Yeah, I know, it's not something you could get away with at a convention or most public places, but darned if I don't want to get metal blades just to satisfy the fanboy in me. I even know exactly what I want:

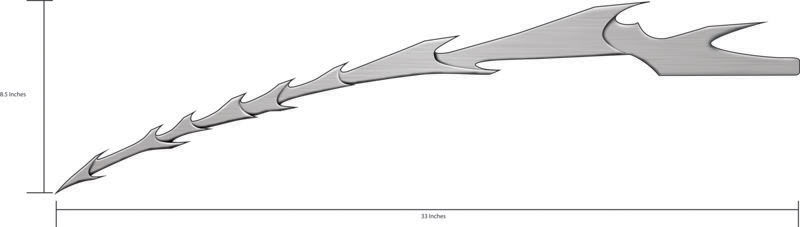

Sooo... The question I seek your wisdom in answering - Where would I get these made? At 33 inches long, they're going to be beasty. I don't plan on making them animatronic at all. These would just be mount and done. What are your thoughts? Anyone have an idea where to start? I mean, obviously I have a drawing, which is a start. But where to start on actually getting them made. Thoughts? Ideas? Directions?

Thank you in advance on any guidance you can offer.

Sooo... The question I seek your wisdom in answering - Where would I get these made? At 33 inches long, they're going to be beasty. I don't plan on making them animatronic at all. These would just be mount and done. What are your thoughts? Anyone have an idea where to start? I mean, obviously I have a drawing, which is a start. But where to start on actually getting them made. Thoughts? Ideas? Directions?

Thank you in advance on any guidance you can offer.