Pannaus Props

Sr Member

Guys, I'm going crazy about this issue.

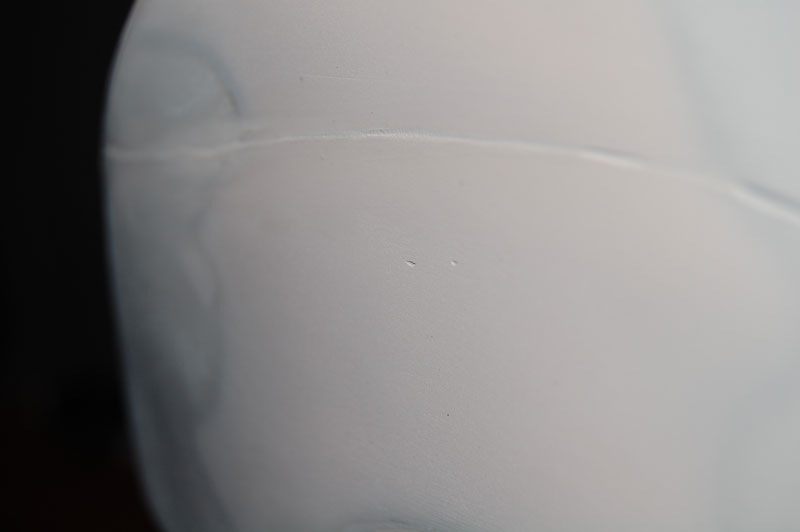

I'm almost done with my iron man helmet and I need to re-do the lines on the sides (above the ears), on the back and on the wings of the faceplate.

I did them on sintra and they were flawless. Then some plaster (milliput first, then bondo) got in the way and when I tried to re-trace them the plaster just broke and made small chips. Result: it sucks! Looks like I've done my lines with a a lawnmower...

So, please, there's any way you know how to carve a thin good line on a already hardened plaster surface?

I use a modelling knife (do you write it this way? modelling knife?), but on plaster it just slips everywhere. Tried the smallest head with my dremel too...but the rotating wonder it's not for me...can carve sintra like I'm the god of plastic, but plaster is killing me.

Any help?

Pllllleeeeeeeeeeaaaaaaassssseeee :cry

If there's a post about this, I'm sorry, I searched the board but couldn't find anything quickly!

I'm almost done with my iron man helmet and I need to re-do the lines on the sides (above the ears), on the back and on the wings of the faceplate.

I did them on sintra and they were flawless. Then some plaster (milliput first, then bondo) got in the way and when I tried to re-trace them the plaster just broke and made small chips. Result: it sucks! Looks like I've done my lines with a a lawnmower...

So, please, there's any way you know how to carve a thin good line on a already hardened plaster surface?

I use a modelling knife (do you write it this way? modelling knife?), but on plaster it just slips everywhere. Tried the smallest head with my dremel too...but the rotating wonder it's not for me...can carve sintra like I'm the god of plastic, but plaster is killing me.

Any help?

Pllllleeeeeeeeeeaaaaaaassssseeee :cry

If there's a post about this, I'm sorry, I searched the board but couldn't find anything quickly!