Hi Gang,

Part II! Enjoy

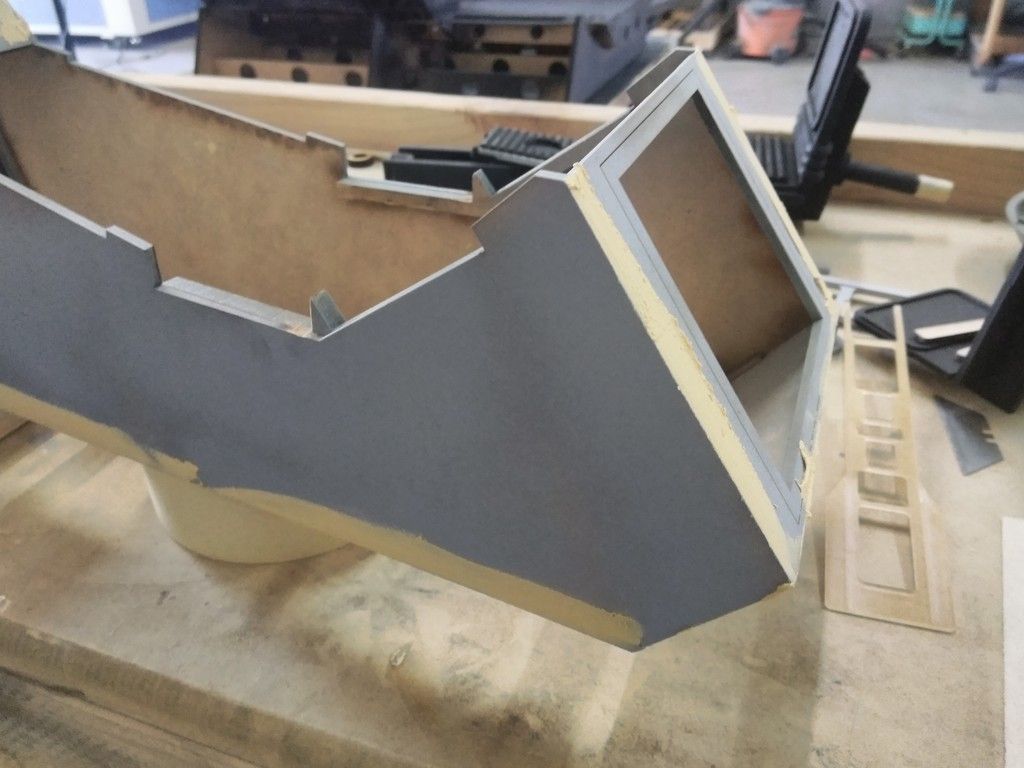

When the cockpit fell over I found a BUNCH of little cracks that will DEF need fixing

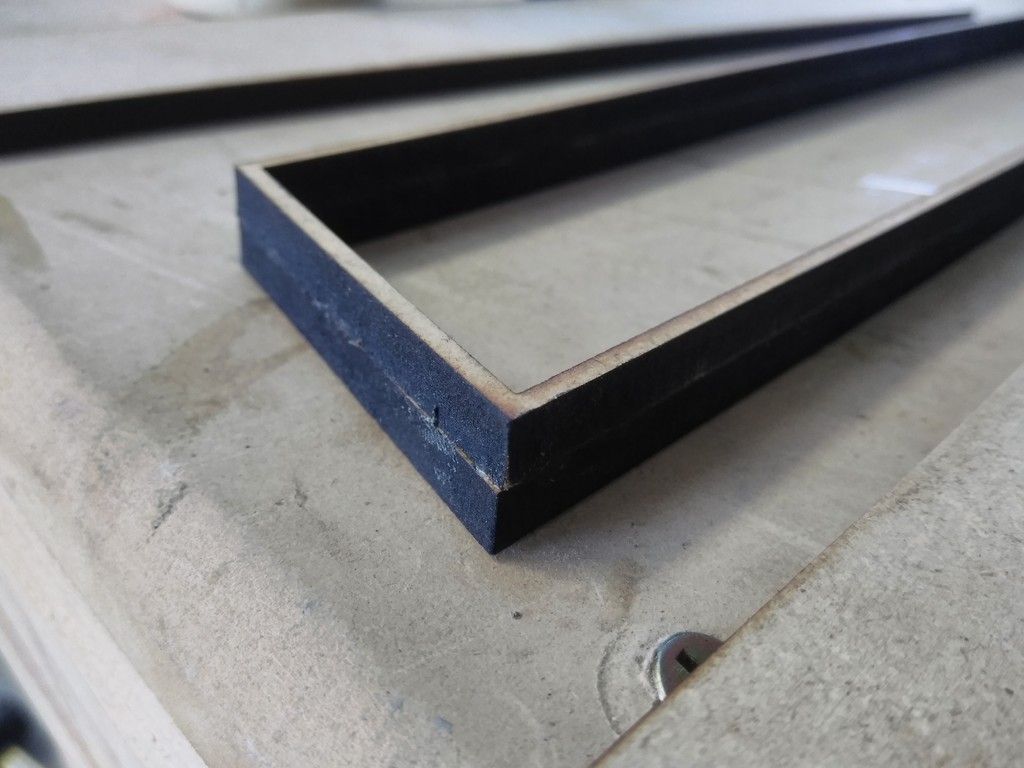

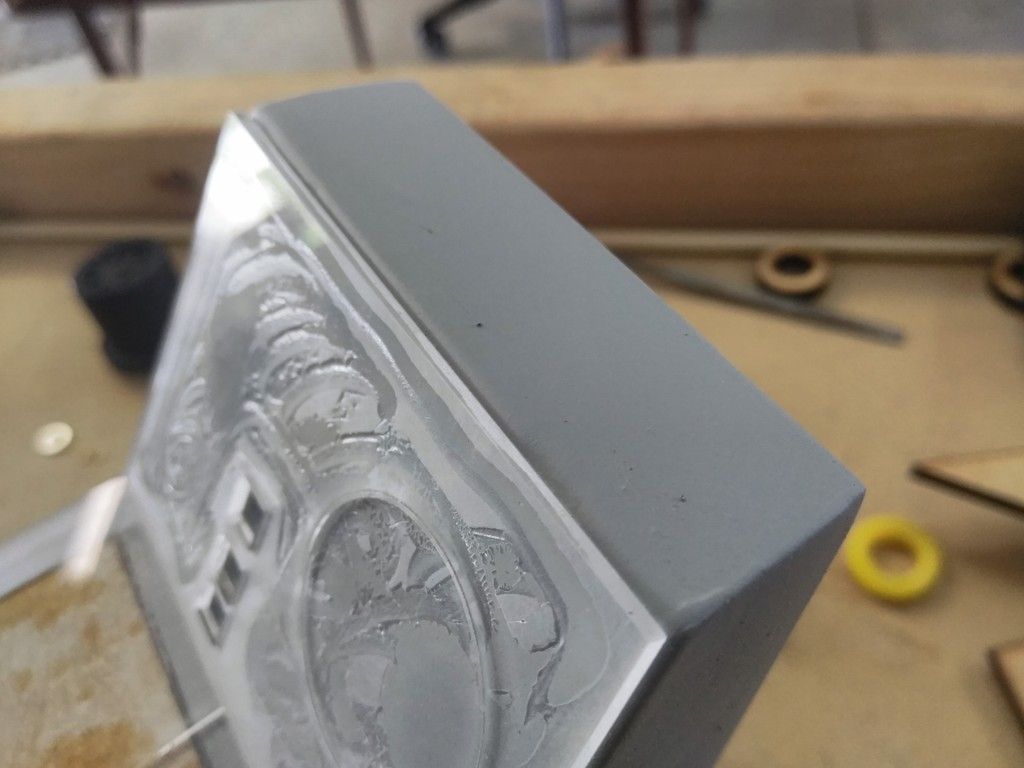

But... Let's move onto the panels. I sprayed a layer of black primer

And grey primer

Painted the floor

Larger bolts are now being used to hold the main body and door section together

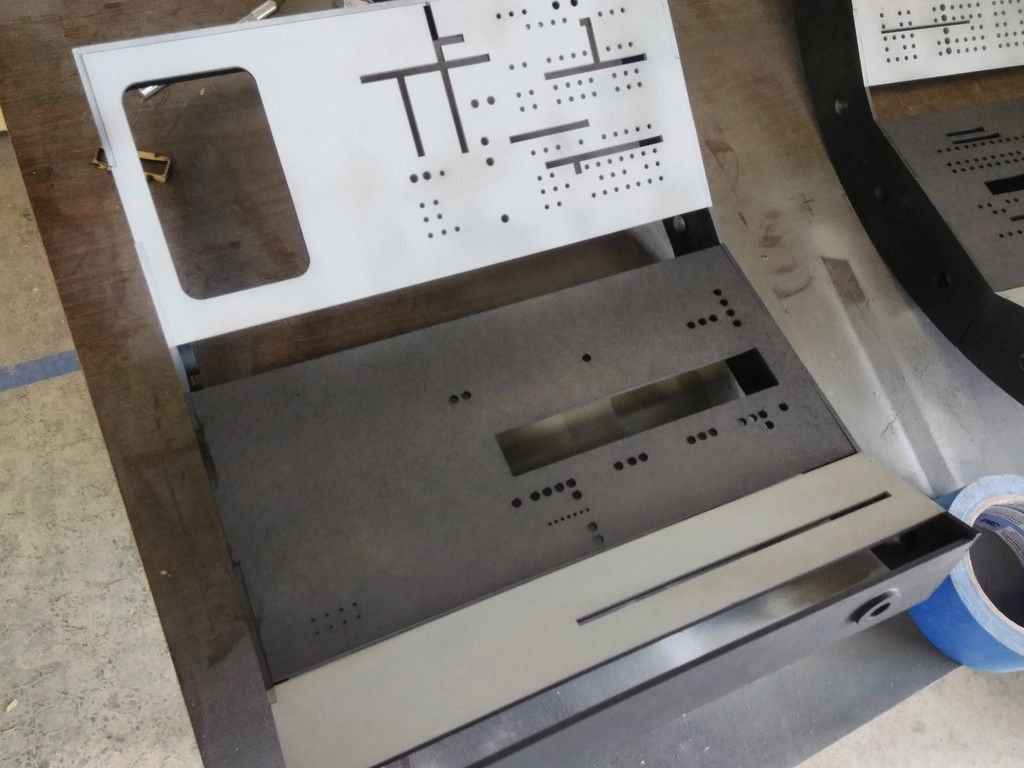

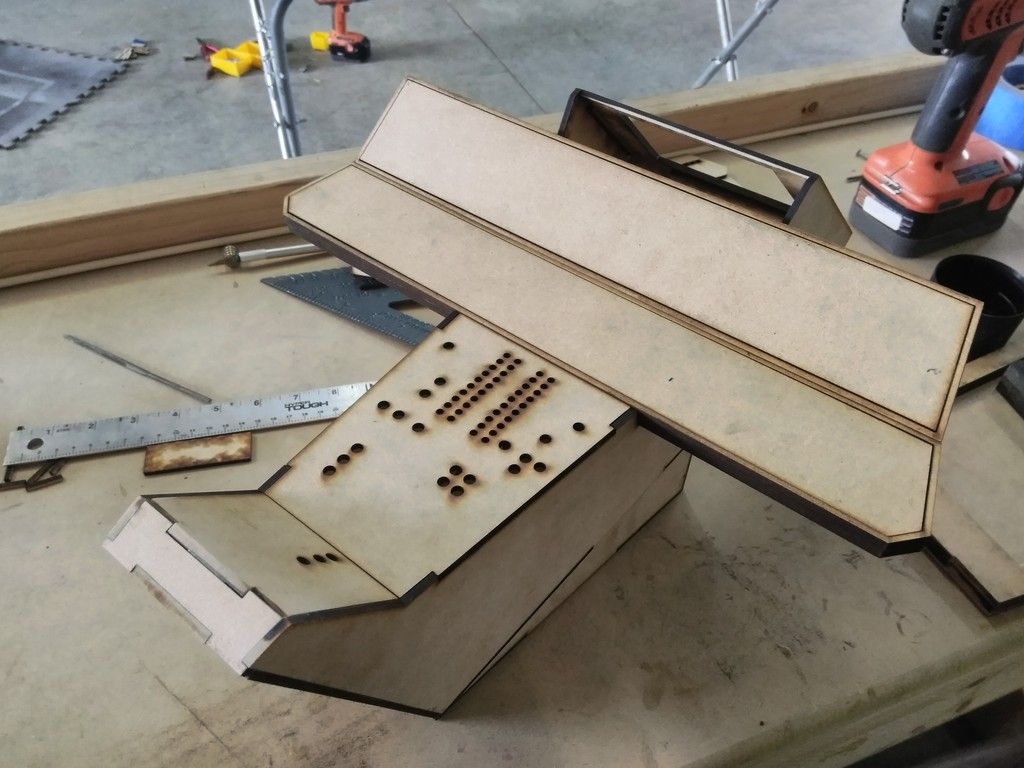

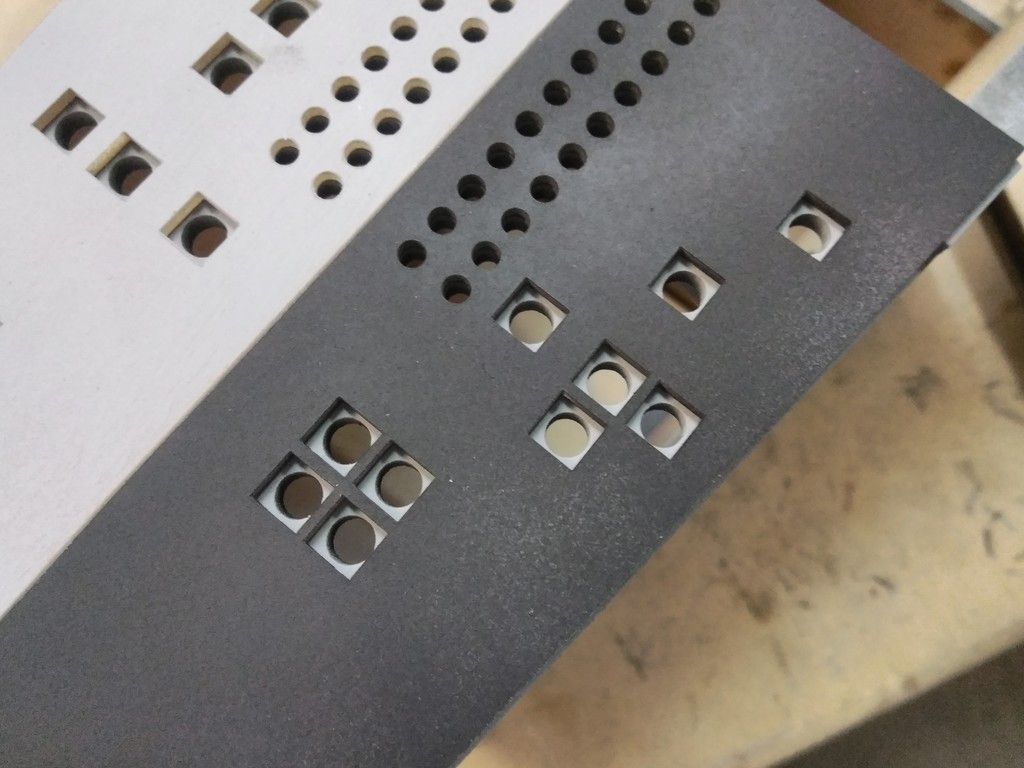

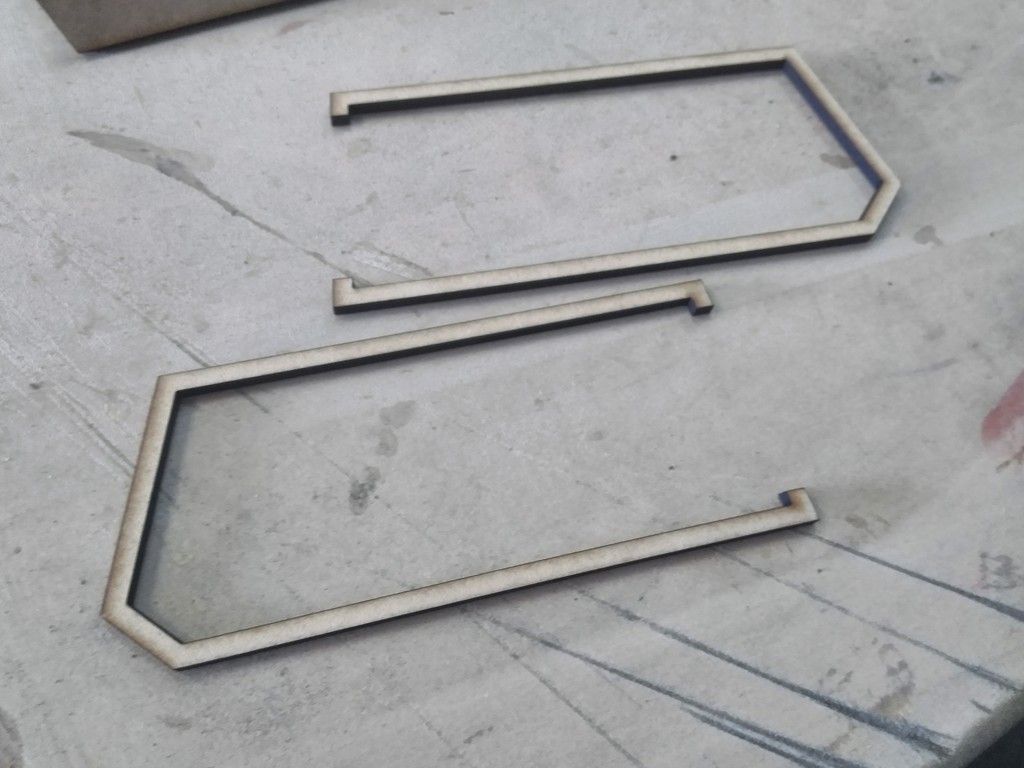

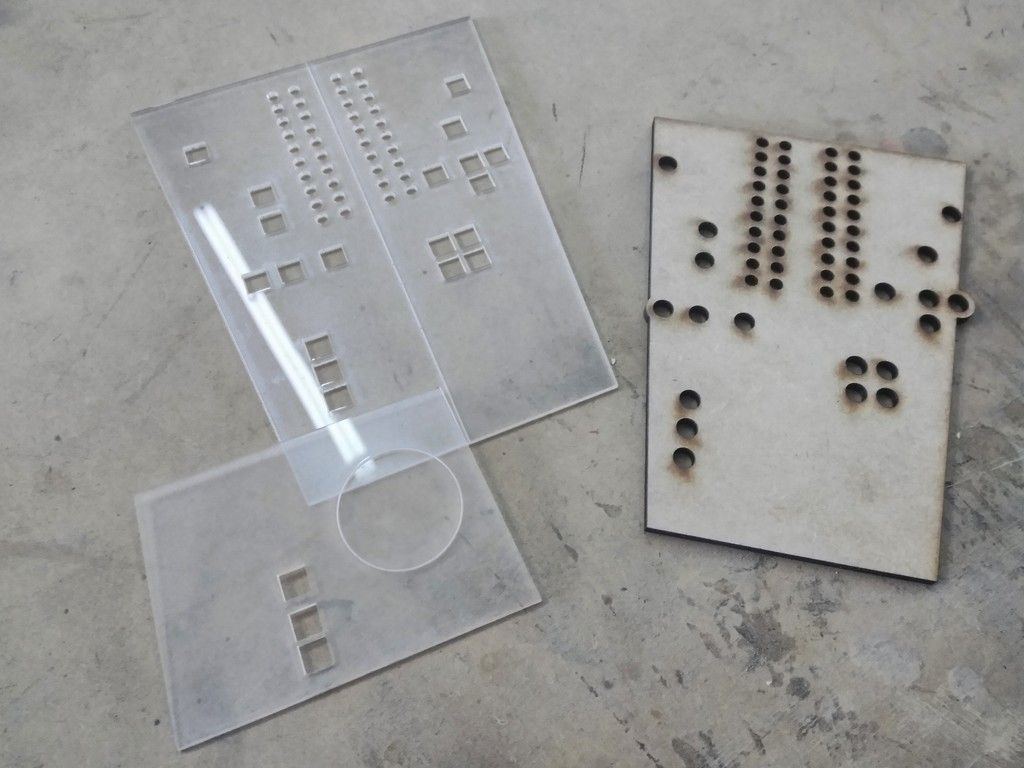

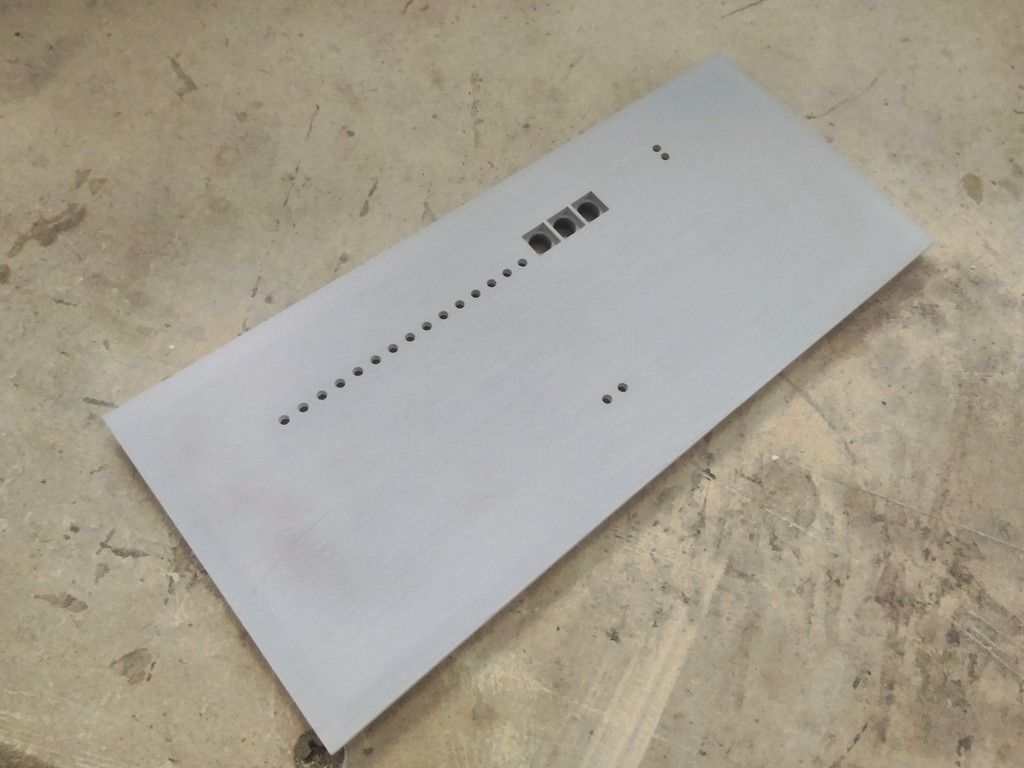

I then worked on the console - laser cut these upper panel parts

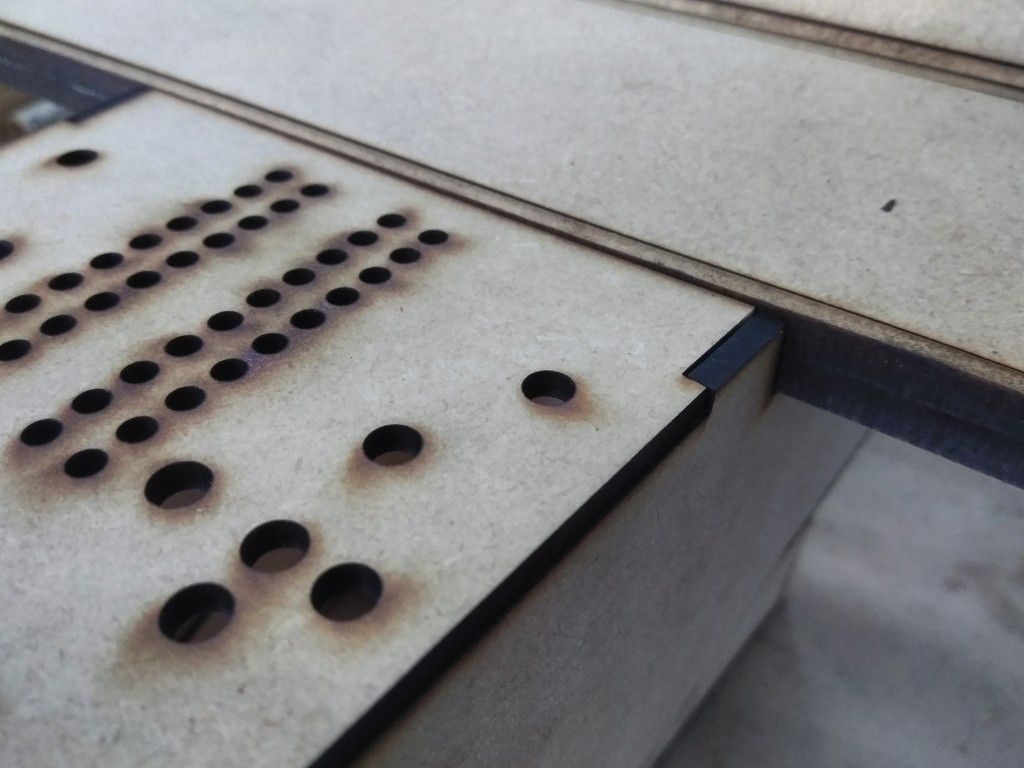

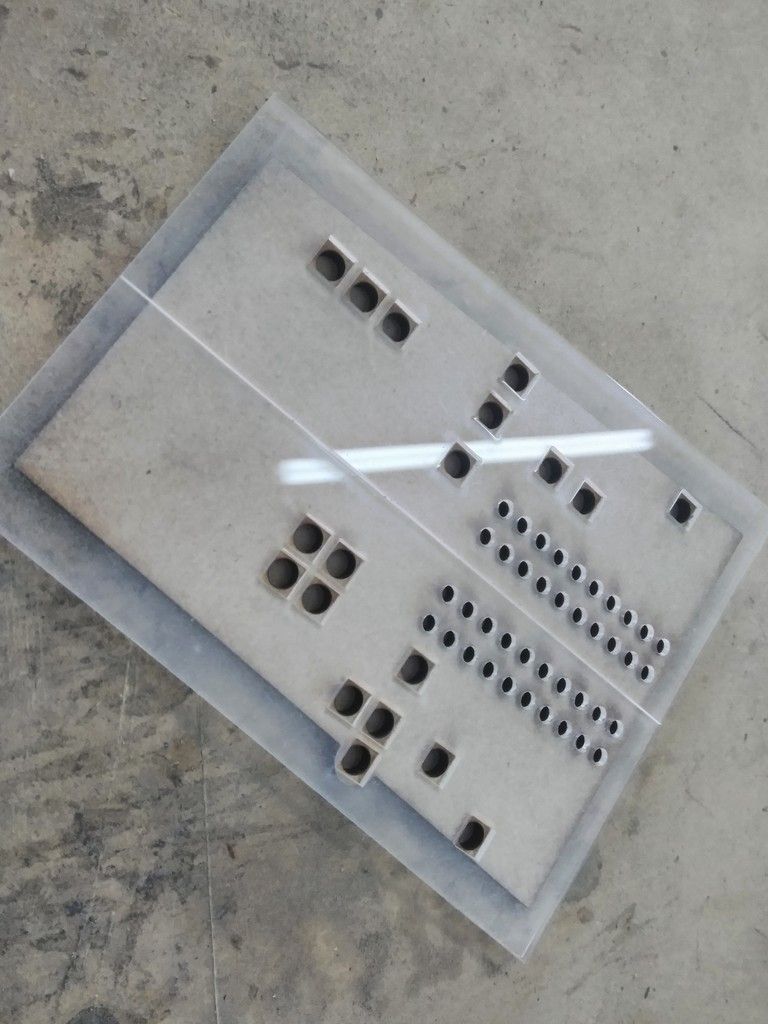

For those who have a laser cutter... save any/all interior pieces where the outer edges of your cut might be too thin to freely hand sand. Insert the interior pieces back into place and this gives a solid base in which to sand without breaking those delicate edges

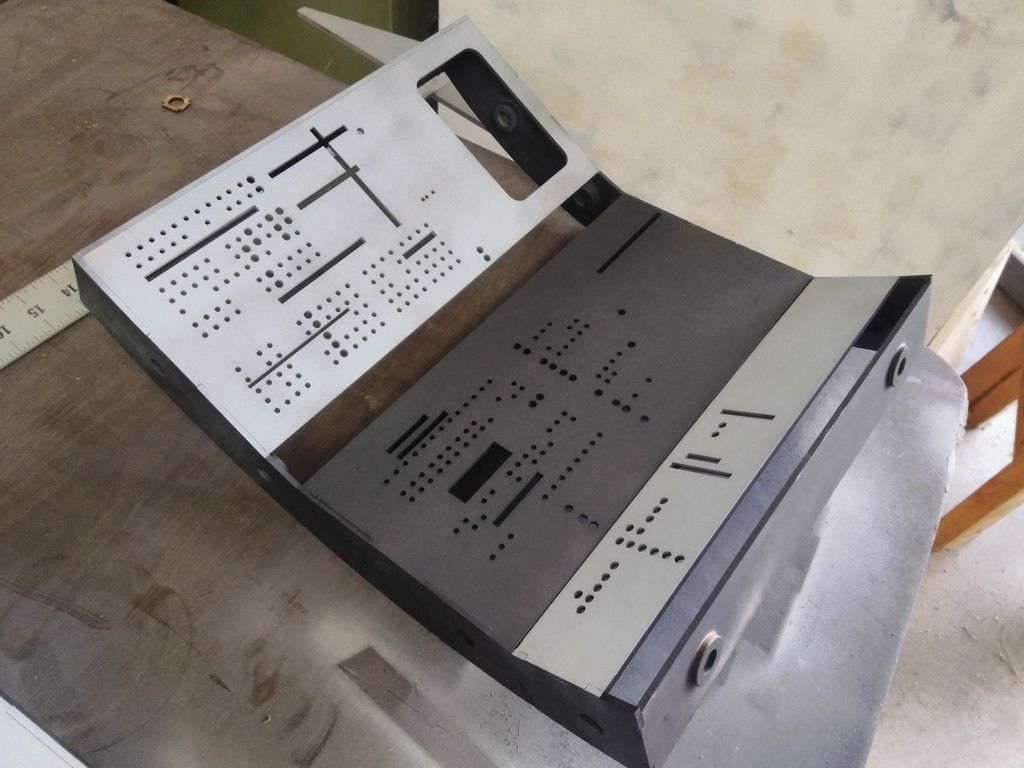

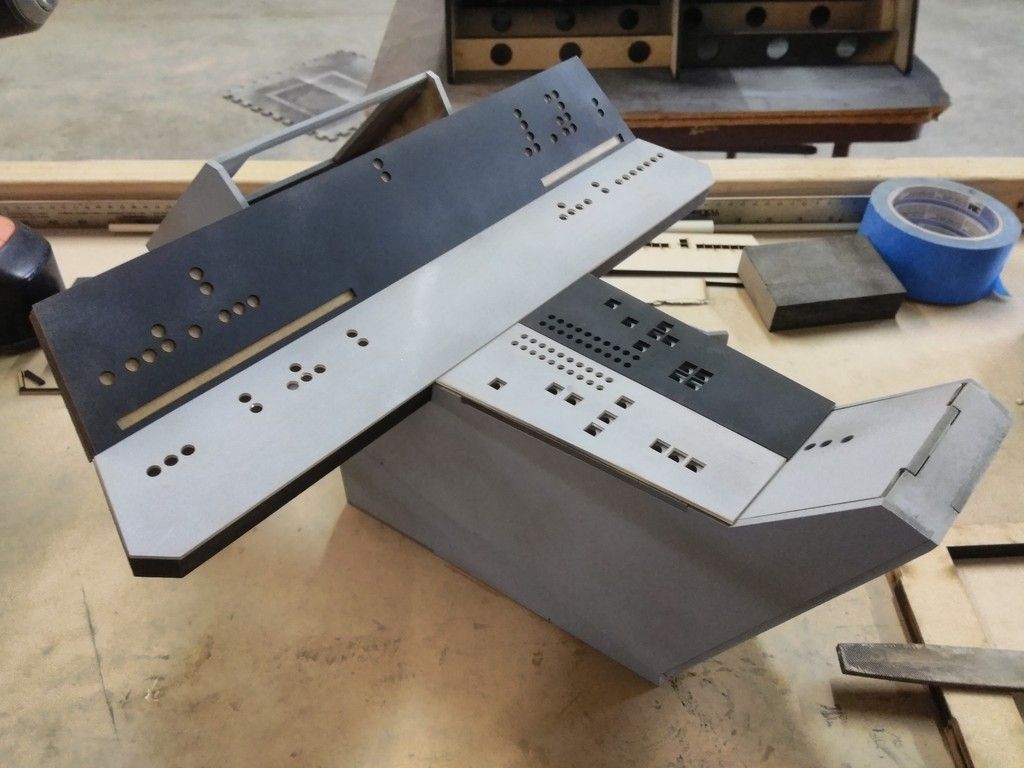

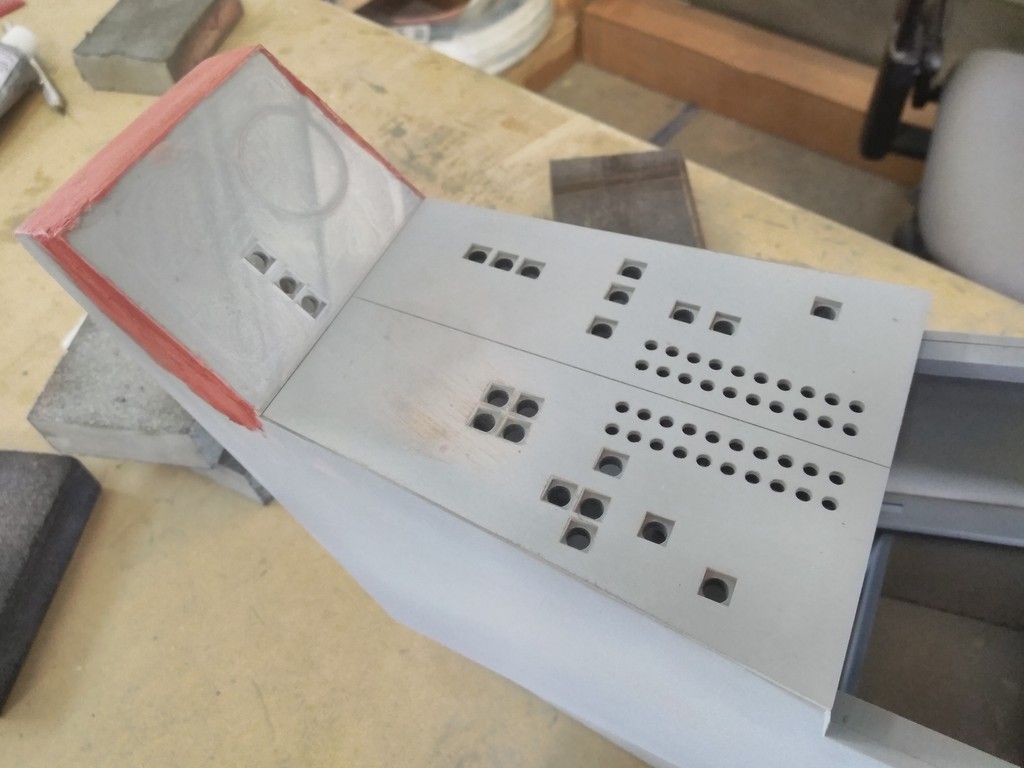

Lower and upper panel edges cut and in place

Perfect fit

Nice and snug

Removed the interior pieces - this is the space I have to play with for the electronics

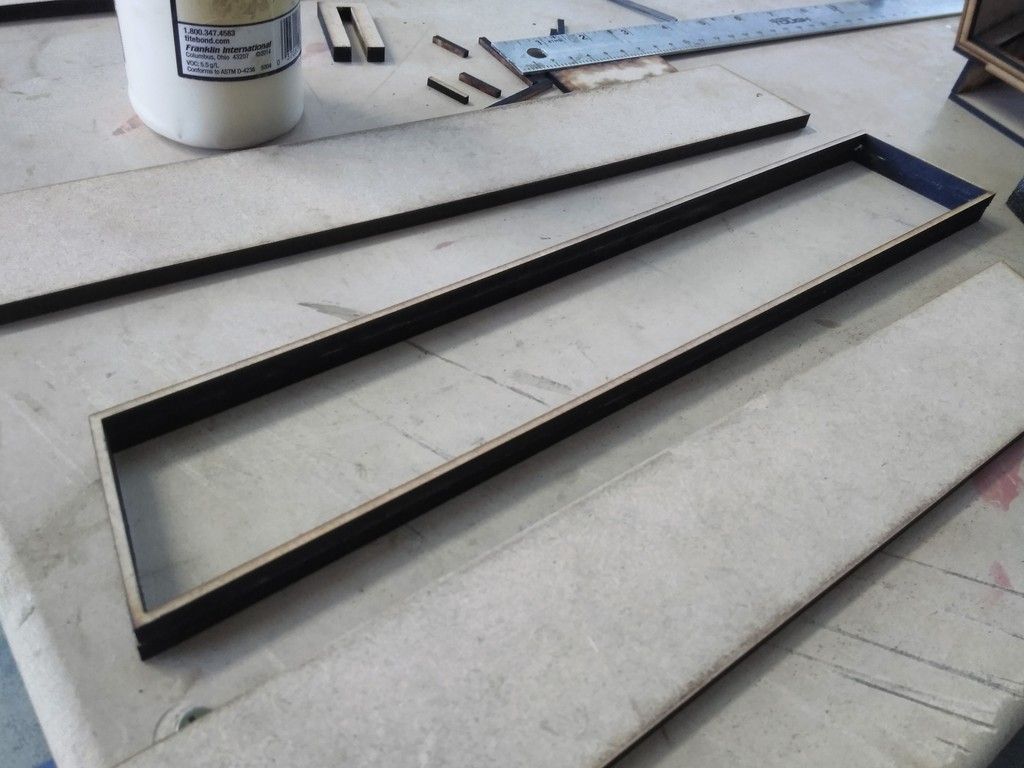

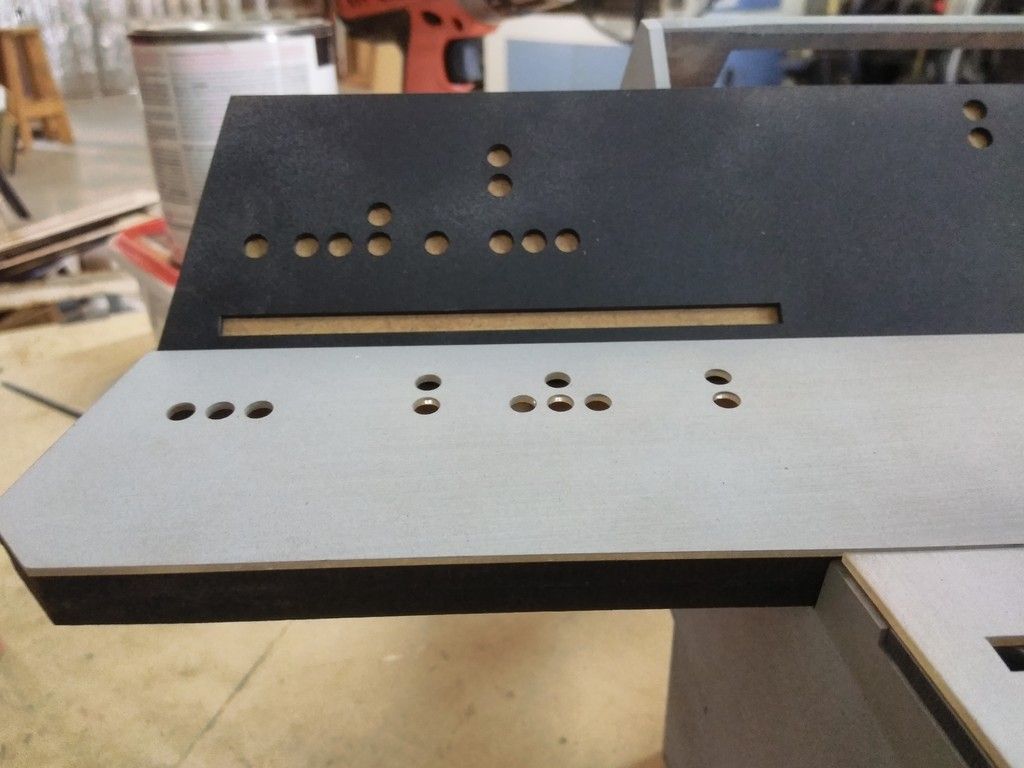

The instrument panels want to move around and stay misaligned. I laser cut these little pieces

Adhered them to the interior side of the console

When the panels go back they have a small shelf to rest and keep them from sliding up and down

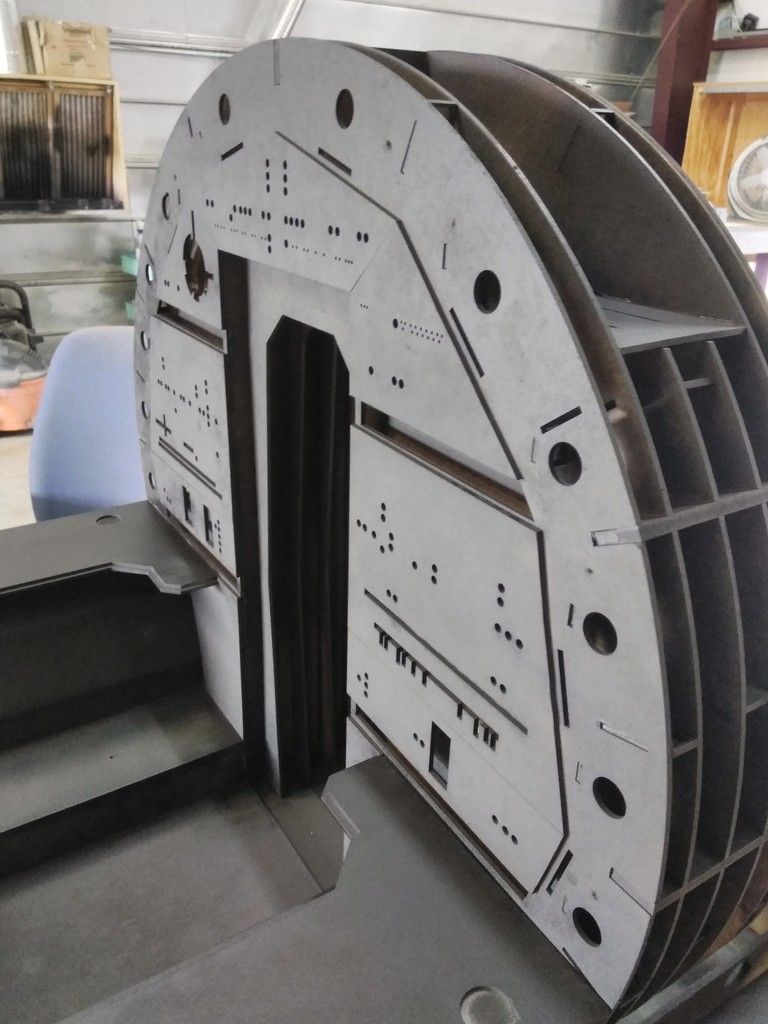

Primed the main body

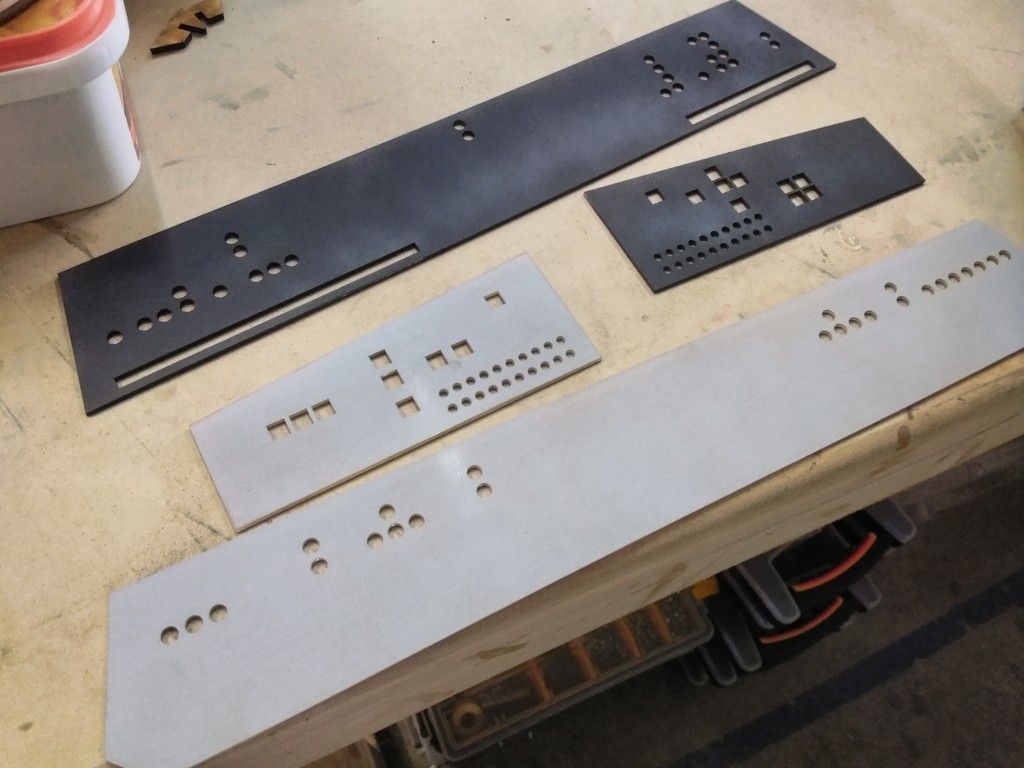

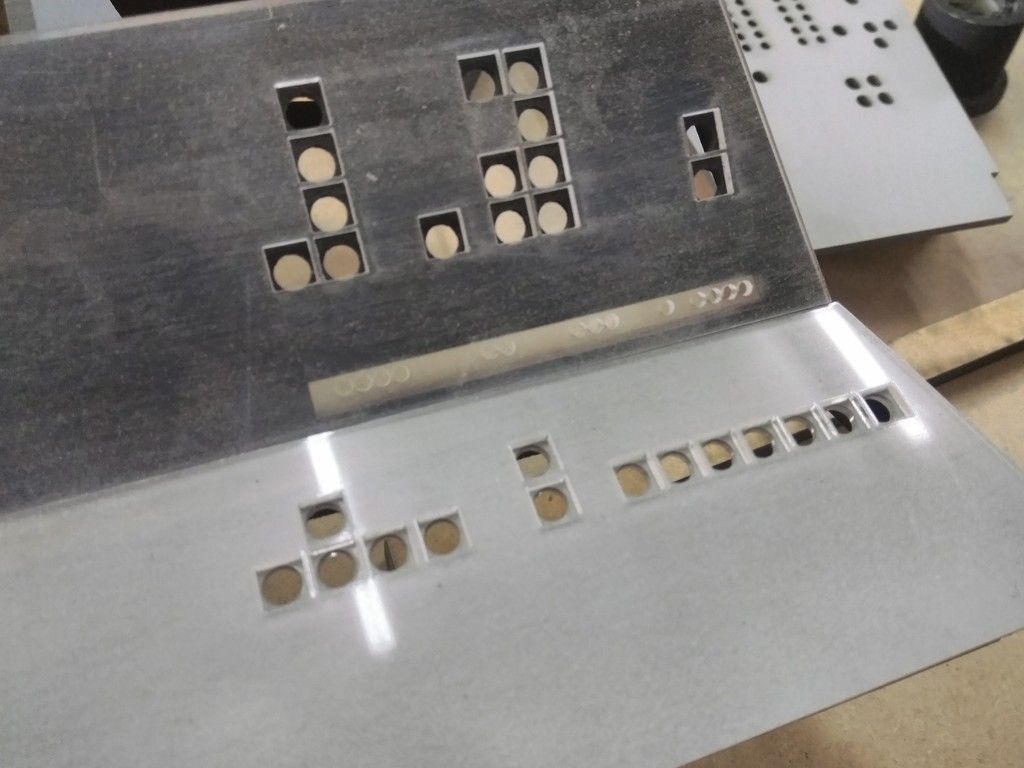

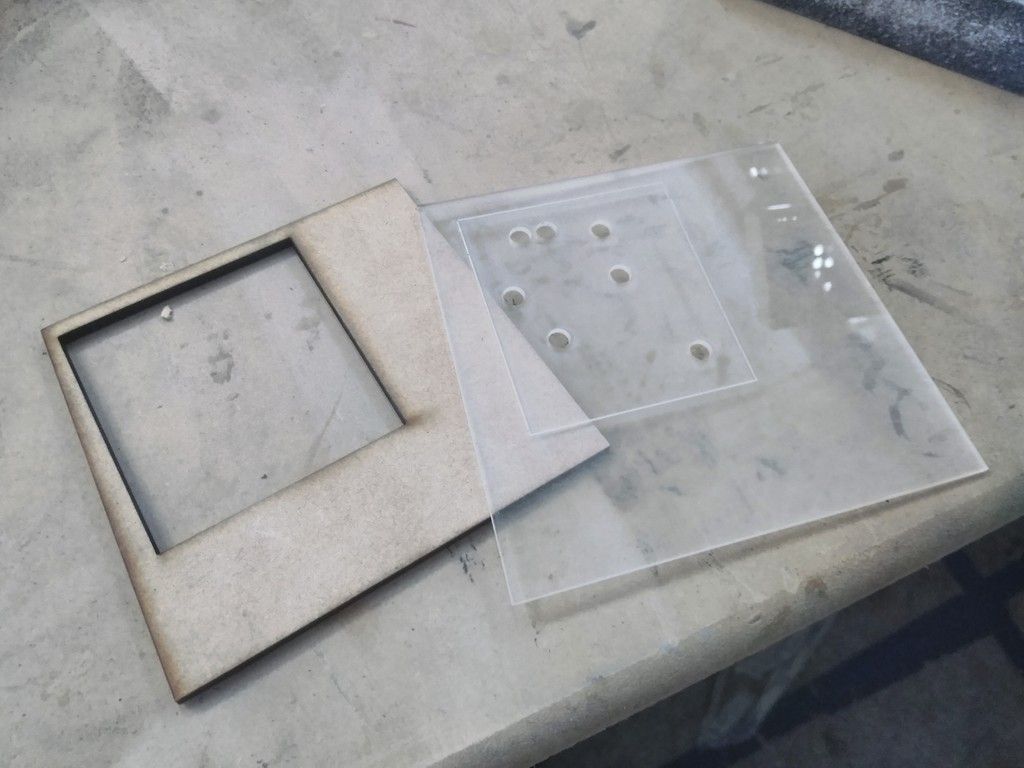

I then laser cut these 1/16th acrylic instrument panel "lower" and "upper" armrest panel faces

Dry fit

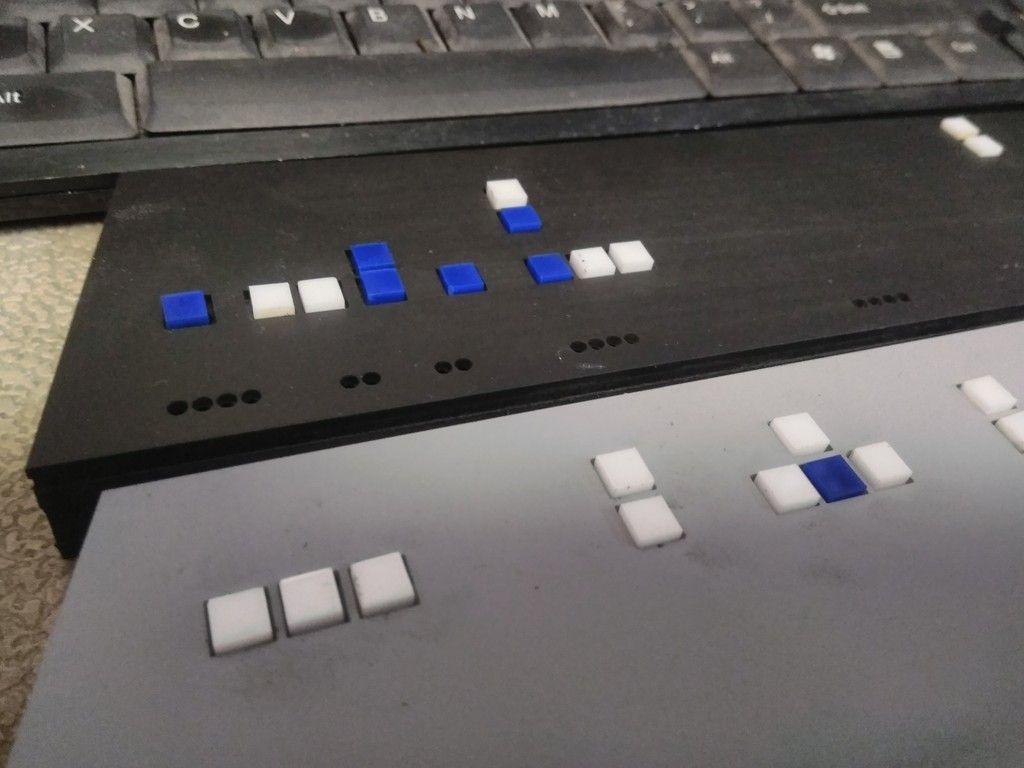

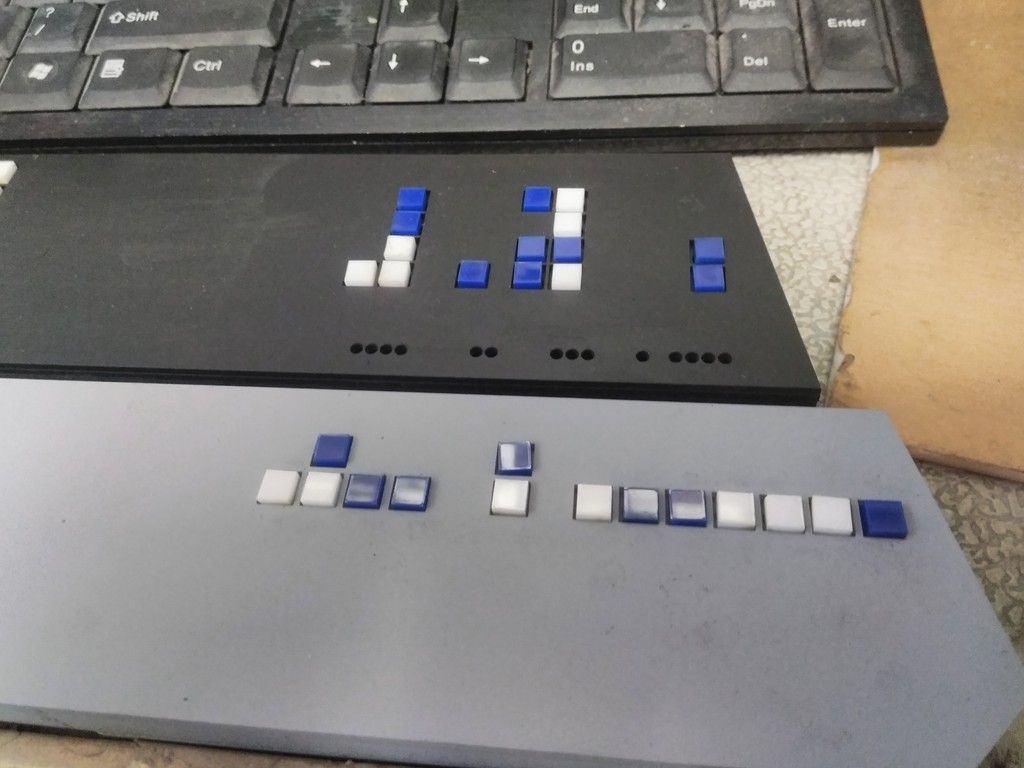

Note the holes for the illumination PLUS a simple guide to simply drop the blue and white tiles in place

That working space gets tighter and tighter

Adhered the 1/16th pieces to the instrument panels

I used the scrap interior pieces to help hold the shape and help keep the edges from deforming

Now she's looking like a proper console

For scale... In my hand (before I painted the cockpit panels grey)

Time to get these edges cleaned up

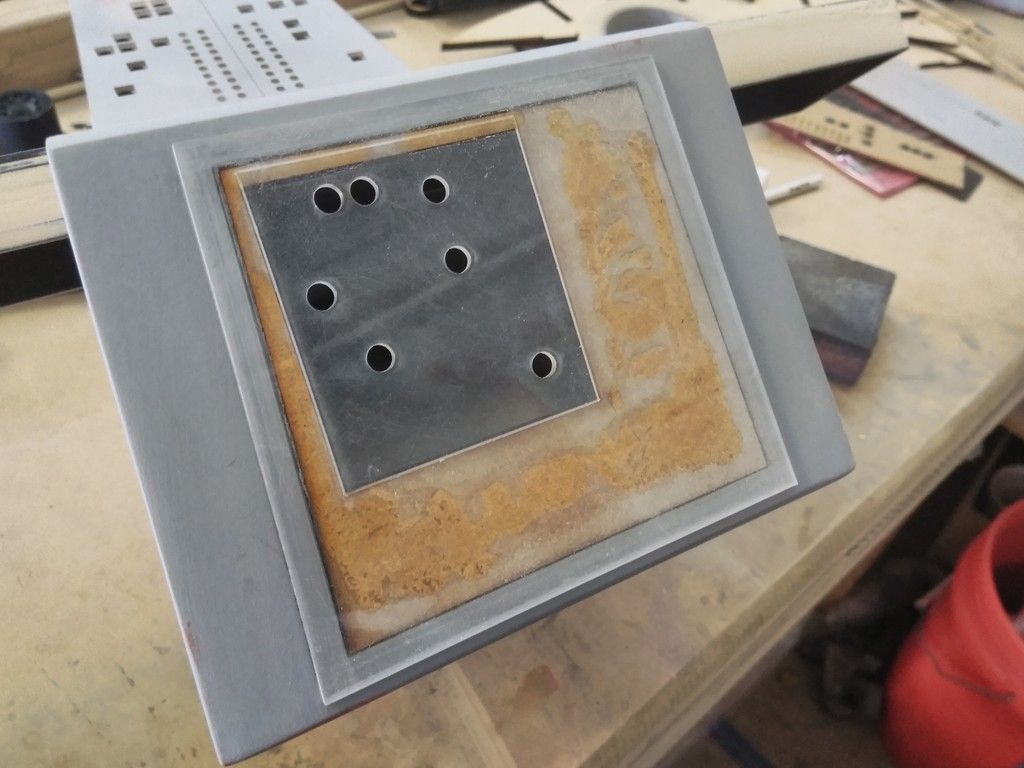

Console base

I designed and laser cut these outer edge trim pieces to help me locate center when I slide the instrument panels into position - also keeps them from sliding left to right

Adhered to the underside of the instrument panel

Nice and snug up against the edges

The cover panel will somehow be attached AND have the LED strip attached

Upper instrument panel gets the same treatment

Snug fit

A little sanding to ensure fit and finish

Nice tight fit!

Time to add the upper panel face to the rest of the console - cut the upper panel face and dry fit

Adhered in place

Lets add the rest of these surface panels to the console

Sanded

Ah... filler

1st round of sanding

So... the upper instrument panel faces are 1/16th inch thick. I laser cut 1/8 inch acrylic into .25 inch square pieces

And did a dry fit of the blue and white tiles. Turns out that I need to laser cut them just a bit larger than .25" to fill in the small gaps and keep them straight

Note the wonky tile...

The armrest panel saw a MAJOR change - had to find a way to permanently adhere the panel, sand the tab on the side smooth but still have access to the wiring - I simply followed the full scale version and laser cut a trim piece with a large opening

Filled and primed the armrest area

Laser cut these new armrest pieces

Adhered the 1/16th inch acrylic to the 1/8th inch MDF

Pops and stays right in place

Lets address this area

Added the 1/16th inch acrylic

Trimmed to fit and adhered to the panel with E-6000

Gotta fill and sand that ugly edge

Filler

Light sanding

Back side vertical panel

Front nose panel

Can't wait to add all the greeblies!

Lots of filler to sand

And this...

Is where we are!

Hope you guys/gals enjoyed Part II! I'm really excited to get back to the shop and get back to it!

More to follow!