sandbagger

Master Member

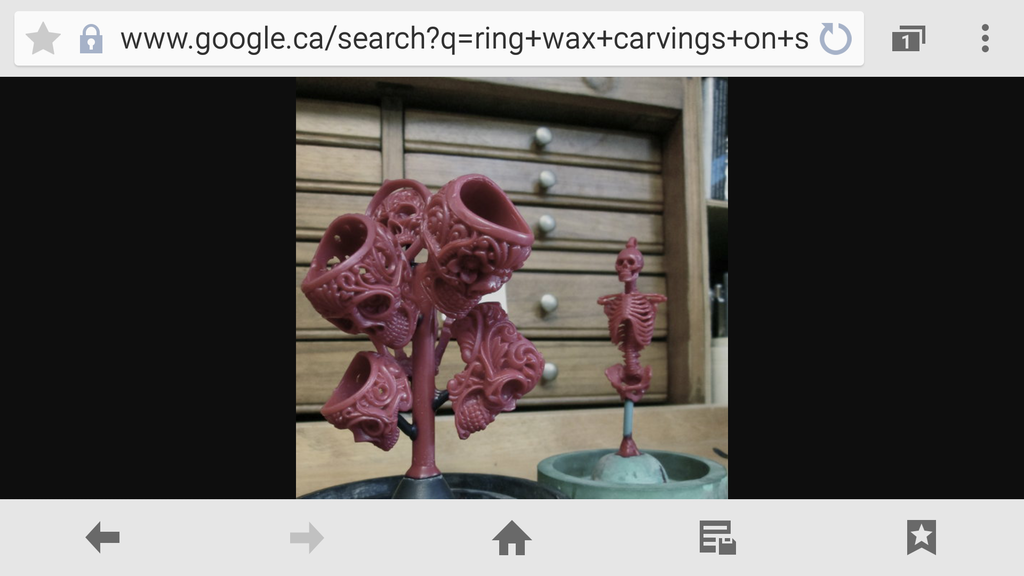

Those thumb pieces are a thing of true beauty.

Your work sir is truly unsurpassed, hats off to you!

Thanks man. :thumbsup

Well it's nearly 1am and I got a few pieces to work perfectly, (Index finger) so I'm going to bed happy. I changed the surface that I pour on to show more through the sand and I poured a LOT faster.

Last edited by a moderator: