You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T-47 Snowspeeder 1:1 full scale prop build

- Thread starter TXarmory

- Start date

Your dedication and professional approach is really impressive, i'm amazed.

I especially love the sense of size/scale in comparison to everyday objects in your hangar.

On the set they seemed really small beside the X-Wings and MF but yours is wider than the Corvette and Countach in the background!

seriously: Who is using the roof of that Lamborghini for storage? :wacko

- that's another replica, right?

LOL Bugstomper I was going to ask about everything in the hanger as well!! Besides the Rutan airplane and the speeder we've seen a Jag Xk120, a Catamaran? sailboat, what looks to be a Ferrari 308 sitting in a bubble, the Corvette, and a Countach being used as a storage place for the foam sheet? What other awesome stuff is in that hanger?

LOVE the build so far!!! Looking forward to seeing the progress!!

Last edited:

JaxAndTheMoon

Sr Member

This thing is just epic. I wish I had enough room for one of these things

Do you think it will be ready in time for Fan Days? I was hoping to check it out. I never could break free from to come check it out.

-Eric

Eric, the T-47 Snowspeeder WILL be on display at Irving / Dallas ComicCon Oct. 16 - 18. Come hell or high water. It won't be 100% finished, but in reality, what is ever 100% finished??? But if all goes according to schedule, the auto opening canopy will be working and you will be able to sit in both pilot and gunner seats for pictures.

Eric, the T-47 Snowspeeder WILL be on display at Irving / Dallas ComicCon Oct. 16 - 18. Come hell or high water. It won't be 100% finished, but in reality, what is ever 100% finished??? But if all goes according to schedule, the auto opening canopy will be working and you will be able to sit in both pilot and gunner seats for pictures.

I'll be sure to drop by and introduce myself in person then. Looking forward to it.

October 3, 2015. Build day 49. Saturday. Too much college football distraction.

The first major project will be building the system that will allow for an automatic opening and closing canopy. The aluminum canopy is 6 feet long and weighs 26 pounds. In order to have a structurally strong enough hinge and actuator support structure, we are building a wood and fiberglass sub-structure underneath the aluminum rear canopy cover. 1/2" plywood walls and roof panels edge glued with epoxy and micro filler. Then each joint is reinforced with dual layers of 4" wide cross weave glass cloth.

The first major project will be building the system that will allow for an automatic opening and closing canopy. The aluminum canopy is 6 feet long and weighs 26 pounds. In order to have a structurally strong enough hinge and actuator support structure, we are building a wood and fiberglass sub-structure underneath the aluminum rear canopy cover. 1/2" plywood walls and roof panels edge glued with epoxy and micro filler. Then each joint is reinforced with dual layers of 4" wide cross weave glass cloth.

Sunday Oct. 4. Day 50. Short work day today.

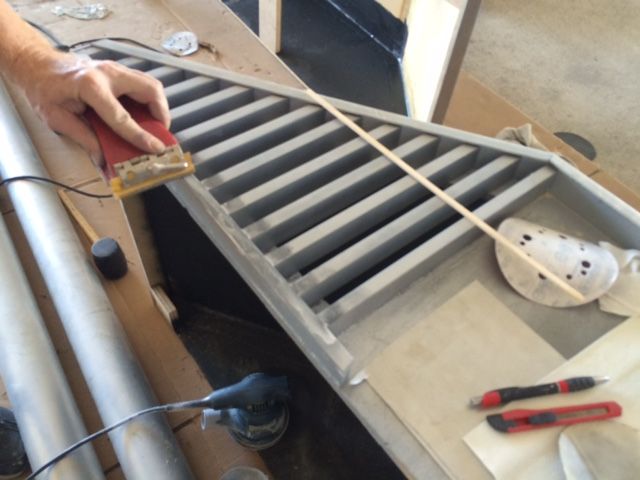

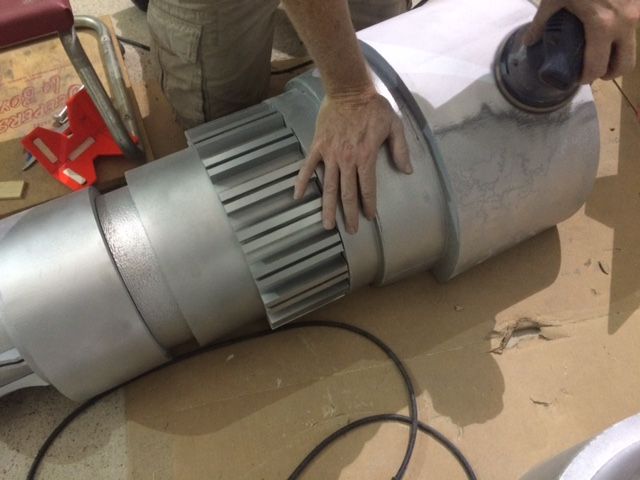

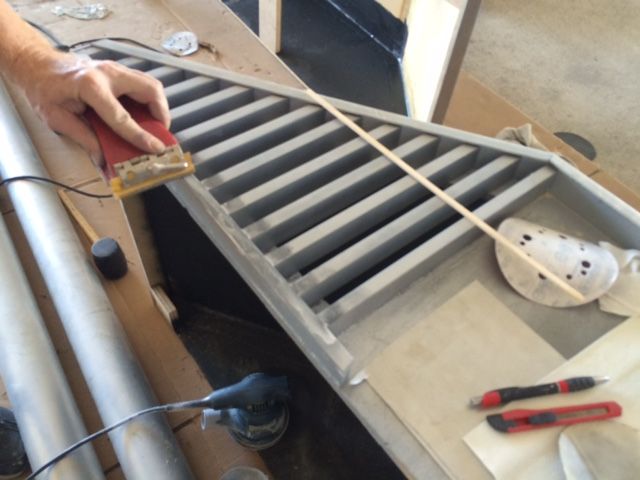

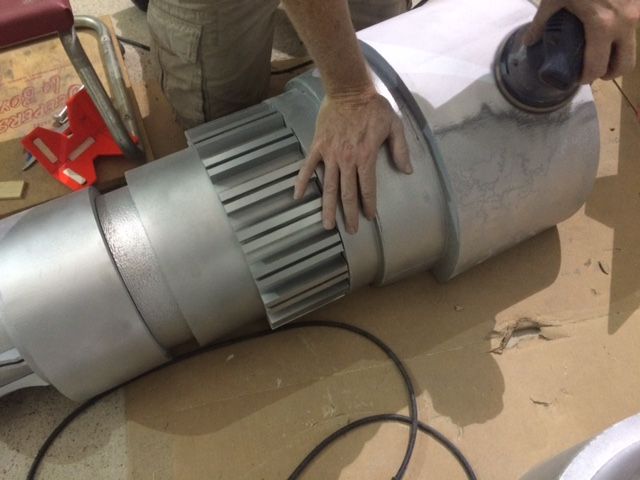

While the canopy structure is hardening (drying), we start identifying and making lists of all the little detail work that needs to be done to the exterior body components. The first coat of paint that we put down back in May, highlighted a lot of minor imperfections in the fit and finish of many pieces. The cannon sub-assemblies are a collection of many individual diameter blocks and glued together greeblies. These need to be caulked and edge filled and completely re-sanded before getting a fresh paint job. Similarly, the grills on the front of the engine boxes need to have the joints prepared with wood filler, sanded flush and repainted.

While the canopy structure is hardening (drying), we start identifying and making lists of all the little detail work that needs to be done to the exterior body components. The first coat of paint that we put down back in May, highlighted a lot of minor imperfections in the fit and finish of many pieces. The cannon sub-assemblies are a collection of many individual diameter blocks and glued together greeblies. These need to be caulked and edge filled and completely re-sanded before getting a fresh paint job. Similarly, the grills on the front of the engine boxes need to have the joints prepared with wood filler, sanded flush and repainted.

Last edited:

LOL Bugstomper I was going to ask about everything in the hanger as well!! Besides the Rutan airplane and the speeder we've seen a Jag Xk120, a Catamaran sailboat, what looks to be a Ferrari 308 sitting in a bubble, the Corvette, and a Countach being used as a storage place for the foam sheet? What other awesome stuff is in that hanger?

You guys are paying way too much attention to the background stuff that is cluttering up my building and not nearly enough attention to the project at hand. Come on guys, focus. Stop goofing off and get back to work. We're on a tight time schedule here.

Monday Oct 5.

Spent most of the evening sitting at the computer clicking my mouse in Autocad 360. The front 3 nose panels on the speeder are currently silver painted fiberglass reinforced plastic (FRP) sheet. They looked pretty good, but when sitting side by side with the real aluminum skin panels on the wings, you could definitely tell by the sheen and color difference that something didn't match. The first batch of parts that I had laser cut did not include these 3 panels. We had not built the wood sub-panels at the time, so I was hesitant to have the sheet metal cut before we had finalized the wood under-body. But now it's time to fix them, and the 3-1/2" wide wing edge panels around the perimeter of each wing. This time, each of the 3 front panels will wrap up under the front leading edge and make a much smoother, single piece look to the nose of the speeder.

Originally I was satisfied with the painted, vacuum formed plastic pieces covering the edges of the wings, but once again they did not look right next to the real aluminum. Since then I have been practicing more with the 4 foot wide metal sheet bender and now feel confident I can hand bend the wrap around wing edge covers out of the same 1/10" aluminum armor plate as the flat wing armor plates.

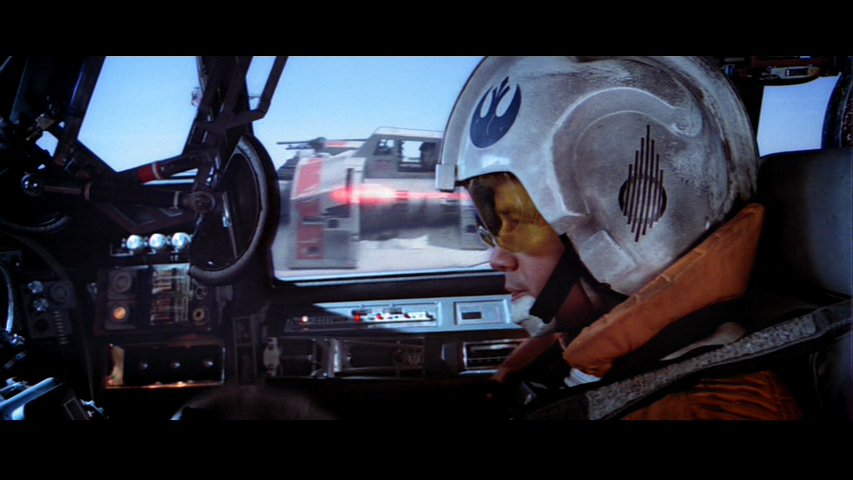

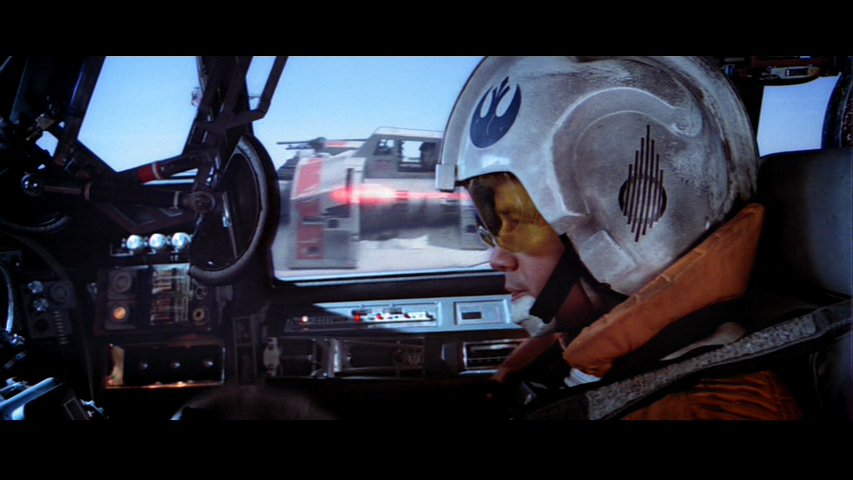

But the most important project of the drafting session is designing the two hinges that will open and close the front 6 foot long canopy. I popped the ESB DVD into the computer and screen captured a couple of good reference shots of the inside of the speeder's cockpit showing the hinge in great detail. Scaling those screenshots provided a very accurate template for CAD drafting the open lattice like hinges. Before calling it a late night and driving home, I emailed the DXF files to the laser cutting company. On the way to the hangar today, I had dropped off two panels of aluminum that would be large enough to make all of the parts needed to finish off the speeder. I don't have any 1/4 or 3/8 inch thick aluminum plate large enough for the two hinges, so I'll have to buy that from the laser cutter's in house inventory. I fortunately caught them when they are not too busy and they expect to be able to get everything cut in 2 days. So hopefully by Wednesday evening I can pick them up after work on my way to the hangar.

Spent most of the evening sitting at the computer clicking my mouse in Autocad 360. The front 3 nose panels on the speeder are currently silver painted fiberglass reinforced plastic (FRP) sheet. They looked pretty good, but when sitting side by side with the real aluminum skin panels on the wings, you could definitely tell by the sheen and color difference that something didn't match. The first batch of parts that I had laser cut did not include these 3 panels. We had not built the wood sub-panels at the time, so I was hesitant to have the sheet metal cut before we had finalized the wood under-body. But now it's time to fix them, and the 3-1/2" wide wing edge panels around the perimeter of each wing. This time, each of the 3 front panels will wrap up under the front leading edge and make a much smoother, single piece look to the nose of the speeder.

Originally I was satisfied with the painted, vacuum formed plastic pieces covering the edges of the wings, but once again they did not look right next to the real aluminum. Since then I have been practicing more with the 4 foot wide metal sheet bender and now feel confident I can hand bend the wrap around wing edge covers out of the same 1/10" aluminum armor plate as the flat wing armor plates.

But the most important project of the drafting session is designing the two hinges that will open and close the front 6 foot long canopy. I popped the ESB DVD into the computer and screen captured a couple of good reference shots of the inside of the speeder's cockpit showing the hinge in great detail. Scaling those screenshots provided a very accurate template for CAD drafting the open lattice like hinges. Before calling it a late night and driving home, I emailed the DXF files to the laser cutting company. On the way to the hangar today, I had dropped off two panels of aluminum that would be large enough to make all of the parts needed to finish off the speeder. I don't have any 1/4 or 3/8 inch thick aluminum plate large enough for the two hinges, so I'll have to buy that from the laser cutter's in house inventory. I fortunately caught them when they are not too busy and they expect to be able to get everything cut in 2 days. So hopefully by Wednesday evening I can pick them up after work on my way to the hangar.

Last edited:

Wow

I have a feeling your will be much better than the ones in the film.

Stormy, Thanks for the vote of confidence. Yes I agree the outside of ours is much more detailed than the full size filming props since we have built the exterior based upon the studio scale miniature. But the interior of the cockpit of the hero speeder on film is very detailed. It's going to take us a while and a good bit of fabricating to get our interior finished out to that level of detail, but that is what we are working towards. I'm behind about a week on chronicling the construction so far. Hold tight Dak.

Last edited:

WOW WOW WOW! Love this!

TX - let me know if you need any interior greeblies. We already have a few ready to mold and should make your life a teeny tiny bit easier.

Keep going! Loving this project!

TX - let me know if you need any interior greeblies. We already have a few ready to mold and should make your life a teeny tiny bit easier.

Keep going! Loving this project!

FYI - on the full scale build, the designers added a tiny support rod under the two barrels to keep them from sagging. See link:

COOL PHOTO!

http://ladymanson.com/galleries/movies/MoviesRS/displayimage.php?pid=105408&fullsize=1

COOL PHOTO!

http://ladymanson.com/galleries/movies/MoviesRS/displayimage.php?pid=105408&fullsize=1

SteveStarkiller

Sr Member

The snowspeeder was my favorite as a kid. I'm loving this build.

FYI - on the full scale build, the designers added a tiny support rod under the two barrels to keep them from sagging. See link:

COOL PHOTO!

http://ladymanson.com/galleries/movies/MoviesRS/displayimage.php?pid=105408&fullsize=1

That's very cool... never saw or noticed that before... but I do also know that they were also mounted to inflatable air cushions so that when you stepped on them to climb aboard, it gave that convincing little hover wobble and was really cool!

Interesting, I always thought they were lifted / resting on forklifts.

Similar threads

- Replies

- 25

- Views

- 1,074