You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Styrene to wood, what glue?

- Thread starter Sulla

- Start date

exoray

Master Member

Contact Cement... Same way you laminate Formica when making countertops...

Roll the contact cement onto both surfaces let dry (you might need two coats on the wood), and then you get one shot to place it together but it will hold like hell...

Contact cement is an instant bond so care should be taken when touching the two pieces together as once they hit they are one...

** Droidboy beat me to it...

Roll the contact cement onto both surfaces let dry (you might need two coats on the wood), and then you get one shot to place it together but it will hold like hell...

Contact cement is an instant bond so care should be taken when touching the two pieces together as once they hit they are one...

** Droidboy beat me to it...

Thing is, Formica is basically paper or HPL (High Pressure Laminate) so contact cement goes great wood to wood. Paper is after all made of wood.

But Styrene to wood can slip on the styrene side with contact cement. Whereas super glue is bulletproof on styrene. Plus you can use capillary action while applying the super glue and not risk the one time shot with contact cement.

As always the exact application makes the final decision.

But Styrene to wood can slip on the styrene side with contact cement. Whereas super glue is bulletproof on styrene. Plus you can use capillary action while applying the super glue and not risk the one time shot with contact cement.

As always the exact application makes the final decision.

exoray

Master Member

Thing is, Formica is basically paper or HPL (High Pressure Laminate) so contact cement goes great wood to wood. Paper is after all made of wood.

Paper saturated with resin, there is no "paper" on the surface of a traditional laminate so it's not a "wood to wood" bond, but rather a phenolic resin to wood bond... Laminate is a cousin to fiberglass but instead of glass fibers, paper is used as the structure fiber... I don't know many people that consider fiberglass "glass" so there is no reason to consider counter laminate "paper"... They are both generally considered resin "plastic" substrates... Also there are fully synthetic laminates that contain no paper but are simply plastic sheets...

I have used contact cement on many substrates without issue, if concerned about it rough up the back of the sheet of plastic...

Forestmoonstudio

Sr Member

I use Household goop. Works great. If you clamp it,watch out for it slipping until it dries.

rickrickrick

Sr Member

I am surprised people are recommending contact cement for styrene. I use little custom vacuformed styrene bits for stuff, and I have to be very careful that contact cement doesn't melt the styrene. Some brands are worse than others, but a heavy application of any of them will almost certainly melt the styrene. It would have to be really thick styrene not to be affected, I should think.

My two cents, based on my own experience.

Rick

My two cents, based on my own experience.

Rick

I am surprised people are recommending contact cement for styrene. I use little custom vacuformed styrene bits for stuff, and I have to be very careful that contact cement doesn't melt the styrene. Some brands are worse than others, but a heavy application of any of them will almost certainly melt the styrene. It would have to be really thick styrene not to be affected, I should think.

My two cents, based on my own experience.

Rick

Ouch. This is VERY thin styrene; 1mm or thinner. I read in Dan Baker's R2 blog that he used liquid nails. How about that stuff? I've never used it.

Ouch. This is VERY thin styrene; 1mm or thinner. I read in Dan Baker's R2 blog that he used liquid nails. How about that stuff? I've never used it.

I've never had a problem with just off the shelf from Home Depot contact cement ever.

Liquid nails will pretty much bond anything it seems, but it takes a long time to cure and it goes on really thick, so it could screw up the thickness of what you are skinning.

Gregg

exoray

Master Member

I am surprised people are recommending contact cement for styrene. I use little custom vacuformed styrene bits for stuff, and I have to be very careful that contact cement doesn't melt the styrene. Some brands are worse than others, but a heavy application of any of them will almost certainly melt the styrene. It would have to be really thick styrene not to be affected, I should think.

My two cents, based on my own experience.

Rick

Get a water based one if there are concerns, the EPA has really cracked down on the more solvent based ones so there is a new wave of water based ones out now that work great and the stink level is way down...

Also contact cement should be applied light not heavy, several very thin coats are preferred as they dry faster and smoother...

I have done my fair share of laminations and working with contact cement and worked with a guy that had years of experience working in a shop where that is all they did, making laminated furniture and fixtures for retail and restaurants...

As always a test can't hurt...

If you go to Home Depot like stores they will usually have generic laminating cement in the glue isle, but if you venture into the kitchen cabinet area they will probably have a few other choices including a water based one...

xeno

Sr Member

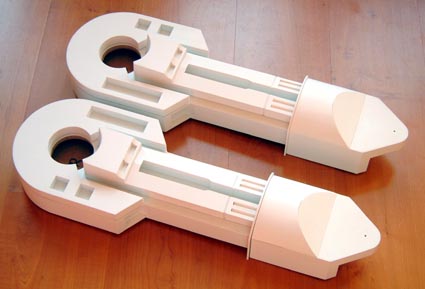

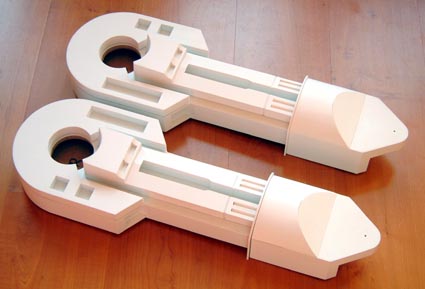

the first R2 I build had wooden legs covered in 1mm and 1,5mm styreen glued with cyano (superglue), as long as you sand it with 150 grid or rougher sandpaper you won't be able to get it off

but you need the gel or thick version, as the wood sucks all the water thin glue

this also works for styreen on aluminium, bit sanded stick pretty good

but you need the gel or thick version, as the wood sucks all the water thin glue

this also works for styreen on aluminium, bit sanded stick pretty good

TK9120

Sr Member

This should work. But I imagine it would get expensive.

http://www.rockler.com/product.cfm?page=10562&filter=wood glue

http://www.rockler.com/product.cfm?page=10562&filter=wood glue

Weld-On 16 or 45.

I used to sell this stuff all the time when I worked as an inside sales all kinds of plastics.

http://www.ipscorp.com/sites/default/files/assemb_selection.html

I used to sell this stuff all the time when I worked as an inside sales all kinds of plastics.

http://www.ipscorp.com/sites/default/files/assemb_selection.html

Last edited:

8 perf

Sr Member

I used spray 77 to stick styrene to my R2 legs. went back and used weldon around all the styrene/ styrene seams to bond it all together. Been in my garage for 2+ years while I concentrated on other projects, and still has yet to show any signs of delamination or melting of any kind.

Similar threads

- Replies

- 5

- Views

- 930

- Replies

- 14

- Views

- 1,174

- Replies

- 1

- Views

- 230