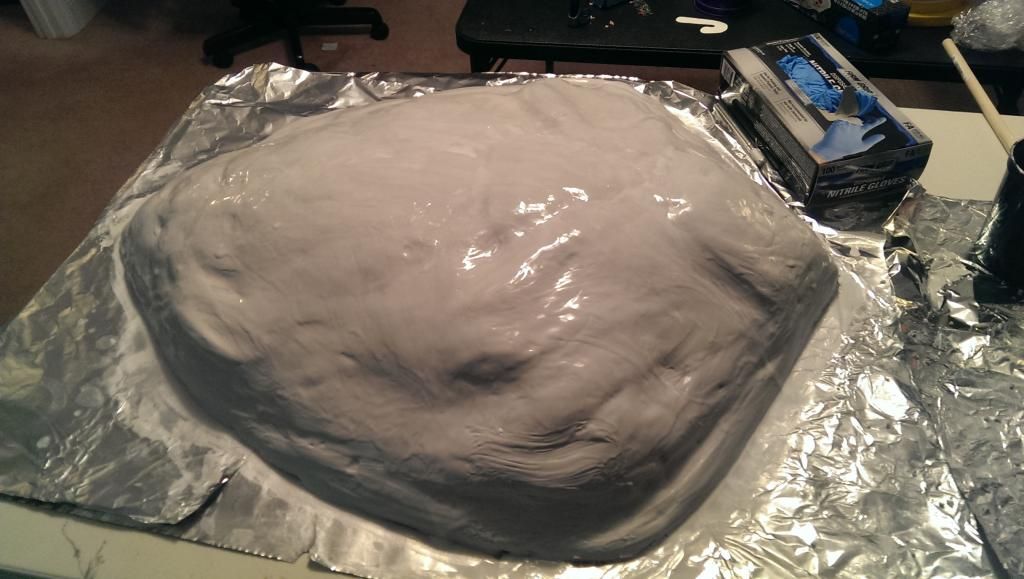

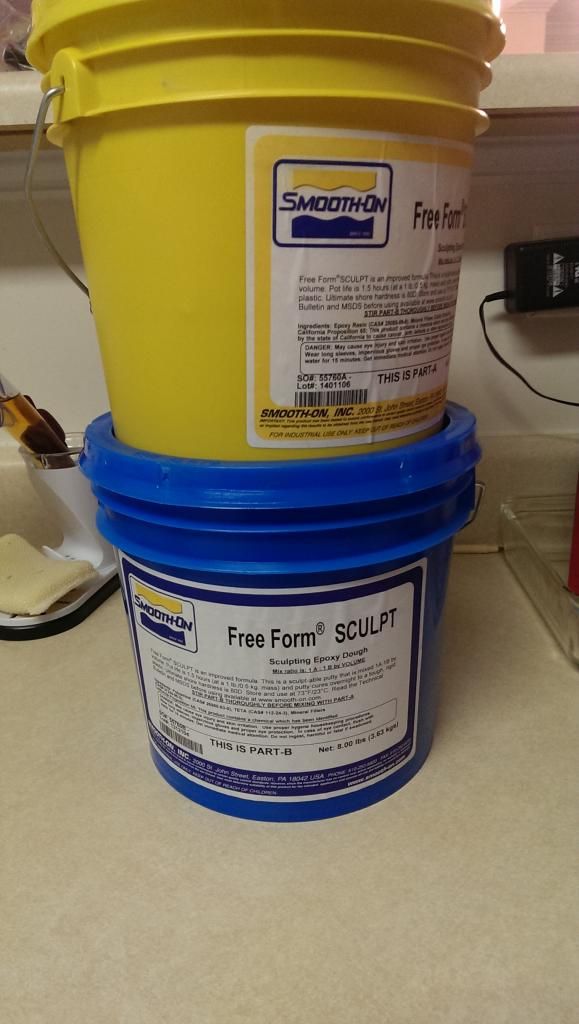

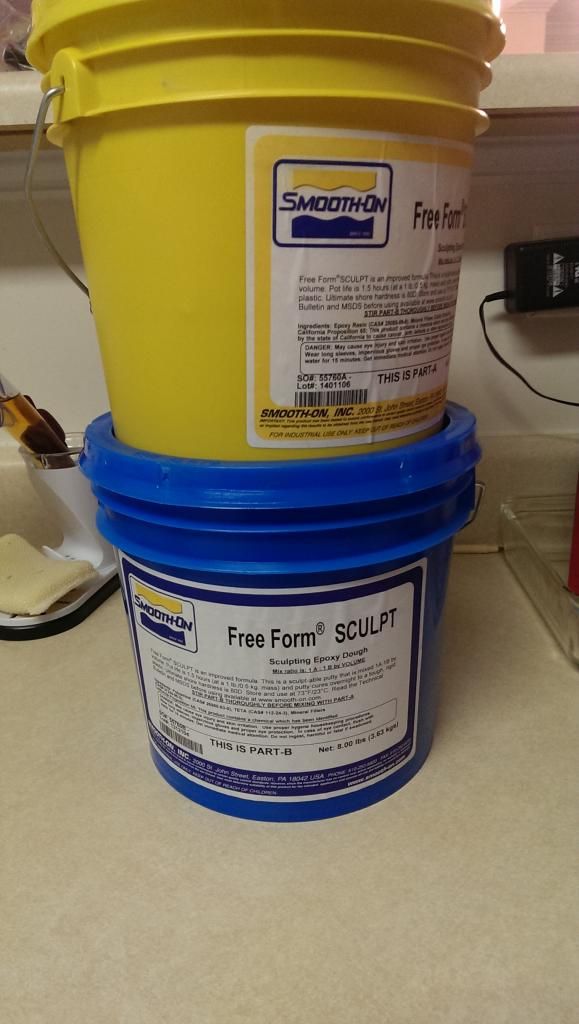

I then used free-form sculpt to cover the whole form:

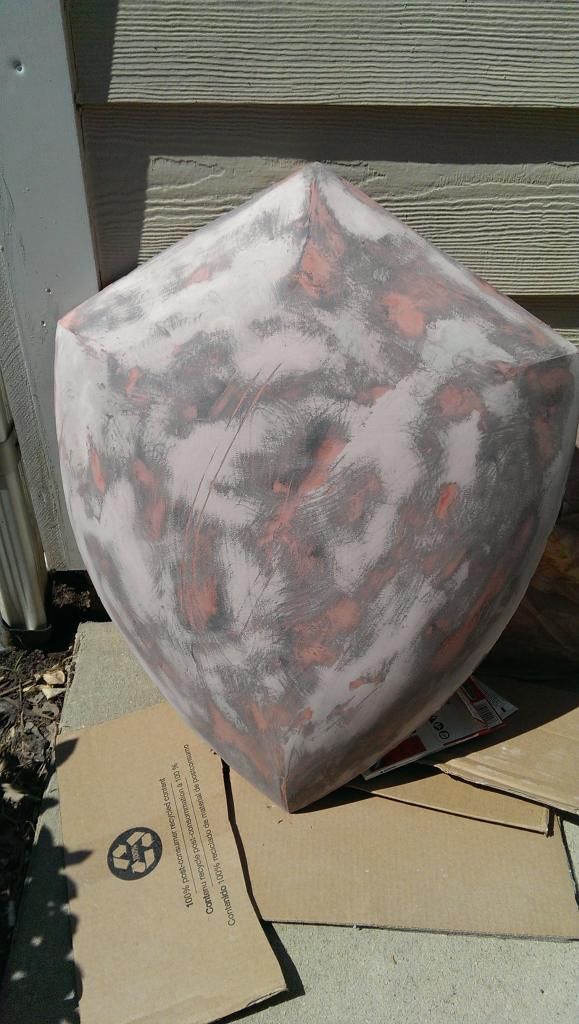

I followed all that with body filler and spot putty to make it smooth.

Then I sculpted the rest of the shields parts with additional free form.

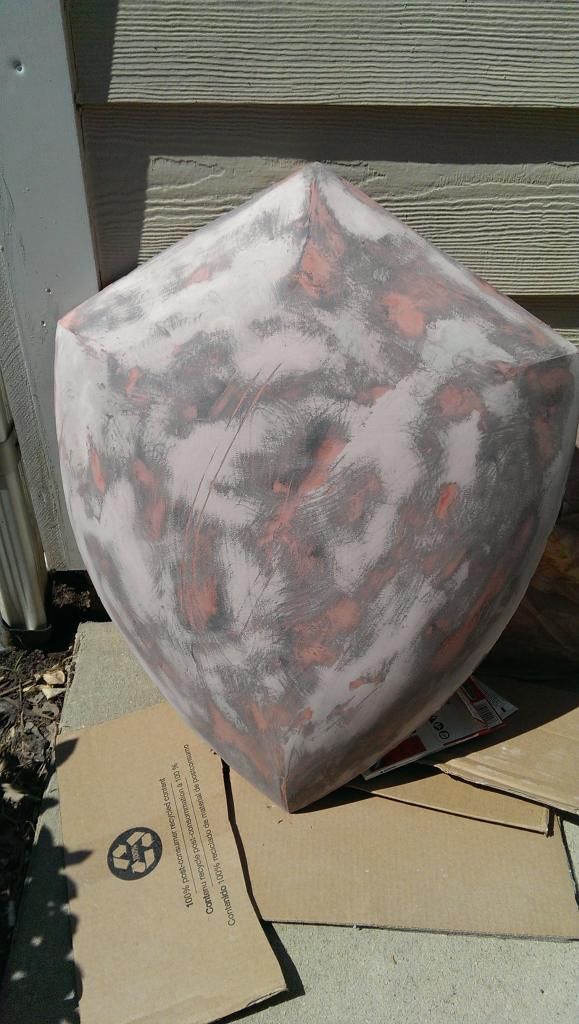

Here it is now after much body work and sanding….priming…filling….repeat

I am planning to mold it so I can make a shield for each of my two kids and maybe make some available.

Let me know what you think.

Thanks for viewing!

-Tony

I started working on this shield mid September and now I’m coming to the end of it. It’s isn’t suppose to be 100% game accurate and is more so based on my own interpretation. I hope you like it

I started out with a bit of foam and carved and shaped it to the basic shape.

I then used free-form sculpt to cover the whole form:

I followed all that with body filler and spot putty to make it smooth.

Then I sculpted the rest of the shields parts with additional free form.

Here it is now after much body work and sanding….priming…filling….repeat

I am planning to mold it so I can make a shield for each of my two kids and maybe make some available.

Let me know what you think.

Thanks for viewing!

-Tony