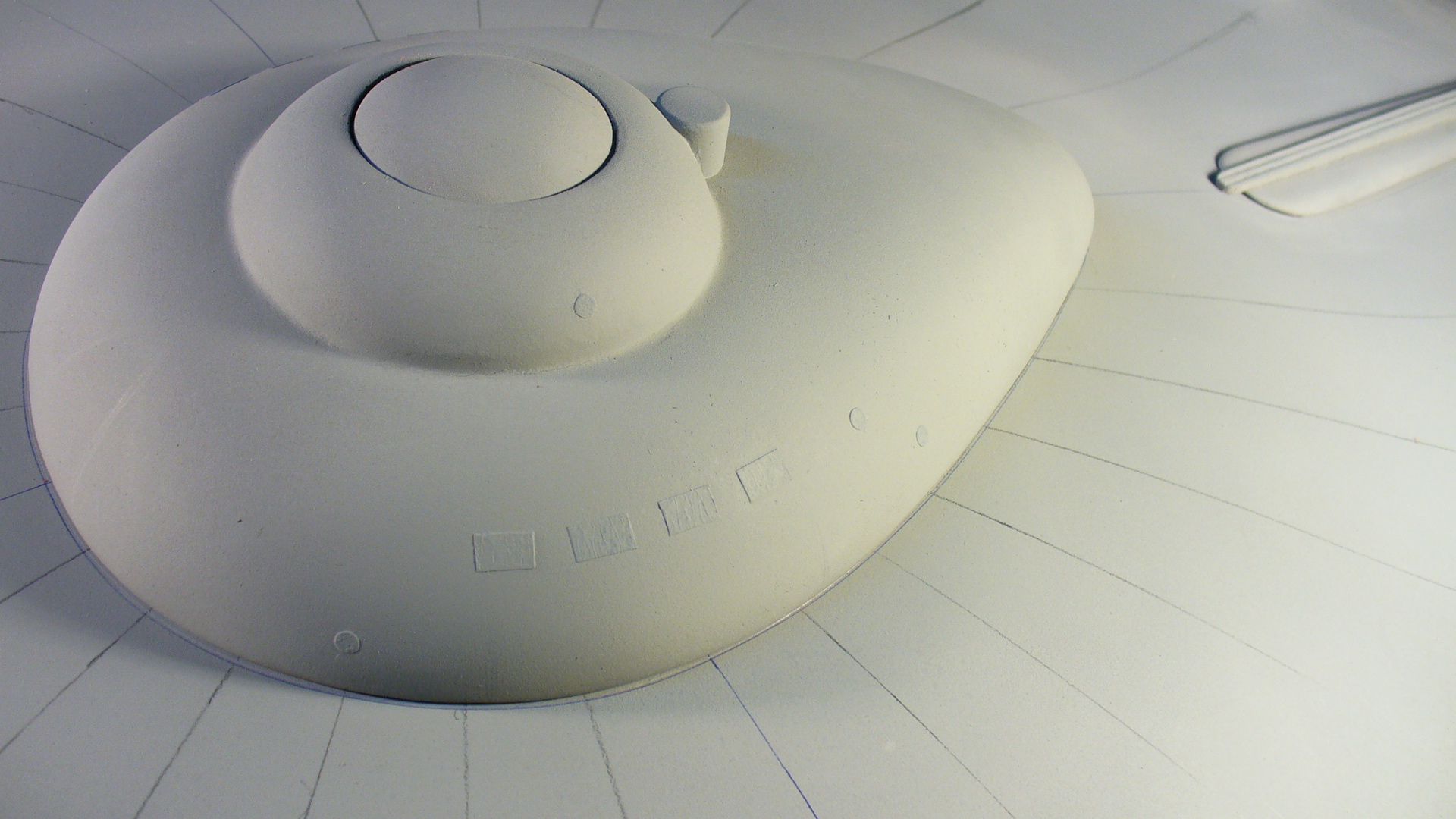

I will, I must, have one of these kits.

I couldn't sleep last so I was going over and over in my mind ideas for a support framework, stand, what to do for lighting, what to do for the motor for the nacelles...

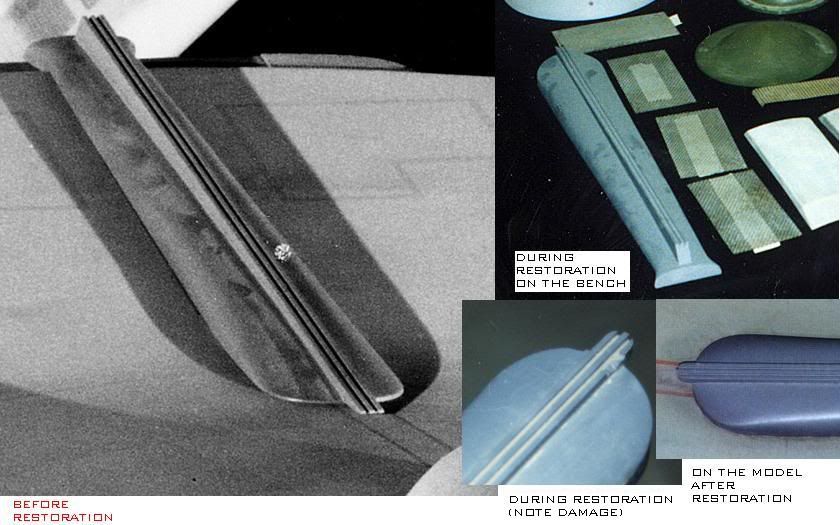

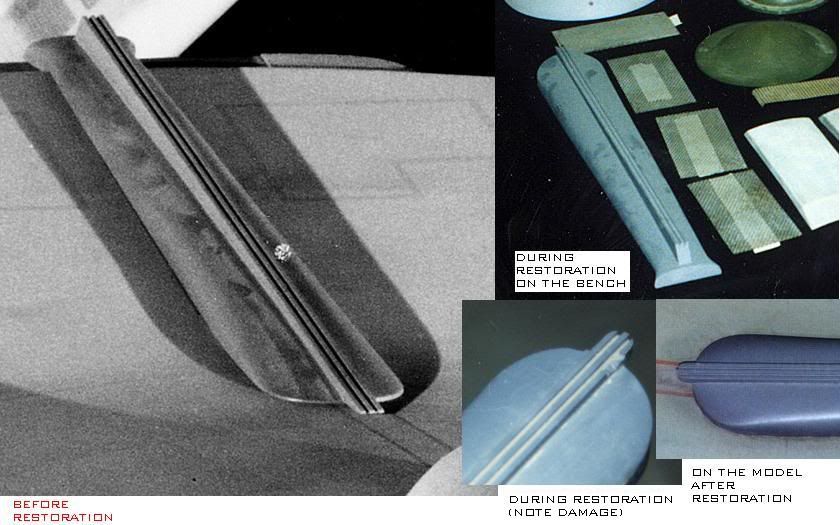

I was looking over the pictures as well and didn't know if this tiny detail warranted a second look (again, not my photo):

The tip of the "accelerator" I guess we're calling it looks to be flat and straight, and the leading edge possibly less rounded, during production but was modified at some point--most likely to accommodate damage. I couldn't quite tell from the pictures of your project how you had decided to shape that part but figured it was based more on the plans plus the Mirecki restoration photos as that's the best documentation to date.

Loving every minute of this!

Dave

I couldn't sleep last so I was going over and over in my mind ideas for a support framework, stand, what to do for lighting, what to do for the motor for the nacelles...

I was looking over the pictures as well and didn't know if this tiny detail warranted a second look (again, not my photo):

The tip of the "accelerator" I guess we're calling it looks to be flat and straight, and the leading edge possibly less rounded, during production but was modified at some point--most likely to accommodate damage. I couldn't quite tell from the pictures of your project how you had decided to shape that part but figured it was based more on the plans plus the Mirecki restoration photos as that's the best documentation to date.

Loving every minute of this!

Dave