ONEYE

Sr Member

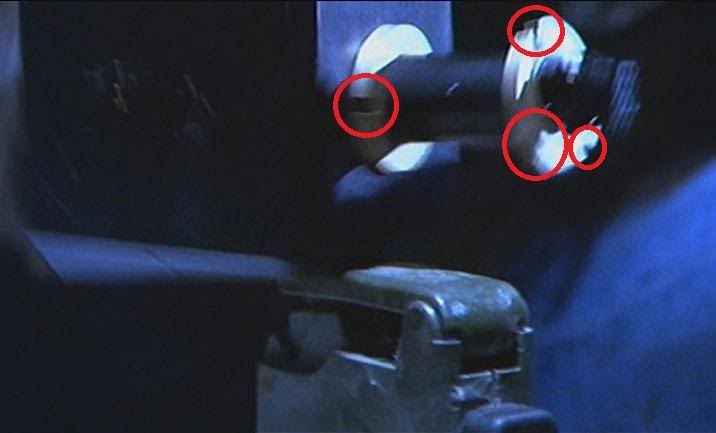

Here are the dimensions for the one that was made long ago in a secret undisclosed location. The mold is gone and the only one that was made has been lost (in time/space).

Terminator Chip pictures by polsnulspace - Photobucket

Not a difficult prop... simple design, 3 components.

-- Block, 4.0" square, 0.375" bevel (all edges).

-- Pipe, 1.25" OD, 2.0" L (showing).

-- Flange, 2.0" OD, 1.25" ID, 0.25" thick.

180+ parts so all I can say to whoever tries to make this - have fun with all the parts. I mean, that's if they want to do it the way I did with individual flanges. Still a lot of parts. Also, casting is not cheap.

Terminator Chip pictures by polsnulspace - Photobucket

Last edited by a moderator: