Thrashers

New Member

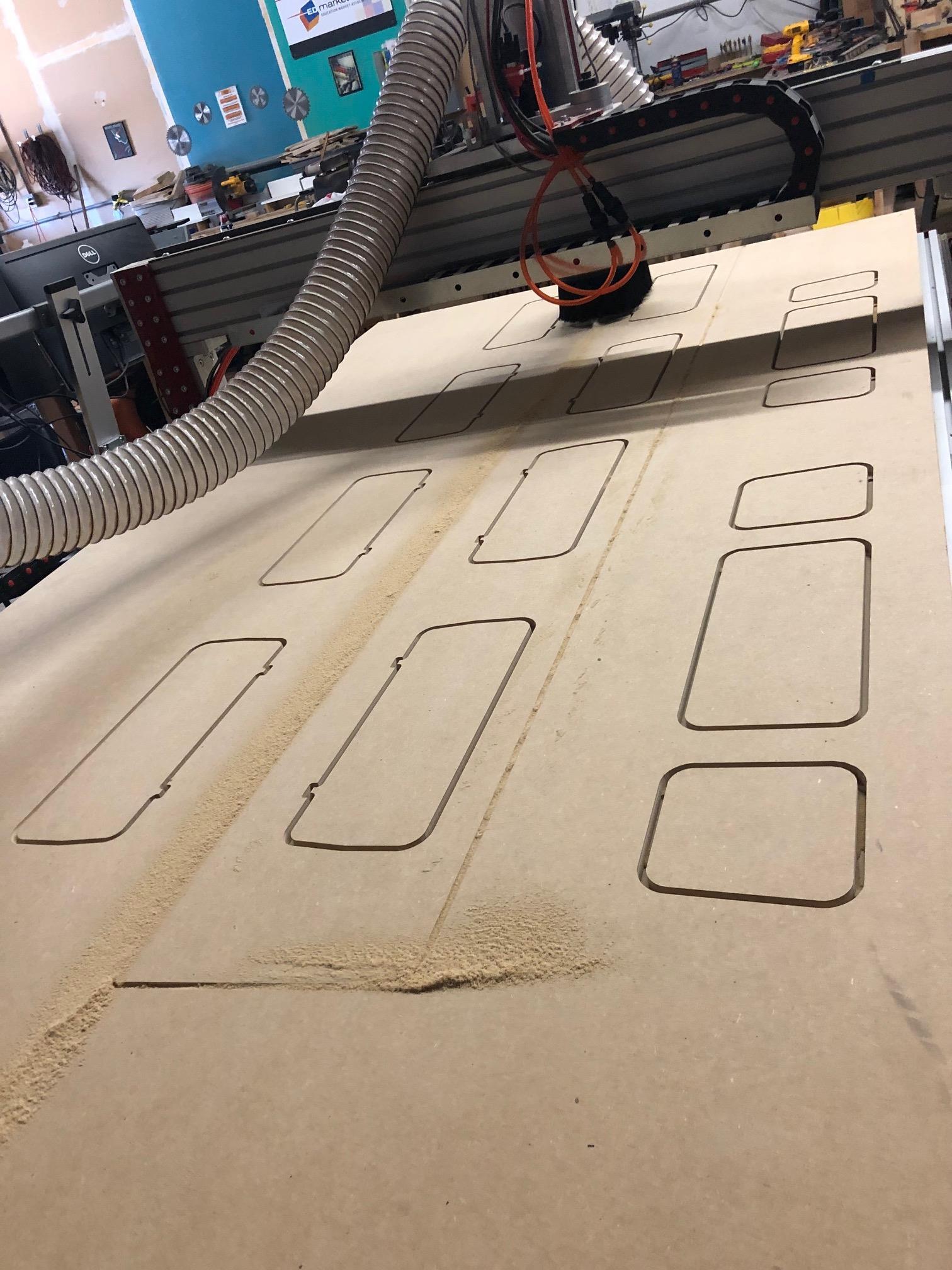

I'm new here been lurking for awhile & figured I document my Han Solo in carbonite build here. I've been planning on this build for several years and just recently pulled the trigger and started. I wanted to do as much of this myself, learn some stuff along the way, & stay budget conscious. I had access to a CNC machine & 3d printers through a maker space i joined so I'm taking advantage of that. I cut my own box using the blueprints and DXF files on the Yahoo HIC builders group. I also am printing out the side panels and greebles from the files that flimzy posted to Thingivere ( they are great need some resizing but VERY APPRECIATED)