Coz

Sr Member

Scored a resin BR blaster kit offa eBay, and decided to go as all-out on it as I can - given that this is my first real resin gun, and I'm a noob.

It's a Wilco kit, great detail, REALLY light and a nice quick resin to work with. Not brittle either. I think I'm gonna have to deal with these guys direct, as they have some other cool stuff too.

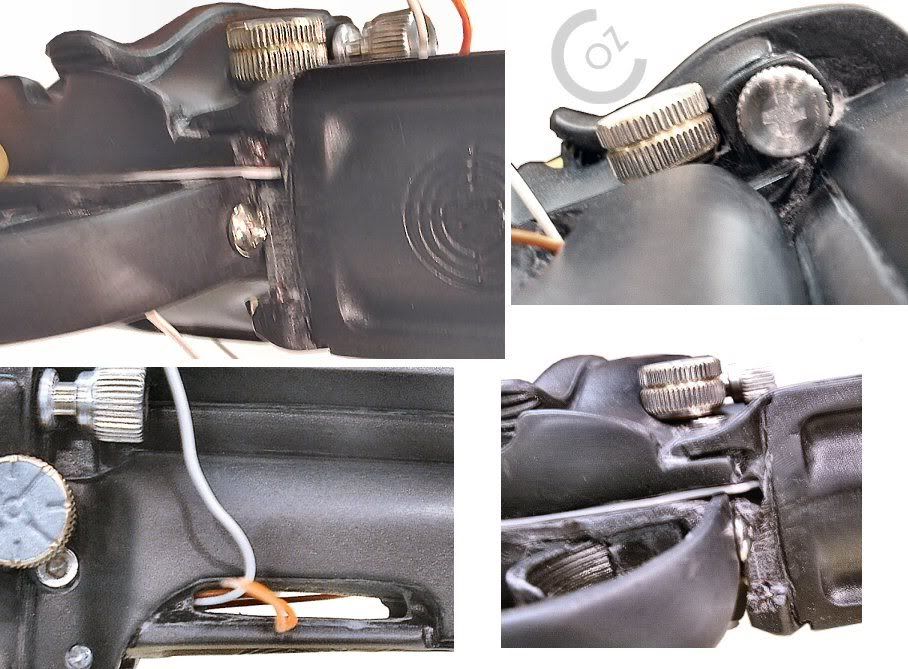

Even though the alan screws and screw heads were almost all blemish free, I decided to replace all of them, and to try and fix some of the inaccuracies.

So I drilled out the heads and ground them down with my Dremel and a milling bit - made a heck of a mess.

Also at this point, I cut off the trigger guard to allow me to add a moving trigger (glutton for punishment.).

Tricky thing was getting the correct size allan bolts - both cap and button head.

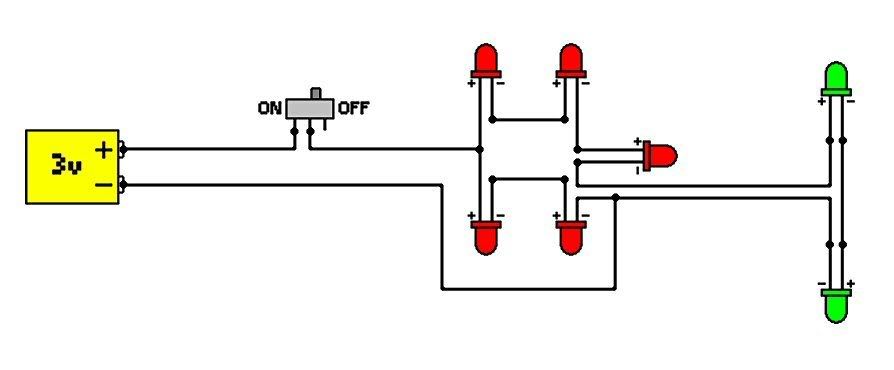

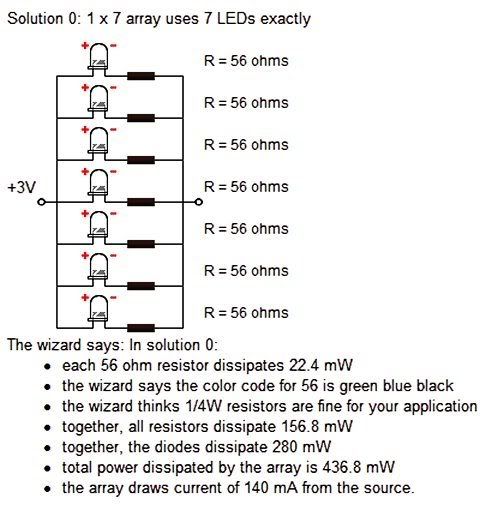

After a little thinkin', I decided to add working LEDs too - which is gonna be a pain in the (guess where.). But fun, anyway.

Pics to follow.

It's a Wilco kit, great detail, REALLY light and a nice quick resin to work with. Not brittle either. I think I'm gonna have to deal with these guys direct, as they have some other cool stuff too.

Even though the alan screws and screw heads were almost all blemish free, I decided to replace all of them, and to try and fix some of the inaccuracies.

So I drilled out the heads and ground them down with my Dremel and a milling bit - made a heck of a mess.

Also at this point, I cut off the trigger guard to allow me to add a moving trigger (glutton for punishment.).

Tricky thing was getting the correct size allan bolts - both cap and button head.

After a little thinkin', I decided to add working LEDs too - which is gonna be a pain in the (guess where.). But fun, anyway.

Pics to follow.