Okay - so I built my first ESB Graflex stunt before I really knew a good chunk of what we do now. It used a Ski Pole as a blade, had random bolt placement, the core was too heavy and it used a threaded rod. Thankfully, the inaccurate modern CX-4 blade I made (coated in 3M Graphic film) technically fit because I drilled that to 3/8, so I got to pair it with a white reflective blade.

I don't have it anymore. It was sold to a family friend in the northeast US who saw Star Wars multiple times a day when it came out in theaters. He is absolutely head over heels and it makes me really happy!

Anyways, that leaves an empty space in my collection. Tom the Bolt Hunter is at it again.

Two things are bothering me.

1) We still don't know how the tang was held in. The countersunk bolts I'm 90% sure just hold the core assembly to the flash. I have embedded a grub screw in the Pipe Stunt core because we only see the 4 outer bolts. Tang removal is impossible with the core slid into the saber. (Granted, I hammered it into the saber)

EDIT: wait, maybe the little threaded hole in the pipe stunt also goes to the tang!? I always thought that was for the red button. The tapped hole does go into the core, but very high up, so I didn't think it was for structural use. Maybe not...

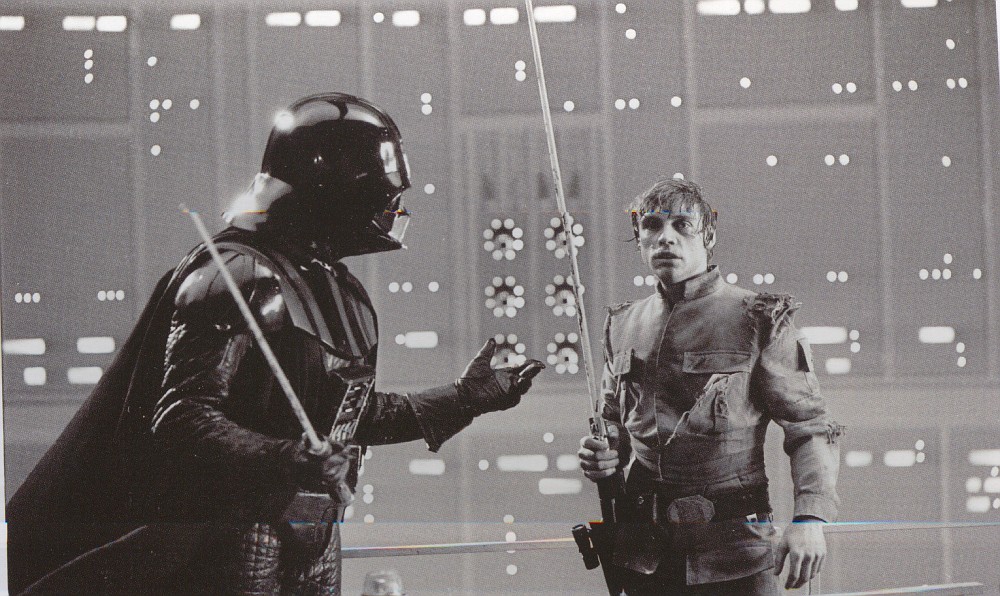

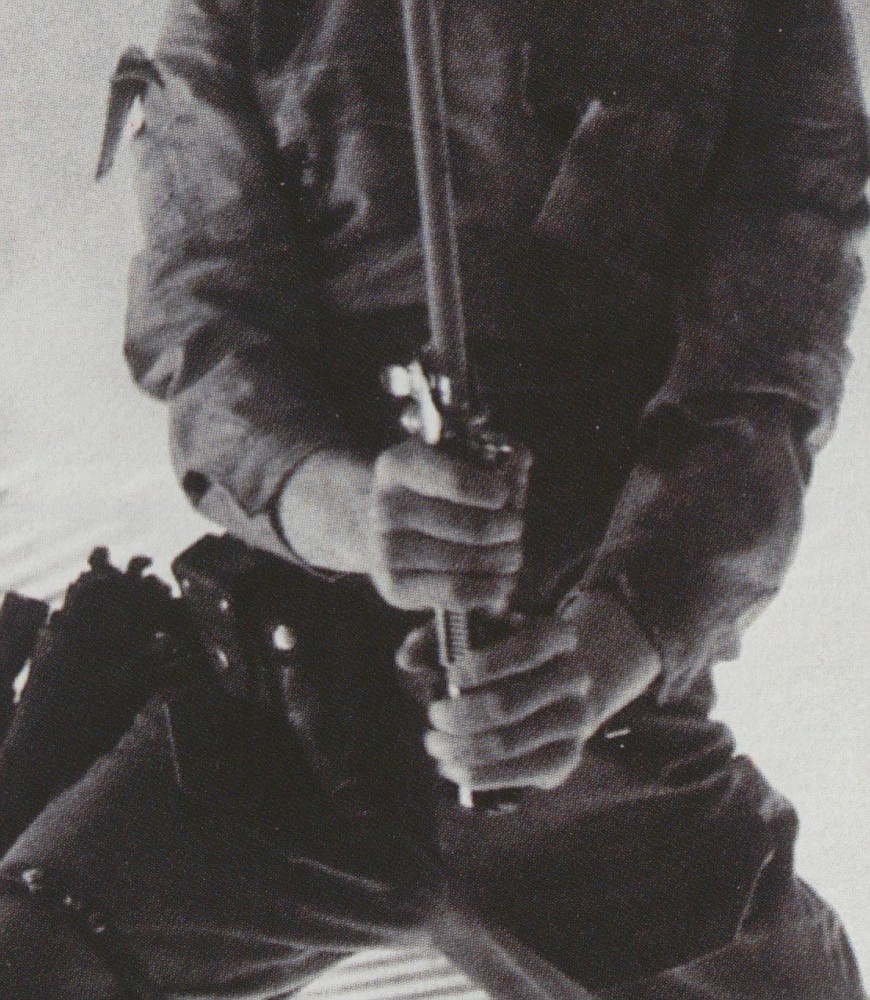

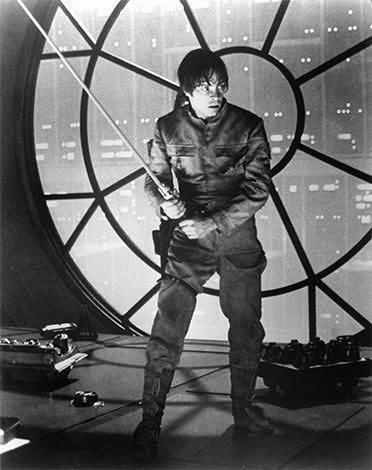

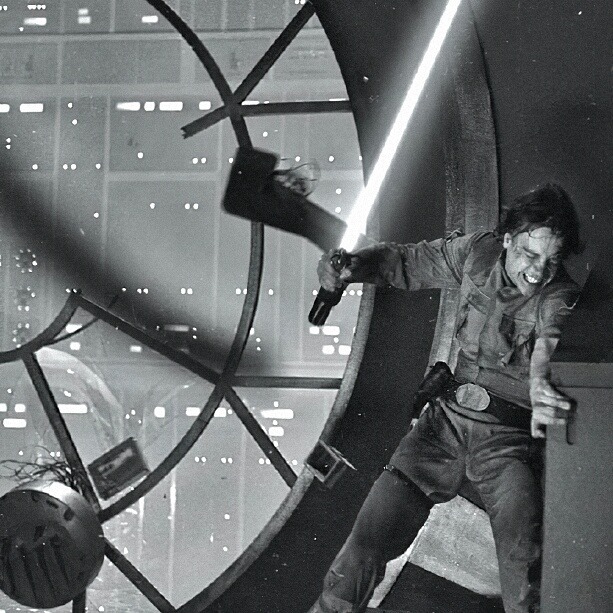

2) All the bolts are usually covered by Mark Hamill or Bob Anderson's hands... or aluminum foil. I'm not mad at him, of course not. The weight of the stunt saber is right behind the bolts. To properly fence you need your hands there. For us PropReplica makers, that makes this very tough.

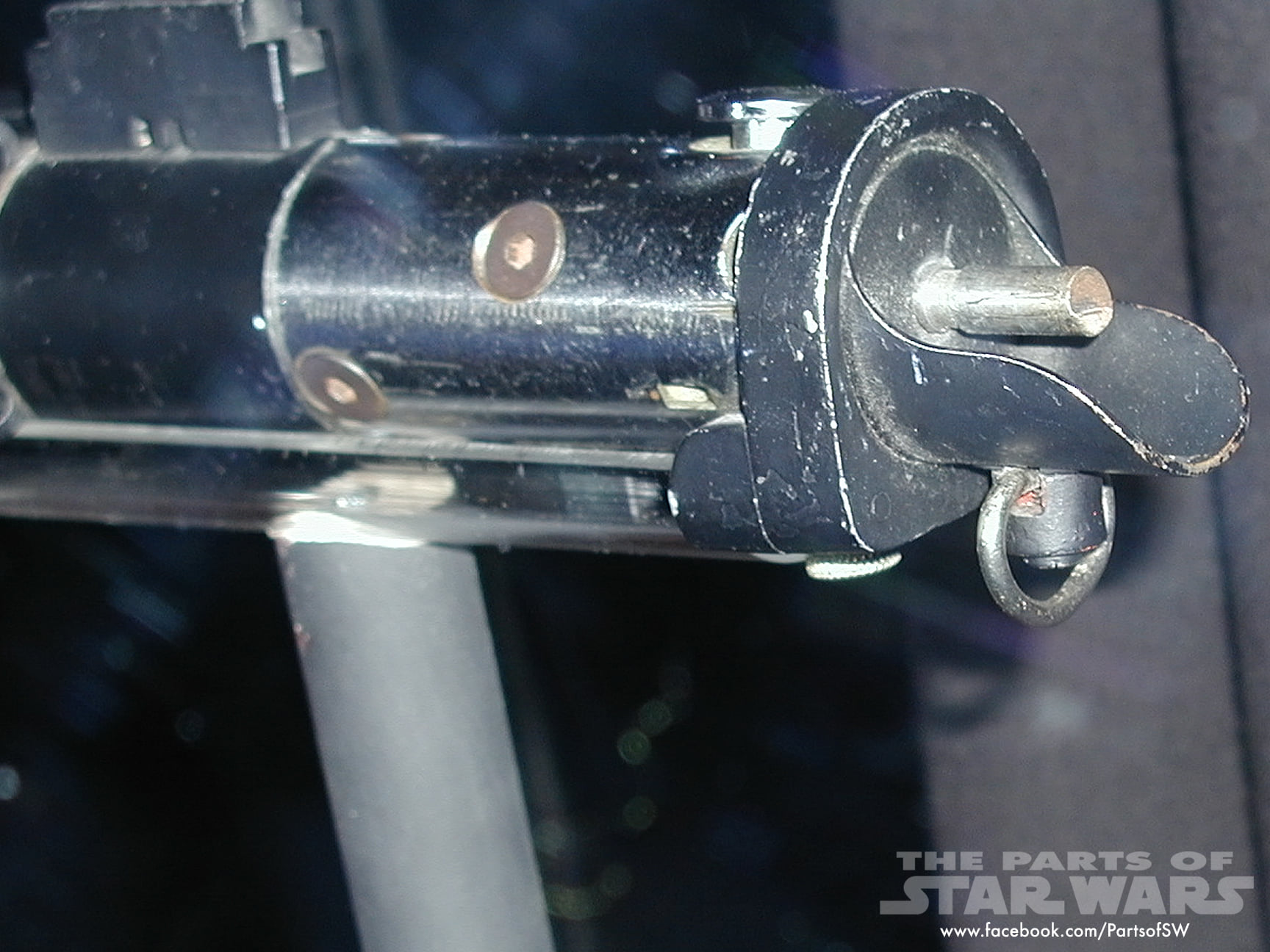

scottjua shot I think

Is this next one a scottjua picture

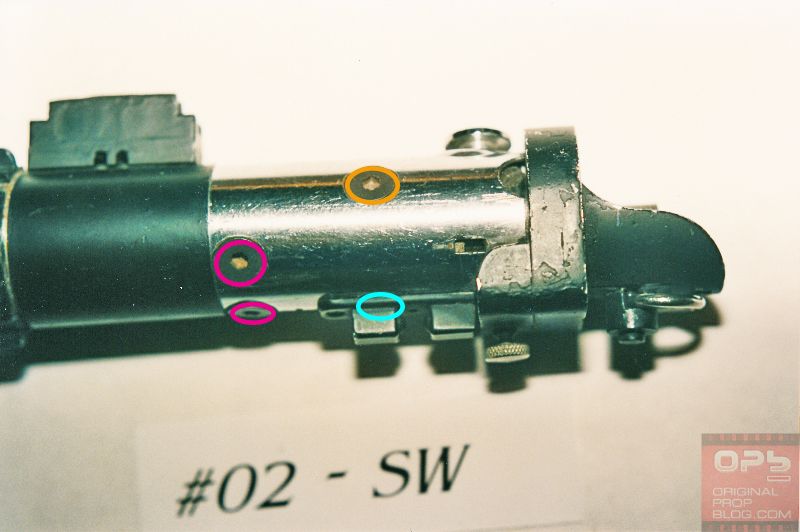

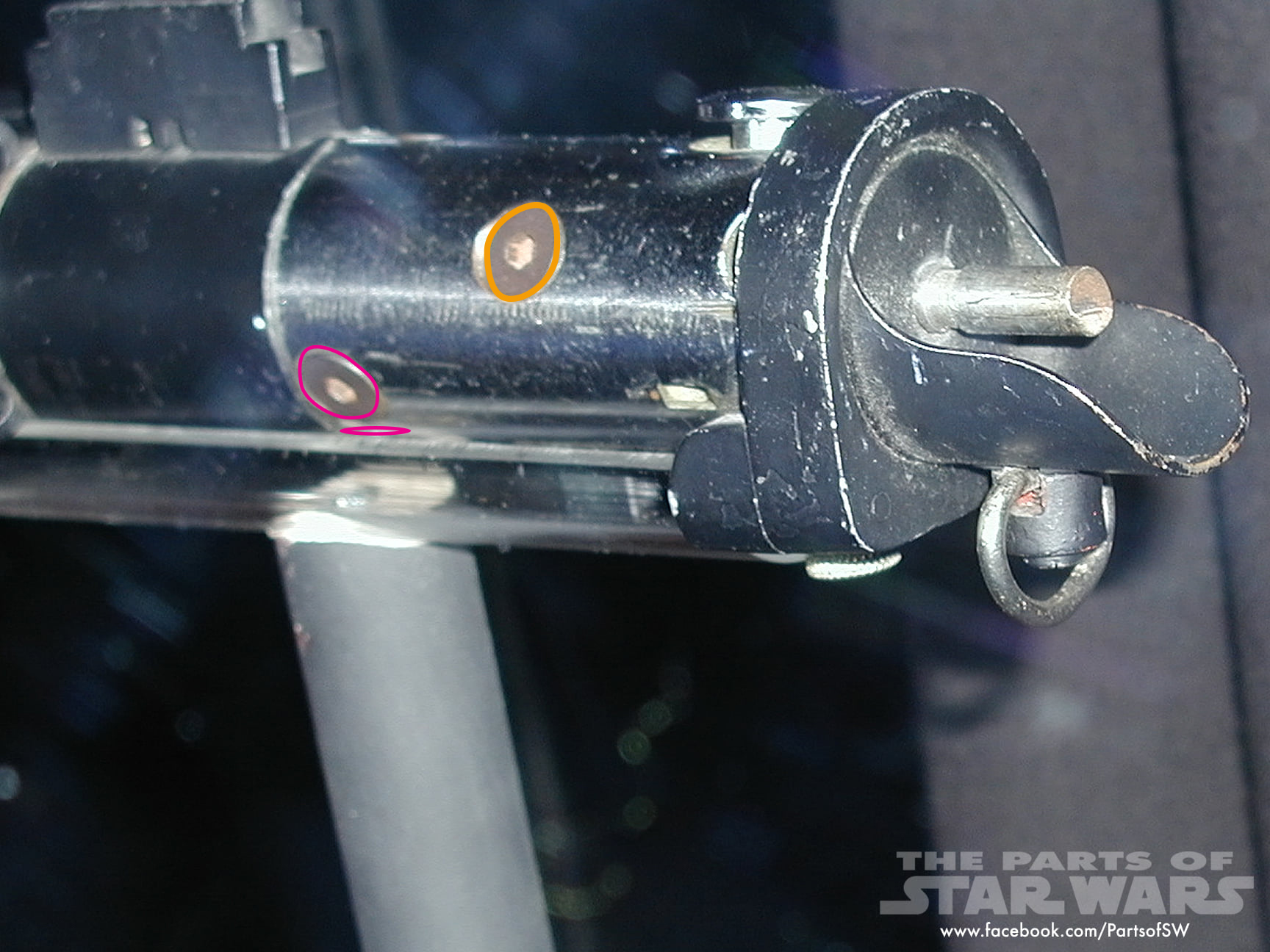

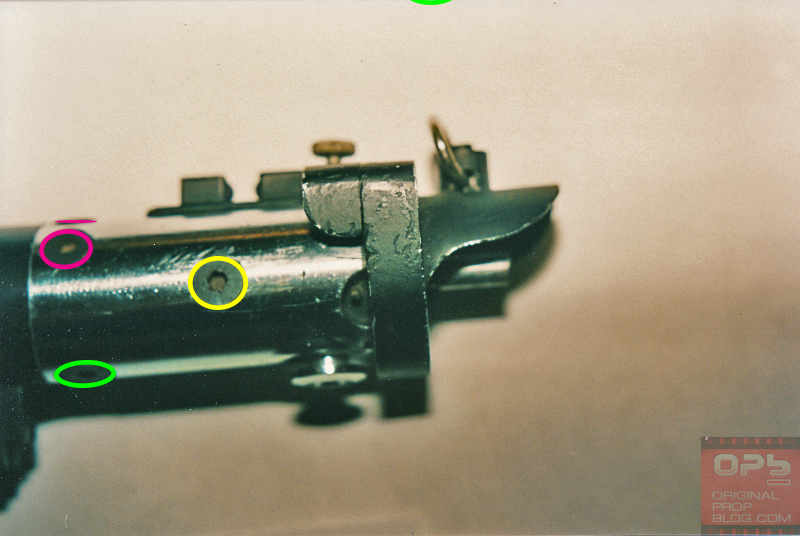

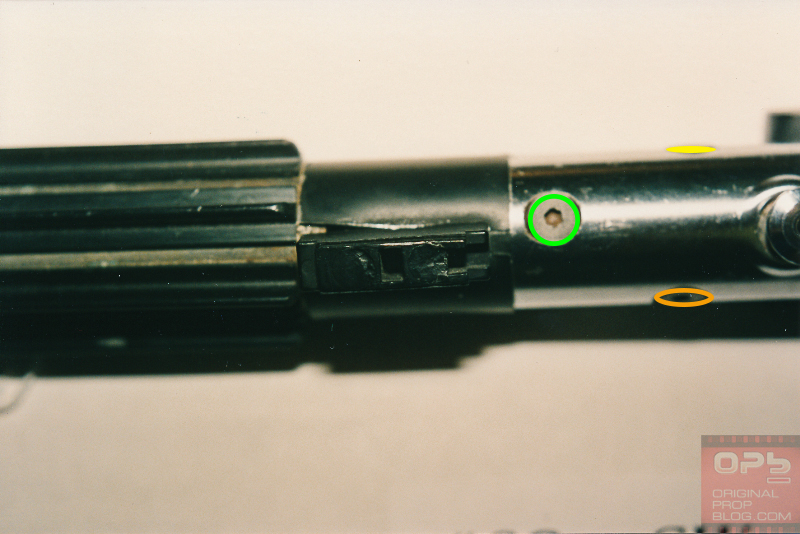

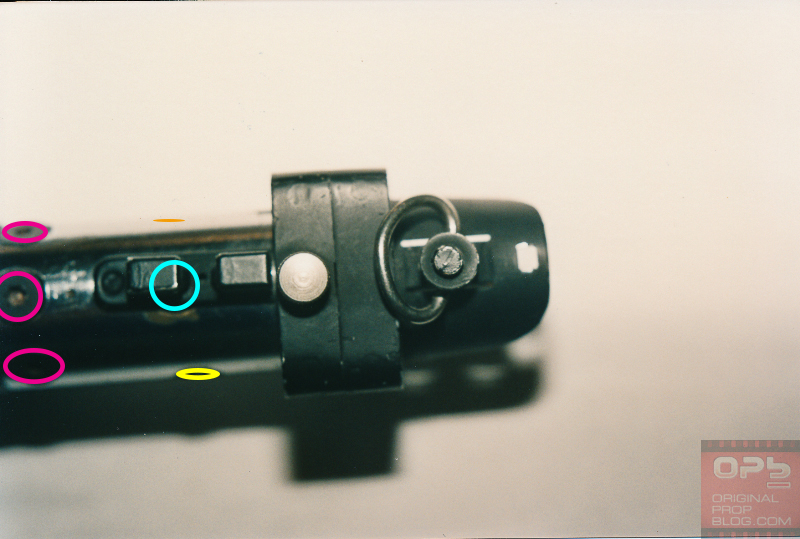

Following is the start of my research. I finally color-coded for my use.

Now, I'll start with this weird thing. The upper "puck" as I call it. The upper 1/3 of the socket is replaced by metal. Maybe they broke the upper piece.... because in some shots I don't see the evidence in the socket. There is also a mark on the side in some shots, that could be a bolt. I can't tell. If not.. we are missing a bolt for this part. The front 4-40 screw is not enough. I've tried this and the back flops up

I think it's painted black here, and the side-profile is hidden by the Vader Shroud. Thank you Parts of SW lonepigeon

Now, onto the bolts. I always thought they added more for the woodchop scene... maybe? I can't find the little group of 3 on the back (for example) in any ESB shots. I also cannot find any with bolts in the clamp. (The V3 mystery clamp) I started to think these might be the same saber when I noticed this off-set bolt

C'mon what are the chances of putting it there twice! There really isn't a reason to offset the bolt.

And now for some others....

The Right Side Bolt

The Left Side Bolt

???????

The Front Offset Bolt

The Back Bolt

So....yea... no left side bolt yet, no group of 3 on the back and no confirmed puck screws. And no tang access.

Unless they heavily lathed down bar stock to a snug fit, 1-3/8 round bar fits inside a graflex with a hair of wiggle room. My pipe stunt needed a press-fit to be snug, so maybe I'll use packing tape, but that may be too thick!

I have a real 3 cell with a nasty clamp and a thin knurled button ready for this project. I've hit a bit of a wall research wise..

I don't have it anymore. It was sold to a family friend in the northeast US who saw Star Wars multiple times a day when it came out in theaters. He is absolutely head over heels and it makes me really happy!

Anyways, that leaves an empty space in my collection. Tom the Bolt Hunter is at it again.

Two things are bothering me.

1) We still don't know how the tang was held in. The countersunk bolts I'm 90% sure just hold the core assembly to the flash. I have embedded a grub screw in the Pipe Stunt core because we only see the 4 outer bolts. Tang removal is impossible with the core slid into the saber. (Granted, I hammered it into the saber)

EDIT: wait, maybe the little threaded hole in the pipe stunt also goes to the tang!? I always thought that was for the red button. The tapped hole does go into the core, but very high up, so I didn't think it was for structural use. Maybe not...

2) All the bolts are usually covered by Mark Hamill or Bob Anderson's hands... or aluminum foil. I'm not mad at him, of course not. The weight of the stunt saber is right behind the bolts. To properly fence you need your hands there. For us PropReplica makers, that makes this very tough.

scottjua shot I think

Is this next one a scottjua picture

Following is the start of my research. I finally color-coded for my use.

Now, I'll start with this weird thing. The upper "puck" as I call it. The upper 1/3 of the socket is replaced by metal. Maybe they broke the upper piece.... because in some shots I don't see the evidence in the socket. There is also a mark on the side in some shots, that could be a bolt. I can't tell. If not.. we are missing a bolt for this part. The front 4-40 screw is not enough. I've tried this and the back flops up

I think it's painted black here, and the side-profile is hidden by the Vader Shroud. Thank you Parts of SW lonepigeon

Now, onto the bolts. I always thought they added more for the woodchop scene... maybe? I can't find the little group of 3 on the back (for example) in any ESB shots. I also cannot find any with bolts in the clamp. (The V3 mystery clamp) I started to think these might be the same saber when I noticed this off-set bolt

C'mon what are the chances of putting it there twice! There really isn't a reason to offset the bolt.

And now for some others....

The Right Side Bolt

The Left Side Bolt

???????

The Front Offset Bolt

The Back Bolt

So....yea... no left side bolt yet, no group of 3 on the back and no confirmed puck screws. And no tang access.

Unless they heavily lathed down bar stock to a snug fit, 1-3/8 round bar fits inside a graflex with a hair of wiggle room. My pipe stunt needed a press-fit to be snug, so maybe I'll use packing tape, but that may be too thick!

I have a real 3 cell with a nasty clamp and a thin knurled button ready for this project. I've hit a bit of a wall research wise..