Kormier

Well-Known Member

Well, I'm the master of ongoing projects... and recently I really got inspired by the Stormtrooper build of Terra1 (find here: http://www.therpf.com/f24/stormtrooper-pepakura-terra-returns-pics-122443/) so I just HAD to give it a go. There's a 501st Garrison in my area and I'd like to join them in the future (long term future) if I can build a suit that fits their criteria. I'm also working on a Warmachine suit and a few other things as well. What can I say, I like to keep busy.

My wife is gone out of town to visit some family for the week-end so I was able to get a good head start on the bucket. Thank you to SpaceCowboy for the pep file! I used the document that is posted on his website.

So here are some pictures of what I have done in about 14 hours of work.

This is the completed pep.

I used part of the support structure that was included in SpaceCowboy's file to add some rigidity to it and get the correct angles for the nose and mouth. I feel like the gap of the mouth is a bit too large but I'll fix that later. I'm not too concerned about the accuracy of the pep at this time.

I then proceeded to coat the exterior with some Smooth-on 320 to add some rigidity and hopefully prevent distortion for when I'll be applying fibreglass mats on the inside.

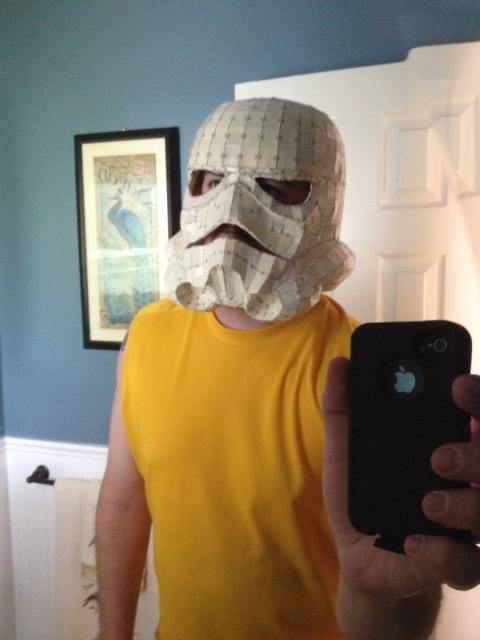

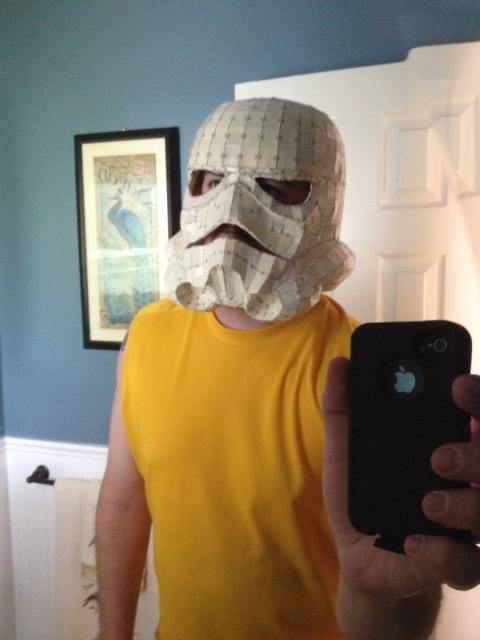

Once the resin was dry I could not resist to do a fit test. It seems to be fitting OK, although I don't have anything to use as a reference since I've never put one on before.

After the resin was dry, I removed the internal support structure and covered the inside with fibreglass mats and resin. It seems that coating the outside with the smooth-on was a good idea since so far I have not observed any warping or distortion. Can you spot other unfinished projects in this picture ??

That's it for now.

I'm not certain yet if I will do a rubber mold and cast the final product like Terra1 did or if I will try vacforming. I have a vacforming machine and I thought it would be nice to try to use it for this project. My question though: does anyone know what the vacforming moulds looked like ? I am assuming that the bucket was vacformed from at least 3 or 4 moulds (front, back and dome) but I could be wrong.

Cheers!

My wife is gone out of town to visit some family for the week-end so I was able to get a good head start on the bucket. Thank you to SpaceCowboy for the pep file! I used the document that is posted on his website.

So here are some pictures of what I have done in about 14 hours of work.

This is the completed pep.

I used part of the support structure that was included in SpaceCowboy's file to add some rigidity to it and get the correct angles for the nose and mouth. I feel like the gap of the mouth is a bit too large but I'll fix that later. I'm not too concerned about the accuracy of the pep at this time.

I then proceeded to coat the exterior with some Smooth-on 320 to add some rigidity and hopefully prevent distortion for when I'll be applying fibreglass mats on the inside.

Once the resin was dry I could not resist to do a fit test. It seems to be fitting OK, although I don't have anything to use as a reference since I've never put one on before.

After the resin was dry, I removed the internal support structure and covered the inside with fibreglass mats and resin. It seems that coating the outside with the smooth-on was a good idea since so far I have not observed any warping or distortion. Can you spot other unfinished projects in this picture ??

That's it for now.

I'm not certain yet if I will do a rubber mold and cast the final product like Terra1 did or if I will try vacforming. I have a vacforming machine and I thought it would be nice to try to use it for this project. My question though: does anyone know what the vacforming moulds looked like ? I am assuming that the bucket was vacformed from at least 3 or 4 moulds (front, back and dome) but I could be wrong.

Cheers!

Last edited: