SteveNeill

Sr Member

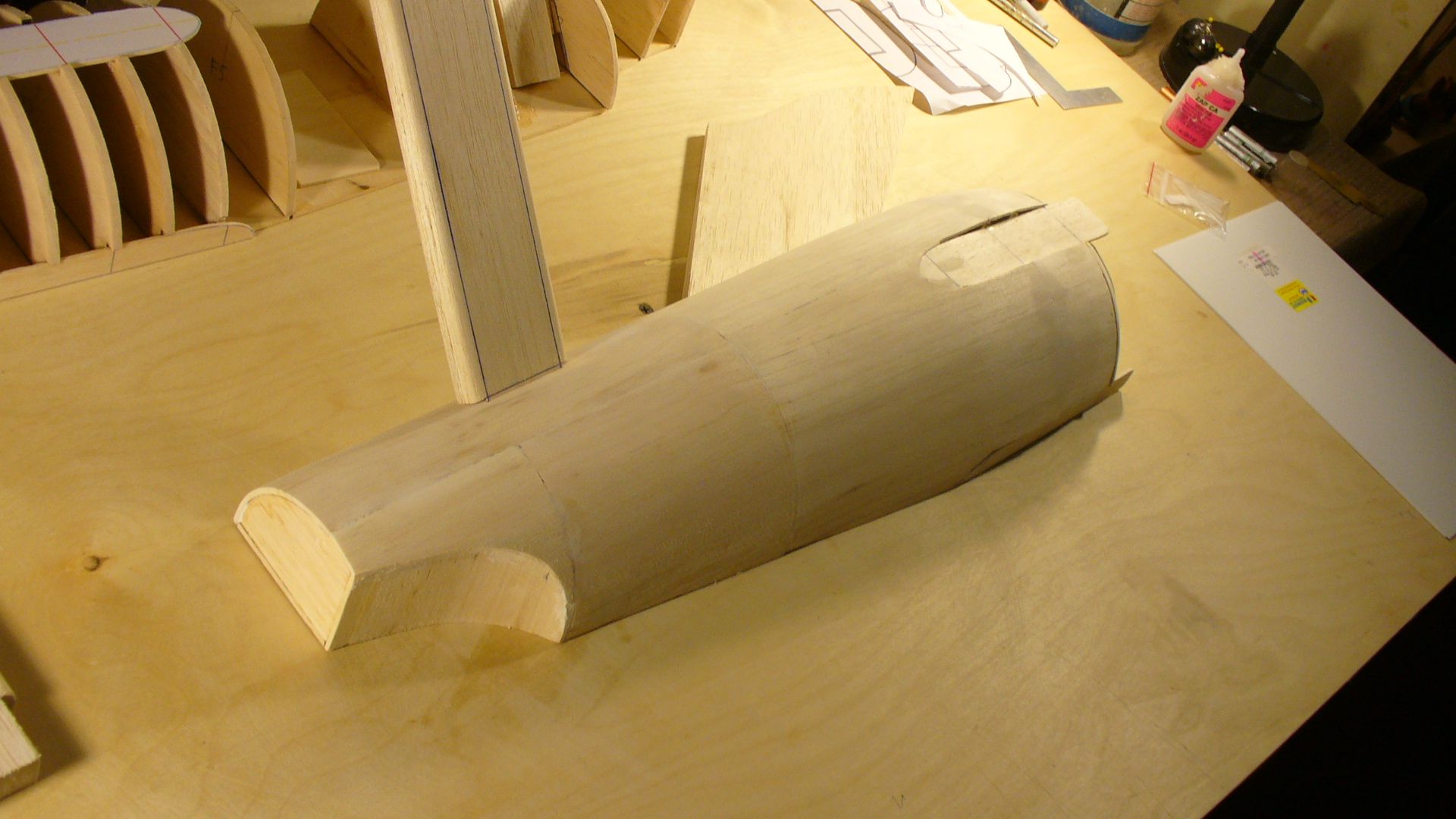

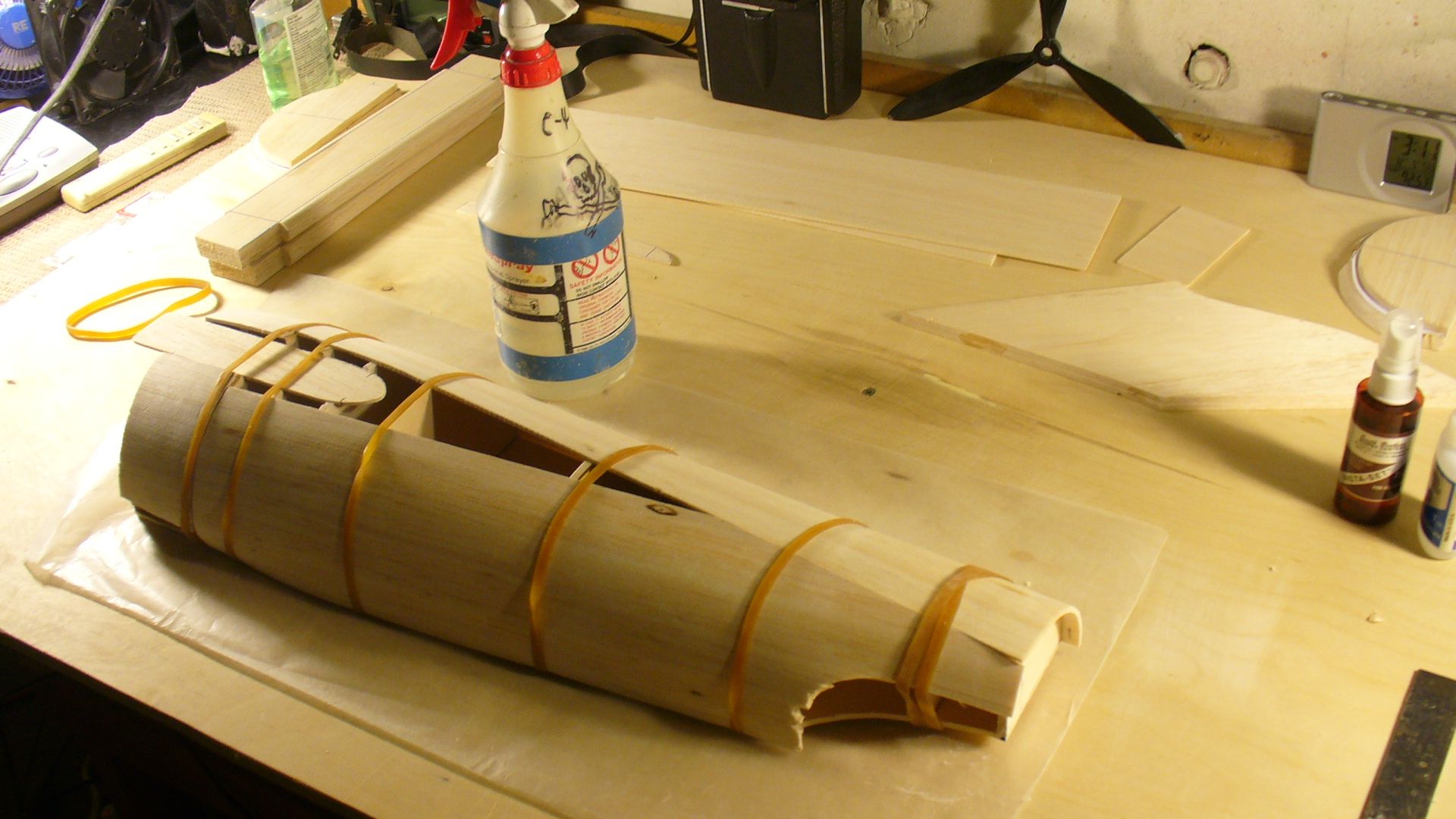

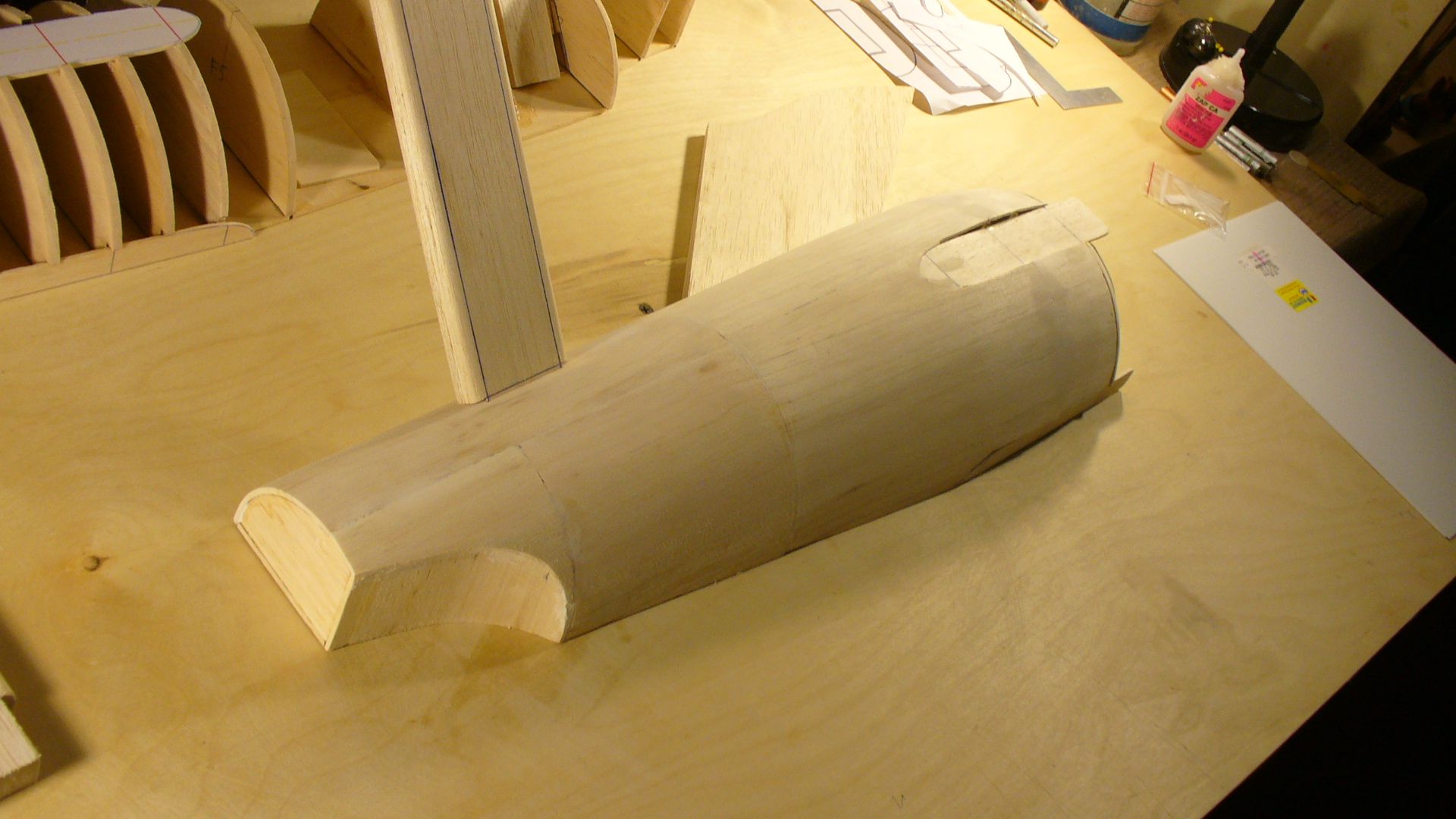

Lots of running around town today picking up more parts and materials and then a bit of sheeting to the secondary hull.

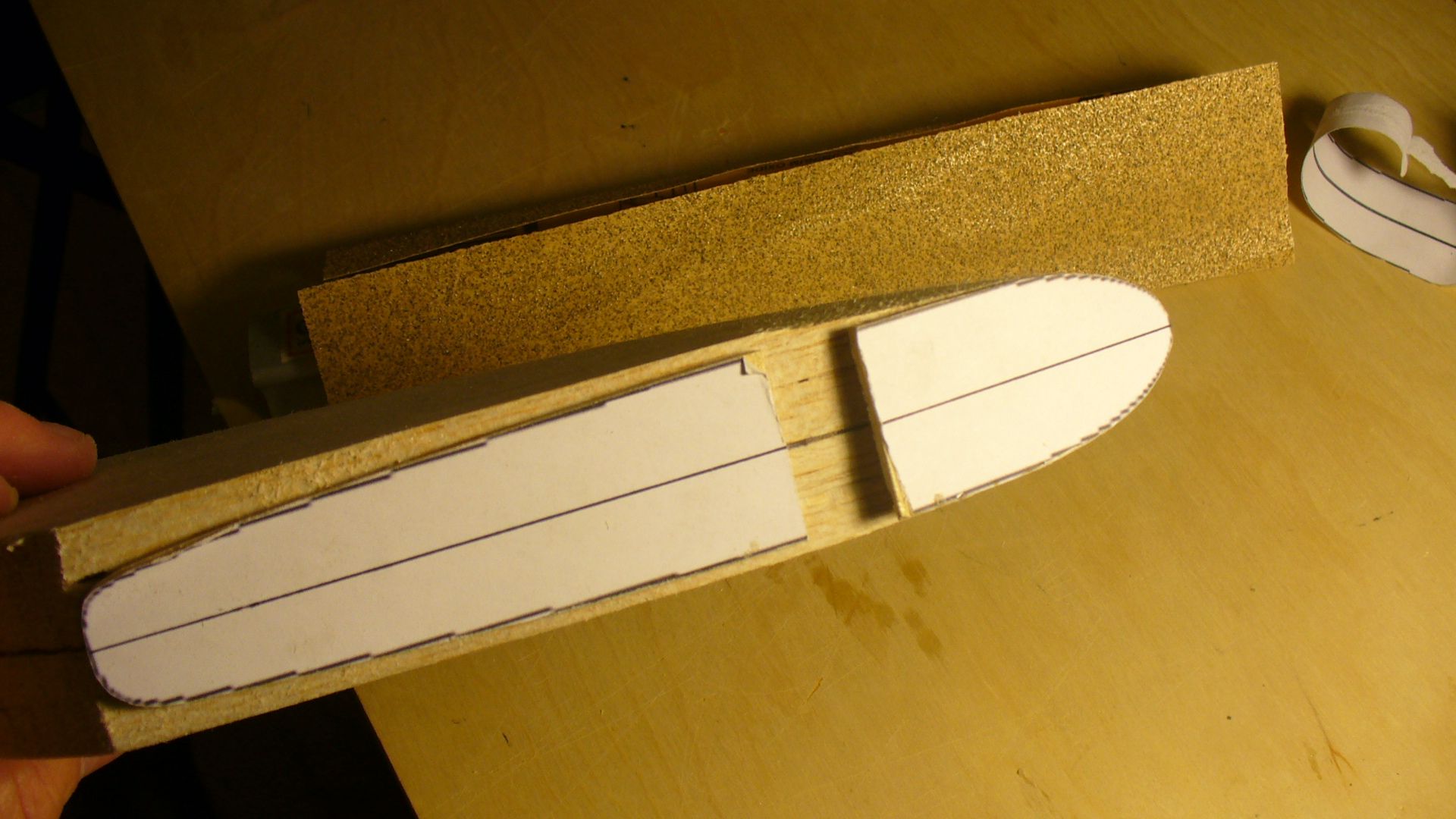

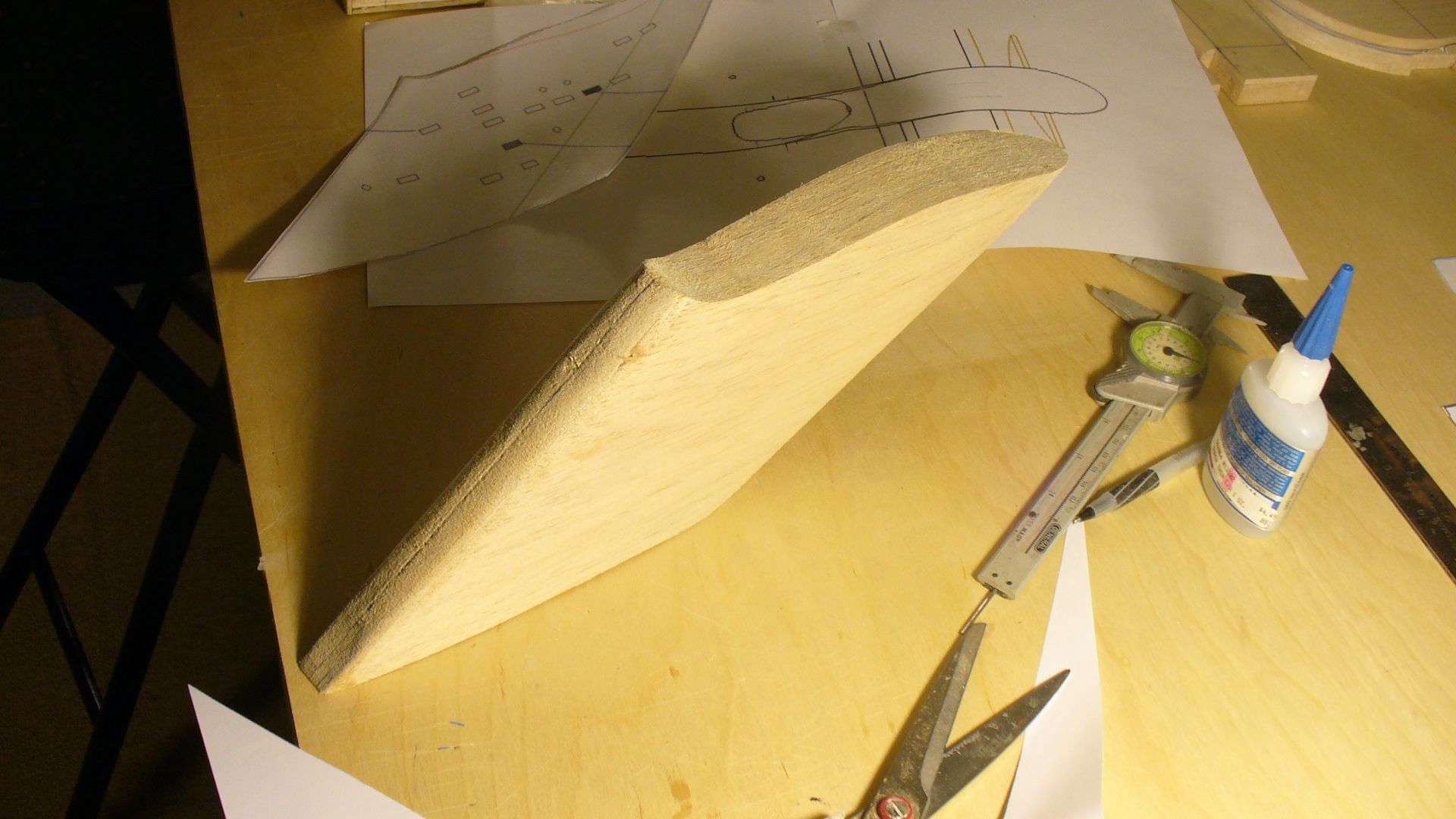

I took Brandon's advise and added some extra support for the pylons internally because before I mold this model I'll stick as much of it together for a look. I'm trying to make this as plug and play as possible. The neck will fit the saucer section in a similar fashion to that of the pylons. Same with the nacelles. Just add glue.

I'm hoping to finish the other half tomorrow and move on to the neck. I will skin all this with glass cloth and epoxy before I can really preen it up, Scribe, yada, yada.

Steve

I took Brandon's advise and added some extra support for the pylons internally because before I mold this model I'll stick as much of it together for a look. I'm trying to make this as plug and play as possible. The neck will fit the saucer section in a similar fashion to that of the pylons. Same with the nacelles. Just add glue.

I'm hoping to finish the other half tomorrow and move on to the neck. I will skin all this with glass cloth and epoxy before I can really preen it up, Scribe, yada, yada.

Steve