Been putting this off for way too long, so I figured starting a thread would hold me to some level of accountability. I mean, I can't just leave all you guys hanging after all...right? RIGHT?

So my budget is INCREDIBLY limited. I've got Kingjawas Han...and that's it. So the rest of this build is going to be scratch built.

That being said, I would have LOVED to get zenix box kit like so many of you get to use, but I couldn't swing it.

Here's a bit of full disclosure. I've been sitting on this build for a LONG time...because the plans with all their odd angles, etc stressed me out.

I decided to grip it and rip it. So on with the show.

First up, the box. More importantly, the cutouts. The goal here is to get accuracy...and repeat-a-bility. That's not a word, big whoop, wanna fight about it?

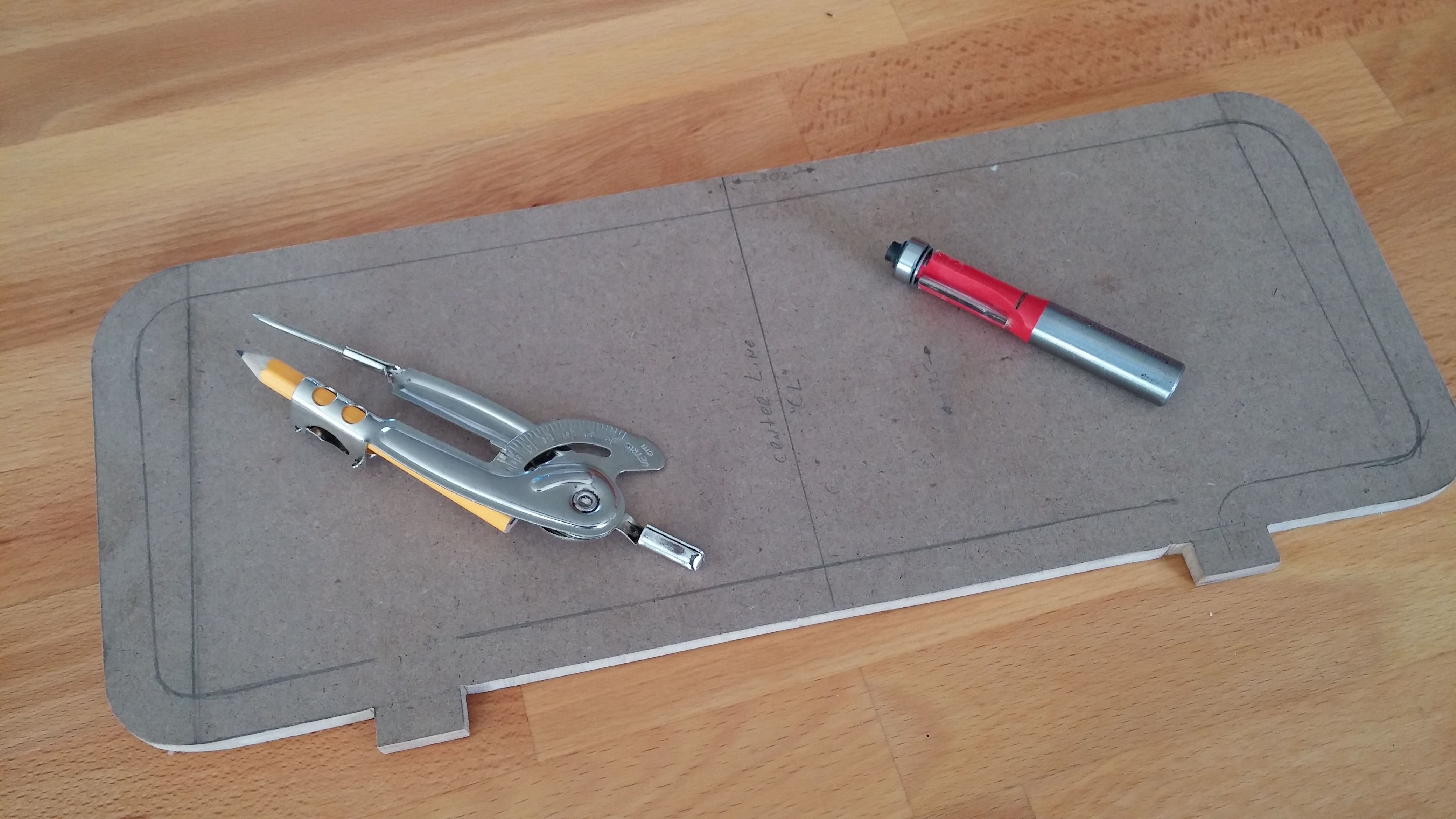

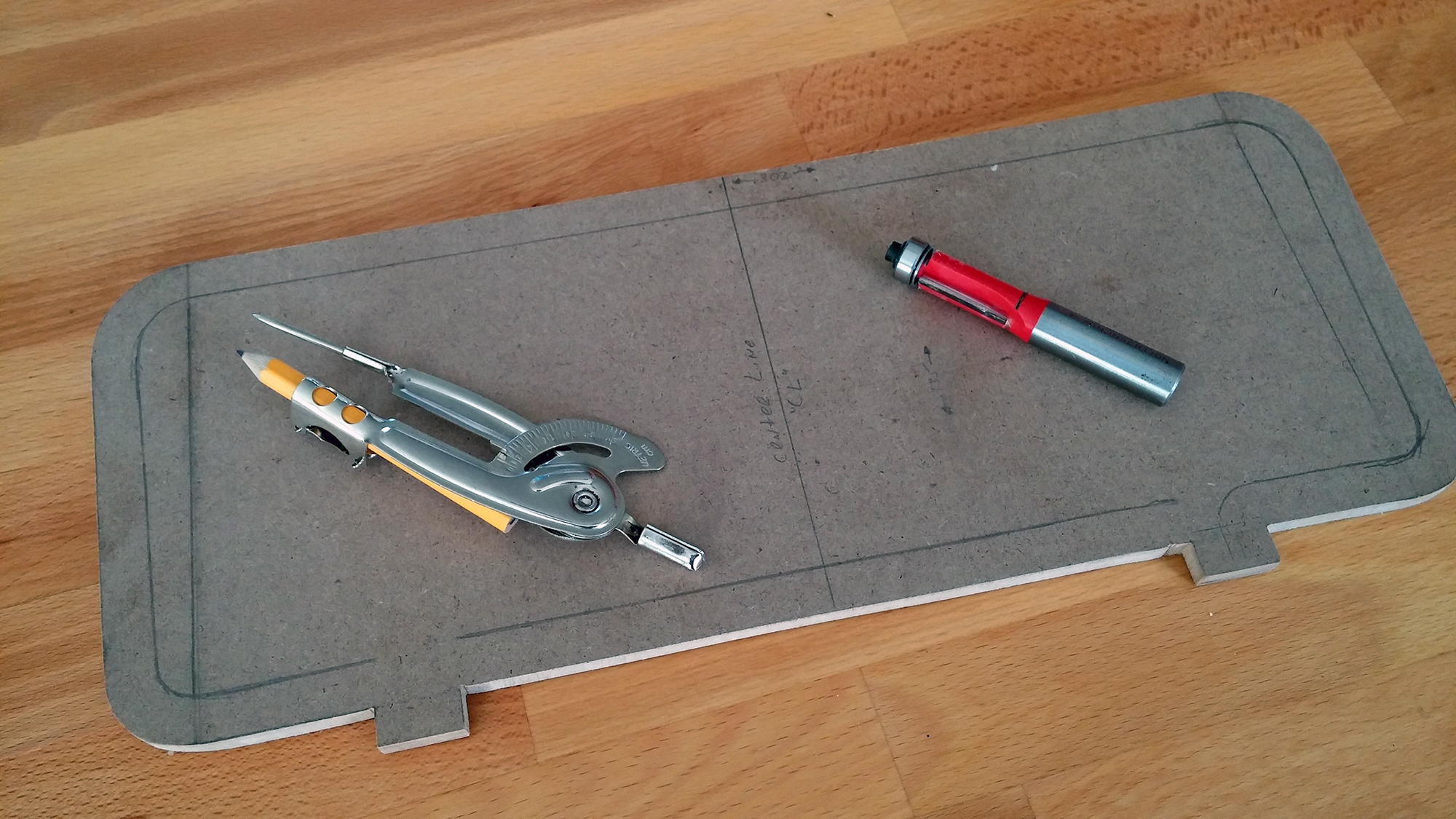

So I grabbed a piece of 1/4" MDF and got to sketching. After some time on the table saw, and 12" disc sander I've got this.

That's to the exact specs of the HIC blue prints for the cutout. I want to use this as a template, so now I have to factor in my pattern bit. I suppose I could have done it to begin with, but I tried...and no matter what I did, it wasn't right. I hate math. Sue me. So I measured the size on the pattern bit from blade to blade with a set of calipers, set my compass, and traced the outside edge marking the distance.

Bandsaw, table saw, and disc sander again...and I ended up with this:

Drill a couple holes to allow my pattern bit access to the template, and secured the reduced template to another 1/4" sheet of MDF with double sided tape.

Ran it through the router table, and I'm left with this:

Cut the inside out, did a little touch up, and voila!

I'll use this on the long sides of the HIC box using the same process. Double sided stick tape and a pattern bit on the router table. This will let me get perfect cuts, and do so quickly. I'm going to get the wood for the box tomorrow, so there should be more to show tomorrow night.

Get an additional $100 off your Glowforge Laser Cutter purchase with this URL: glowforge.com/referred/?kid=FrvUGs

Offer good until 10/24/2015!

So my budget is INCREDIBLY limited. I've got Kingjawas Han...and that's it. So the rest of this build is going to be scratch built.

That being said, I would have LOVED to get zenix box kit like so many of you get to use, but I couldn't swing it.

Here's a bit of full disclosure. I've been sitting on this build for a LONG time...because the plans with all their odd angles, etc stressed me out.

I decided to grip it and rip it. So on with the show.

First up, the box. More importantly, the cutouts. The goal here is to get accuracy...and repeat-a-bility. That's not a word, big whoop, wanna fight about it?

So I grabbed a piece of 1/4" MDF and got to sketching. After some time on the table saw, and 12" disc sander I've got this.

That's to the exact specs of the HIC blue prints for the cutout. I want to use this as a template, so now I have to factor in my pattern bit. I suppose I could have done it to begin with, but I tried...and no matter what I did, it wasn't right. I hate math. Sue me. So I measured the size on the pattern bit from blade to blade with a set of calipers, set my compass, and traced the outside edge marking the distance.

Bandsaw, table saw, and disc sander again...and I ended up with this:

Drill a couple holes to allow my pattern bit access to the template, and secured the reduced template to another 1/4" sheet of MDF with double sided tape.

Ran it through the router table, and I'm left with this:

Cut the inside out, did a little touch up, and voila!

I'll use this on the long sides of the HIC box using the same process. Double sided stick tape and a pattern bit on the router table. This will let me get perfect cuts, and do so quickly. I'm going to get the wood for the box tomorrow, so there should be more to show tomorrow night.

Get an additional $100 off your Glowforge Laser Cutter purchase with this URL: glowforge.com/referred/?kid=FrvUGs

Offer good until 10/24/2015!

Last edited by a moderator: