You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DL-44 FDM c96 & MGC replicas…

- Thread starter chubsANDdoggers

- Start date

I really appreciate you giving some insight on this. It’s really coming down a circuit or the silhouette I’m thinking. I grabbed this blaster off one of your threads. Is this rail created from your silhouette? Looks great and this is also one of the things I’d like to use it for as well. Make life a little easier and help calm the OCDism that can fester..I have an older Silhouette, picked it from from a gal at work (only $60! She’s always buying new craft gadgets). I’ve used it for masks a lot of times - I did the scratches on my DL-44 with it (can dig up pics, maybe you remember?), as well as the markings on a 1/350 Enterprise and a few other things. It can kind of cut styrene too, but not super clean. Very useful otherwise though! I’m not sure if the newer machines are that much better for this purpose.

Yes definitely. It’s not that difficult really. Im sure others have either done it or something similar anyways. A few things can go wrong so u do have to measure, line up and drill appropriately. I’m more than happy to share. Let me just gather my thoughts first..Can you show us more about how you mod the top so it sits differently?

Yep, that's the one, thought I've made a lot of "special modifications" since then.I really appreciate you giving some insight on this. It’s really coming down a circuit or the silhouette I’m thinking. I grabbed this blaster off one of your threads. Is this rail created from your silhouette? Looks great and this is also one of the things I’d like to use it for as well. Make life a little easier and help calm the OCDism that can fester..View attachment 1452355

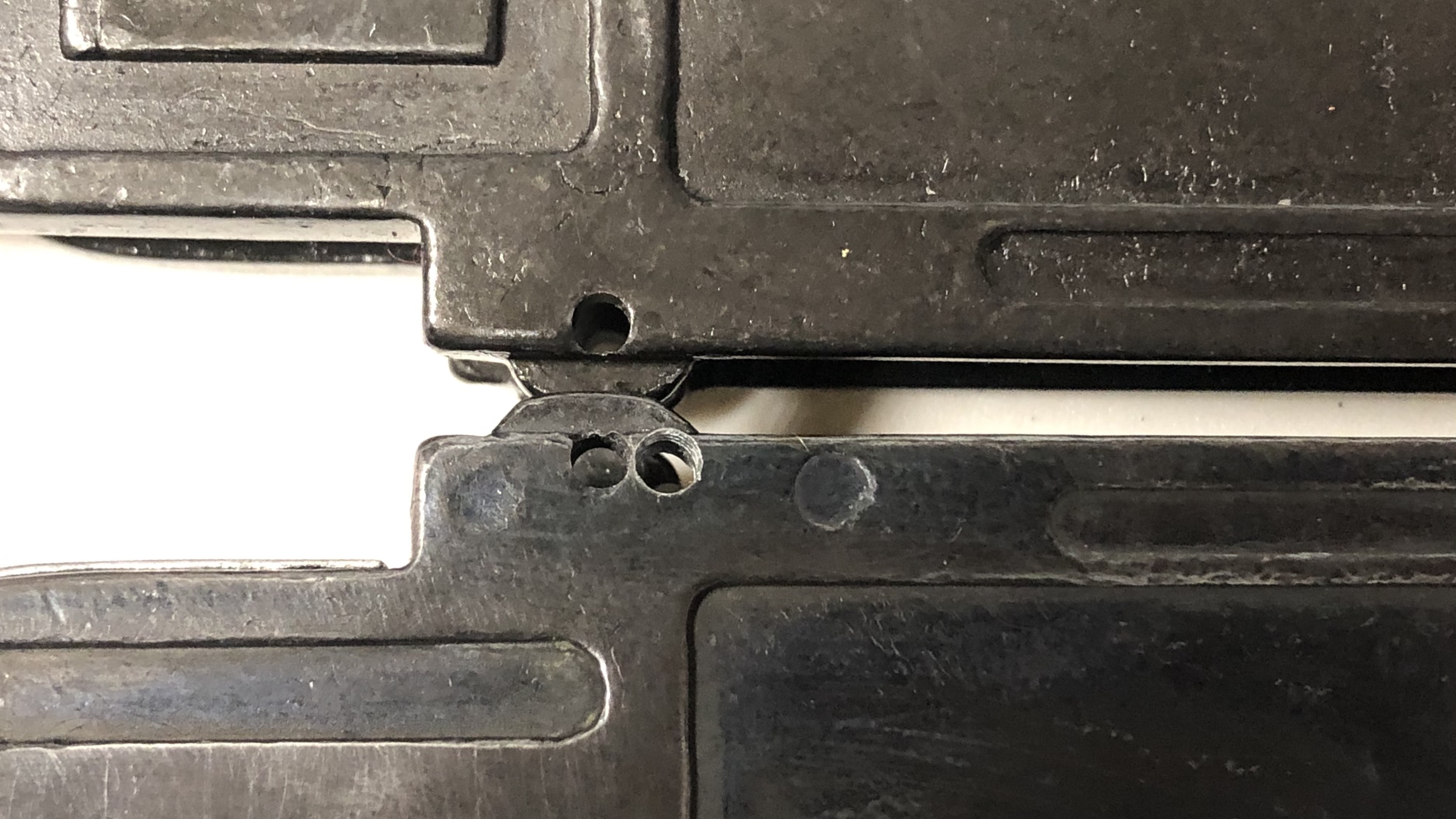

There are 4 mods you need to do to slide the top of the denix forward. Once you get the denix separated you can begin by sanding down the front two lips on the bottom half of the denix. This will allow you to slide forward the top half and proceed to the next mod. Dremel works perfect here..

Next you need to create two new holes in the back for new pin placement. This can be tough because if you don’t do it right your denix will sit awkwardly on an angle or the pins won’t fit at all..

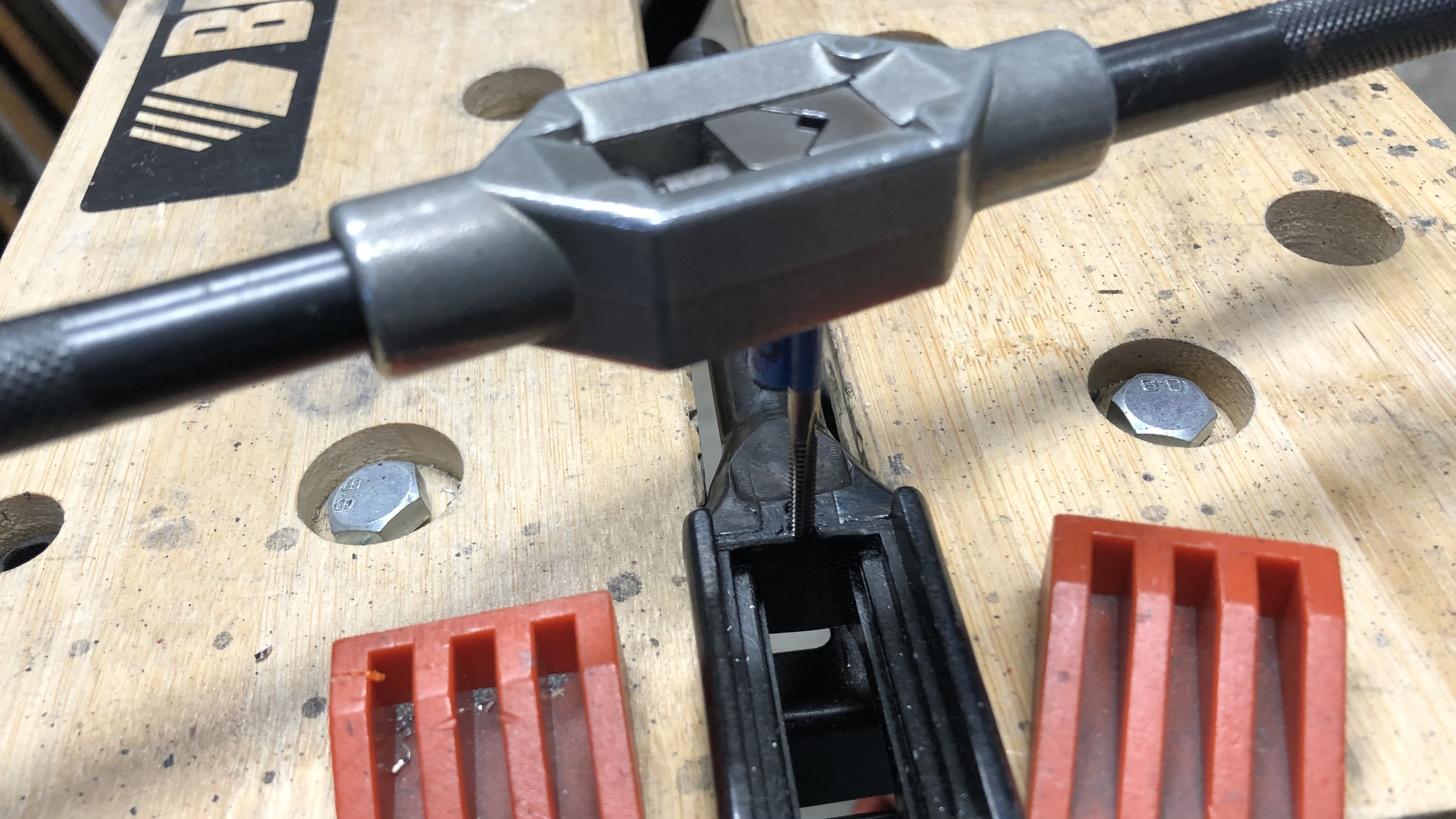

So the best method I’ve figured out to avoid all that.. is simply to use the pin itself, a hammer and a center punch..

Attach the top now that the front lips have been removed. Line everything up and hammer the pin in place so it will leave a circle mark as a guide. From there use the center punch to mark it and start drilling. I use a 1/8 drill bit so the whole is big enough for the pin..

Now IMHO the hardest part of this mod. I have a mini mill which helps a lot here but I originally did it will a drill. You have to move that front hole back on the top part of the denix. But just make sure you drill straight down when creating this new hole. If not the hole will slip out the back or towards the front hole itself and then you’re up the creek at this point.

I basically use the center punch to create a hole that is dead center to the hole that’s there and the back. Then drill straight down..

After I have this hole template I redrill with a 7/64 drill and tap with a 6/32 tap..

The last mod is taking off some metal on the inside metal part. Sorry I don’t know the technical names of these parts but it should be obvious what I mean I guess. Simply reduce the sides so it allows the modded top and bottom to fit accordingly. Cut approximately 0.160 inch off each side. Otherwise it will restrict the top from sliding back..

After that, unless I missed something you should be good to go. Just reassemble everything and here you have it..

If you see how this can be done differently or think of any tricks to improve these mods please share. Feedback is more than welcomed as well.

But once you get all the parts in place and do those earlier mods I posted about (redoing the grips and shaving down the frame) as well as adding a new trigger and hammer I think the results do speak for themselves? I did create a c96 hammer FYI that you can sub in directly and it will line up perfectly with all these mods..

Next you need to create two new holes in the back for new pin placement. This can be tough because if you don’t do it right your denix will sit awkwardly on an angle or the pins won’t fit at all..

So the best method I’ve figured out to avoid all that.. is simply to use the pin itself, a hammer and a center punch..

Attach the top now that the front lips have been removed. Line everything up and hammer the pin in place so it will leave a circle mark as a guide. From there use the center punch to mark it and start drilling. I use a 1/8 drill bit so the whole is big enough for the pin..

Now IMHO the hardest part of this mod. I have a mini mill which helps a lot here but I originally did it will a drill. You have to move that front hole back on the top part of the denix. But just make sure you drill straight down when creating this new hole. If not the hole will slip out the back or towards the front hole itself and then you’re up the creek at this point.

I basically use the center punch to create a hole that is dead center to the hole that’s there and the back. Then drill straight down..

After I have this hole template I redrill with a 7/64 drill and tap with a 6/32 tap..

The last mod is taking off some metal on the inside metal part. Sorry I don’t know the technical names of these parts but it should be obvious what I mean I guess. Simply reduce the sides so it allows the modded top and bottom to fit accordingly. Cut approximately 0.160 inch off each side. Otherwise it will restrict the top from sliding back..

After that, unless I missed something you should be good to go. Just reassemble everything and here you have it..

If you see how this can be done differently or think of any tricks to improve these mods please share. Feedback is more than welcomed as well.

But once you get all the parts in place and do those earlier mods I posted about (redoing the grips and shaving down the frame) as well as adding a new trigger and hammer I think the results do speak for themselves? I did create a c96 hammer FYI that you can sub in directly and it will line up perfectly with all these mods..

Last edited:

Thanks for the detail! Time to get to work...  I hate that screw under the barrel anyway, on mine I ground it diwn flat so at least it’s less visible. I think maybe a grin screw and cap could be a good fix here.

I hate that screw under the barrel anyway, on mine I ground it diwn flat so at least it’s less visible. I think maybe a grin screw and cap could be a good fix here.

Oh, and you can get a small drill press for about the cost of a Denix, might be worth it since you make so many! I love mine.

Oh, and you can get a small drill press for about the cost of a Denix, might be worth it since you make so many! I love mine.

Pedro ive been looking at a drill press but I’ve actually been saving for a bigger “mini” mill that will also work as a press I’m hoping. My mini mill works wonders for my needs but I do break a few to many of the bits unfortunately.

I also use that same mill to take down that front screw so its as flat as possible. You’re 100% it definitely helps with the look for sure. I’ll have to look into a “grin screw” as I’m not even sure what that is honestly. But another option is just not using the screw but just epoxying it together. If you don’t mind not being able to take it apart that is. You can fill in all the pin holes and definitely improve the look. I don’t do that anymore simply because when I add the lock frame I need to scratch off the excess glue once dried. It’s easier to use aluminum black to fix it afterwords but to cover the pins you would need to paint so I haven’t figured out a way to do both unfortunately just yet??

I also just invested in a cricut as it was on sale at target. I appreciate your offer and if I have trouble designing mine up I’ll probably take you up on it. I’d like to have a go myself first though. That’s the part I find most enjoyable about the hobby personally. The creation

Here is this Mauser I was moding all finished as a Bespin

I also use that same mill to take down that front screw so its as flat as possible. You’re 100% it definitely helps with the look for sure. I’ll have to look into a “grin screw” as I’m not even sure what that is honestly. But another option is just not using the screw but just epoxying it together. If you don’t mind not being able to take it apart that is. You can fill in all the pin holes and definitely improve the look. I don’t do that anymore simply because when I add the lock frame I need to scratch off the excess glue once dried. It’s easier to use aluminum black to fix it afterwords but to cover the pins you would need to paint so I haven’t figured out a way to do both unfortunately just yet??

I also just invested in a cricut as it was on sale at target. I appreciate your offer and if I have trouble designing mine up I’ll probably take you up on it. I’d like to have a go myself first though. That’s the part I find most enjoyable about the hobby personally. The creation

Here is this Mauser I was moding all finished as a Bespin

Last edited:

May the 4th be with you.. always!

Hahah! "Grin" screw = autocorrect! I meant a GRUB screw lol (or set screw).

Which mill do you have? I've almost bought a Proxon about 10 times now but went with 3d printing instead, which I think I get more use out of. Love the pic with the Luke figure...I adored that figure when I was a kid! His little Graflex!! <3

Which mill do you have? I've almost bought a Proxon about 10 times now but went with 3d printing instead, which I think I get more use out of. Love the pic with the Luke figure...I adored that figure when I was a kid! His little Graflex!! <3

Proxxon micro mill. Probably the exact same one you uve been contemplating. It takes a little getting use to as everything has to be done by hand but I’ve figured it out pretty well. Once you do have the turns figured out you can repeat the process pretty quickly. It’s extremely accurate and I’m able to create the extraction details to a T! I have an extraction mark deisgned up that I 3d print, then mill in the spacing for it with that mini mill. I do the bullbarrel for my ANH as well as a few other details. Honestly it’s truly amazing what you can accomplish with it. I love it.

Here is also a Han Bespin set up the same as that Luke. This is a repackaged original Kenner figure but ya these are very nostalgic!

Here is also a Han Bespin set up the same as that Luke. This is a repackaged original Kenner figure but ya these are very nostalgic!

Last edited:

Currently using an old Elegoo Mars and Kelant s400. I intend to get a new 8.9” 4K printer soon, but dammit if the FM Mando blaster wasn’t on sale the other day haha! Even with the older printers I get very good results, but resin printing is tricky, and resin does tend to be brittle (can get less brittle resin for $$ though!)

Thanks man! It actually wasn’t that difficult all things considering. That mill is very accurate so basically just trace out the shape and then start counting ur turns along the way until it’s all traced out. But regardless it’s a pretty good feeling when it does fit so snugly. These builds are like the best adult LEGO’s one can have. Truly very rewarding. If you ever want to try you hand with some of my parts or you want me to mill in some of these details let me. I’d be happy to help if I can.Nice work on those extractors!! That must have taken some practice! I had some laser cut from stainless steel for my blasters, cheap too! But no milled recess. Yours are so cool!

Last edited:

My Stembridge replica parts vs the actual Filming prop..

Very nice as always!

Is that a photo of the actual Stembridge at the top there?

Is that a photo of the actual Stembridge at the top there?

YepVery nice as always!

Is that a photo of the actual Stembridge at the top there?

Here’s a helpful pic (3rd below) of the Stembridge prop I doctored to help bring out its details. It’s a blend of these first two pics of the actual film prop itself..

Yes that’s the mill I use to create all my details. I can’t recommend it enough but unfortunately it won’t do the Endor blasters left side though. The machine and the mill bits themselves are just to small. I did create these parts though that work in a pinch if needed..Is the Proxxon mill you have the MF 70? Do you think it would work for the mill marks on the side of the ROTJ DL-44?

Similar threads

- Replies

- 2

- Views

- 556

- Replies

- 9

- Views

- 734

- Replies

- 0

- Views

- 330