It is my opinion that people put way more faith in laser scanning technology than they should.

It is by far not a perfect medium for replicating and will never be better than actual silicone touching the part.

Also, there is inevitable human error that comes into play as well when correcting flaws in the actual scan.

People's perceptions are that laser scanning can produce perfect duplicates in the real world.

But it can't.

It's not the same thing as a 'replicator' in Star Trek.

The more you understand this particular technology, the more you understand the advantages/disadvantages.

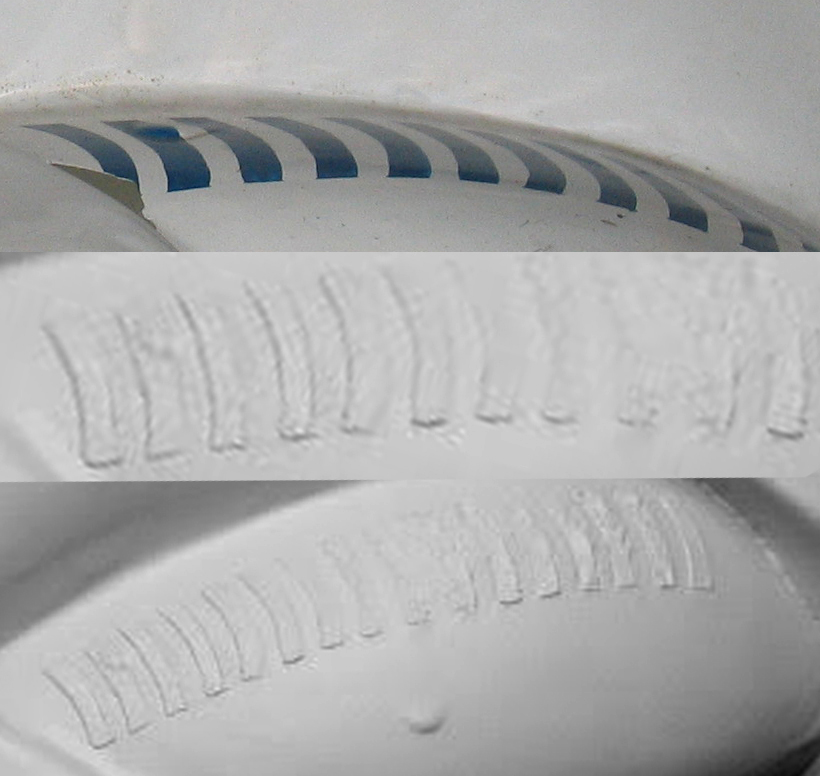

For example, observe some of the painted details.

It appears that the tubestripes and trap details are actually significantly raised off the surface on the scan modeling and subsequent print.

On that original helmet, they are not nearly as raised (if at all).

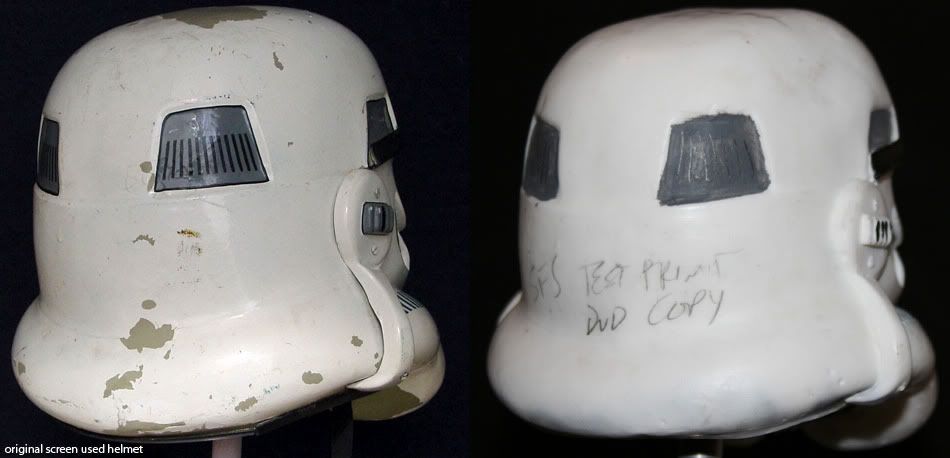

You can see that on the original, there is a paint flake on the front tube stripe, whereas on the scan, the front tube stripe is intact.

Something is amiss.

Here's a hi-res pic of the original SFS helmet at almost eye level showing what I mean.

Laser scanning and printing is great and can be used very effectively in certain applications.

But to say that it can create perfect tangible replicas is not quite accurate.

It will never be able to accurately print surface nuances. That is one of the greatest limitations of this technology.

.