Thursday, April 30. Day 27 of build.

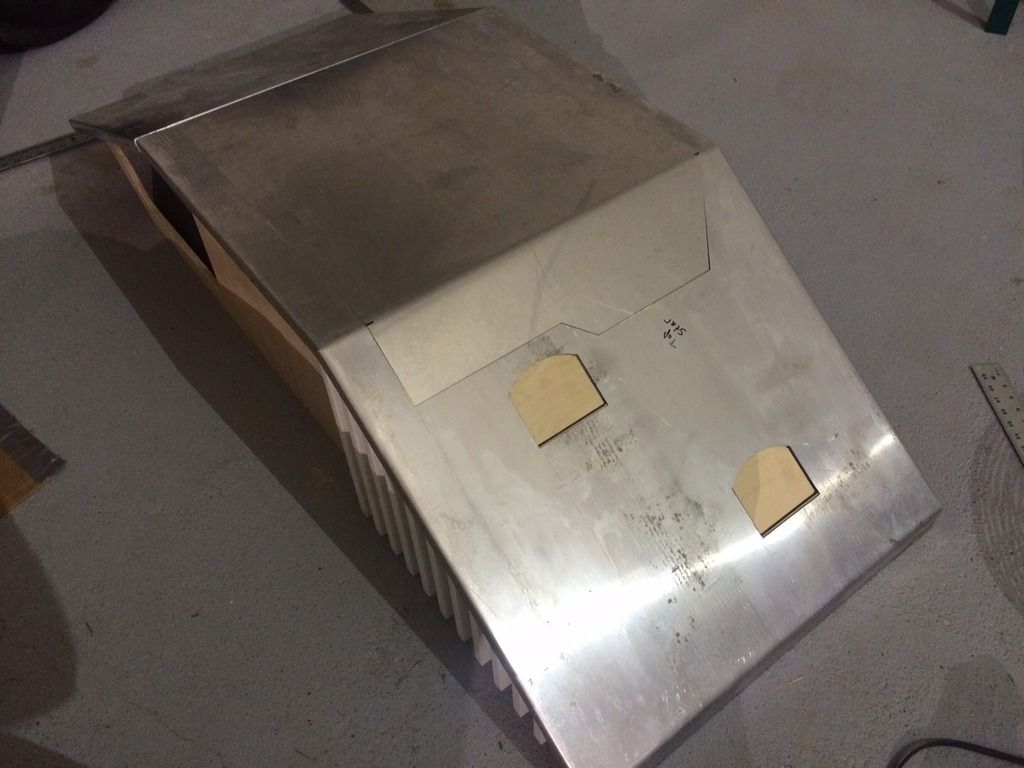

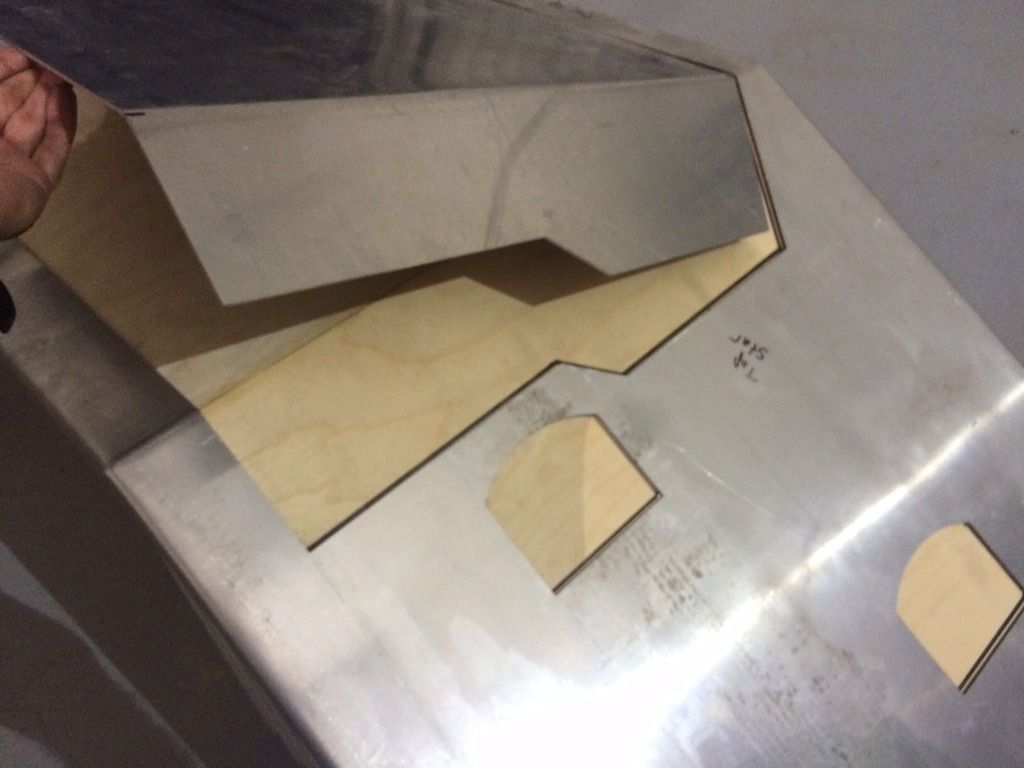

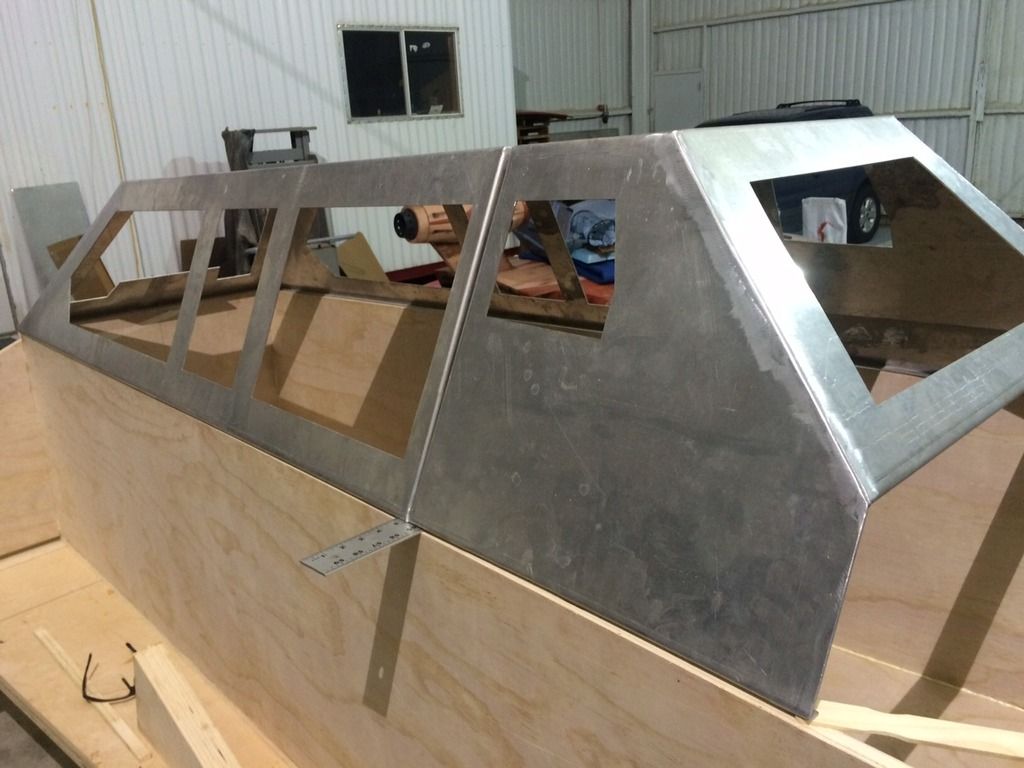

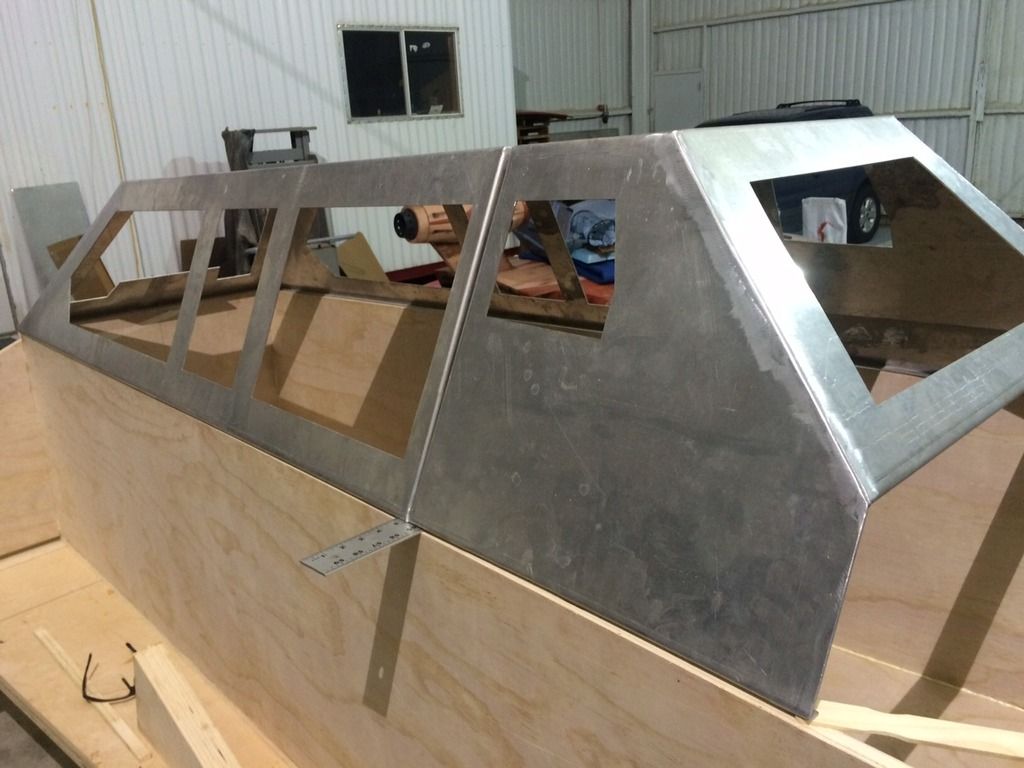

Rear canopy sitting in place.

Inside view looking through rear window.

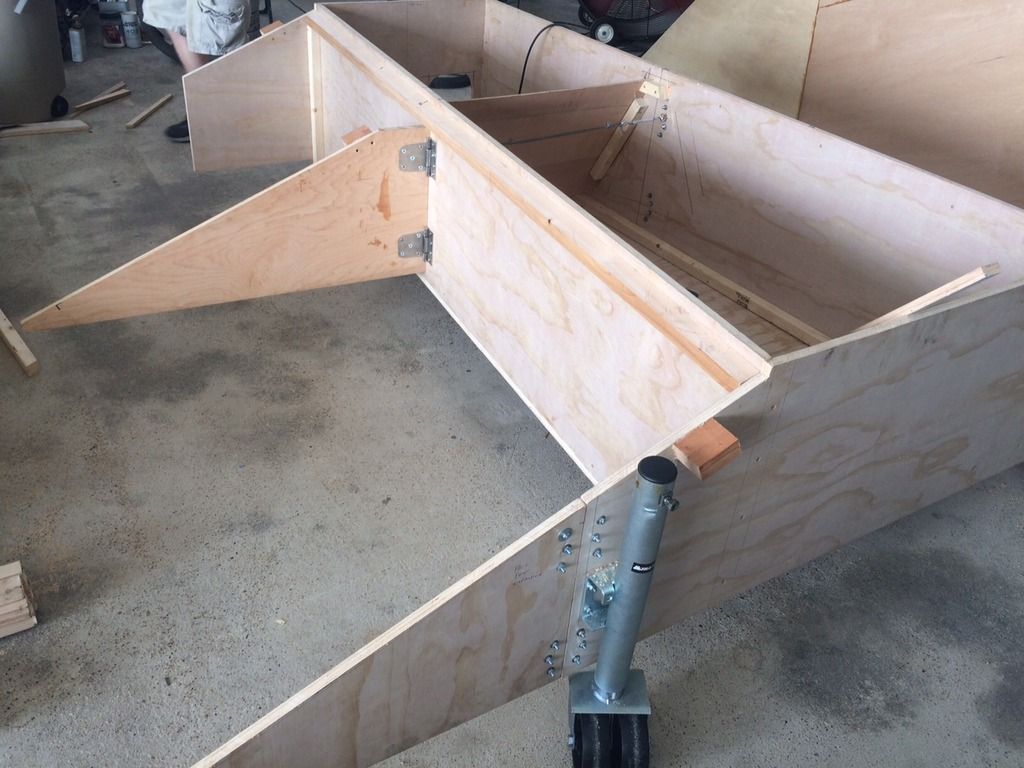

We reinforced all of the glued joints, at every right angle, with a 1-1/2" x 1-1/2" pine board that is through screwed with 2" long deck screws about every 8" to 12". Making the main tub very rigid.

The "landing gear" for the speeder is a three point set of 1000 pound, dual wheel, trailer lift screw jacks. Each set is through bolted with 4, 3/8" bolts. One wheel jack in the front.

Two at the rear.

The original turn handle would be in the way of the body panels, so we cut off each original arm and replaced the arm with a 5/8" nut welded onto the short stub. We will use a 5/8" ratchet drive when we need to raise and lower the speeder. Pushing the speeder on and off the trailer, and up ramps at convention halls, might require us to raise the speeder up 5" to 10" above its 6" designed ground clearance height while on display.

The starboard wing panel is propped up on blocks and sitting in place. We cut a 4" hole in the wing to allow the top of the wheel jack to pass through the wing. This will be hidden inside of the rear engine box. The 5/8" nut will be accessed through a small peephole in the back wall of the engine box.

We still have not cut the rear flap of the wing panel. The solid edge keeps it stronger when we move it.

Rear canopy sitting in place.

Inside view looking through rear window.

We reinforced all of the glued joints, at every right angle, with a 1-1/2" x 1-1/2" pine board that is through screwed with 2" long deck screws about every 8" to 12". Making the main tub very rigid.

The "landing gear" for the speeder is a three point set of 1000 pound, dual wheel, trailer lift screw jacks. Each set is through bolted with 4, 3/8" bolts. One wheel jack in the front.

Two at the rear.

The original turn handle would be in the way of the body panels, so we cut off each original arm and replaced the arm with a 5/8" nut welded onto the short stub. We will use a 5/8" ratchet drive when we need to raise and lower the speeder. Pushing the speeder on and off the trailer, and up ramps at convention halls, might require us to raise the speeder up 5" to 10" above its 6" designed ground clearance height while on display.

The starboard wing panel is propped up on blocks and sitting in place. We cut a 4" hole in the wing to allow the top of the wheel jack to pass through the wing. This will be hidden inside of the rear engine box. The 5/8" nut will be accessed through a small peephole in the back wall of the engine box.

We still have not cut the rear flap of the wing panel. The solid edge keeps it stronger when we move it.

Last edited: