You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stark Medical Scanner

- Thread starter Starmind001

- Start date

-

- Tags

- iron man 2 medical scanner

Starmind001

New Member

Any updates on this?

Currently, Yes and no. What I have been doing is trying to have a display made for this. I made a new circuit using a pro mini to light a led matrix on button press. That new led matrix can be made smaller, but the leds would be surface mounts and would be easier to have the board made than to do it myself.

Right now, I am just doing the waiting game. I ordered some boards for testing and was told that it would take 2 weeks and I failed to look at where I ordered from and it is coming from over seas. According to the tracking it has been sitting in California customs for about 20 days now. If it doesn't release here soon I will use one of the US based manufactures.

Here is the test board after I designed it in designspark.

Starmind001

New Member

Yes, quite a bit! I purchased a new 3d printer and a new cnc as I wanted to have some new ways to make better products. This particular props was making me build all kinds of stuff, but after a short email about how the display actually worked and from watching Iron man 2 over and over, I was able to find a simple fix to the display problems.

According what I found out, I am working on that solution now. The display was the reason this prop was getting held back. That and I was working on other projects until my new toys showed up this weekend.

How is the display going work? If you watch the movie you will see that it is not a dot matrix or oled. While those are nice, it was actually much simpler just like my original test. But after watching the movie I noticed how it worked and a pro mini is needed for it to work. Also noticed that the prop had something on the side that neither mine or anyone else had. That part will be seen later when I finish the prop. Let's put it this way, it was how I knew how the display was made. RDJ had his hand on it and for a split second it was noticeable.(bathroom scene)

I should have a new pics sometime next week.

According what I found out, I am working on that solution now. The display was the reason this prop was getting held back. That and I was working on other projects until my new toys showed up this weekend.

How is the display going work? If you watch the movie you will see that it is not a dot matrix or oled. While those are nice, it was actually much simpler just like my original test. But after watching the movie I noticed how it worked and a pro mini is needed for it to work. Also noticed that the prop had something on the side that neither mine or anyone else had. That part will be seen later when I finish the prop. Let's put it this way, it was how I knew how the display was made. RDJ had his hand on it and for a split second it was noticeable.(bathroom scene)

I should have a new pics sometime next week.

Starmind001

New Member

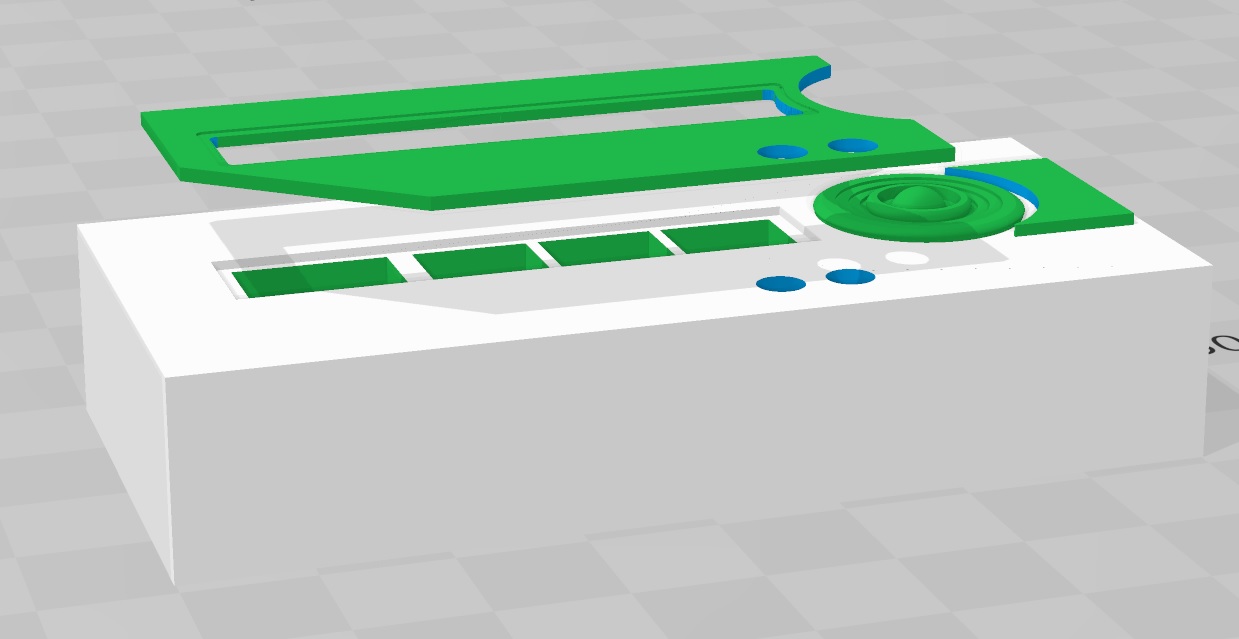

Small update! I was able to print out the models on my new resin printer. Also did a proto circuit board that works with the pro mini. I printed the models out in both resin and abs, mainly to see the difference. Even though I printed out new models, I have new models that are improved versions to accept the pro mini, battery and circuitry. Enjoy the new pics!

Starmind001

New Member

Had to go back to the drawing board, but I have a finished circuit with arduino code. Now I just need to put it all together. In my test I used a arduino nano, but the final version will use a pro mini. I think you all will like the final result.

Starmind001

New Member

It is currently on hold until a few other projects are completed.

propmaster2000

Sr Member

Not sure if this will help, but if the words are lit individually, instead of each letter seperatly, then a type of light box

with LED chambers (Green, Green, Green, Red) will suffice?

Use a simple Ink Printed Transparency with the appropriate color words with a black edge around the letters (background)

and turn on each segment with your controller.

(just thinking out loud)

with LED chambers (Green, Green, Green, Red) will suffice?

Use a simple Ink Printed Transparency with the appropriate color words with a black edge around the letters (background)

and turn on each segment with your controller.

(just thinking out loud)

Starmind001

New Member

Not sure if this will help, but if the words are lit individually, instead of each letter seperatly, then a type of light box

with LED chambers (Green, Green, Green, Red) will suffice?

Use a simple Ink Printed Transparency with the appropriate color words with a black edge around the letters (background)

and turn on each segment with your controller.

(just thinking out loud)

Agreed, I did that at the start, but others thought it would be better to to use a display. My thoughts were give the people what they want until I asked the right people about how it was really made and I went that route.

I will tell you that printing on transparent film does not work. Light bleeds through.

Right now it is a matter of fine tuning. Currently this runs on an arduino nano, 3 coin batteries and ten micro leds. I have been testing for the finish. So far I know that most here do not like the rattle can paint idea, so I have been testing. Using an actual metal case using bismuth, aluminum, pewter, zinc or resin airbrushed with alclad chrome, steel and few others. Even tried rub and buff.

But honestly for me it comes down to how many projects I have in the fire and I have alot on my plate at this time. I just had to set things aside for the moment, while I finish the paying jobs.

Thank you though!

antarusfree

Well-Known Member

Looking good. Made a 3D model of this scanner some time ago.

xl97

Master Member

Nice share propmaster2000

If the the letters/text are just printed upon some transparency (like a mask/stencil).. then we wouldnt be able to change the % (or anything else)

Why isnt an OLED display an option?

-- NM I went back and re-read.. the display 'port/opening' is smaller... ut cant you adjust size or spacing or both to fit inside the 'window' you do have?

A matrix of LEDS can be done.. (surface mount and a MAX72xx chip (or 2)...) but I'm not sure I see the benefit? (or purpose?)

If the the letters/text are just printed upon some transparency (like a mask/stencil).. then we wouldnt be able to change the % (or anything else)

Why isnt an OLED display an option?

-- NM I went back and re-read.. the display 'port/opening' is smaller... ut cant you adjust size or spacing or both to fit inside the 'window' you do have?

A matrix of LEDS can be done.. (surface mount and a MAX72xx chip (or 2)...) but I'm not sure I see the benefit? (or purpose?)

xl97

Master Member

I have still/always wanted to take a crack at the electronics for this..

I believe the 'window' (opening) is 12mm x 45mm (so roughly .47in x 1.77in)

I found an OLED screen that has dimensions of: 43mm x 18mm

Question:

How much more space do we have OUTSIDE of/BEYOND the display window/opening?

* The PCB might be bigger than the screen portion in some of these options.. so I'm curious what the 'INSIDE' dimensions are?

* If the found screen is a little 'bigger' then the opening window... that should matter right? as long as the displayed text fits in there (I believe you can control where/offset the text to be displayed wherever.)

I believe the 'window' (opening) is 12mm x 45mm (so roughly .47in x 1.77in)

I found an OLED screen that has dimensions of: 43mm x 18mm

Question:

How much more space do we have OUTSIDE of/BEYOND the display window/opening?

* The PCB might be bigger than the screen portion in some of these options.. so I'm curious what the 'INSIDE' dimensions are?

* If the found screen is a little 'bigger' then the opening window... that should matter right? as long as the displayed text fits in there (I believe you can control where/offset the text to be displayed wherever.)

Similar threads

- Replies

- 5

- Views

- 1,252

- Replies

- 1

- Views

- 1,066