Hi Gang,

For all those patriots celebrating the 4th of July, Happy Birthday America!

Time for the holiday weekend Update Part I

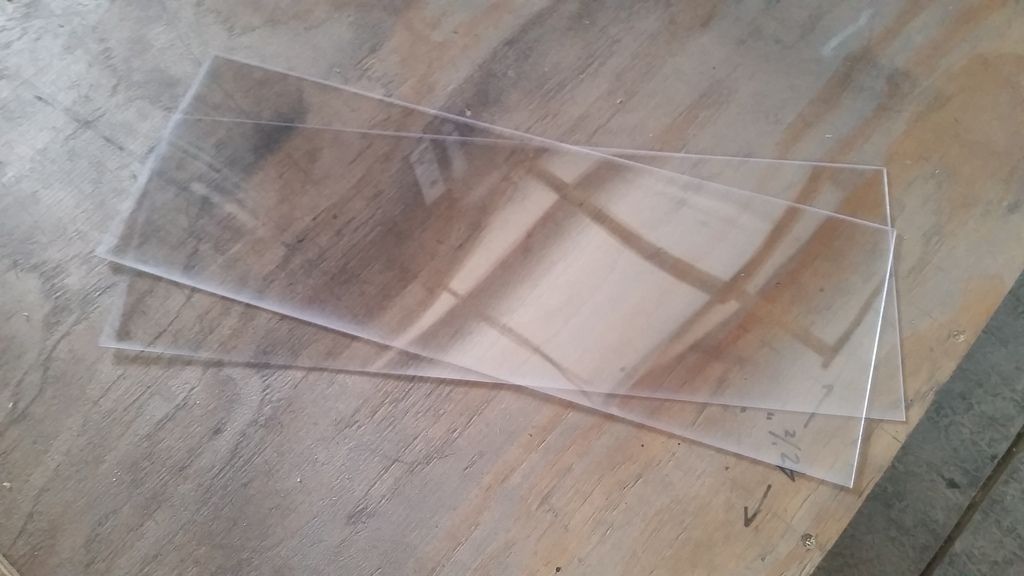

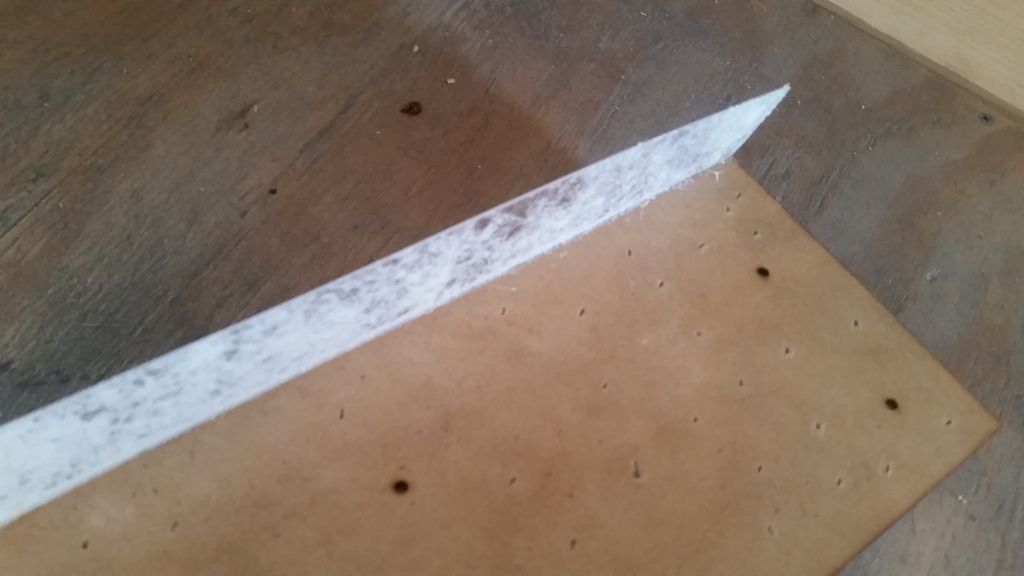

I laser cut these nav chair nacelle skins

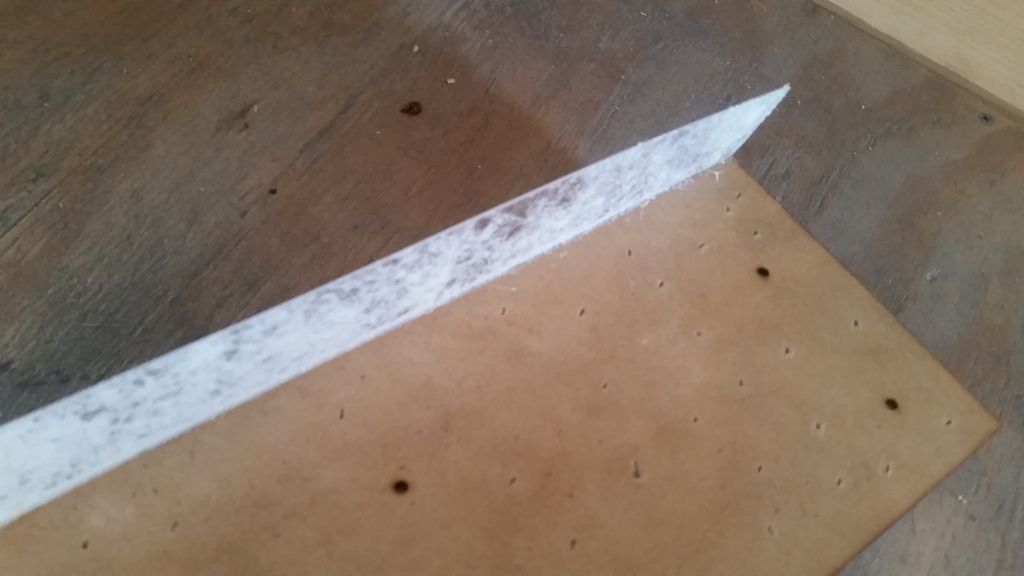

Sprayed adhesive

Then wrapped each nacelle

This edge is the area of most concern - the plexi wants to pop away from the edge

I bent the edges over and rested the nacelle on the actually edge - fingers crossed it works

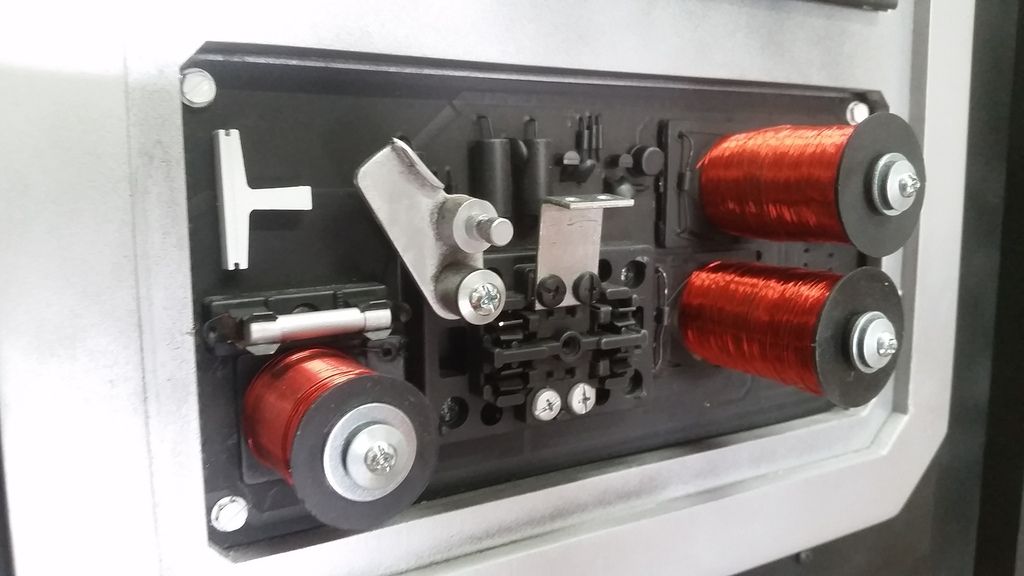

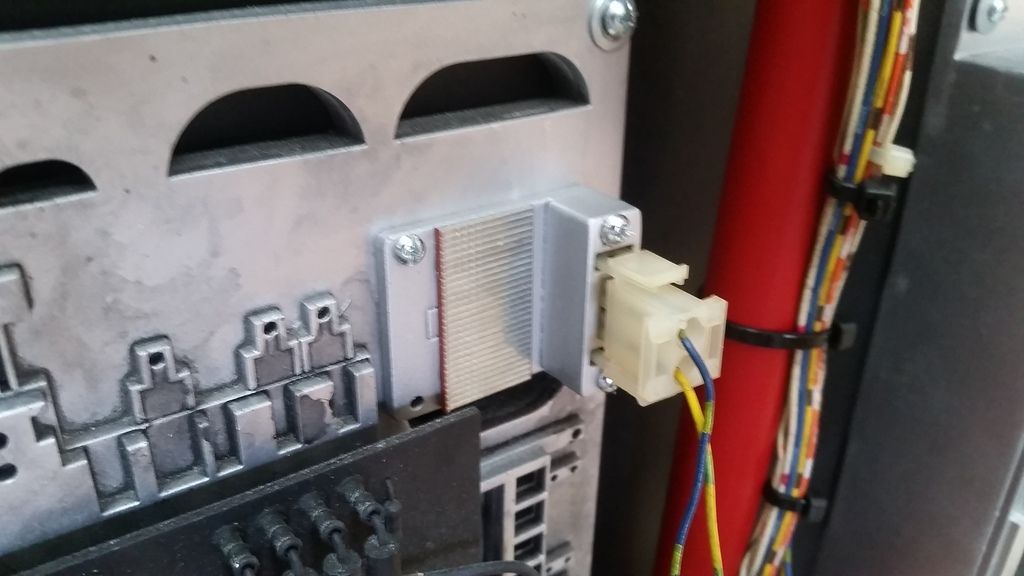

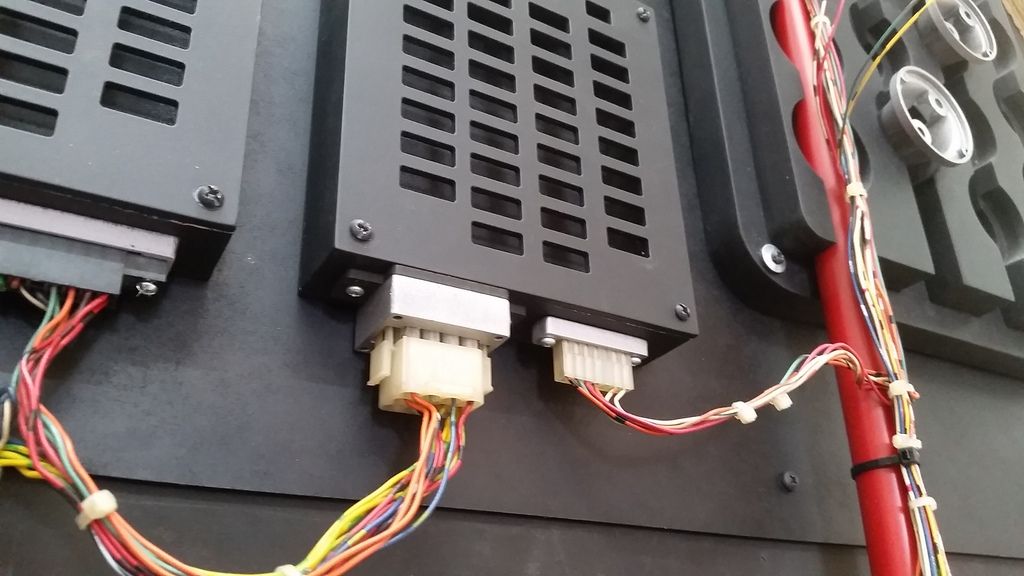

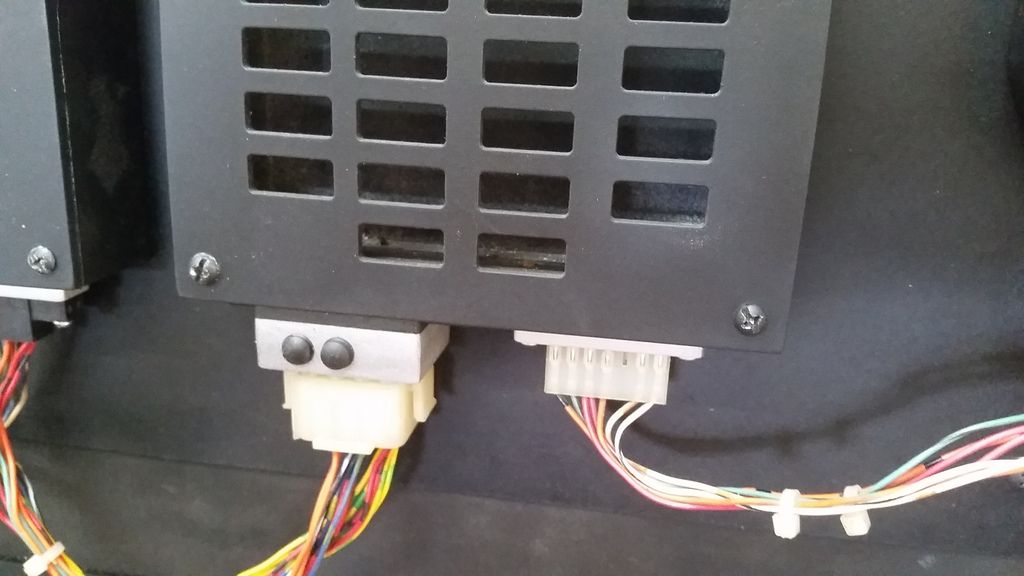

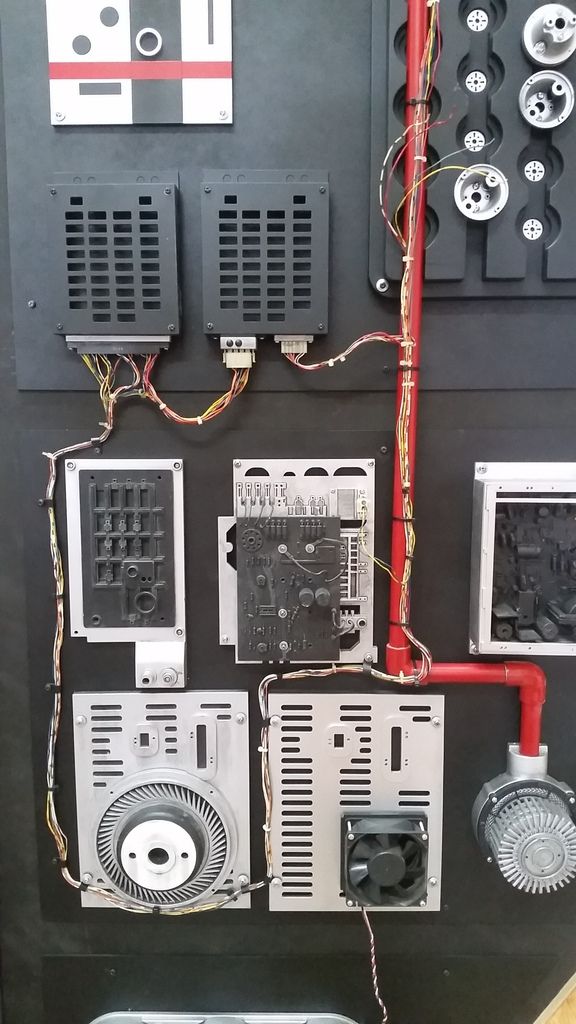

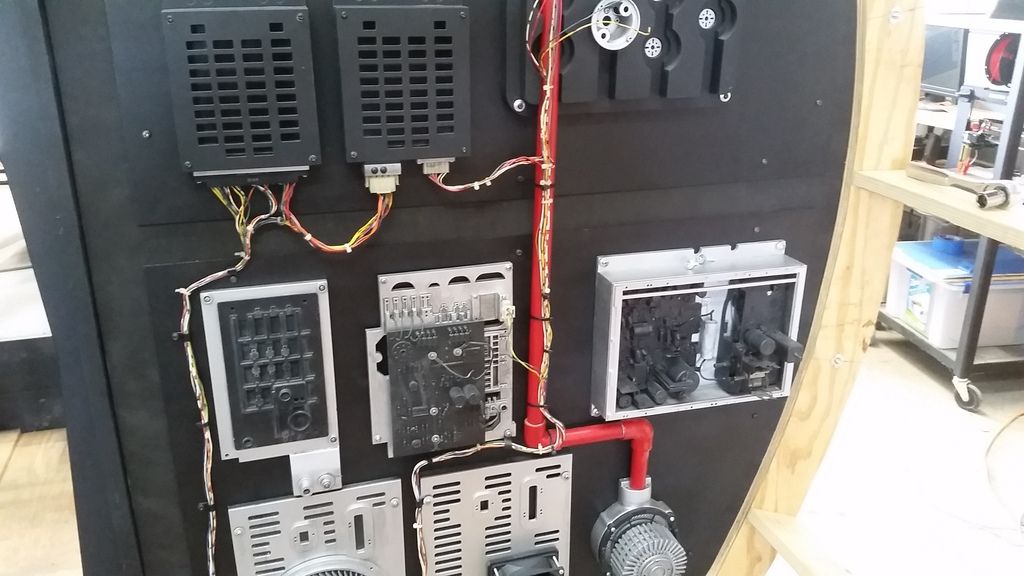

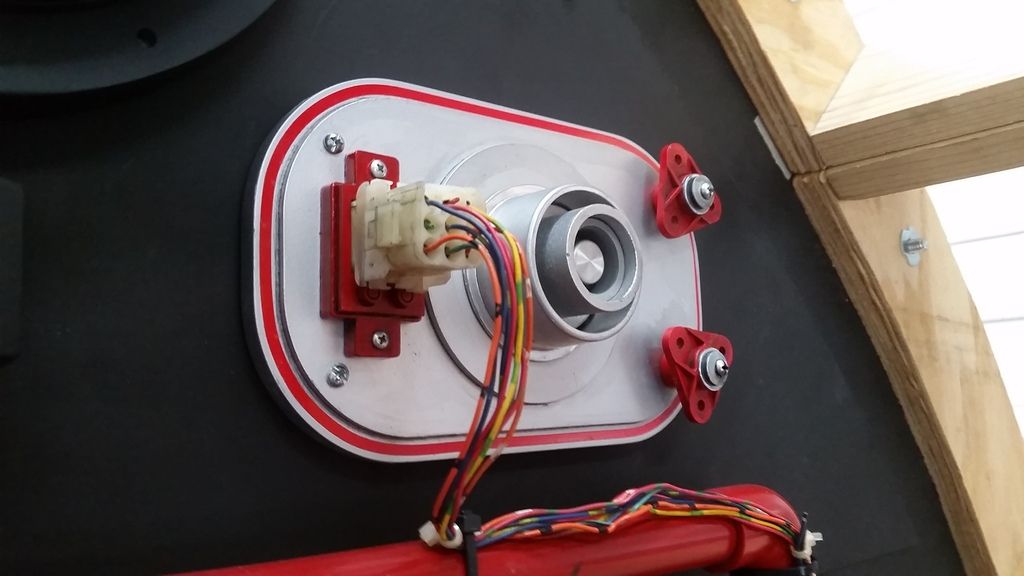

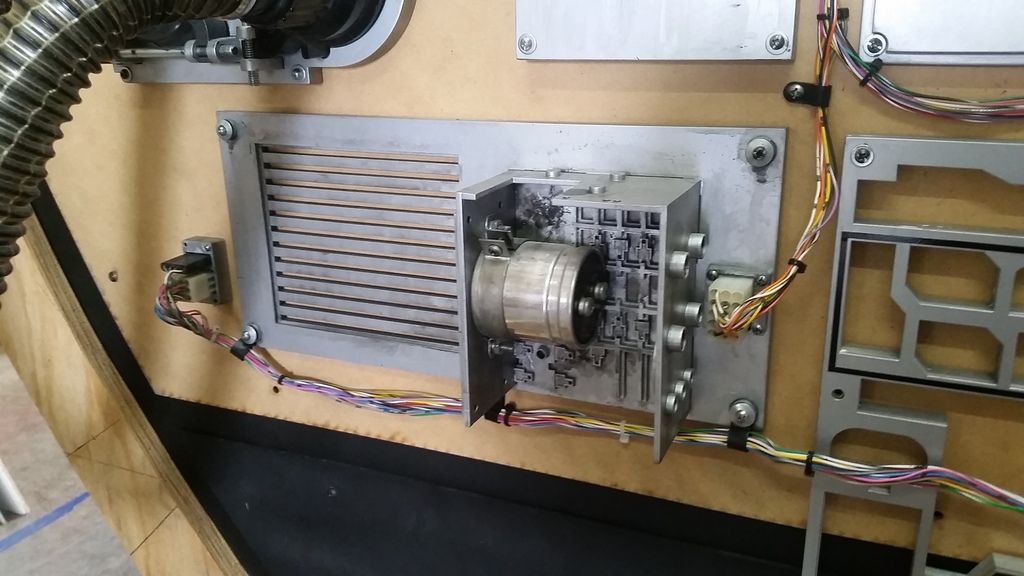

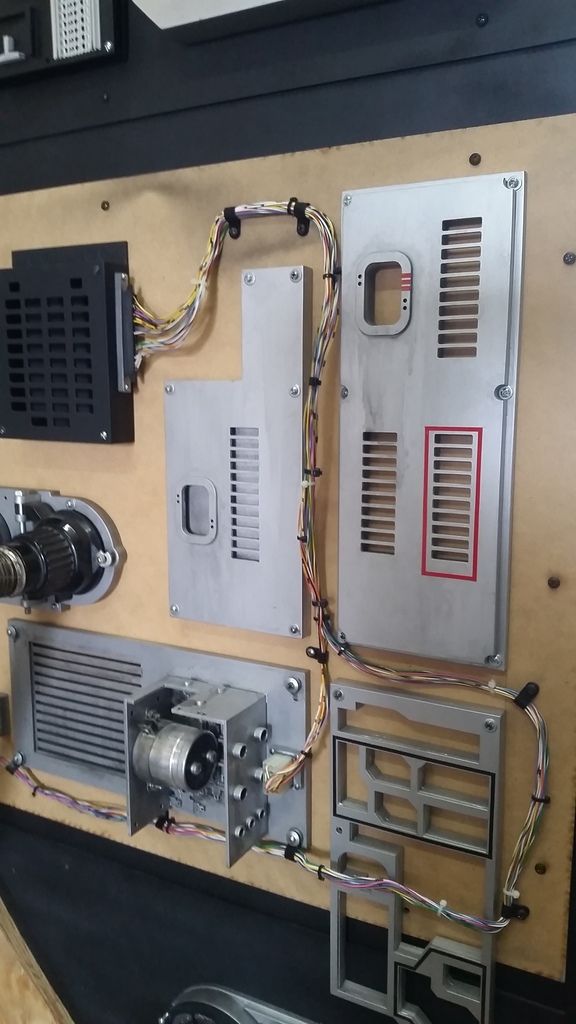

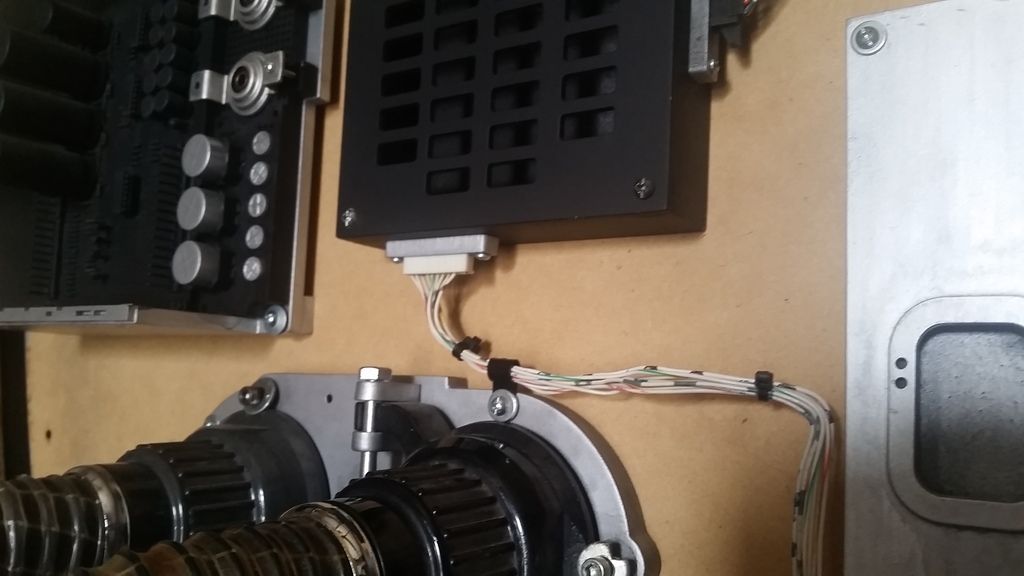

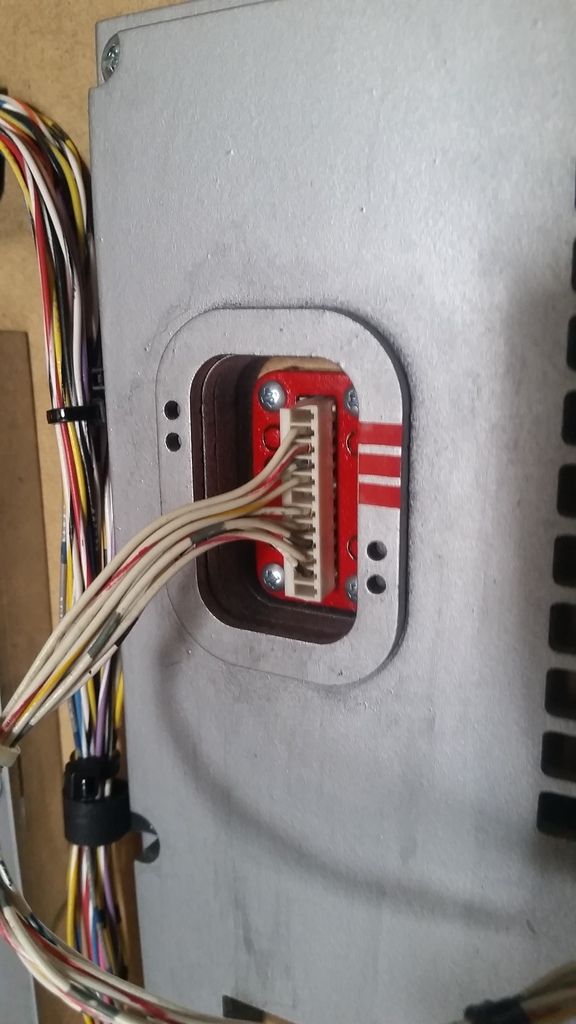

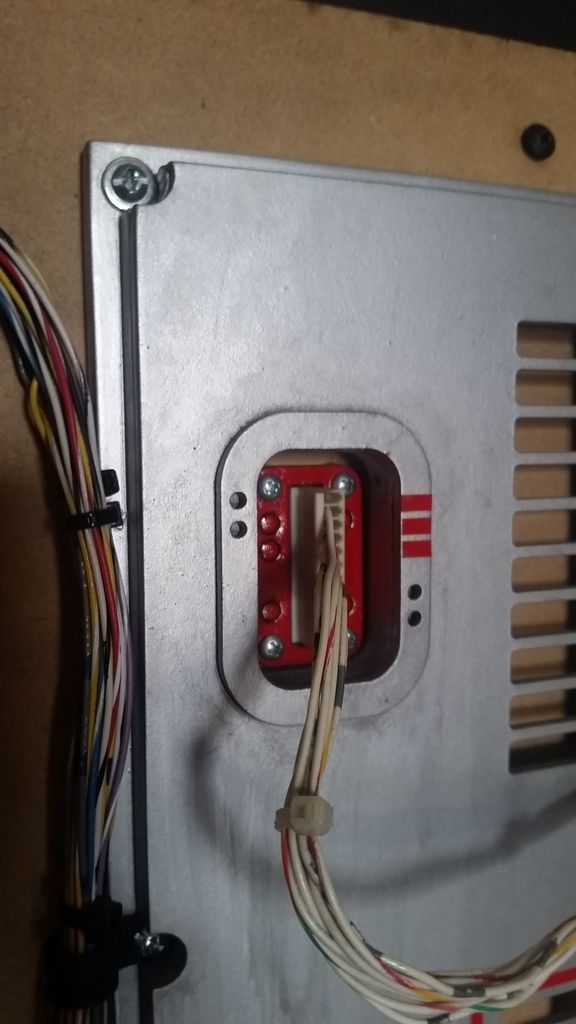

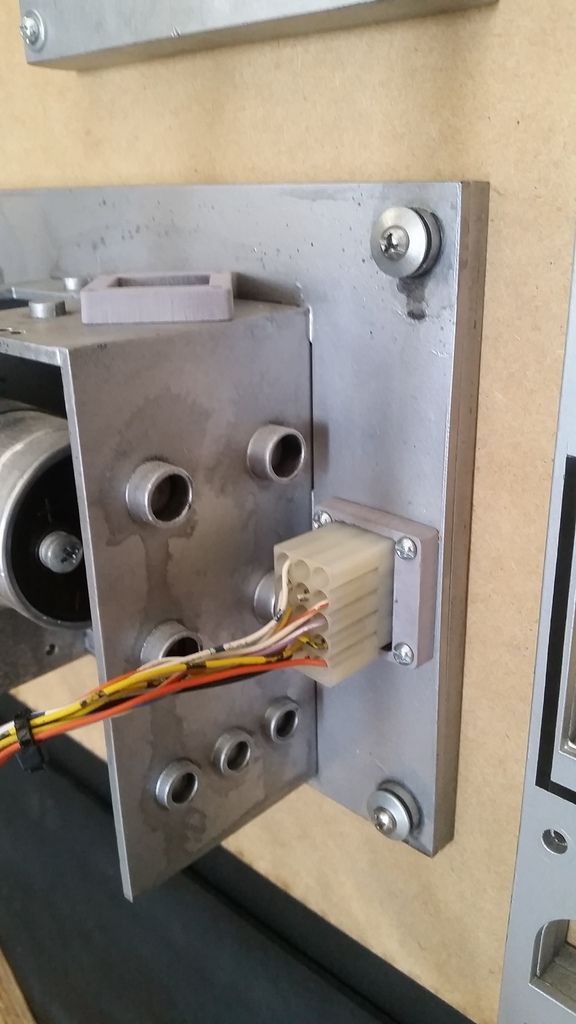

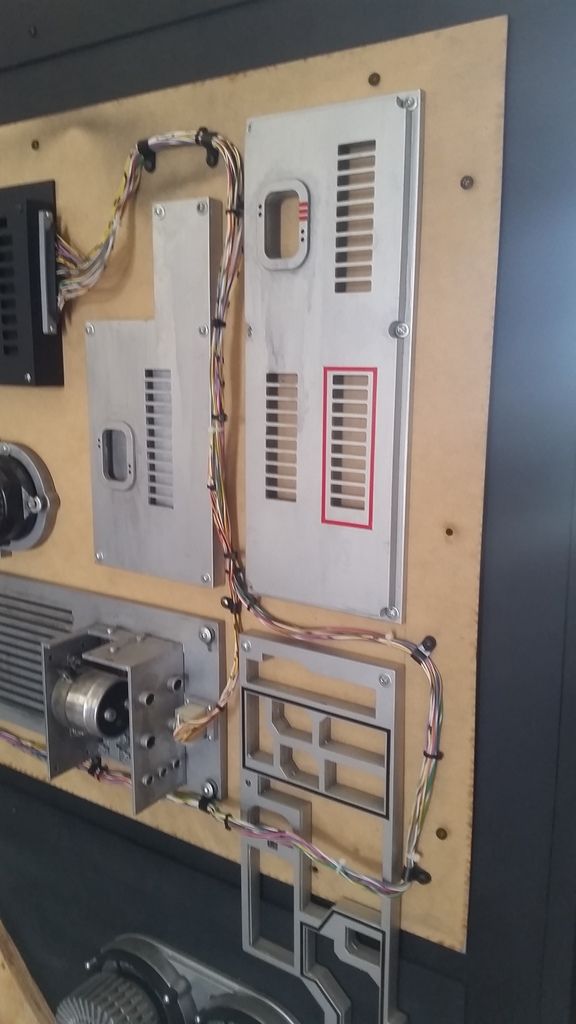

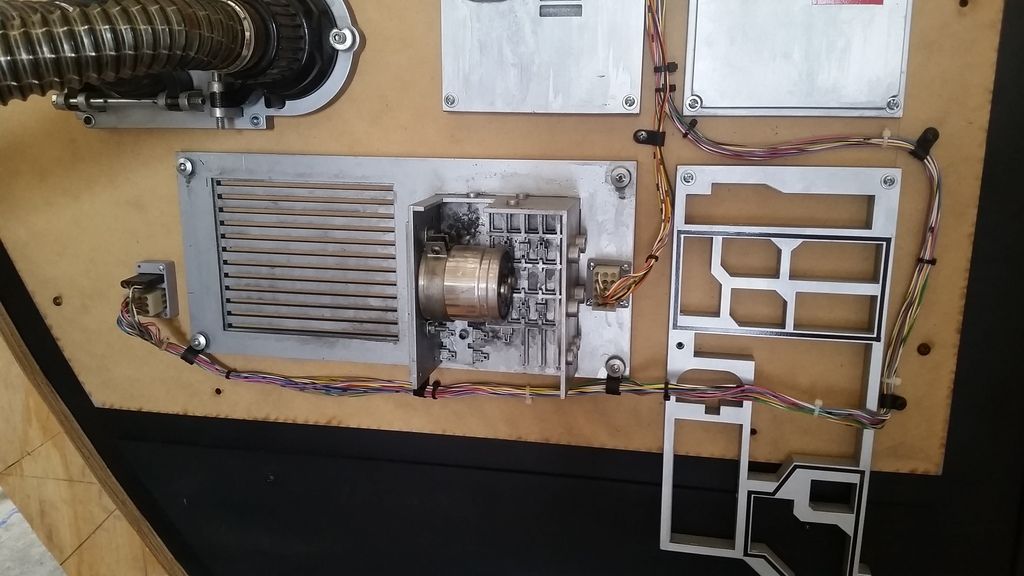

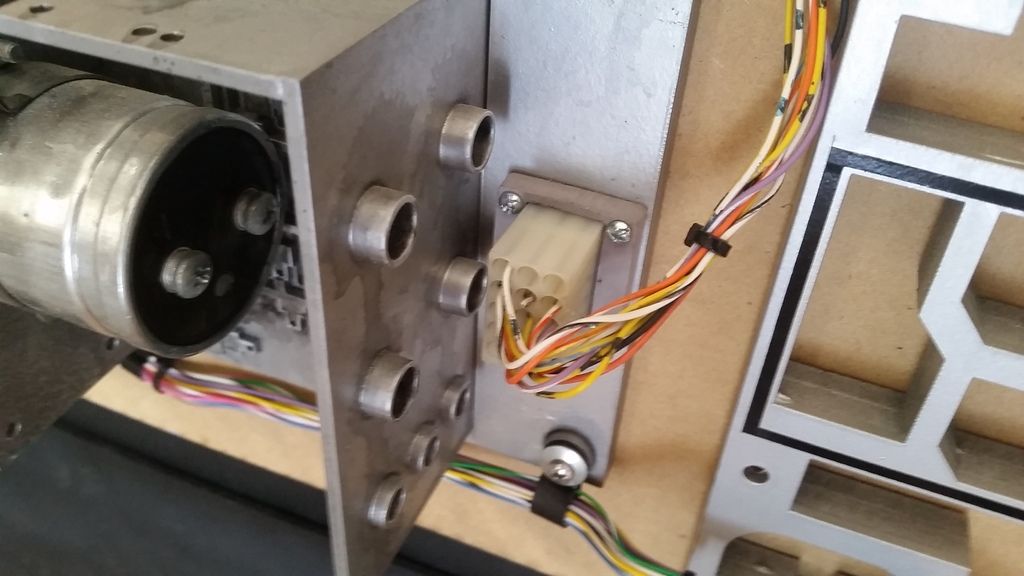

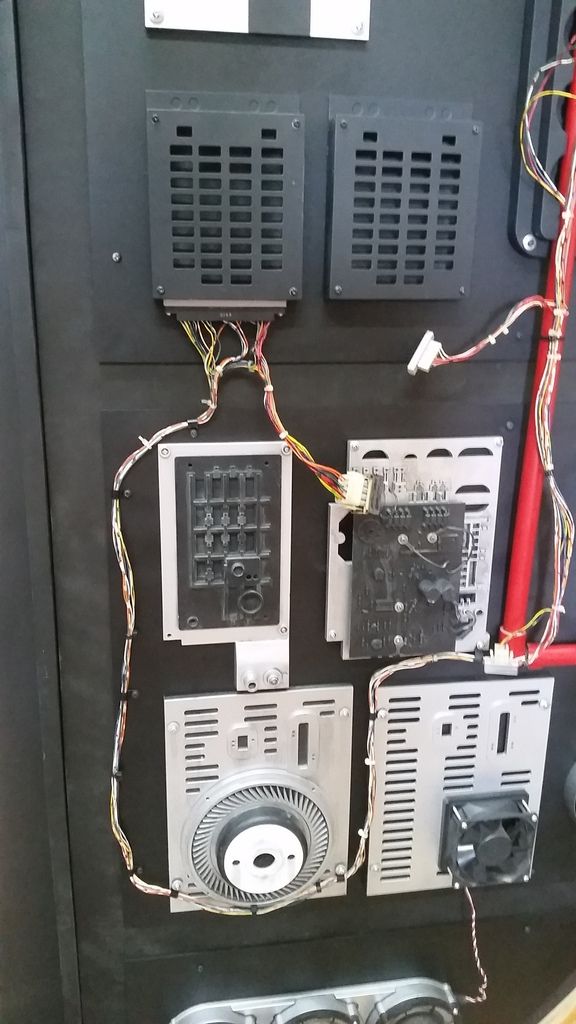

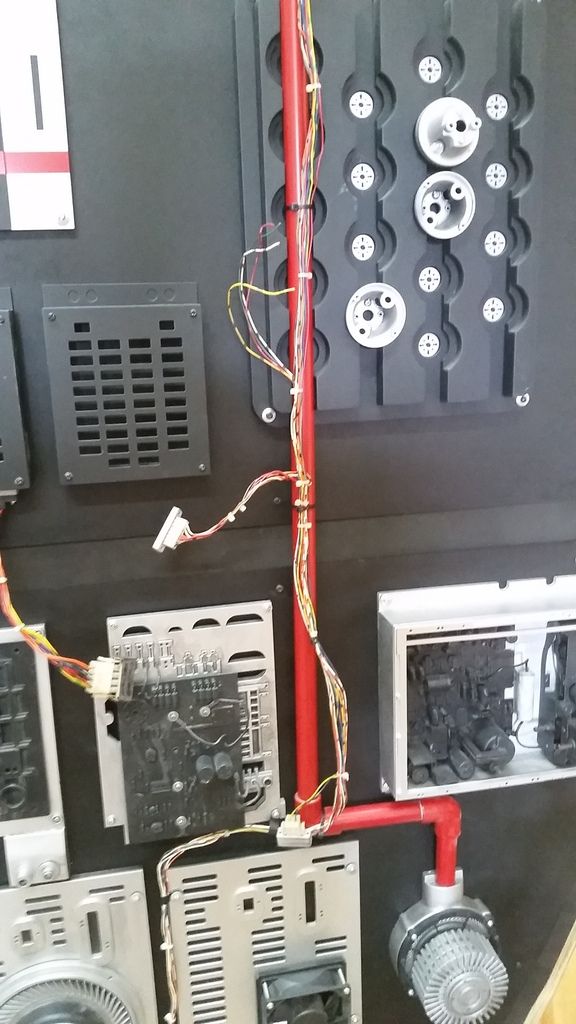

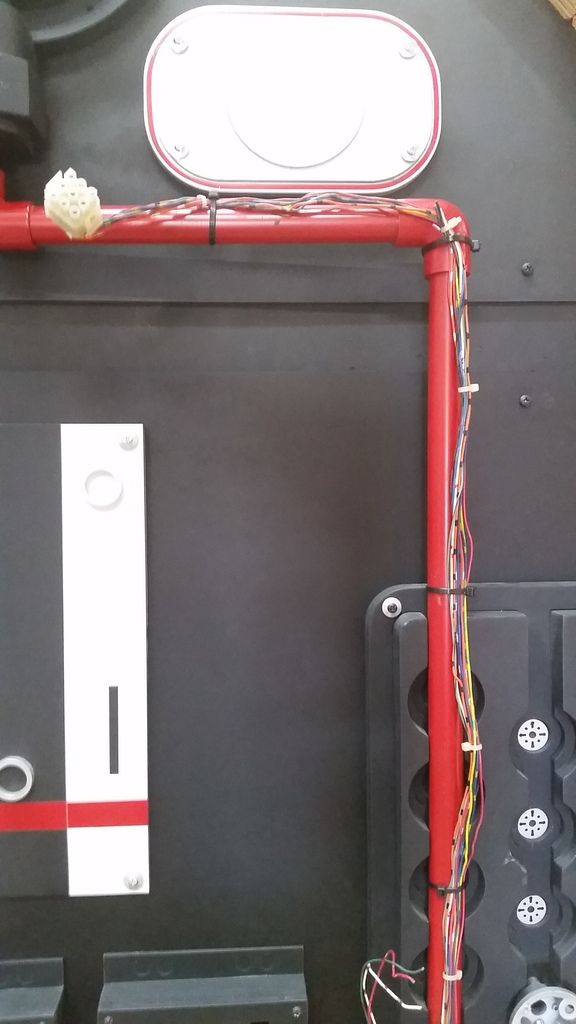

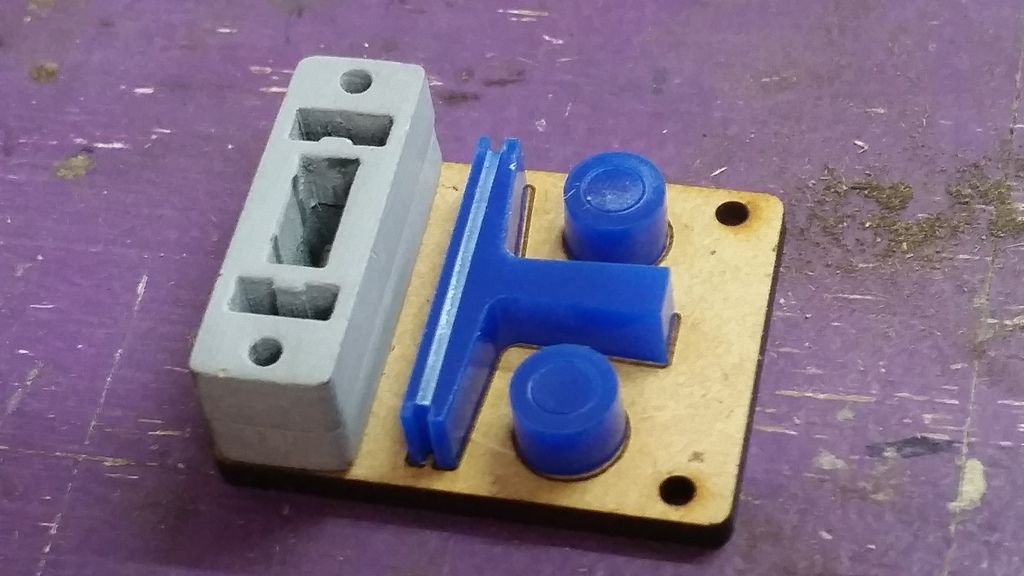

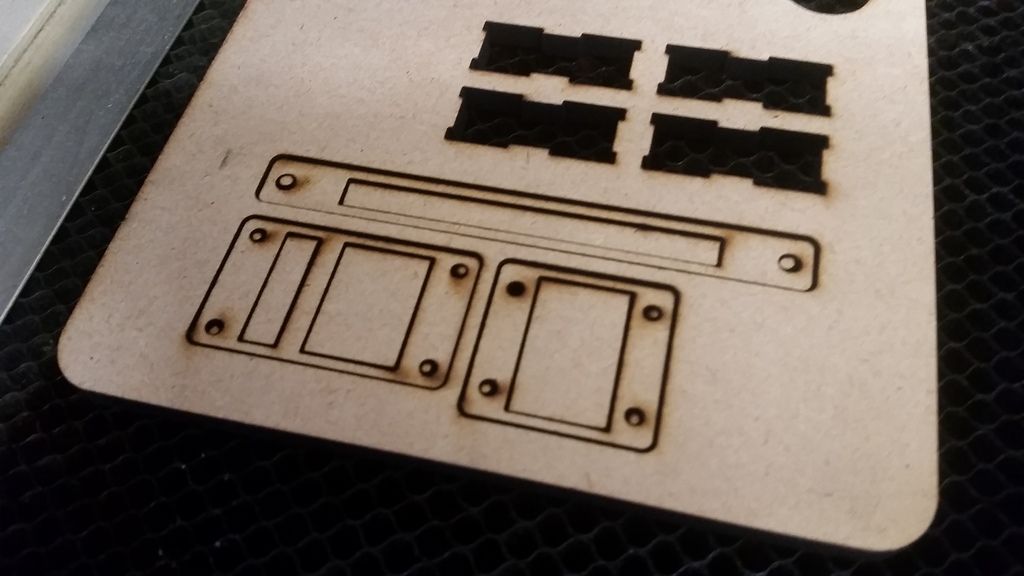

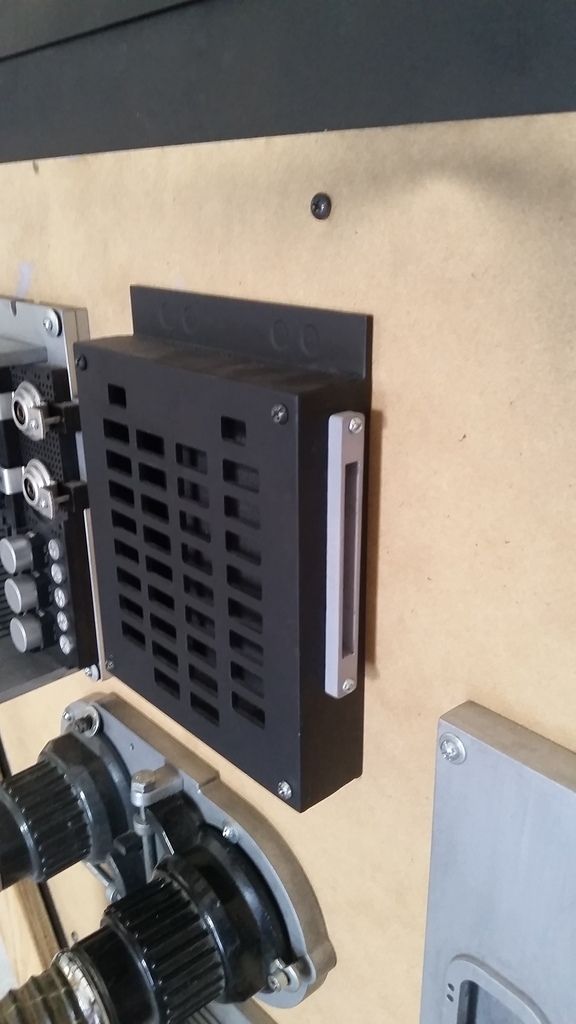

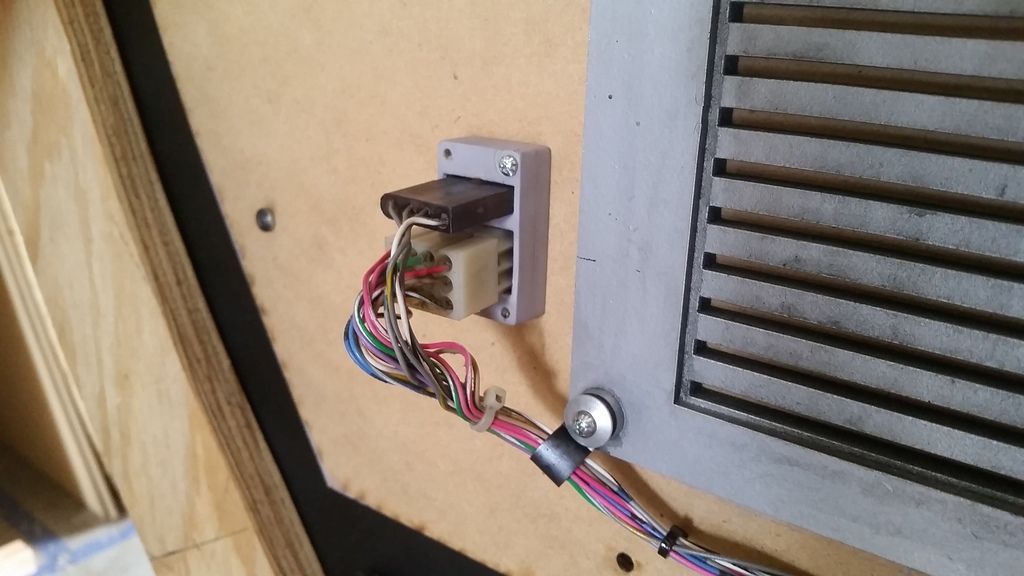

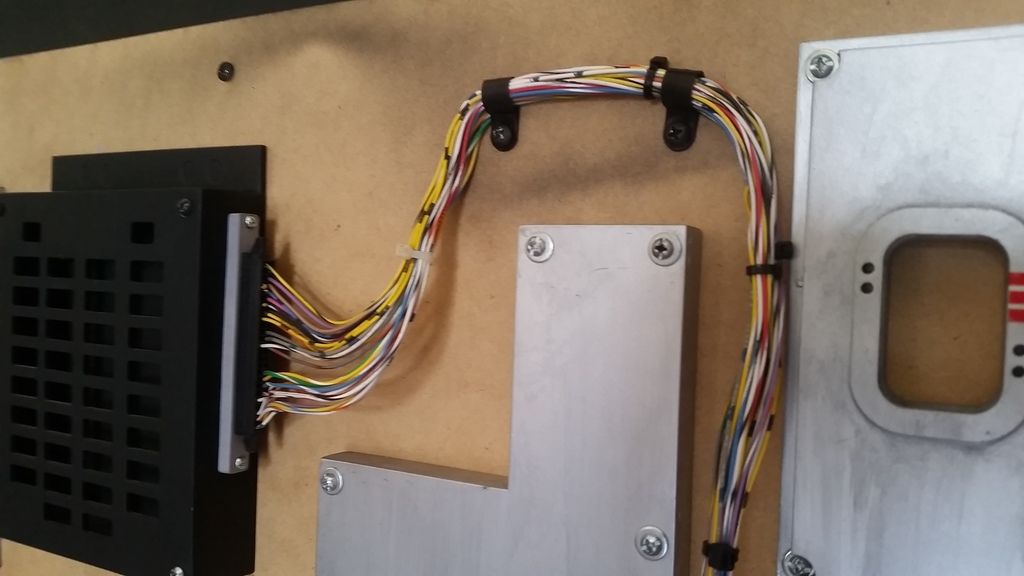

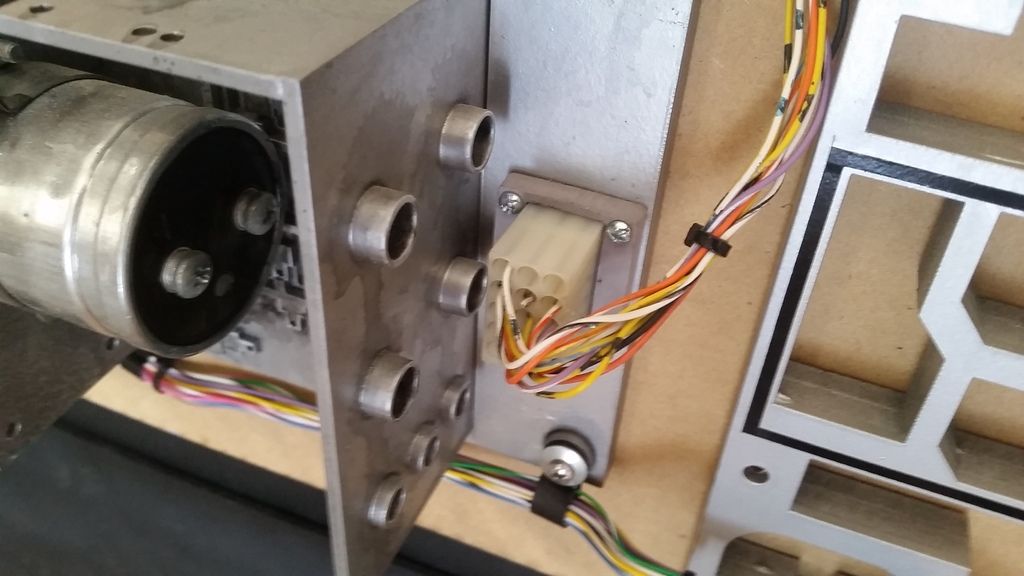

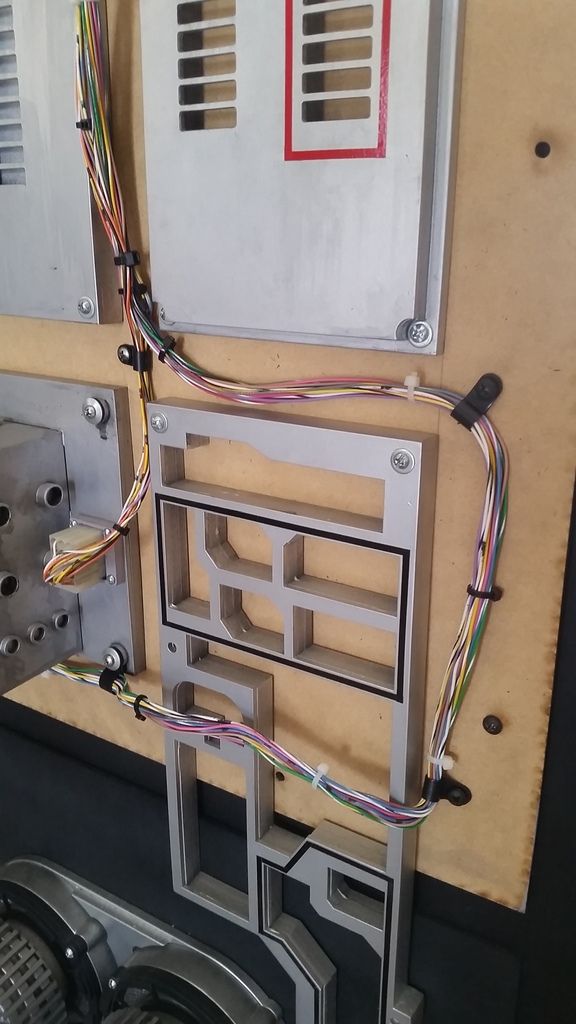

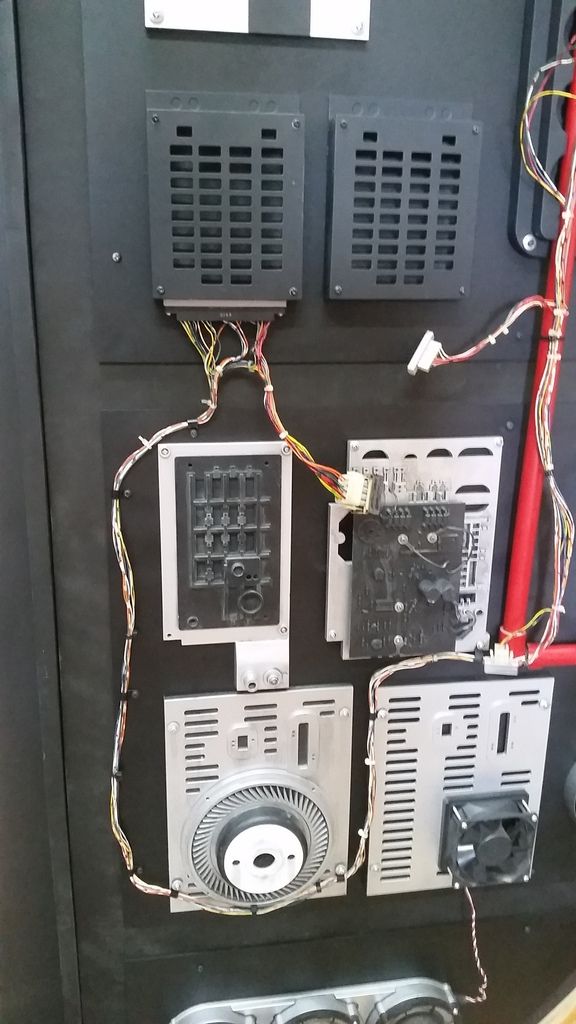

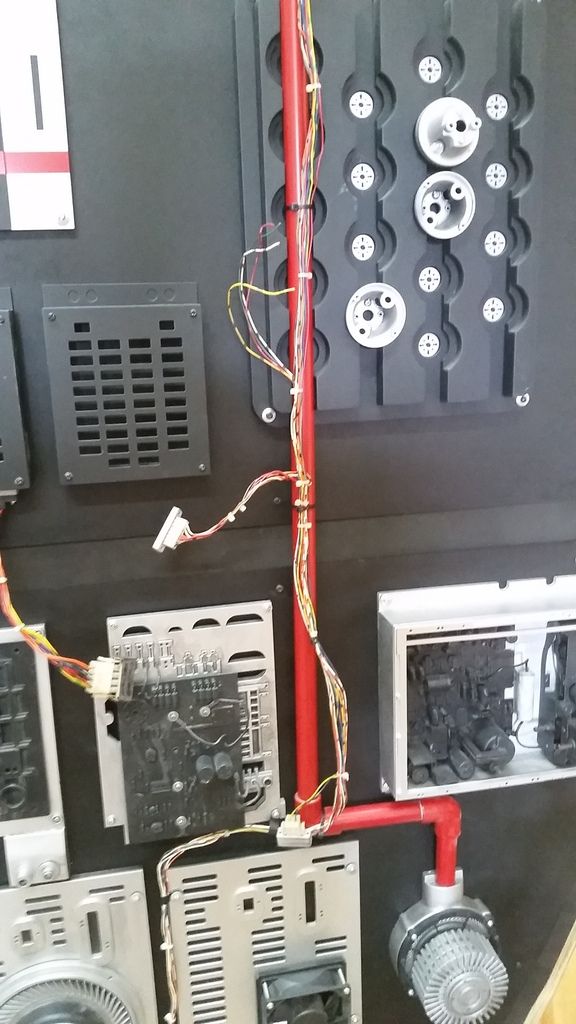

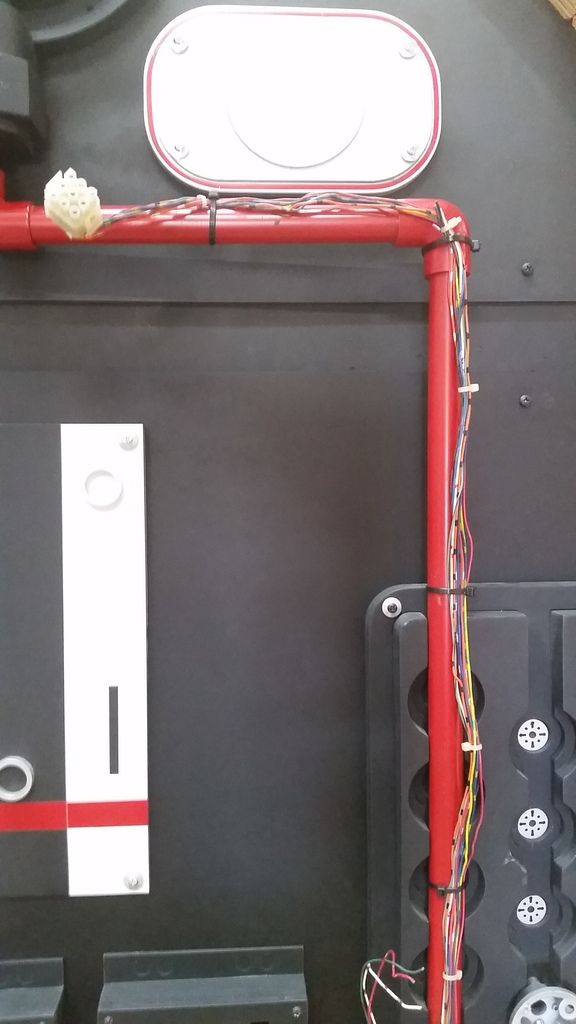

It was time to dress the cockpit entrance with all the saved wiring harnesses I've had lying around. So, I measured, designed and laser cut several different sized connectors that will mount to the entrance wall and greeblies

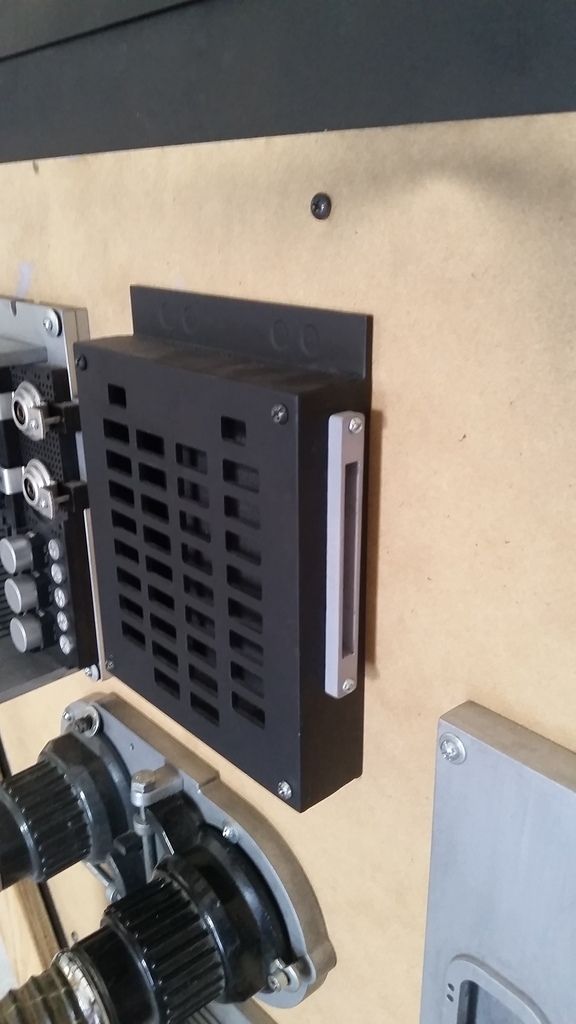

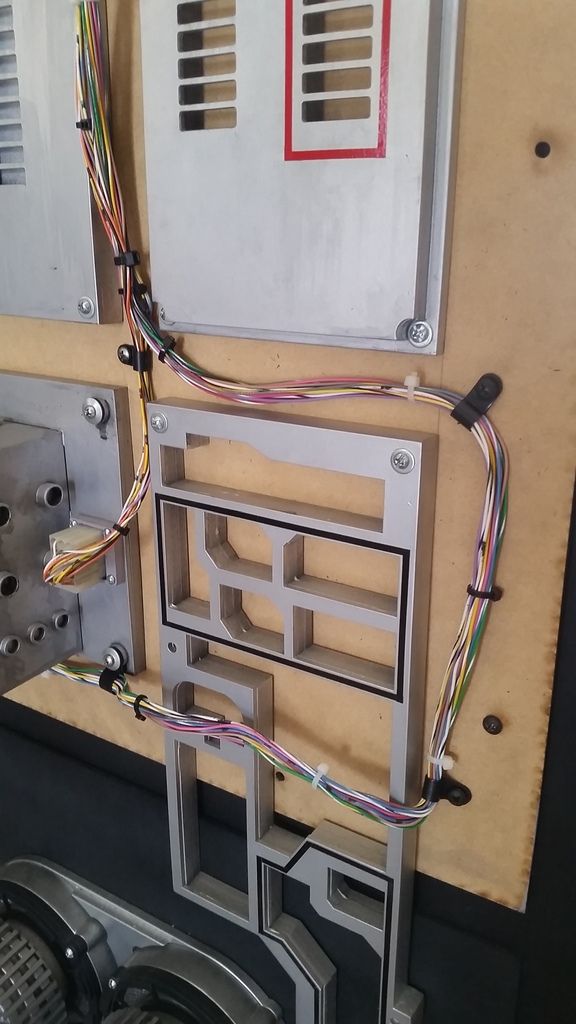

Dry fitting

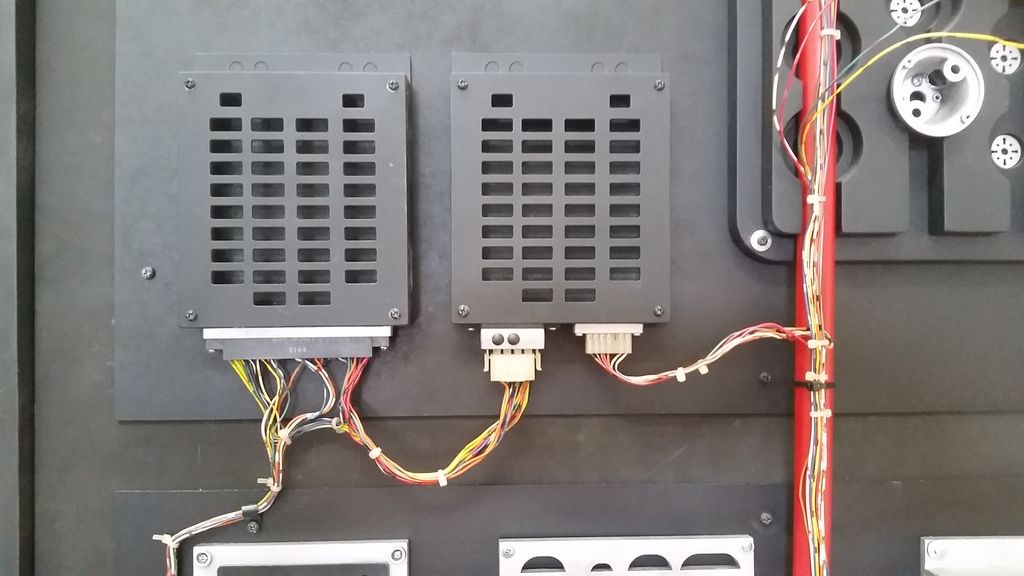

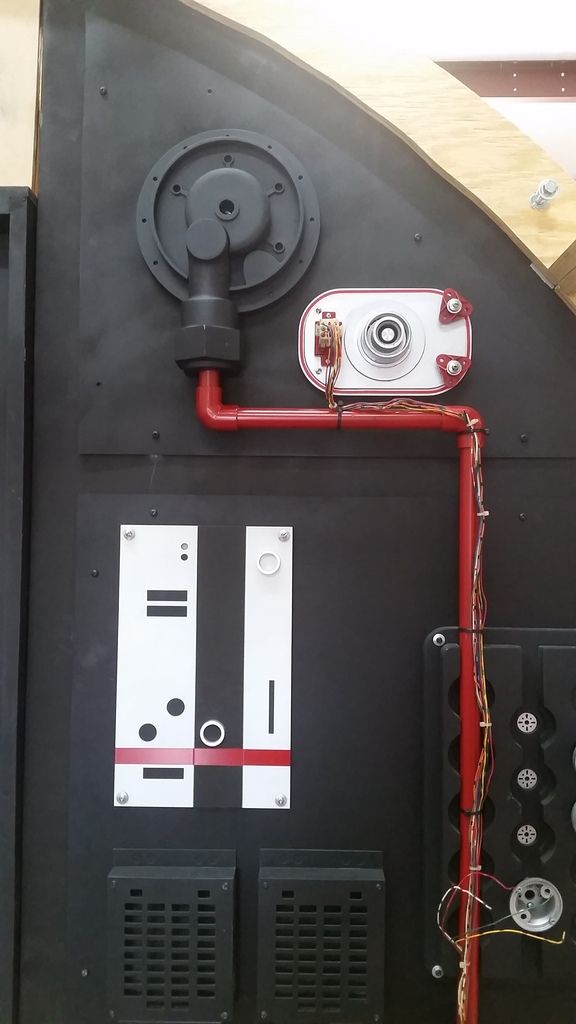

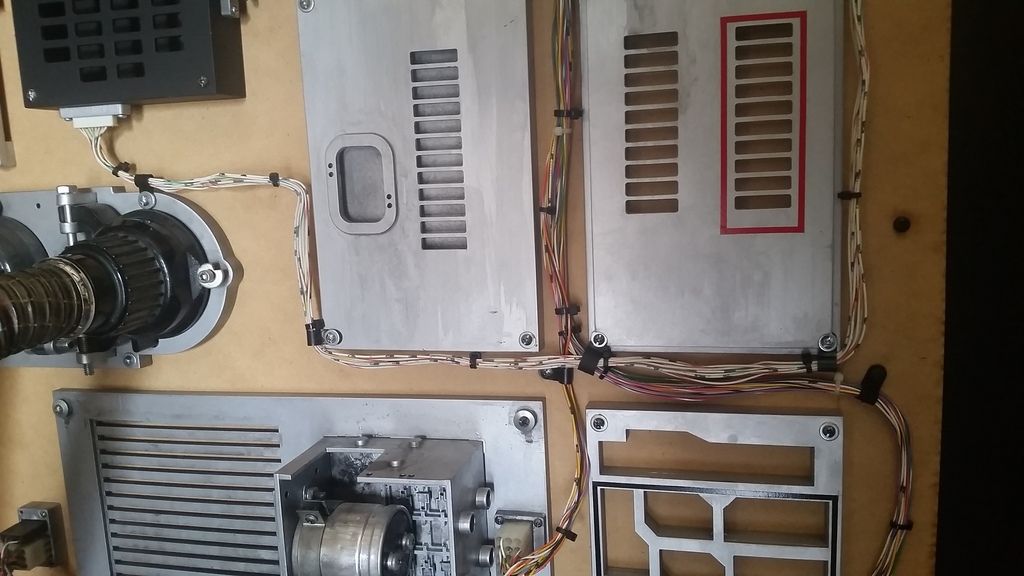

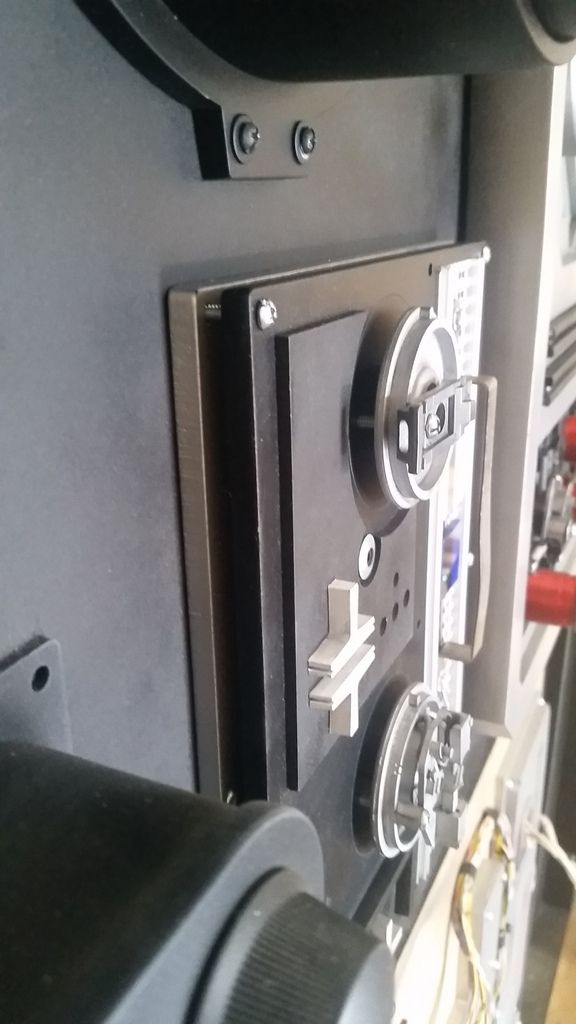

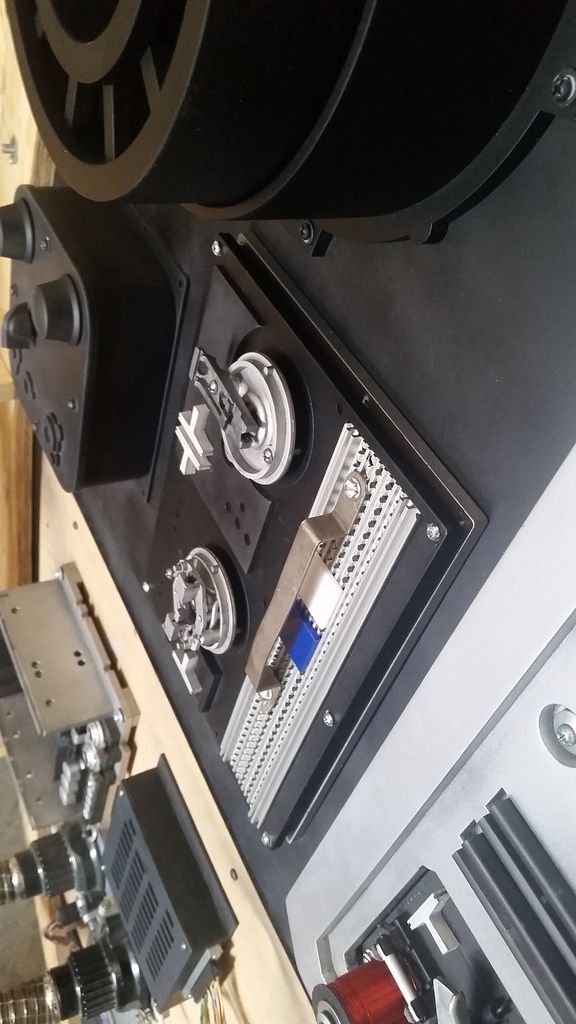

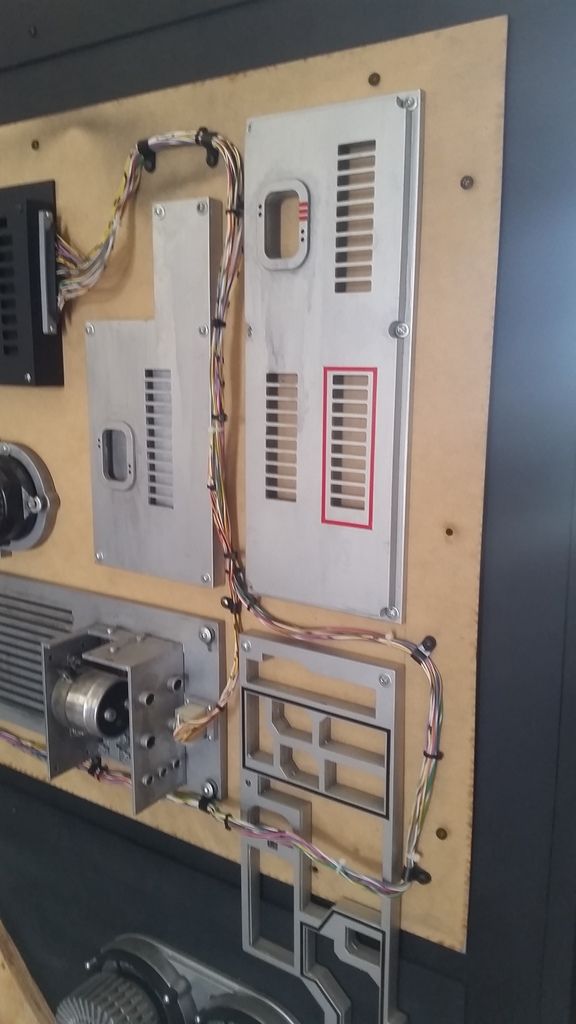

Love this image! Still need to paint that panel - I'm going to remove all the greeblies and spray paint (using a paint gun) the cockpit entrance frame and panels in one shot)

Chewie's side

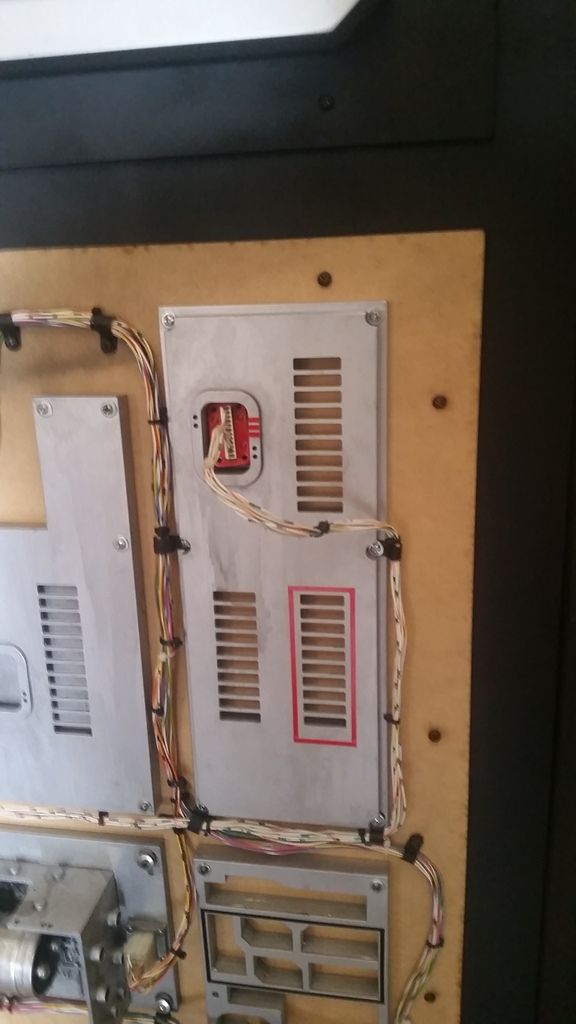

I'm not thrilled with the harness so I'm going to remove and start over - fortunately I used existing holes and zip ties

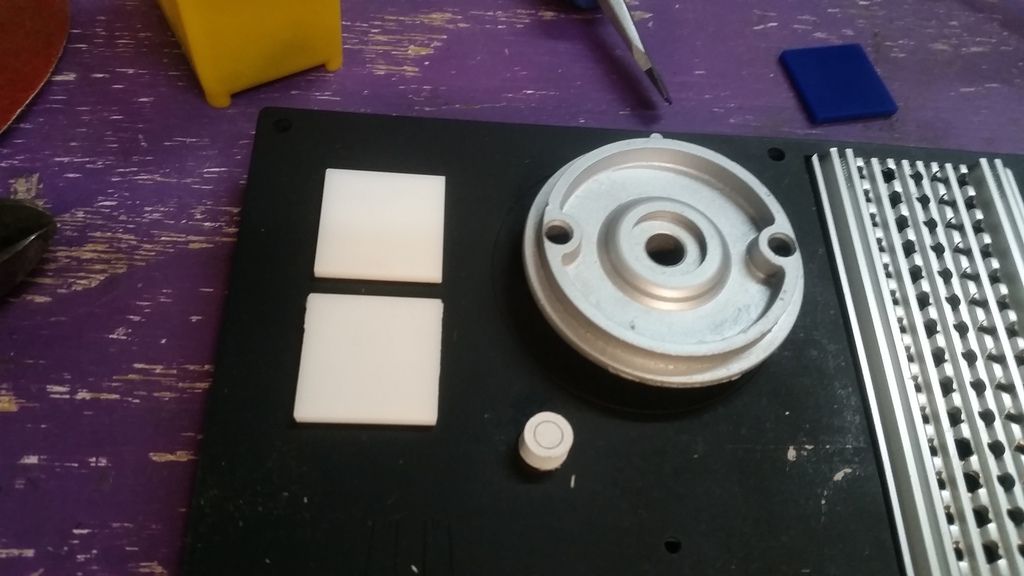

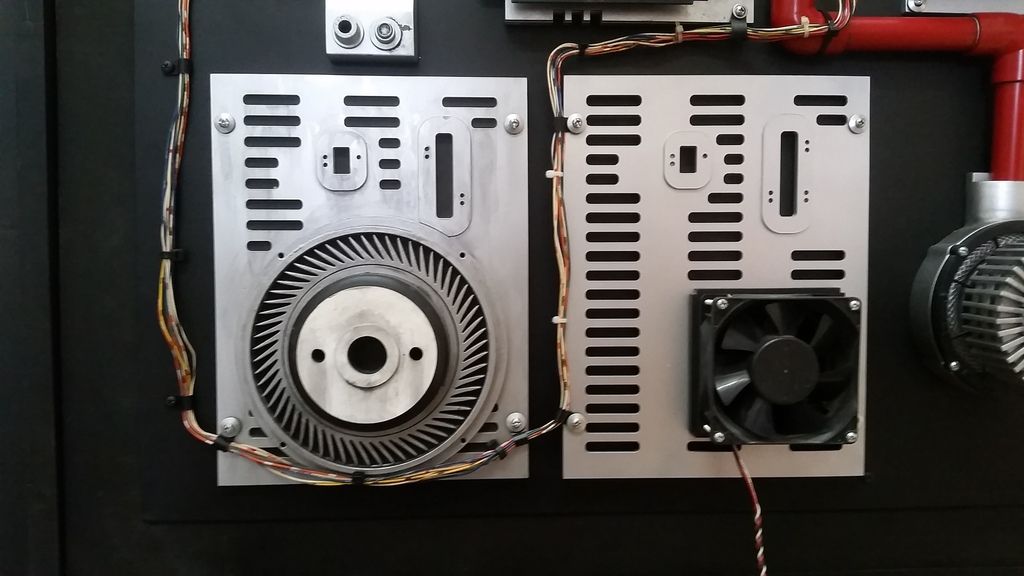

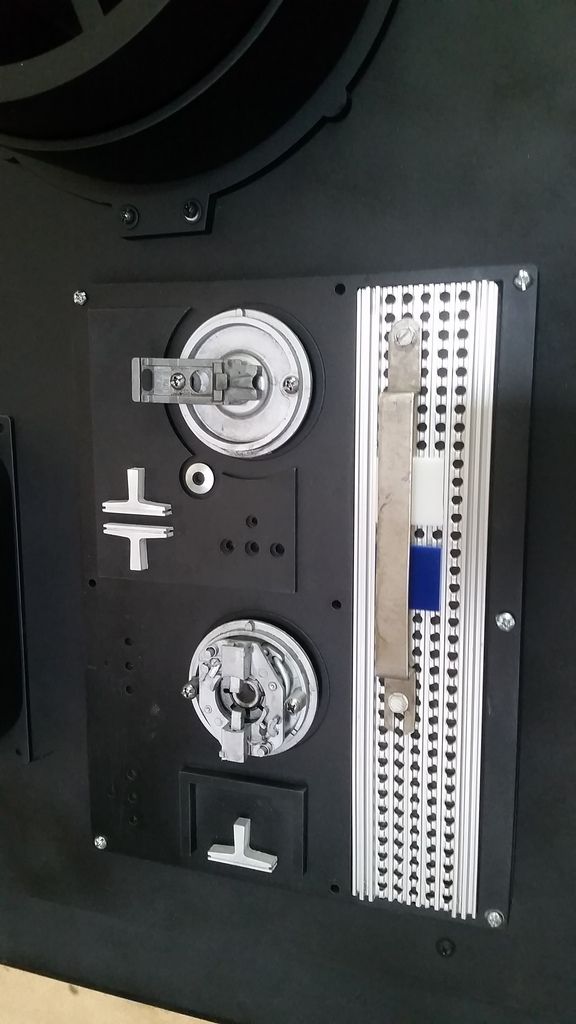

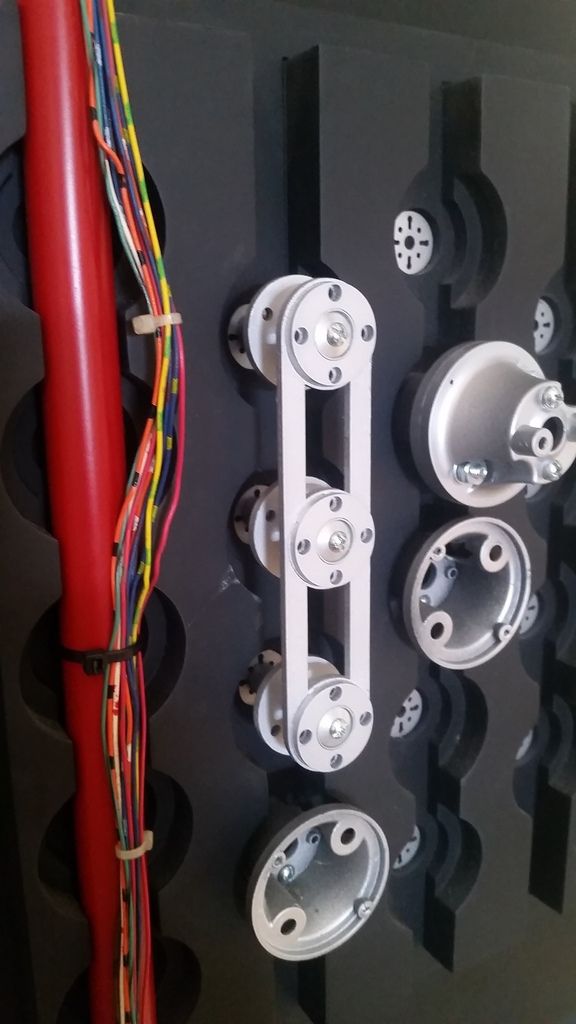

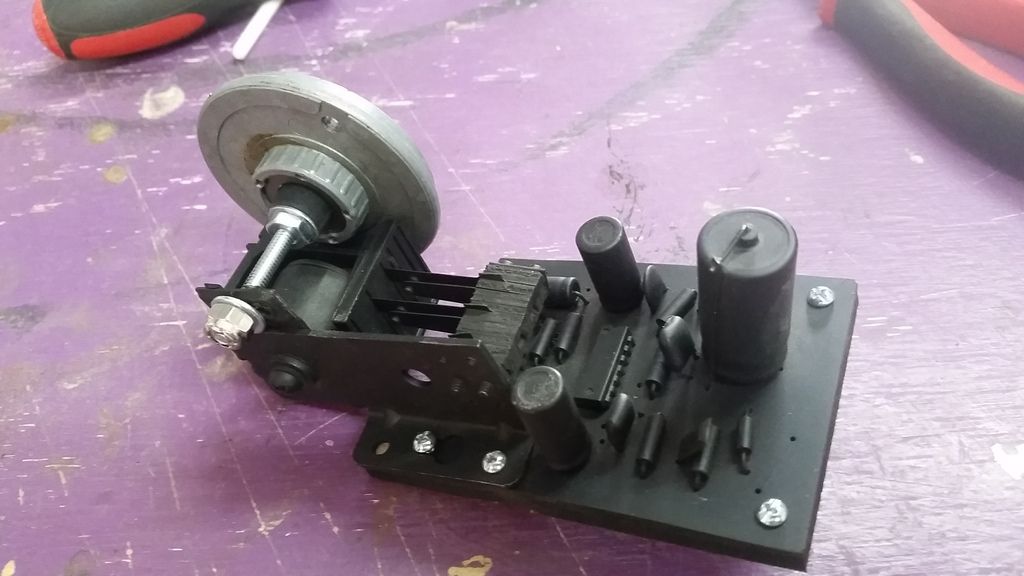

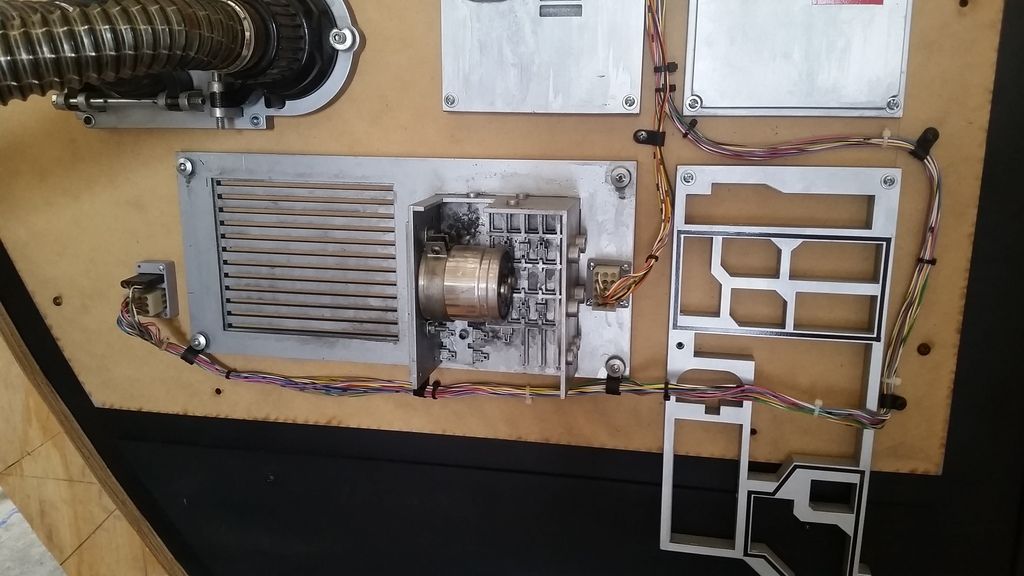

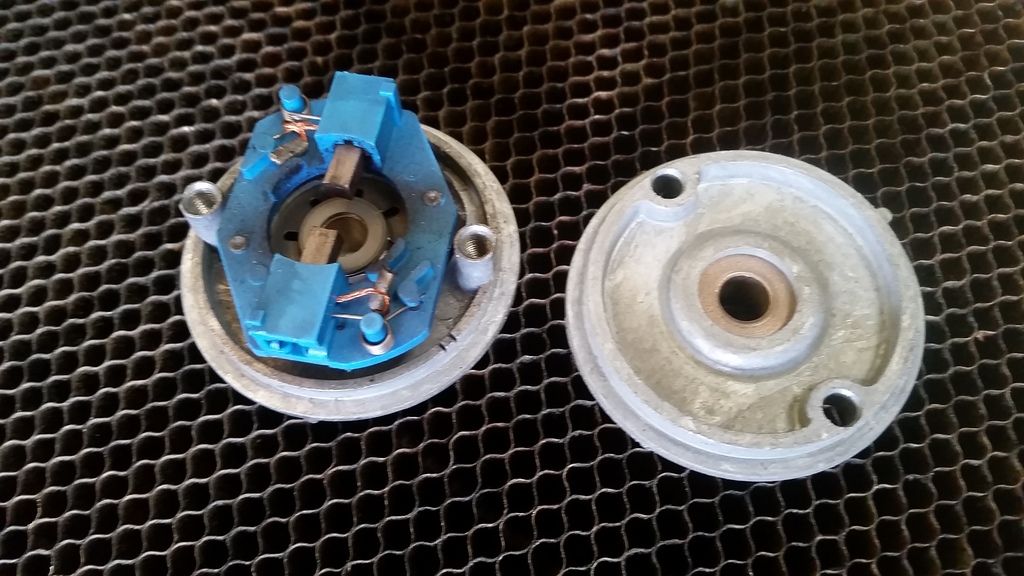

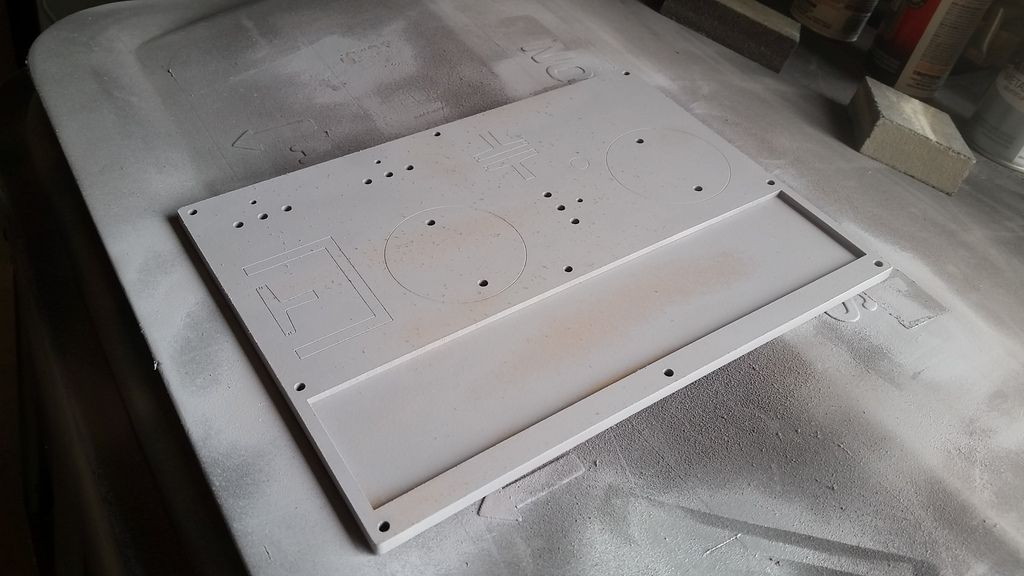

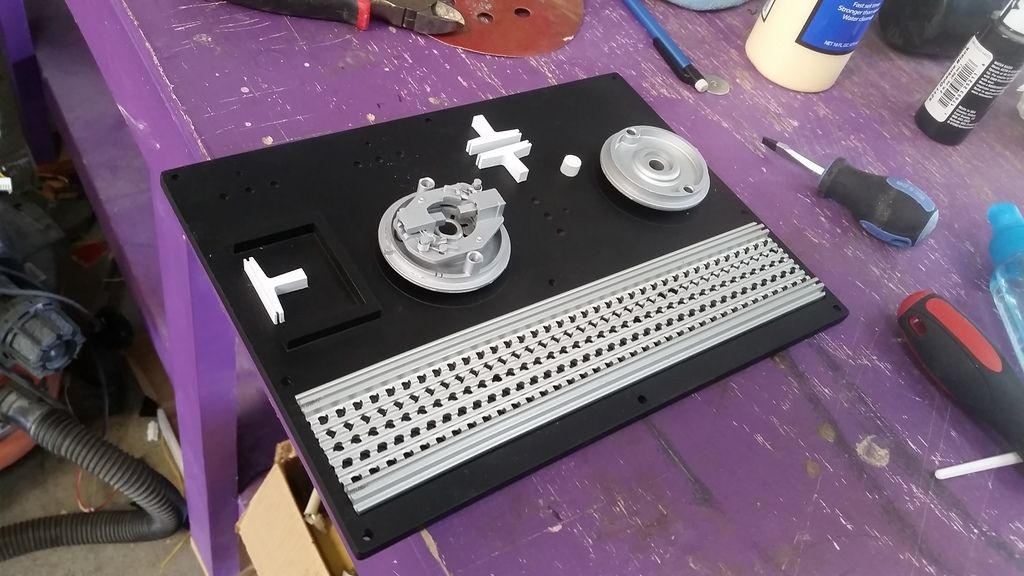

I then dug through the many greeblie boxes we have and wanted to create a few more greeblies to fill in some of the massive blank spaces on some of the panels. So, I took these...

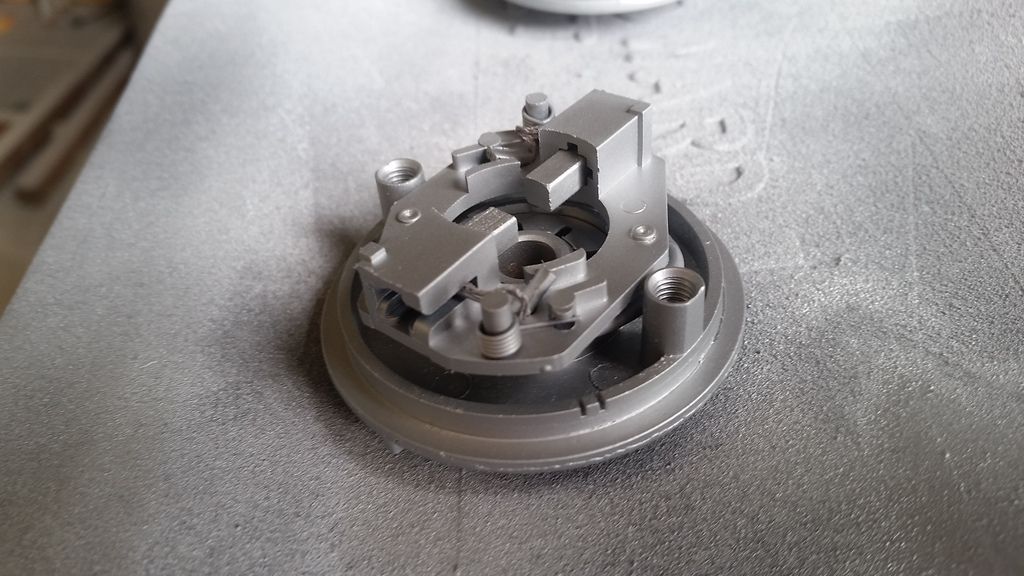

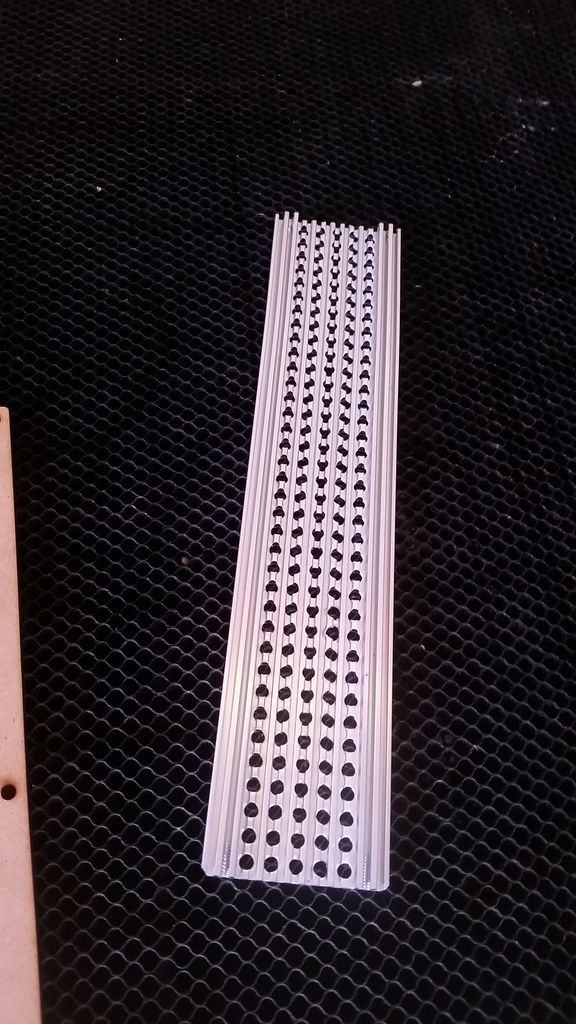

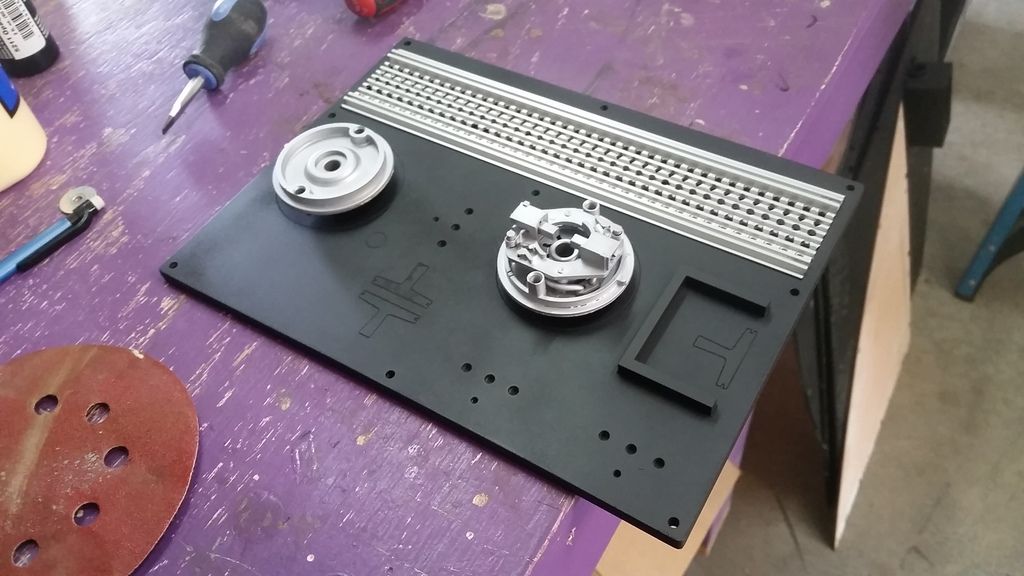

And this...

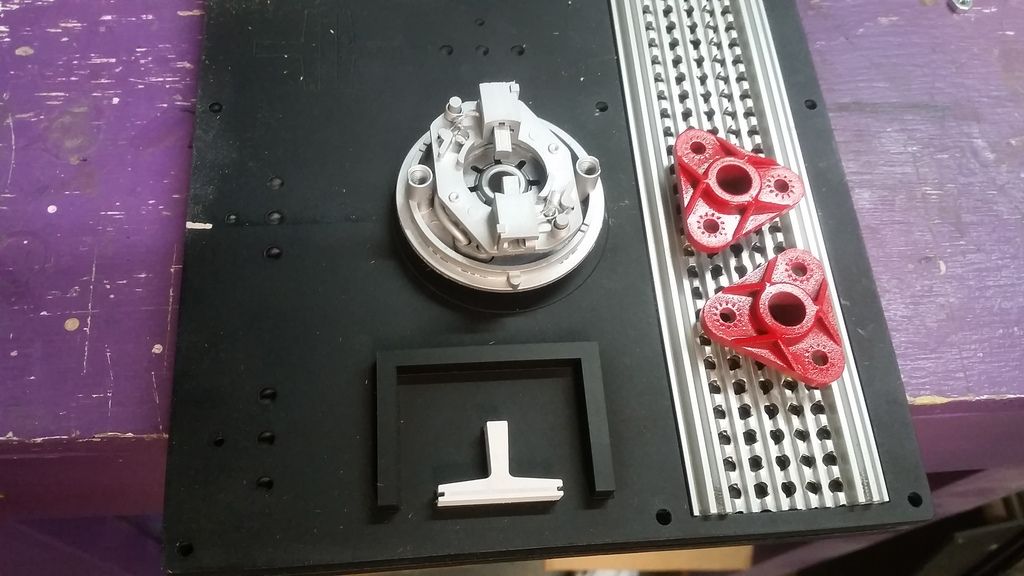

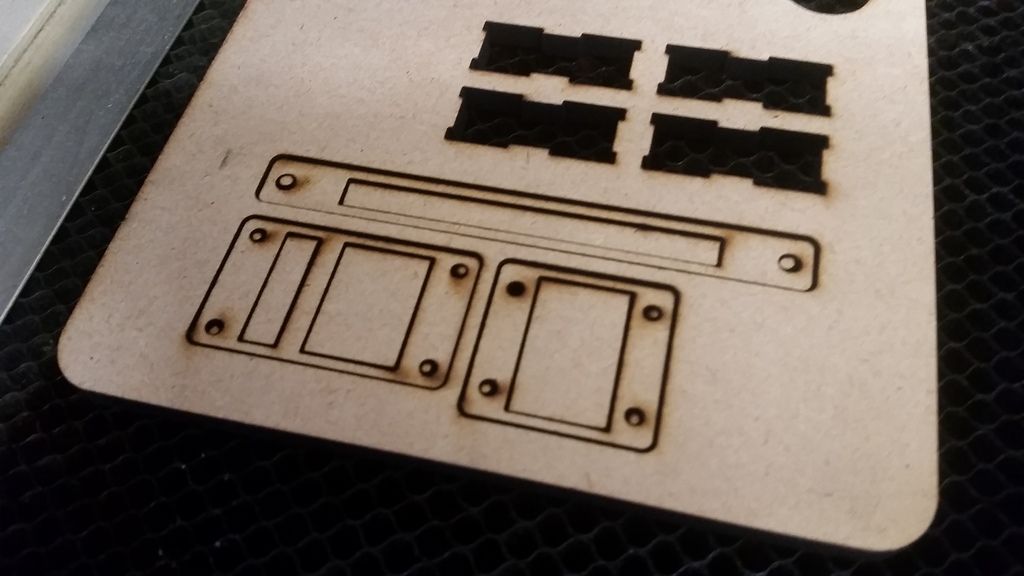

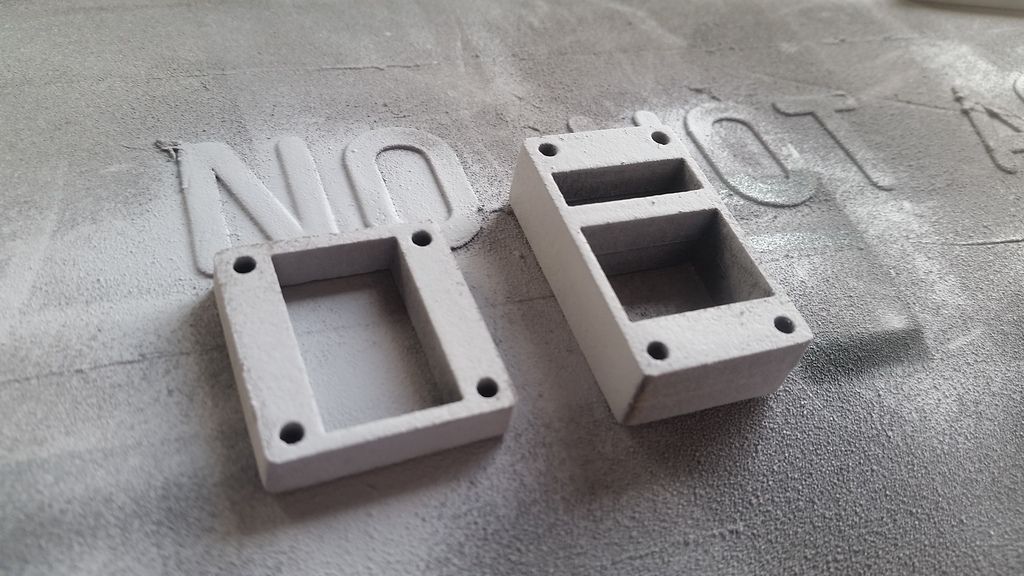

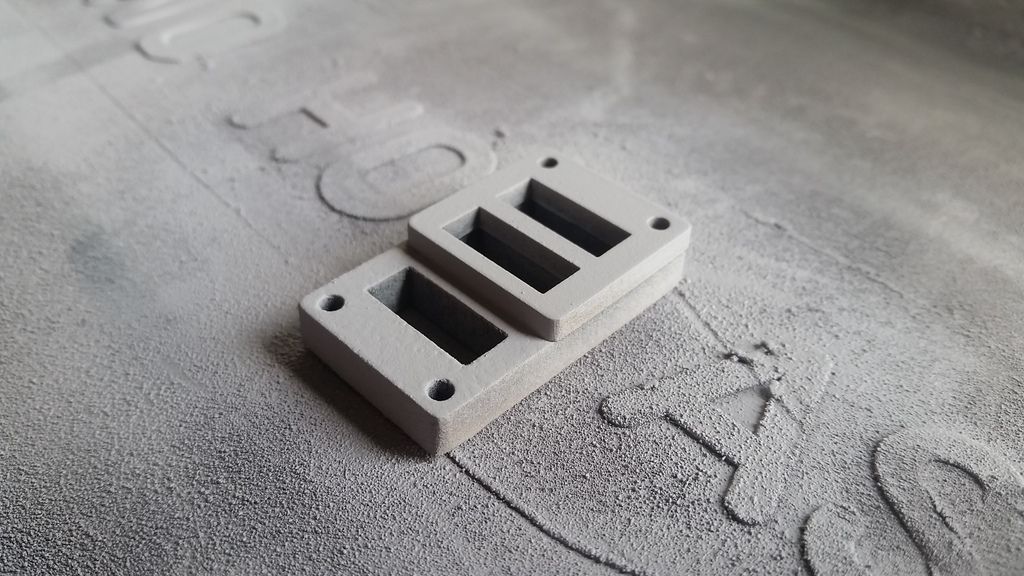

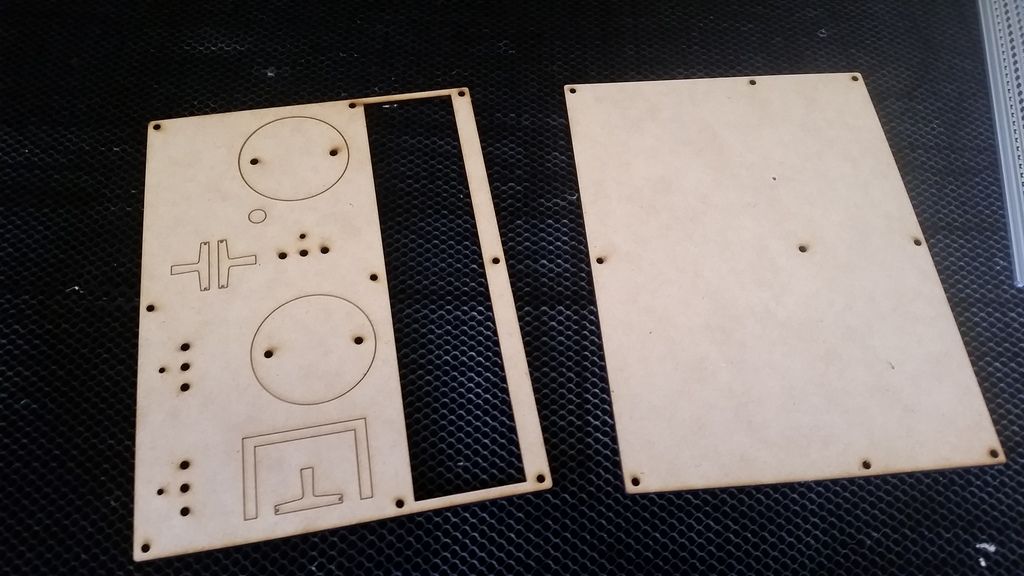

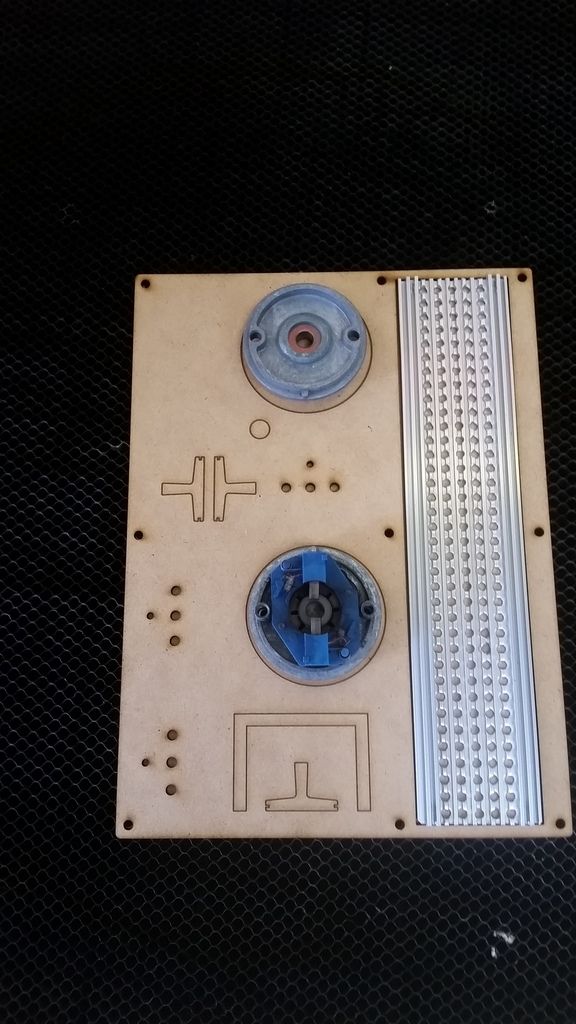

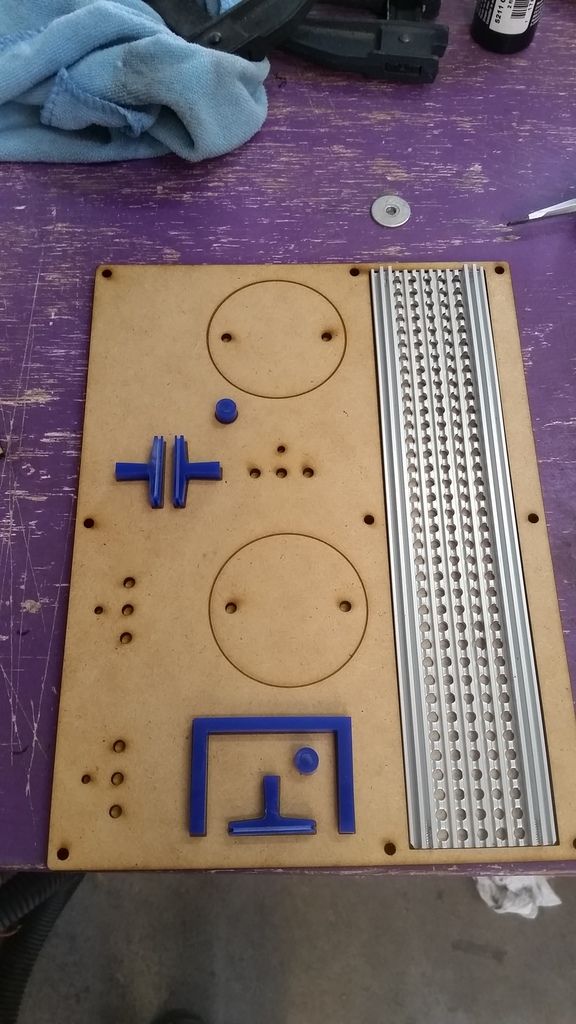

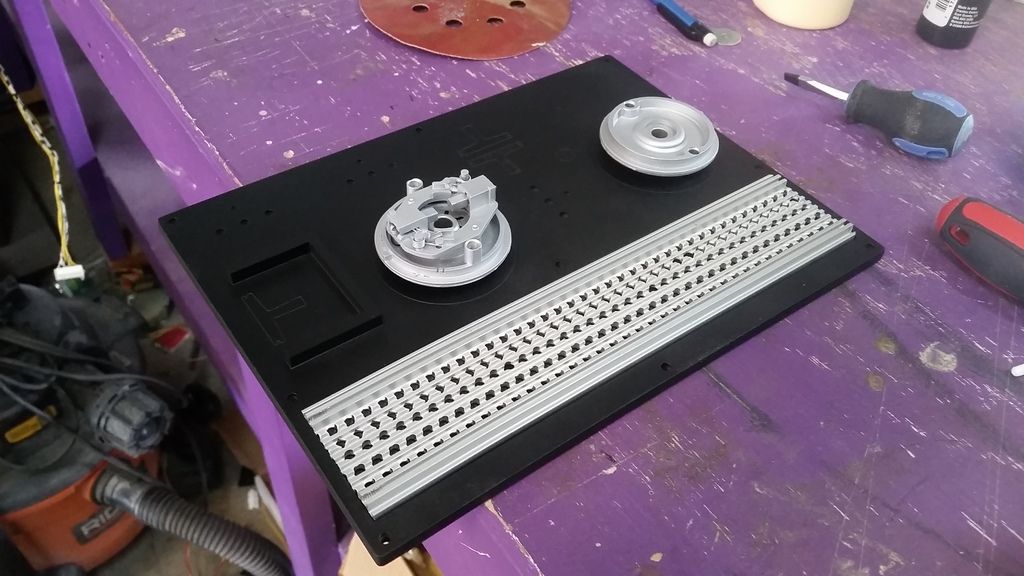

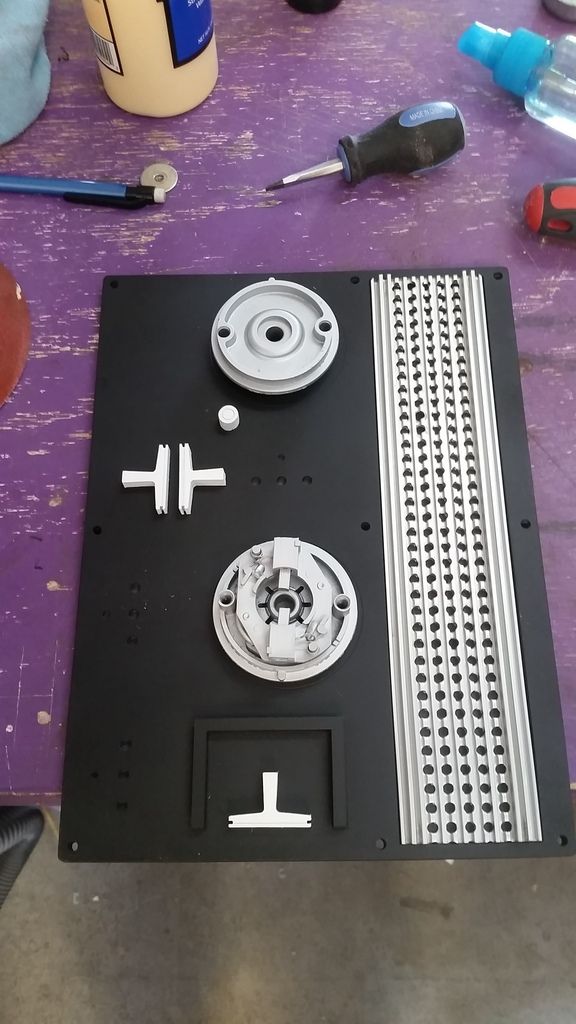

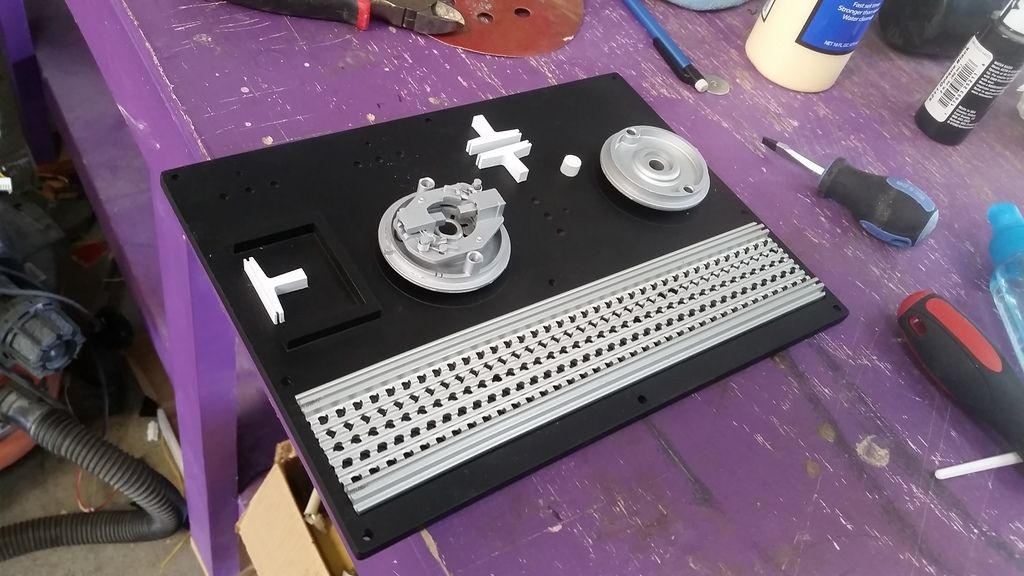

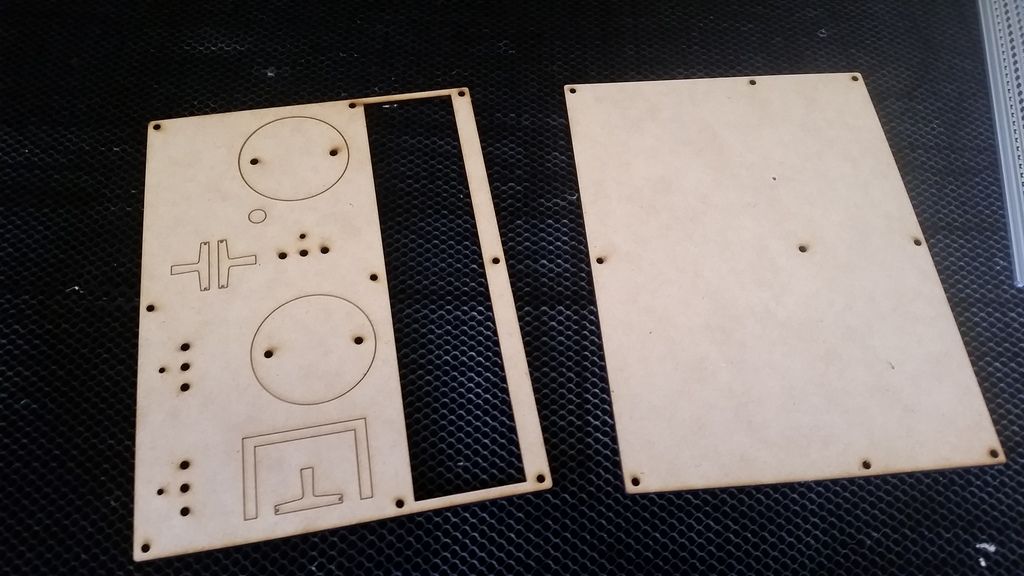

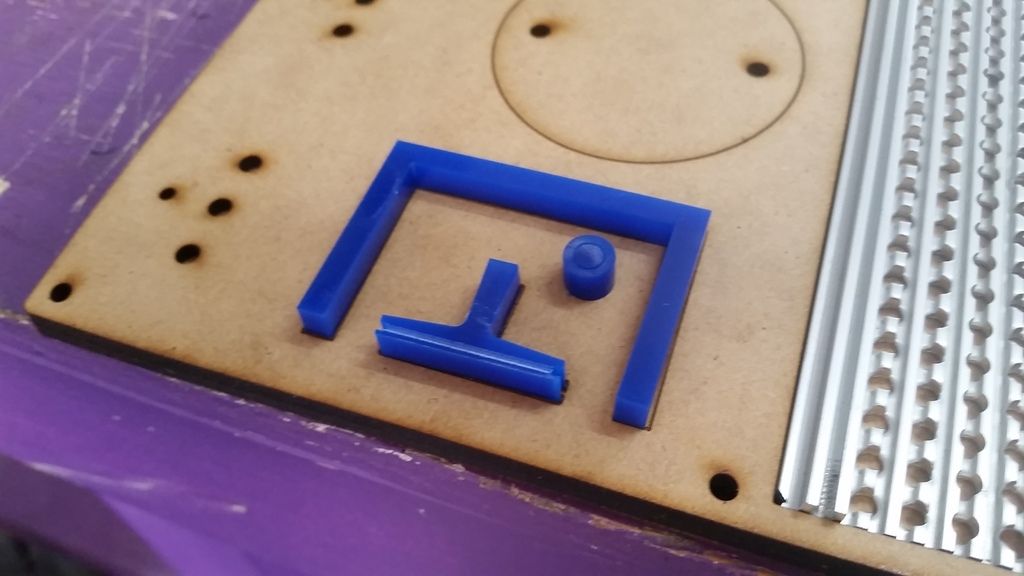

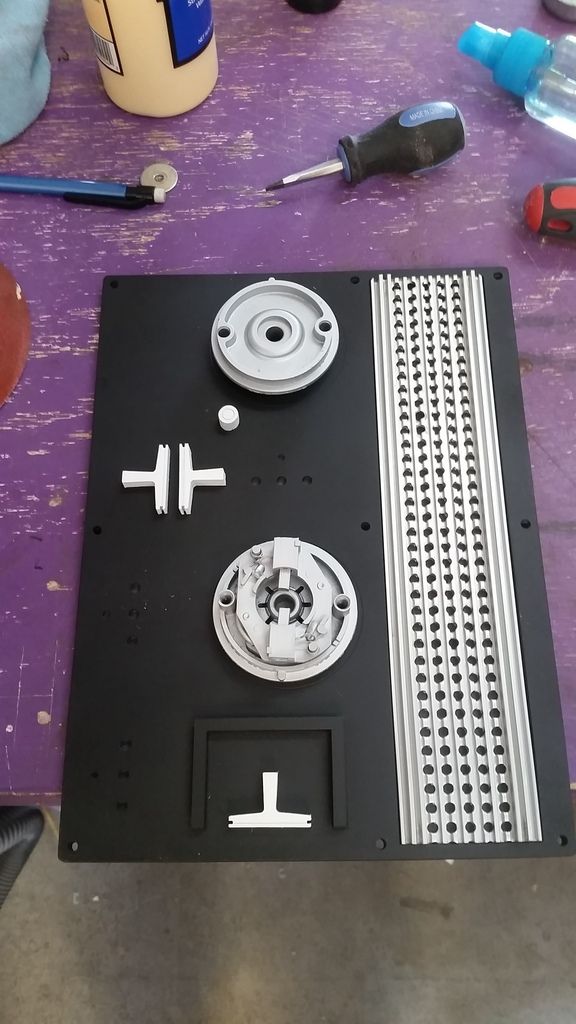

Designed and laser cut these...

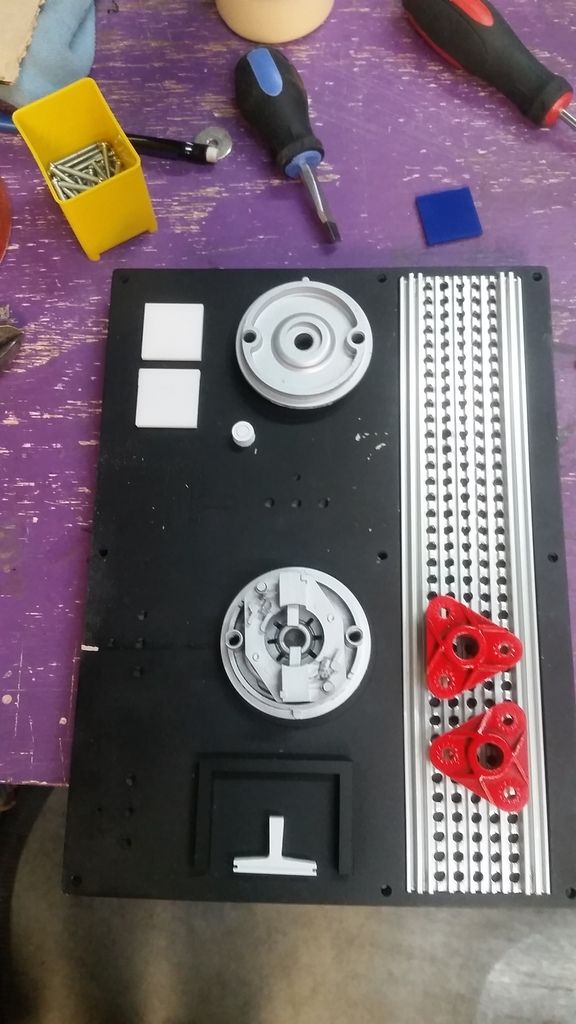

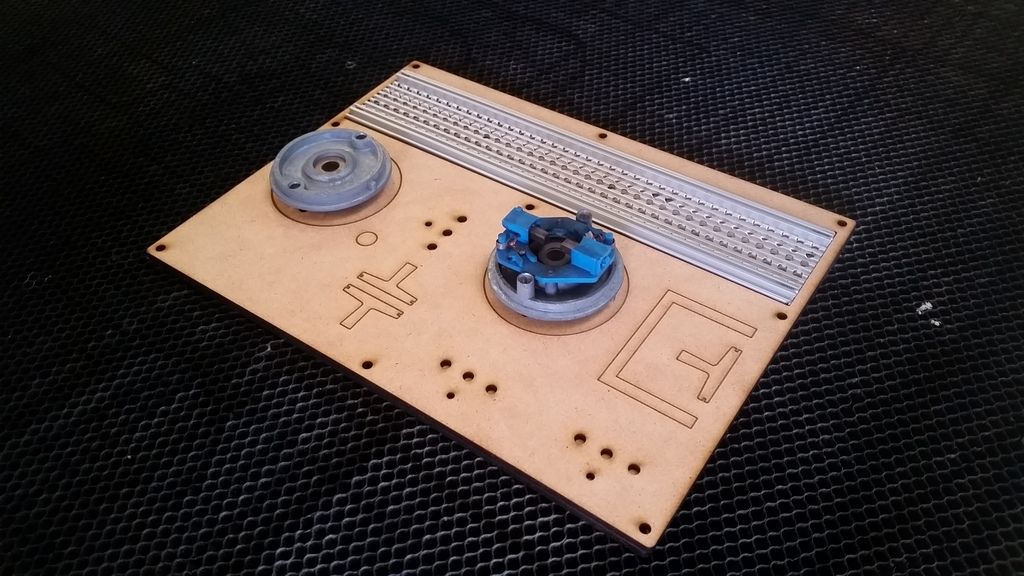

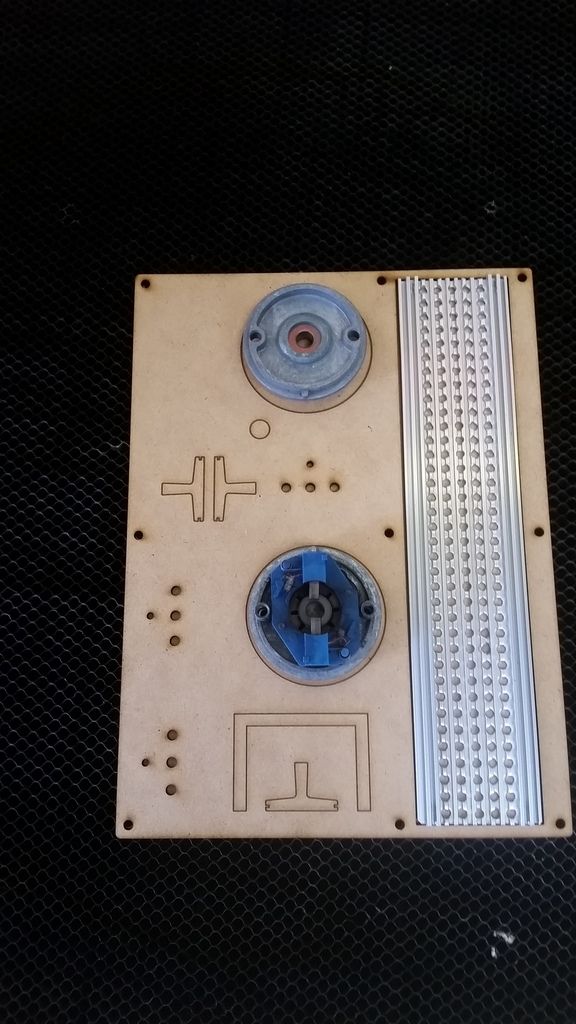

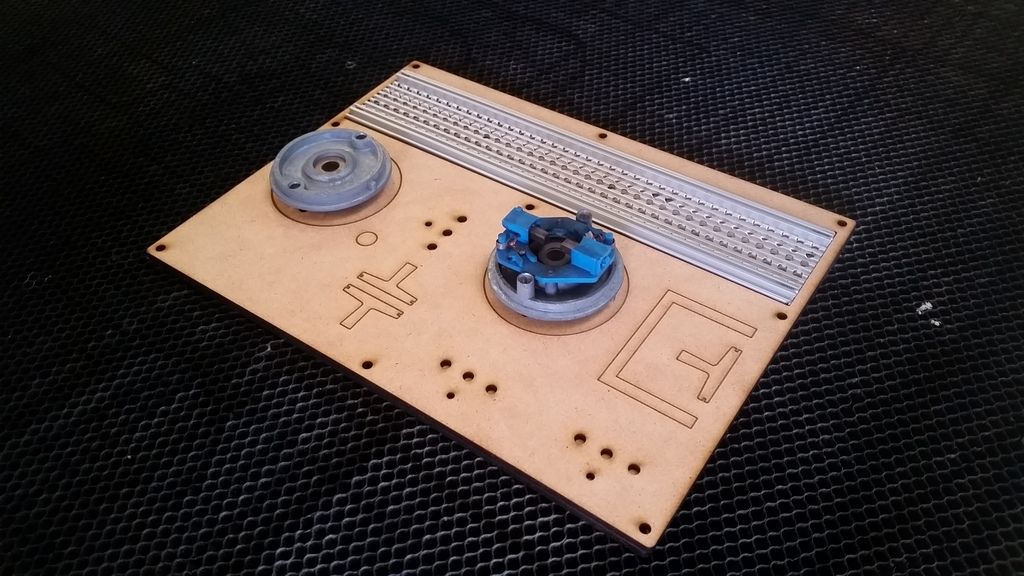

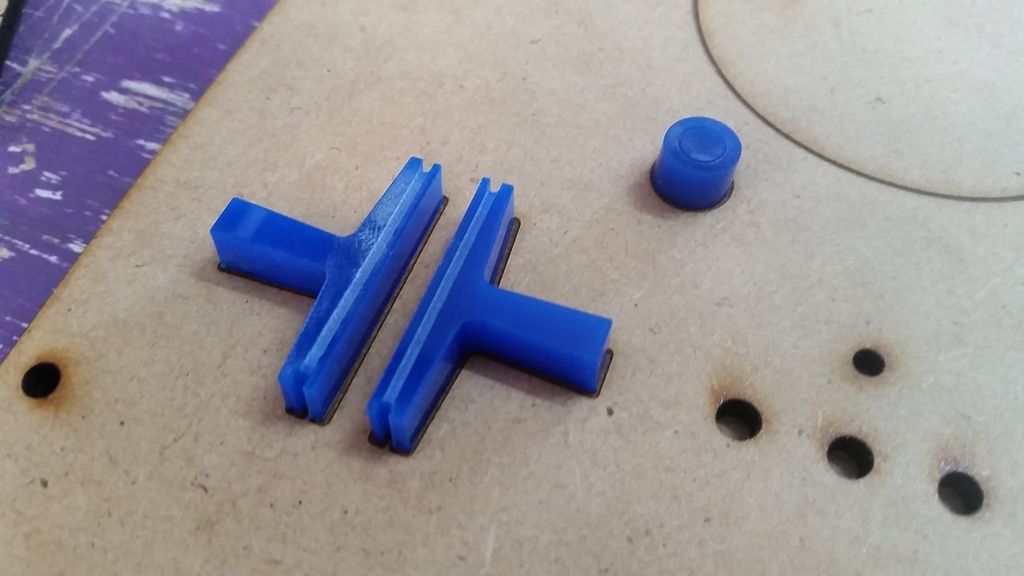

Started to dry fit

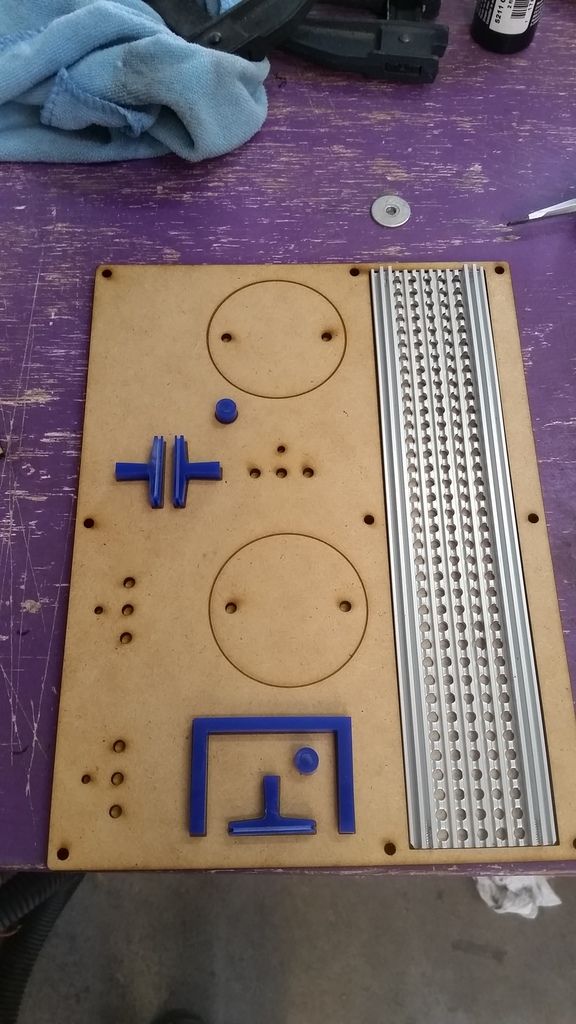

This panel will mount here

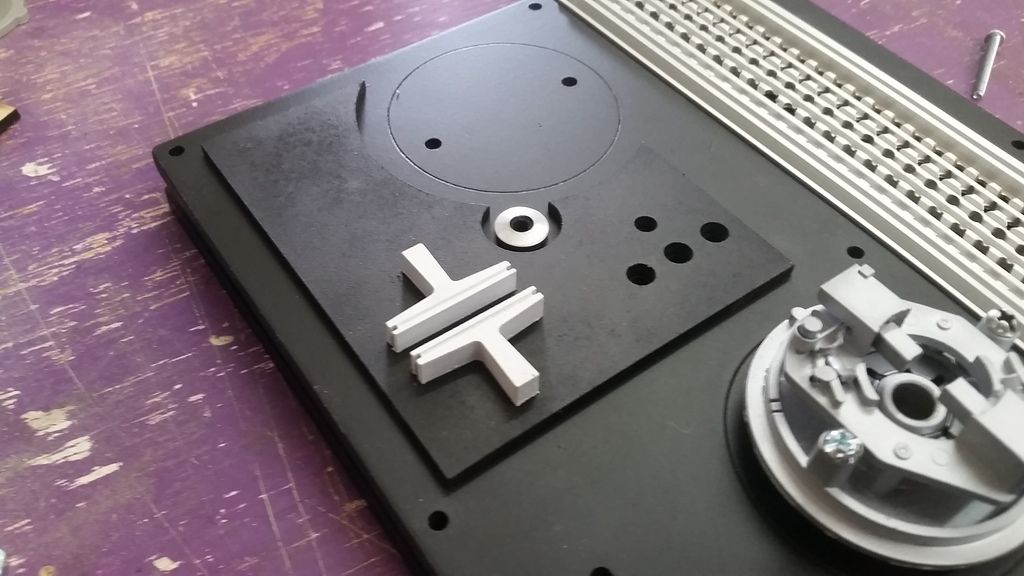

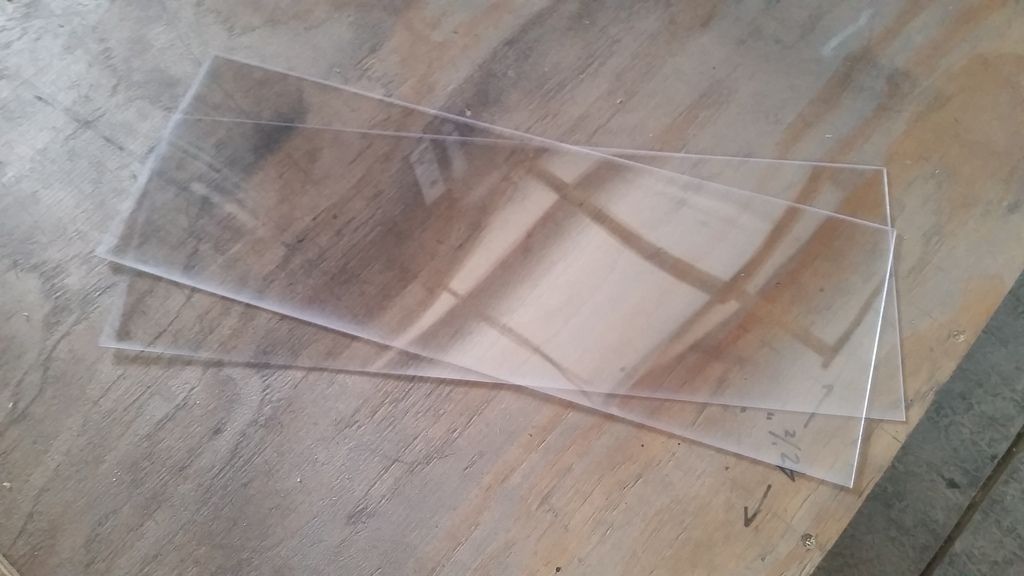

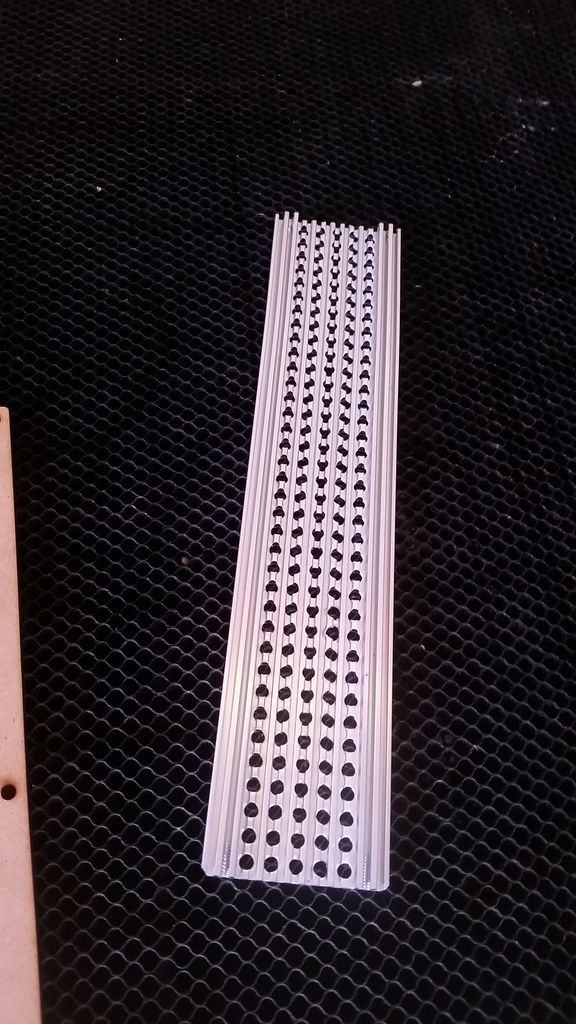

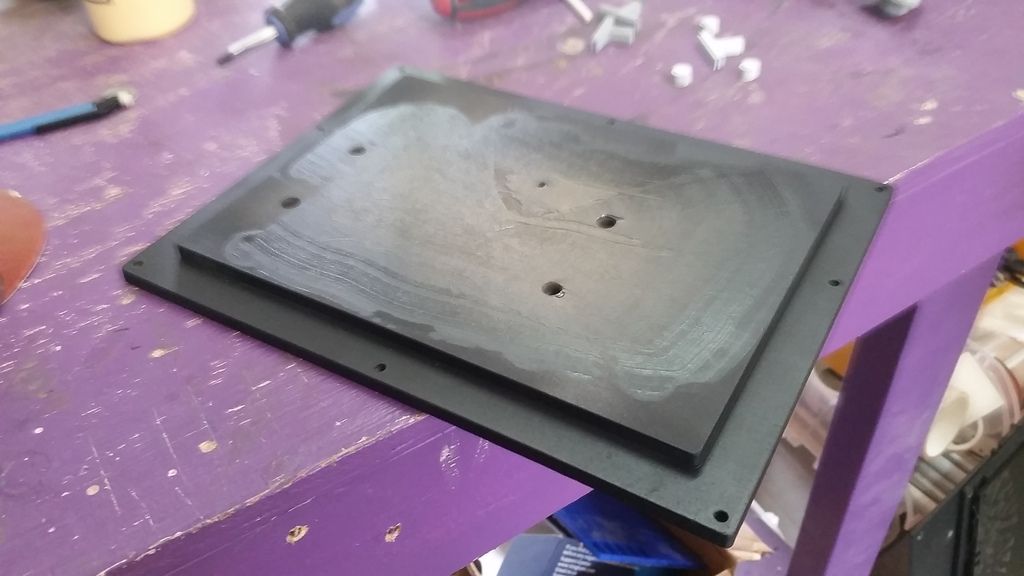

I then laser cut these acrylic pieces

Added paint

Love the detail

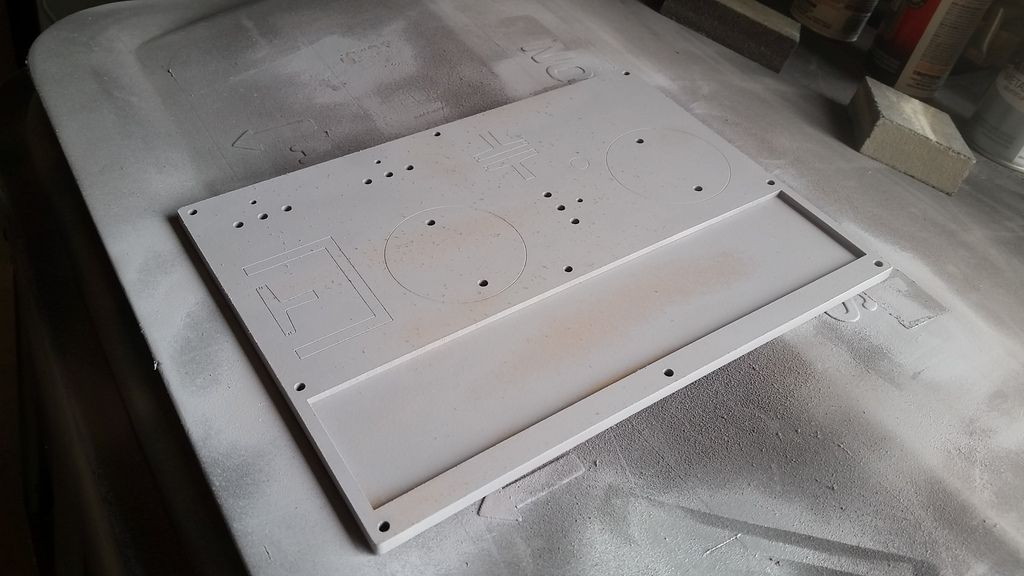

Primer

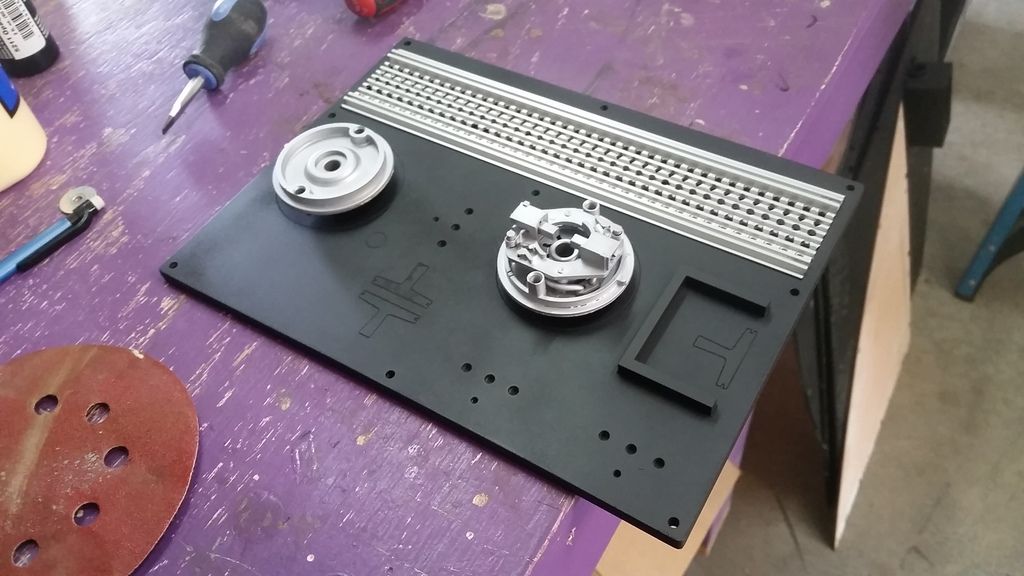

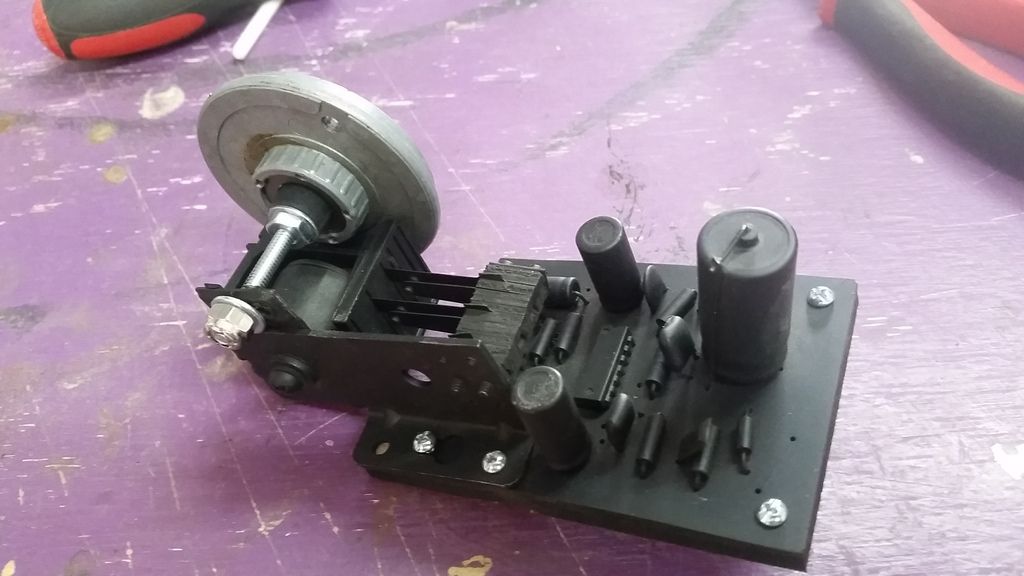

Another dry fit

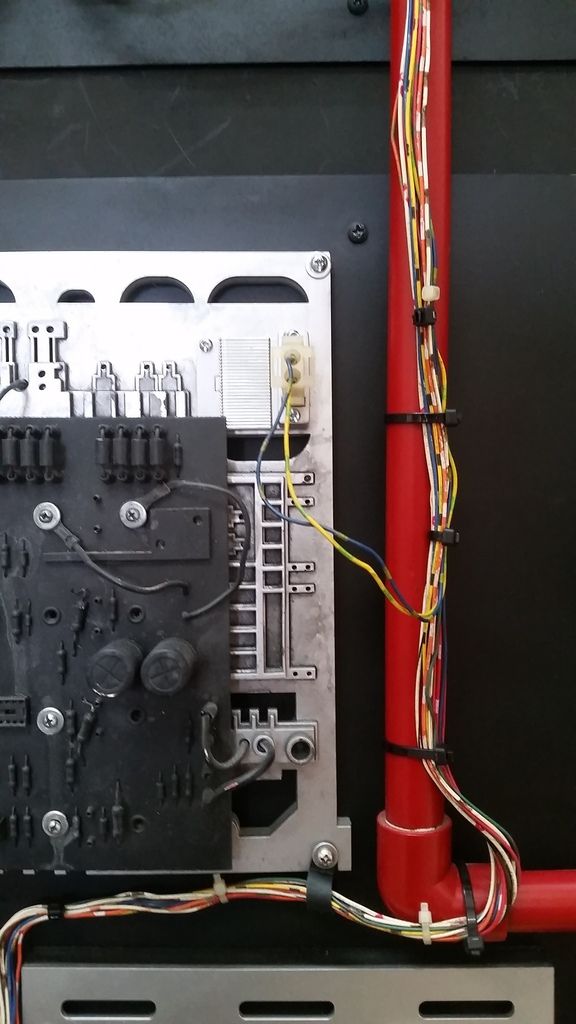

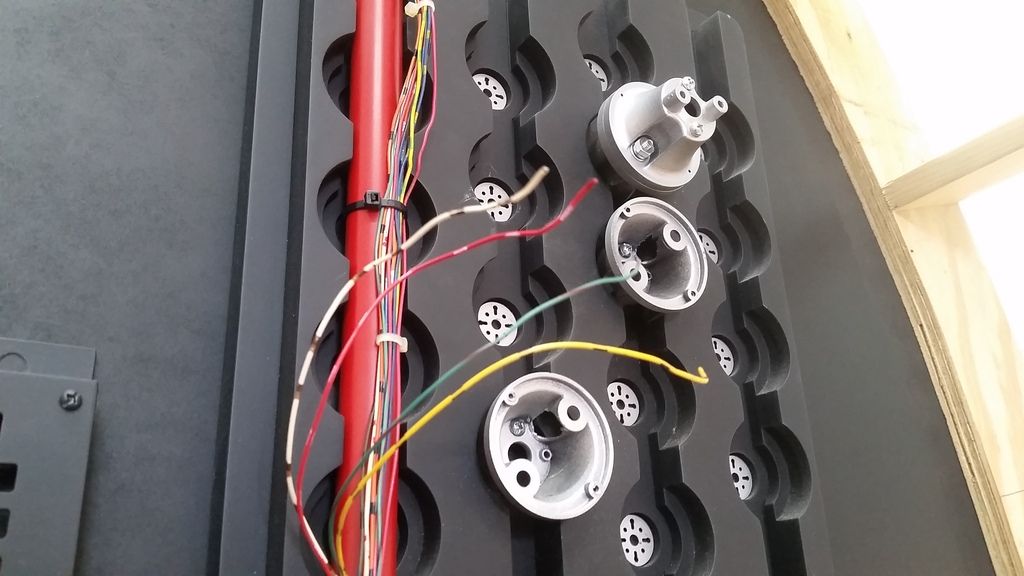

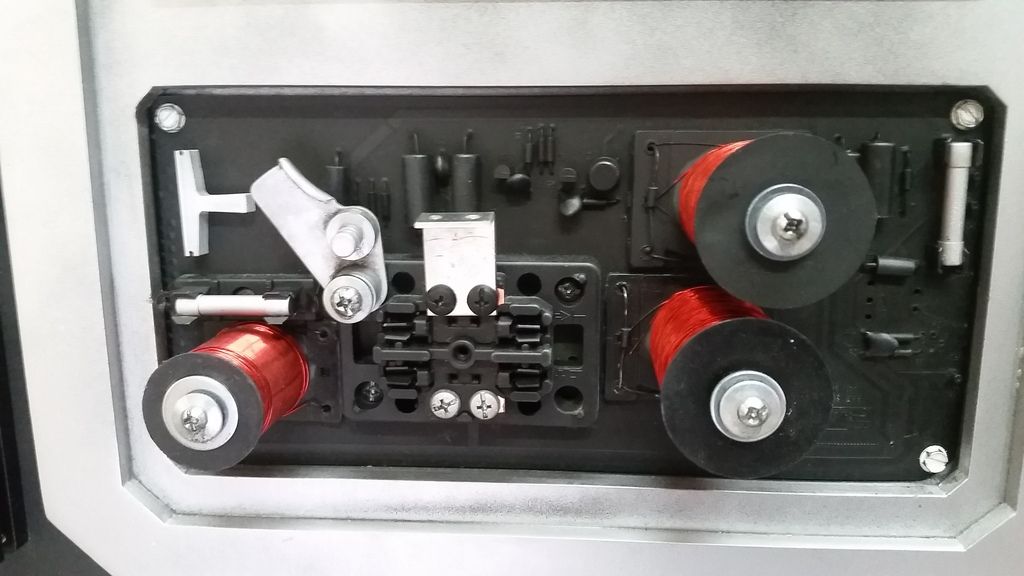

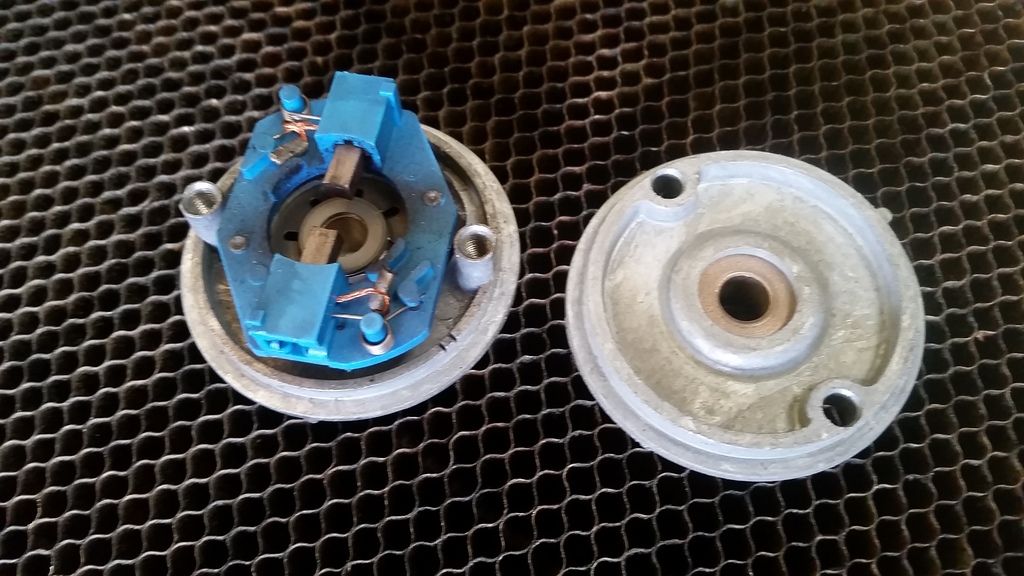

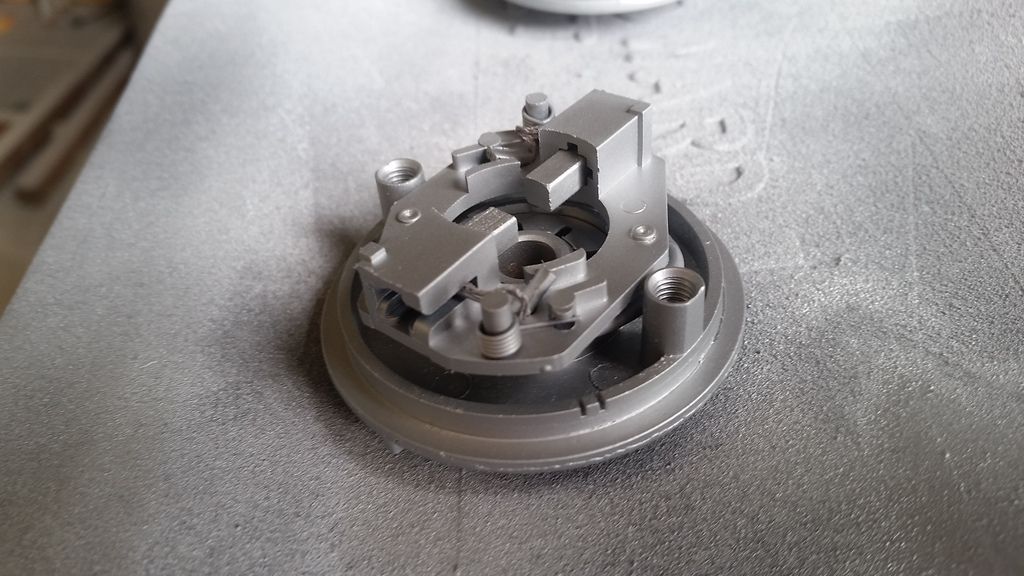

Dug through some more and found these

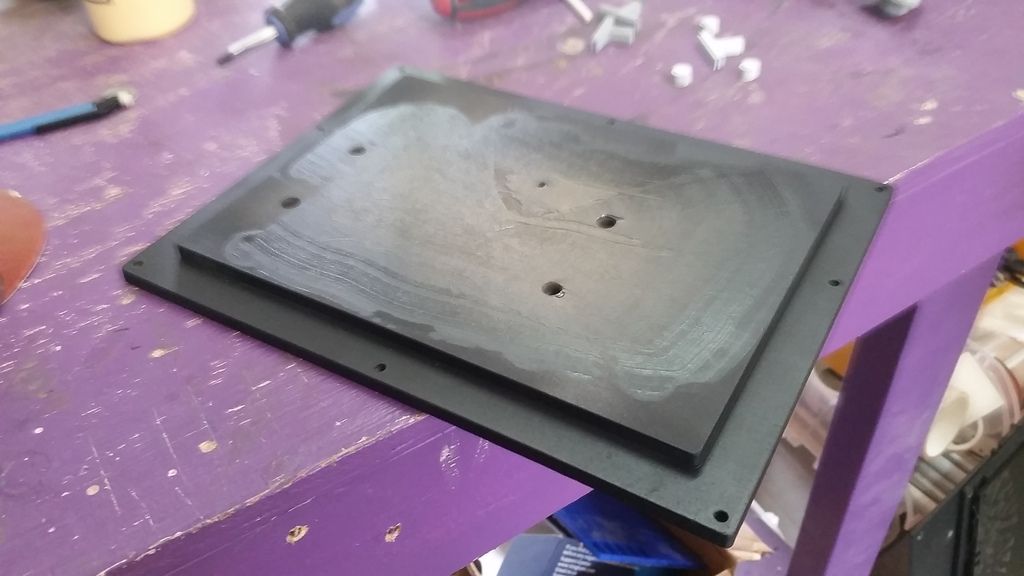

Finally, I created a base for the panel - I should have this finished up today!

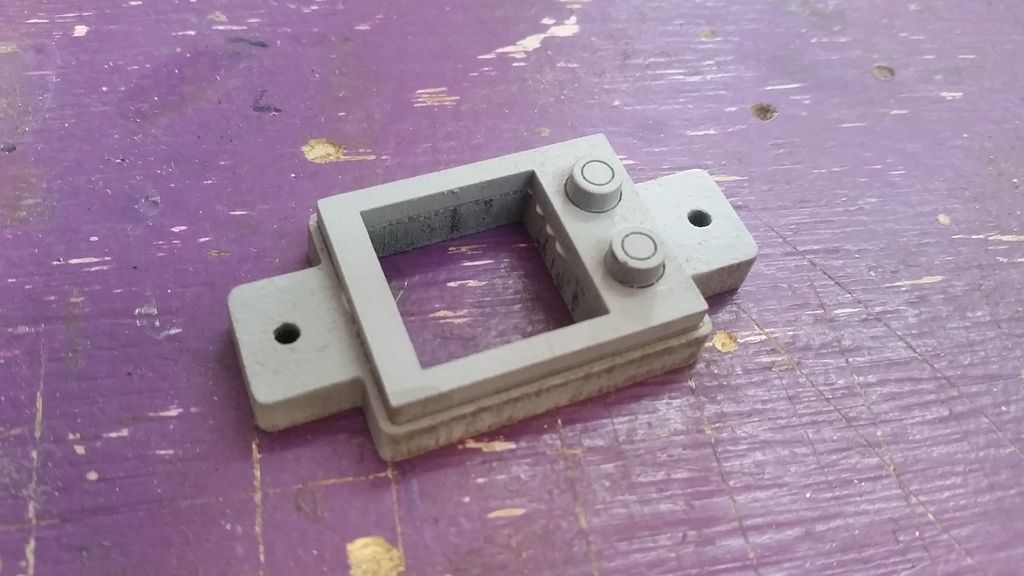

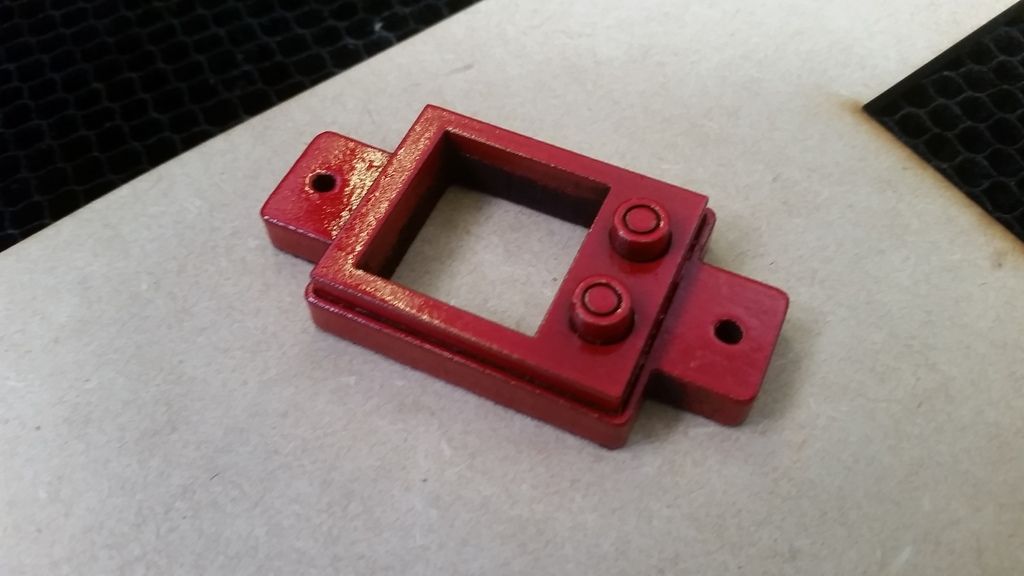

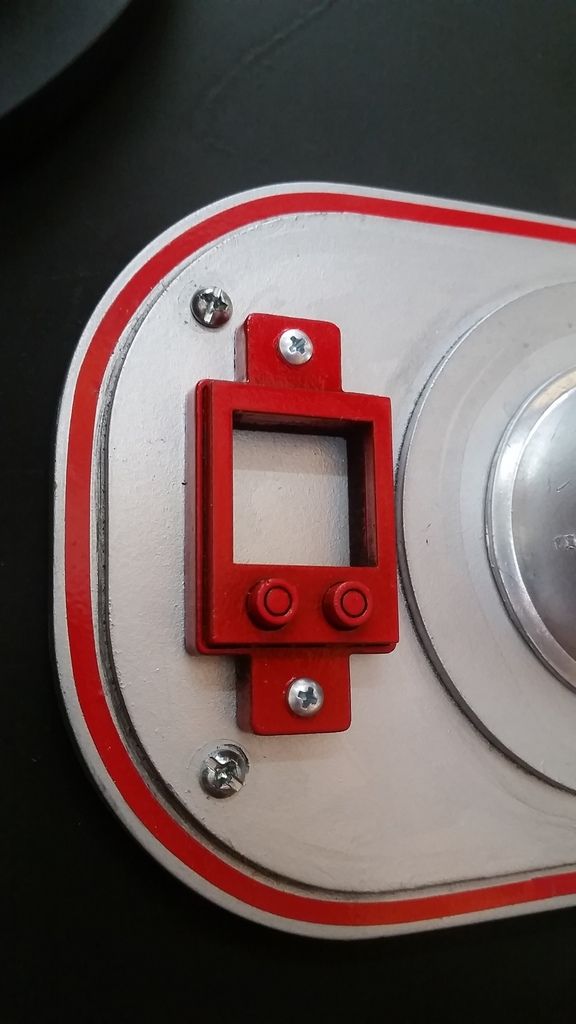

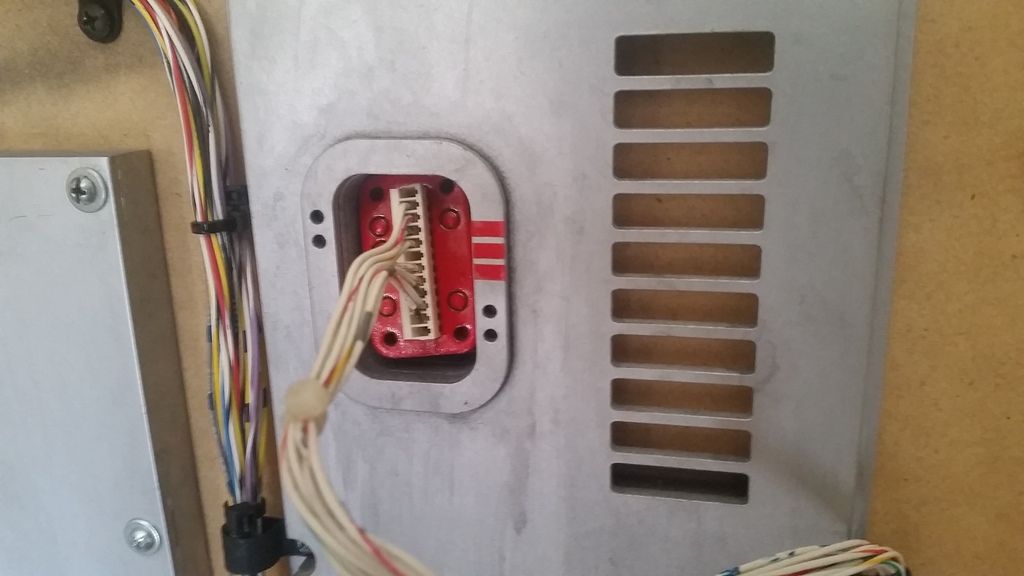

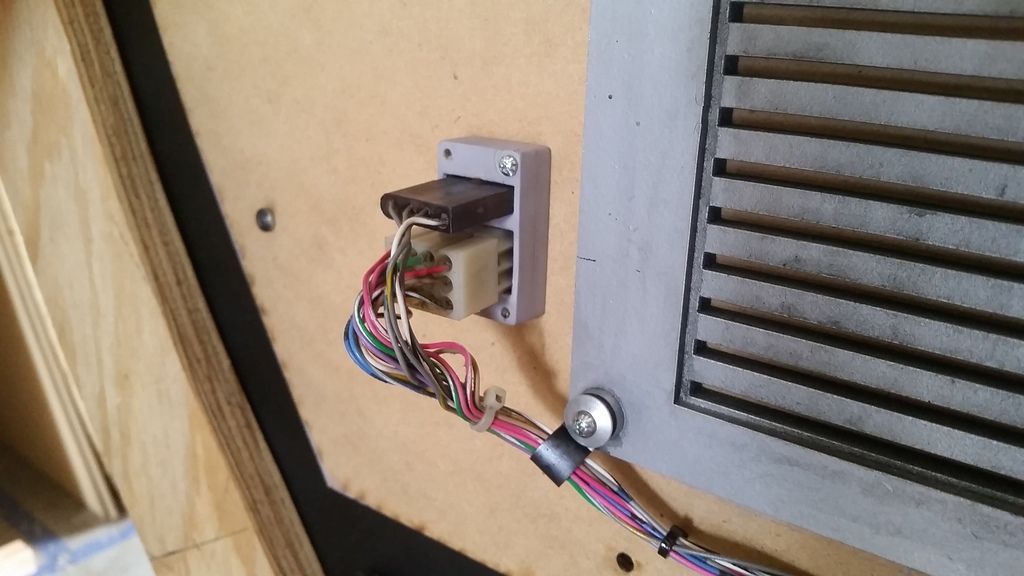

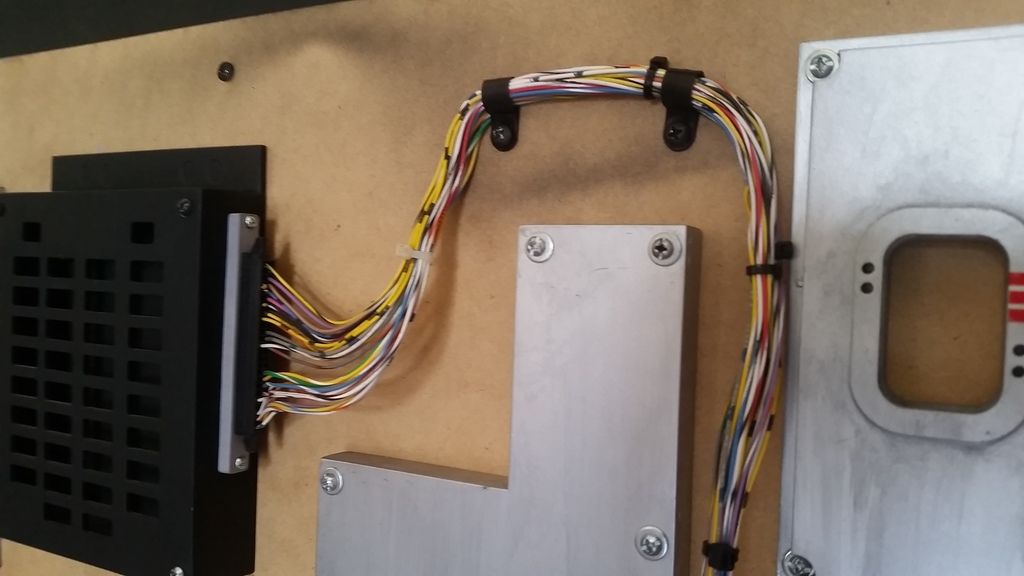

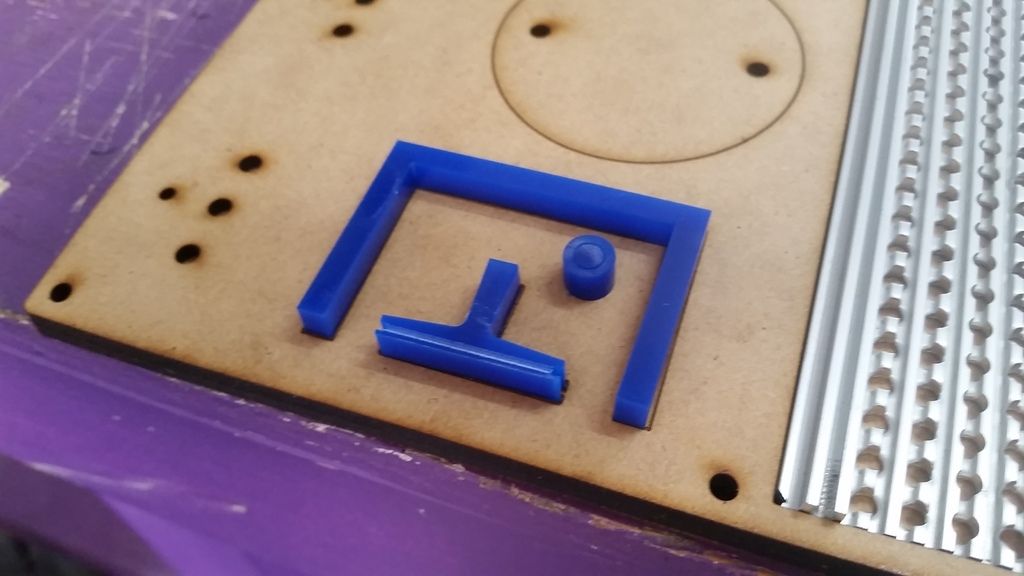

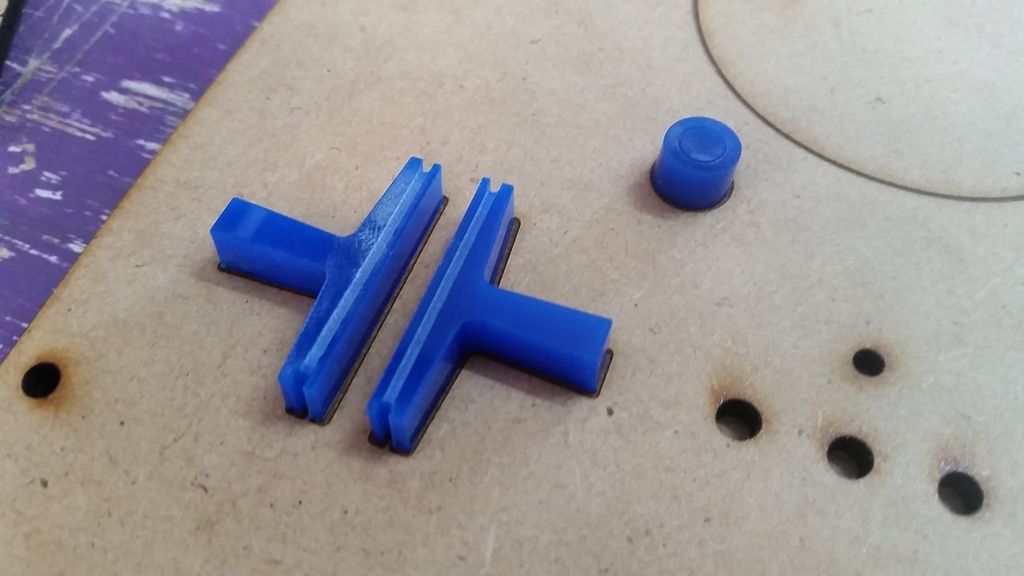

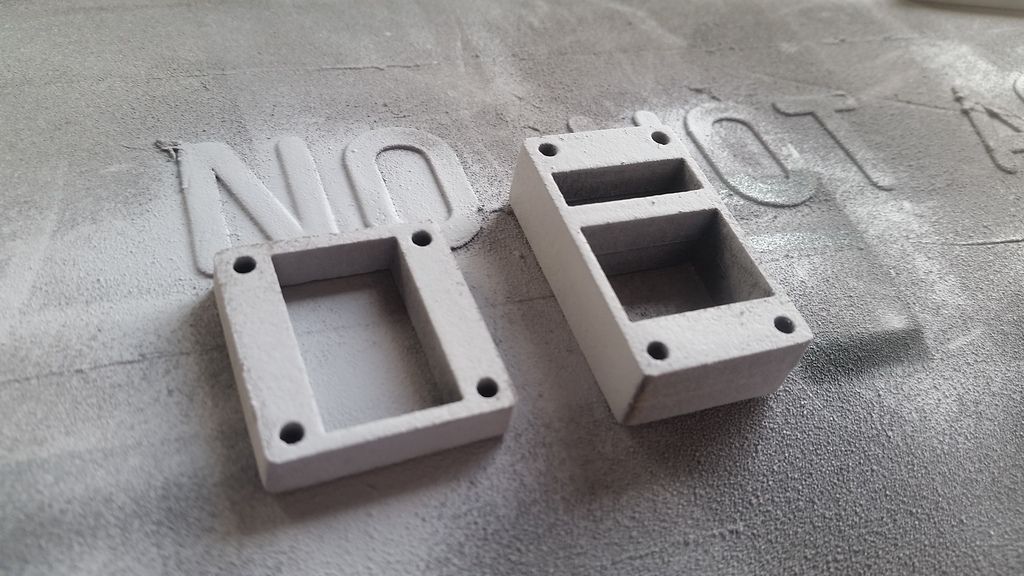

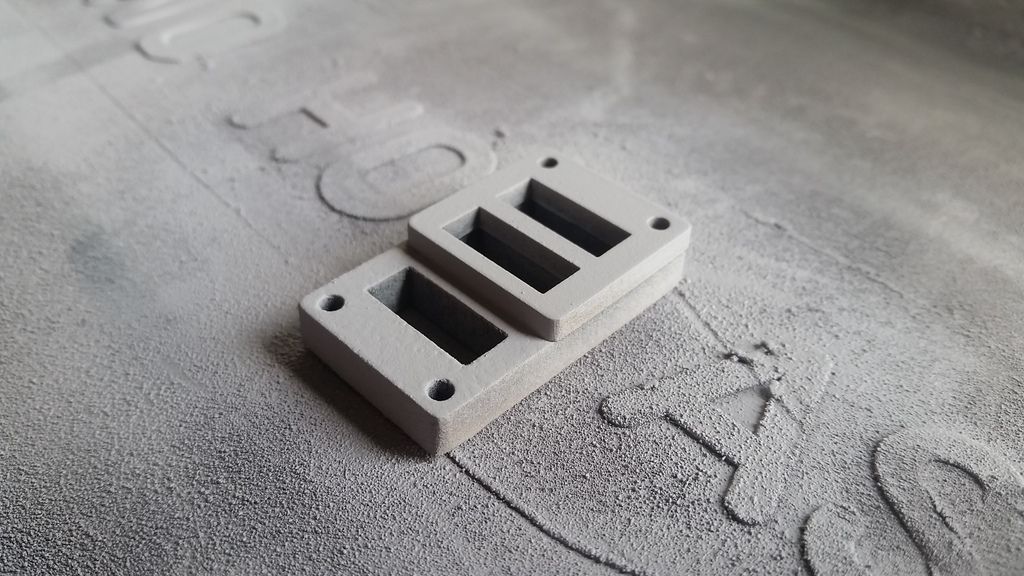

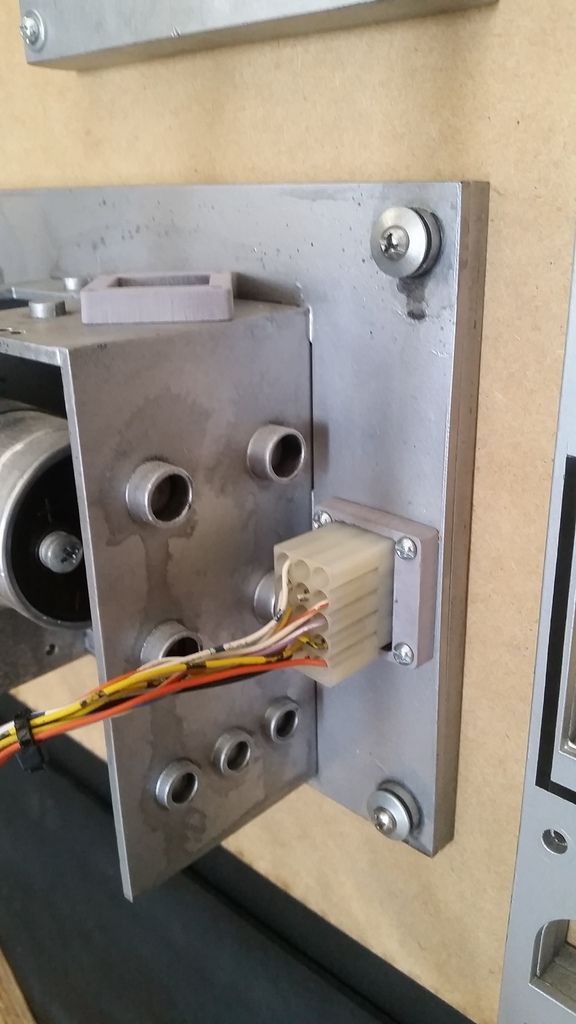

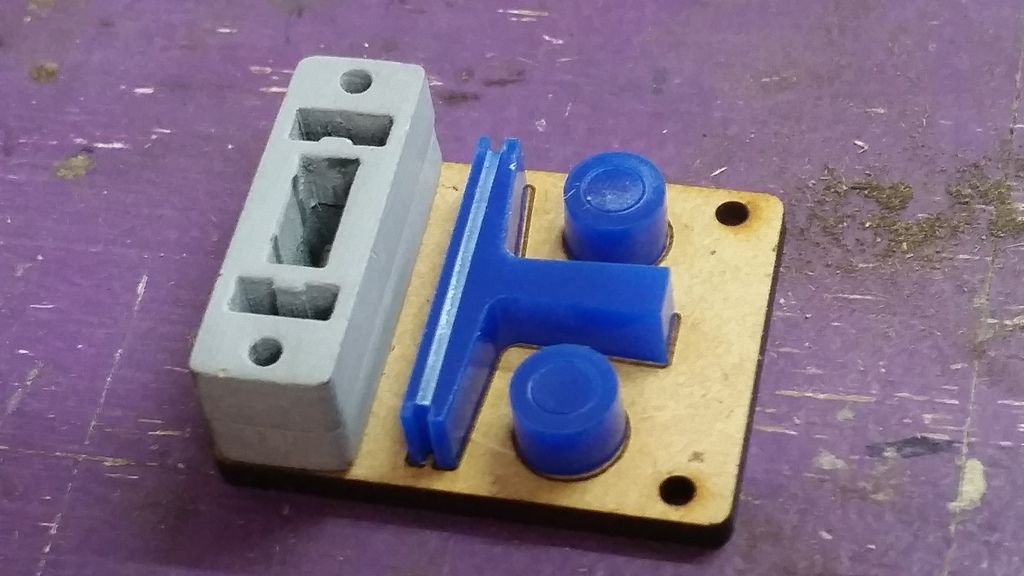

Then I jumped around... Another wire connector

Another greeblie I created

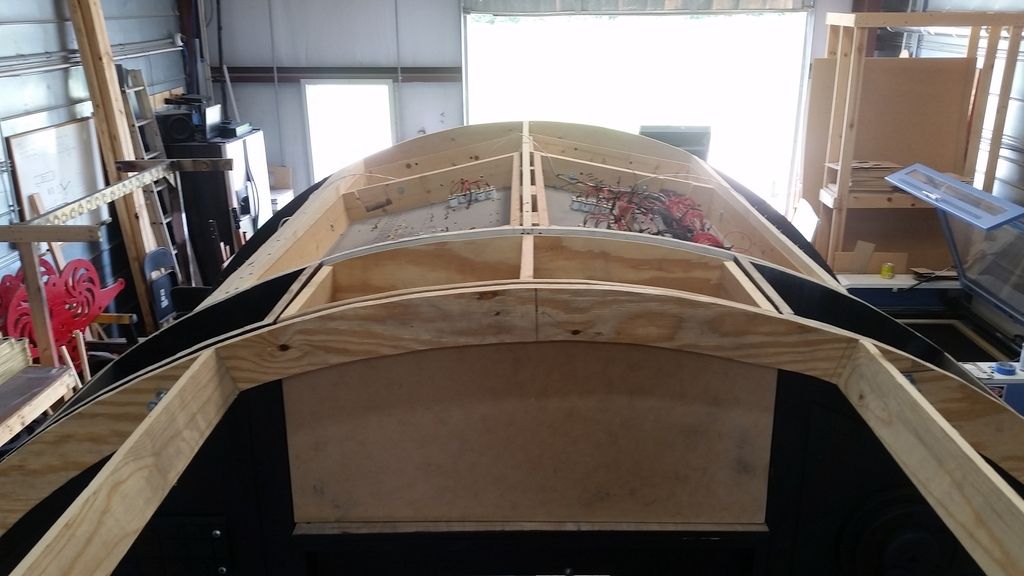

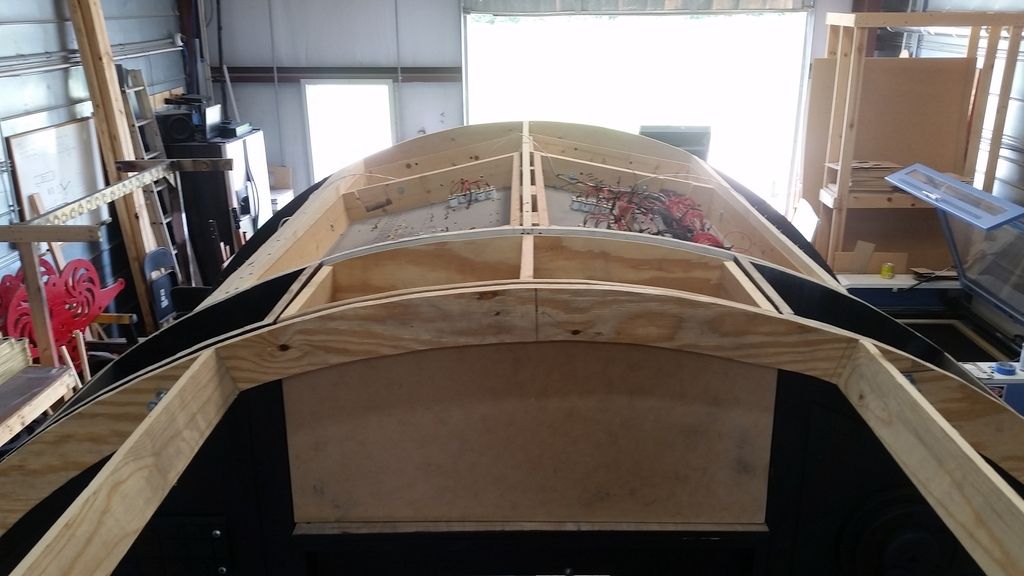

It was then time to get this LAST arch frame done!

Not sure how it happened but I was 1/2" off on one side?

First panel cut and now fits

YUCK! Lots of dips and uneven cuts! I hate using the jig saw. I managed to break 4 tracing bits during this phase? But, she's framed

Need to finish adding the vertical supports

Trimmed up a LOT of these framed and got it more square

Top View

And this is where we are!

Stay Tuned! Part II Coming!

For all those patriots celebrating the 4th of July, Happy Birthday America!

Time for the holiday weekend Update Part I

I laser cut these nav chair nacelle skins

Sprayed adhesive

Then wrapped each nacelle

This edge is the area of most concern - the plexi wants to pop away from the edge

I bent the edges over and rested the nacelle on the actually edge - fingers crossed it works

It was time to dress the cockpit entrance with all the saved wiring harnesses I've had lying around. So, I measured, designed and laser cut several different sized connectors that will mount to the entrance wall and greeblies

Dry fitting

Love this image! Still need to paint that panel - I'm going to remove all the greeblies and spray paint (using a paint gun) the cockpit entrance frame and panels in one shot)

Chewie's side

I'm not thrilled with the harness so I'm going to remove and start over - fortunately I used existing holes and zip ties

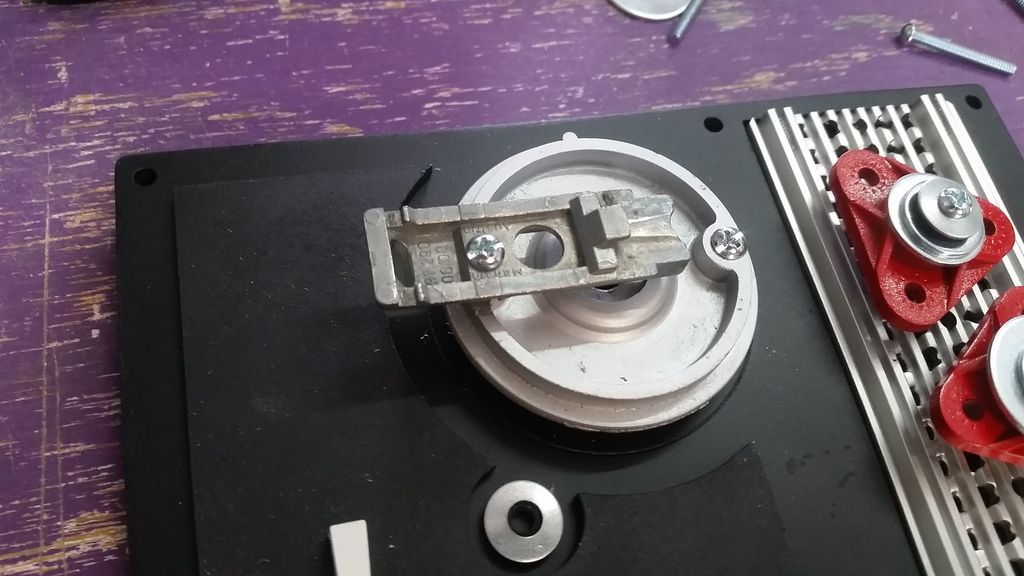

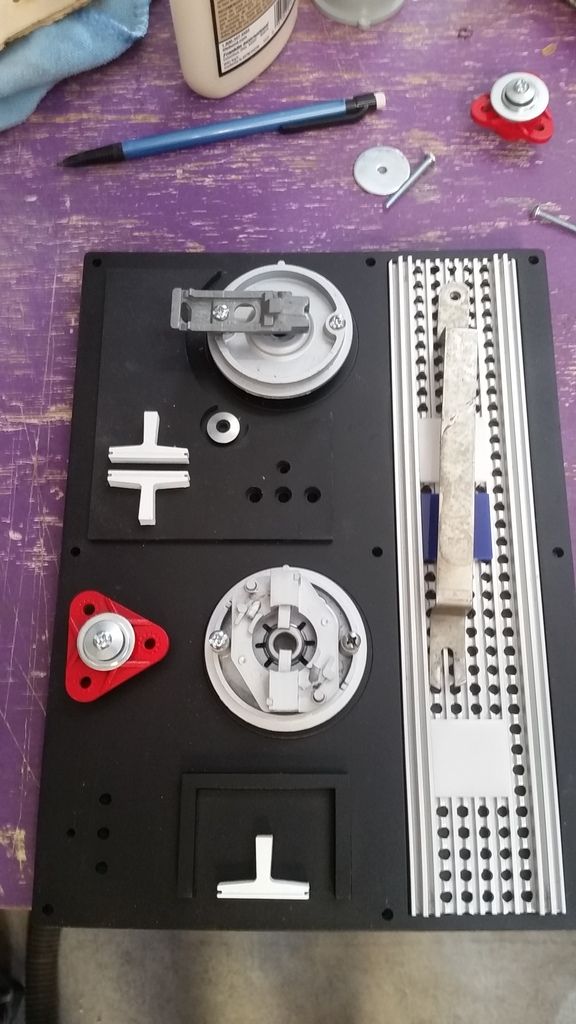

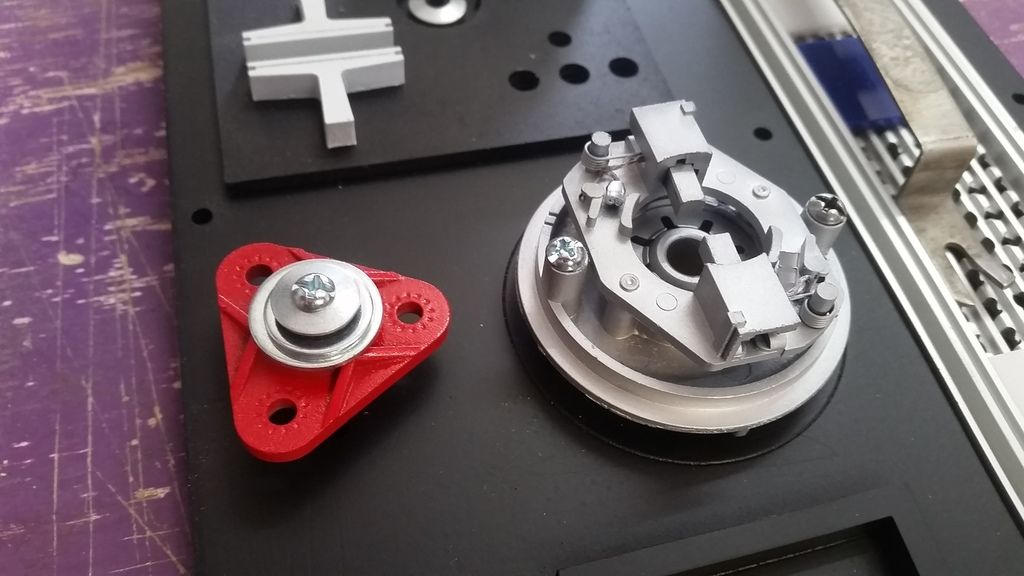

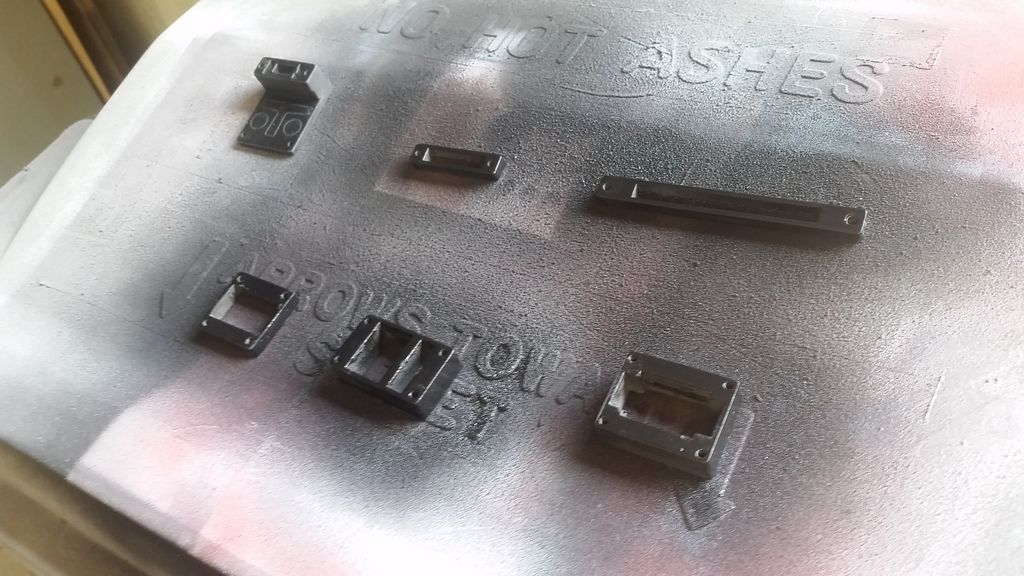

I then dug through the many greeblie boxes we have and wanted to create a few more greeblies to fill in some of the massive blank spaces on some of the panels. So, I took these...

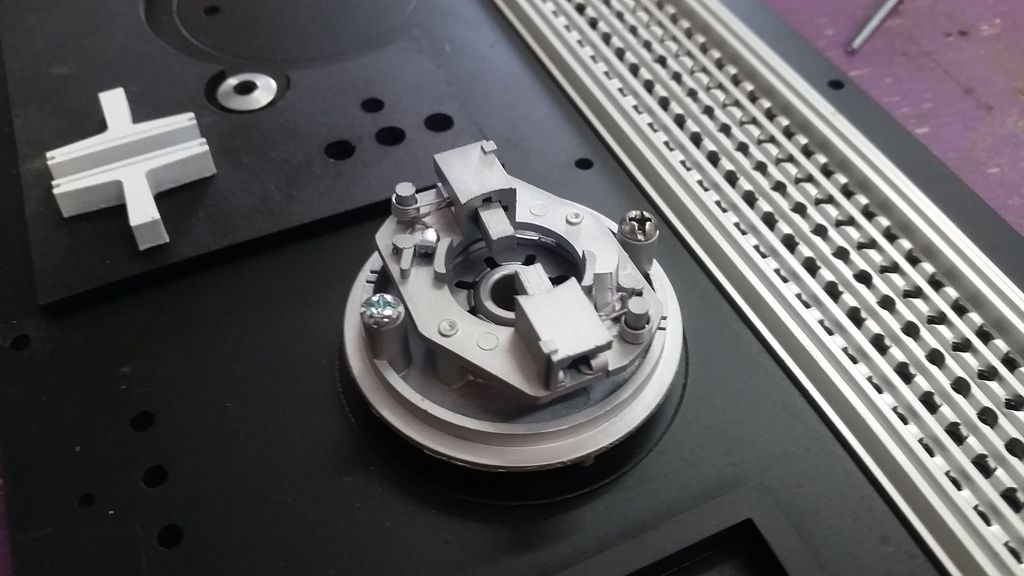

And this...

Designed and laser cut these...

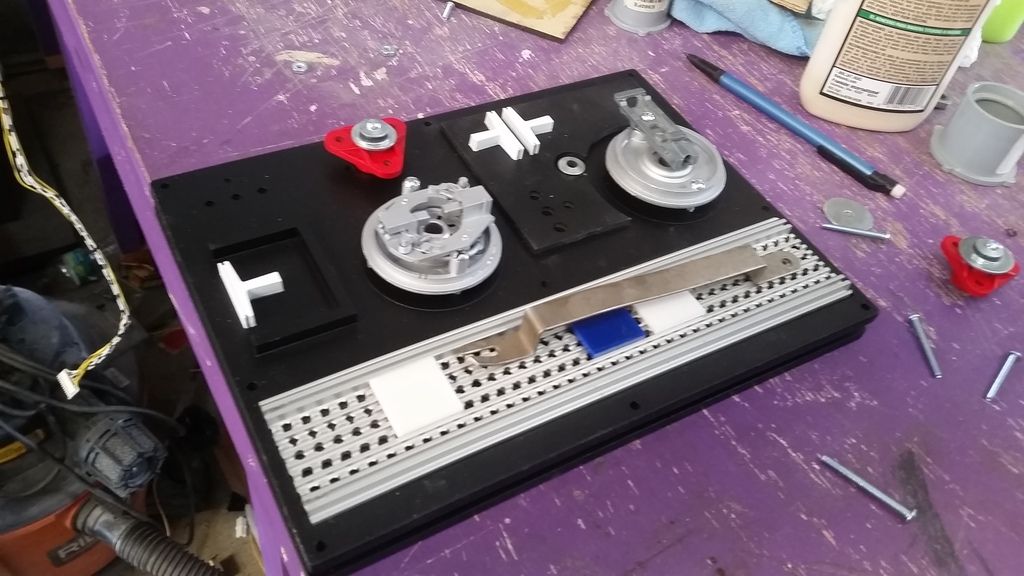

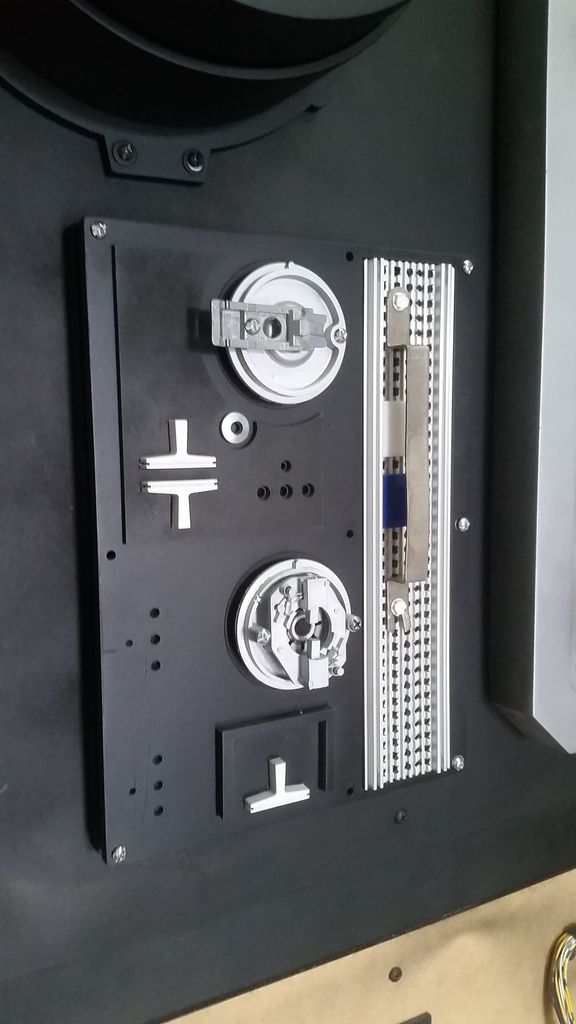

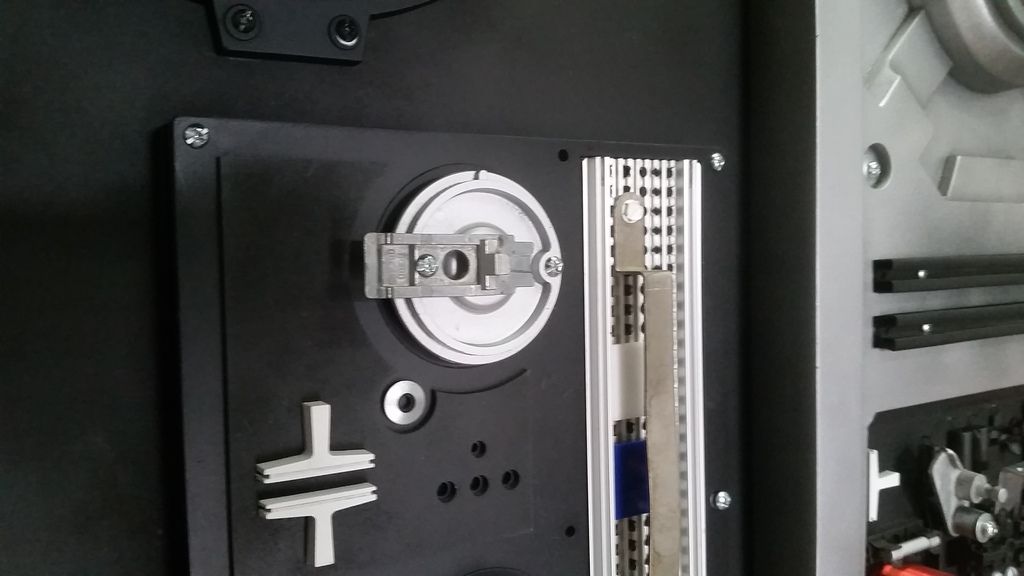

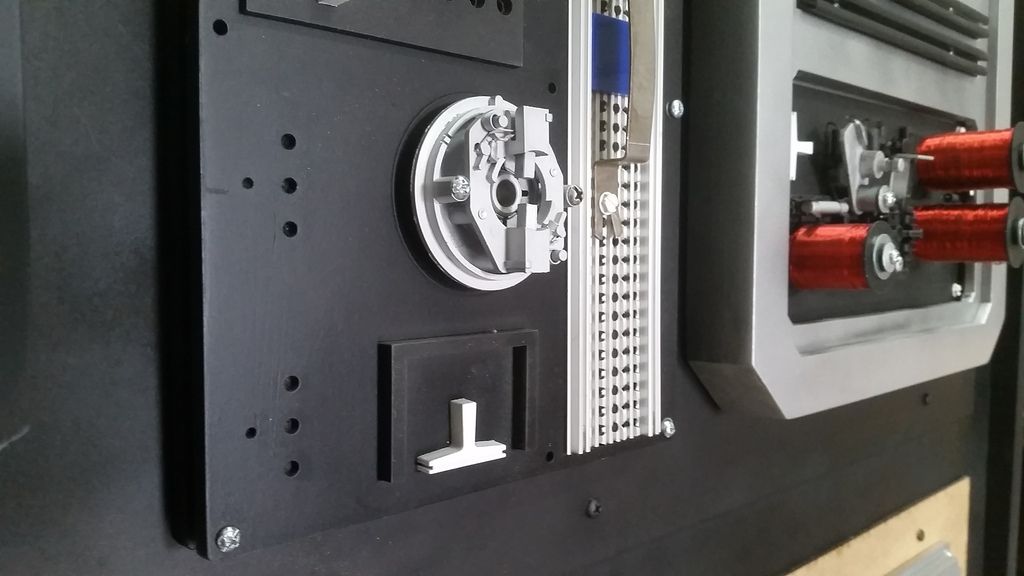

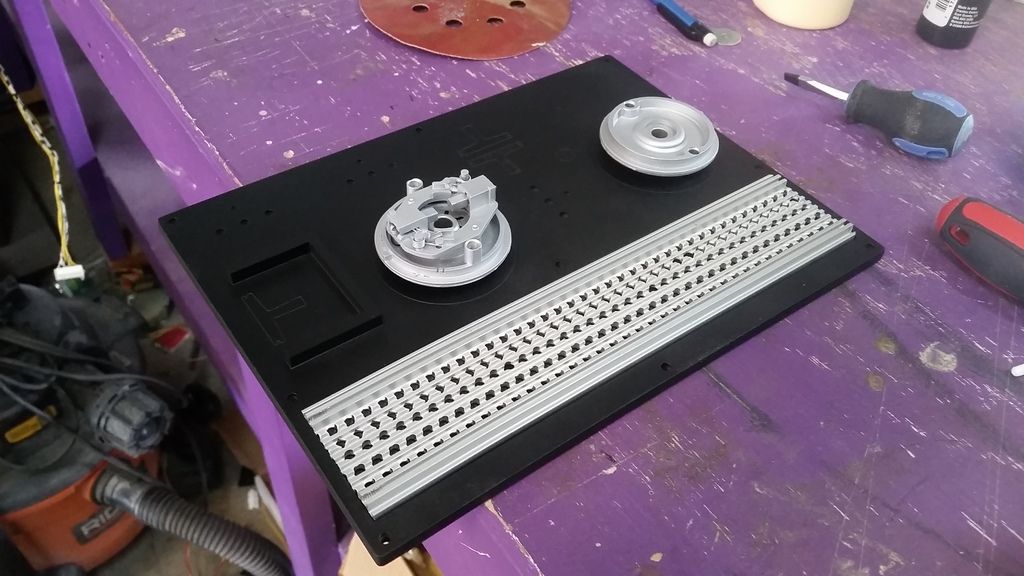

Started to dry fit

This panel will mount here

I then laser cut these acrylic pieces

Added paint

Love the detail

Primer

Another dry fit

Dug through some more and found these

Finally, I created a base for the panel - I should have this finished up today!

Then I jumped around... Another wire connector

Another greeblie I created

It was then time to get this LAST arch frame done!

Not sure how it happened but I was 1/2" off on one side?

First panel cut and now fits

YUCK! Lots of dips and uneven cuts! I hate using the jig saw. I managed to break 4 tracing bits during this phase? But, she's framed

Need to finish adding the vertical supports

Trimmed up a LOT of these framed and got it more square

Top View

And this is where we are!

Stay Tuned! Part II Coming!