SteveNeill

Sr Member

Thanks Spock Boy and the answer is yes. I will make a few for those that really want them.

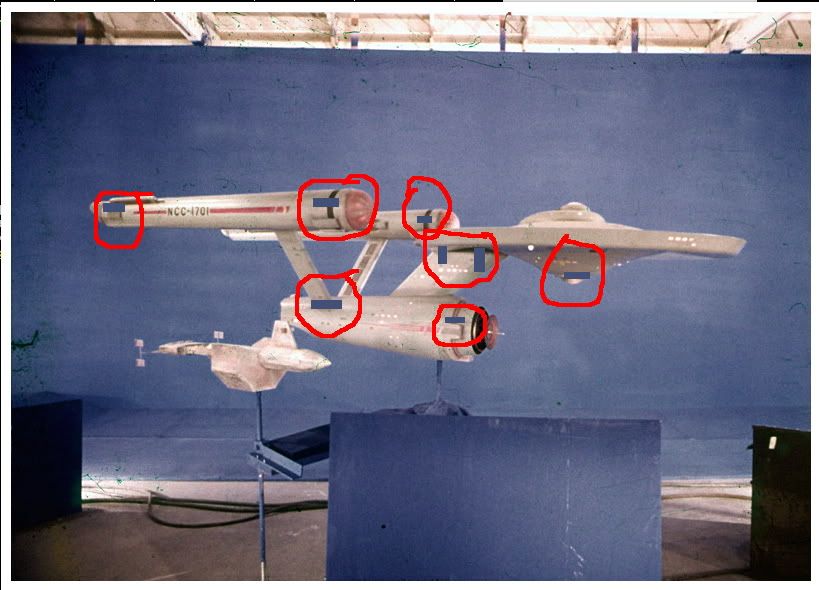

What the heck is that picture? An early prototype??

Well I just about have these nacelles where I want them. I still have to cap the ends of the main bodies with some styrene and zero them out for a clean fit of the bussards and the end caps. And yes I did the end caps a second time.

The recess is looking nice but now that it's nearly all cleaned up I glued the detail parts on. Now I still need to go around with a bit of putty and clean their fit. But overall all the hard stuff is done.

Next week I'll be working on the Nautilus but a couple of hours a night I'll work on the clean up and the intercoolers and vents.

Steve

What the heck is that picture? An early prototype??

Well I just about have these nacelles where I want them. I still have to cap the ends of the main bodies with some styrene and zero them out for a clean fit of the bussards and the end caps. And yes I did the end caps a second time.

The recess is looking nice but now that it's nearly all cleaned up I glued the detail parts on. Now I still need to go around with a bit of putty and clean their fit. But overall all the hard stuff is done.

Next week I'll be working on the Nautilus but a couple of hours a night I'll work on the clean up and the intercoolers and vents.

Steve