Pyramidrep

Sr Member

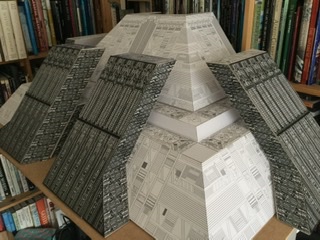

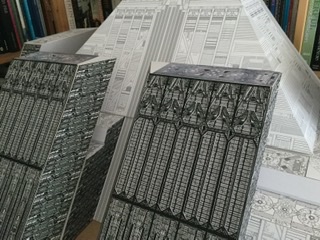

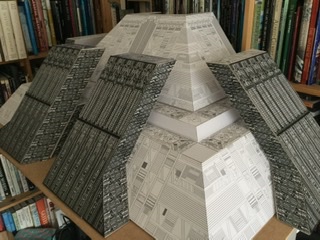

So I finally joined the forum after years of looking at the fantastic work posted here. So my particular interest in the Tyrell Pyramid began when I first saw the movie in the 1980’s and a burning ambition to build a replica never left me. I have an architectural background ( but don’t work in the industry anymore) so building model buildings is something I‘ve done a lot of In the past. But this is a huge project and good reference scare.

So the only way to build this is to find any photo reference of original castings, obtaining castings( any generation), identifying parts and measurements. And most importantly find the “Rosetta stone” to begin. So this is the beginning ( 4 years to this point).

So the only way to build this is to find any photo reference of original castings, obtaining castings( any generation), identifying parts and measurements. And most importantly find the “Rosetta stone” to begin. So this is the beginning ( 4 years to this point).