Ahhhh, you've scratched my "need an update" itch. Glad to hear the project continues.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Star Trek TOS Inspired Home Office Remodel

- Thread starter Starbase101

- Start date

Starbase101

Sr Member

Yes, it's in a "lull" period again while I wait for another Maverick order and figure out the wall panel electronics. (The all-in-one GM Props kit I bought isn't going to work out - staticky/tinny audio and the alert light oscillates at a different rate than the sound, so I'm making my own custom circuit.)Ahhhh, you've scratched my "need an update" itch. Glad to hear the project continues.

Starbase101

Sr Member

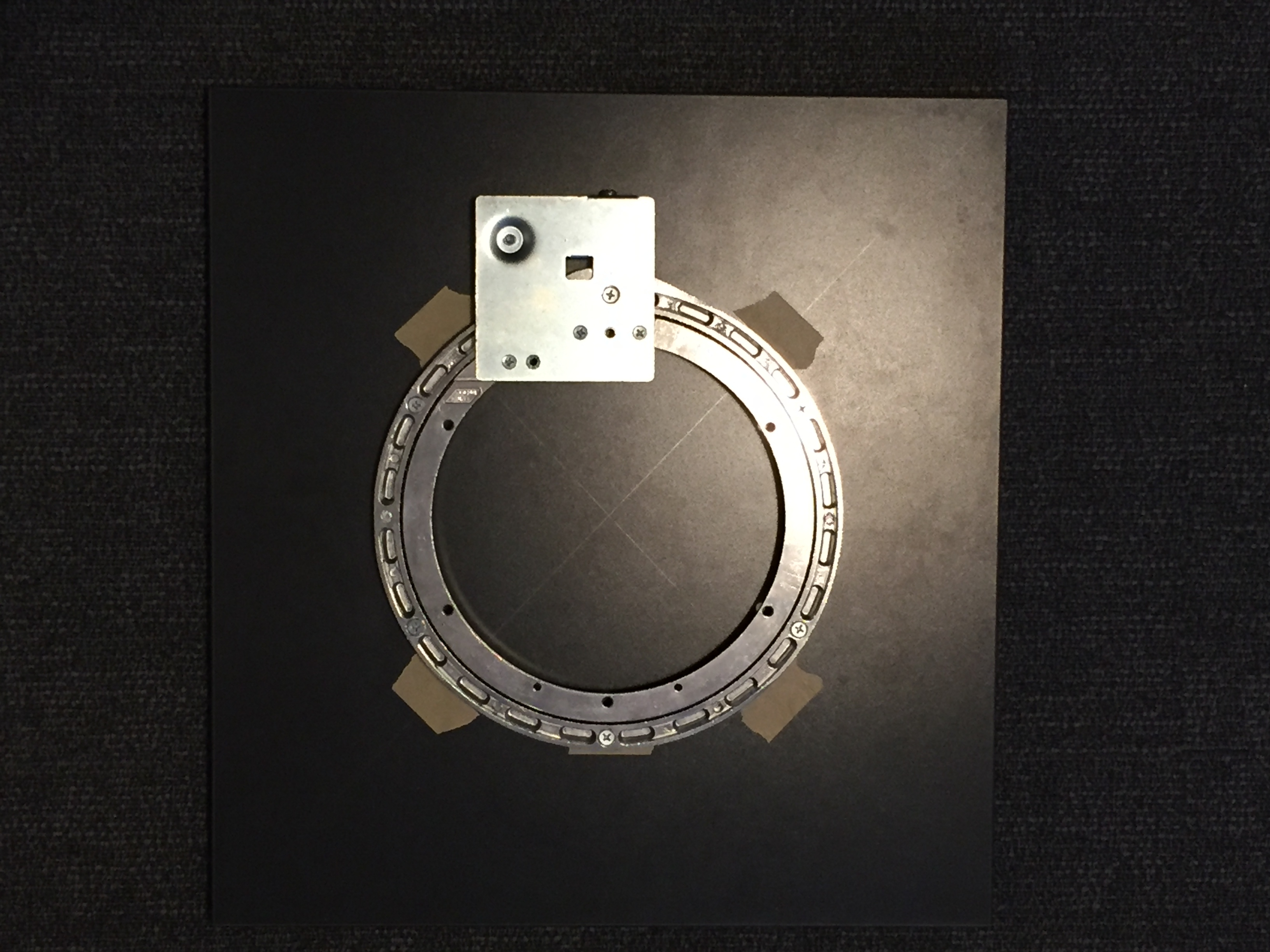

All the parts have arrived for making the 3D printer's turntable, so the first step was to get it centered onto the platform's underside:

Next, its position was located on the workbench and then attached:

Then the platform, a custom-cut Maverick workbench top with charcoal laminate and edge banding, was attached:

Does it work? Of course, it was installed by an Engineer:

Tomorrow "the beast" will get set on top of it and this area of the room can finally start getting set up.

Next, its position was located on the workbench and then attached:

Then the platform, a custom-cut Maverick workbench top with charcoal laminate and edge banding, was attached:

Does it work? Of course, it was installed by an Engineer:

Tomorrow "the beast" will get set on top of it and this area of the room can finally start getting set up.

Starbase101

Sr Member

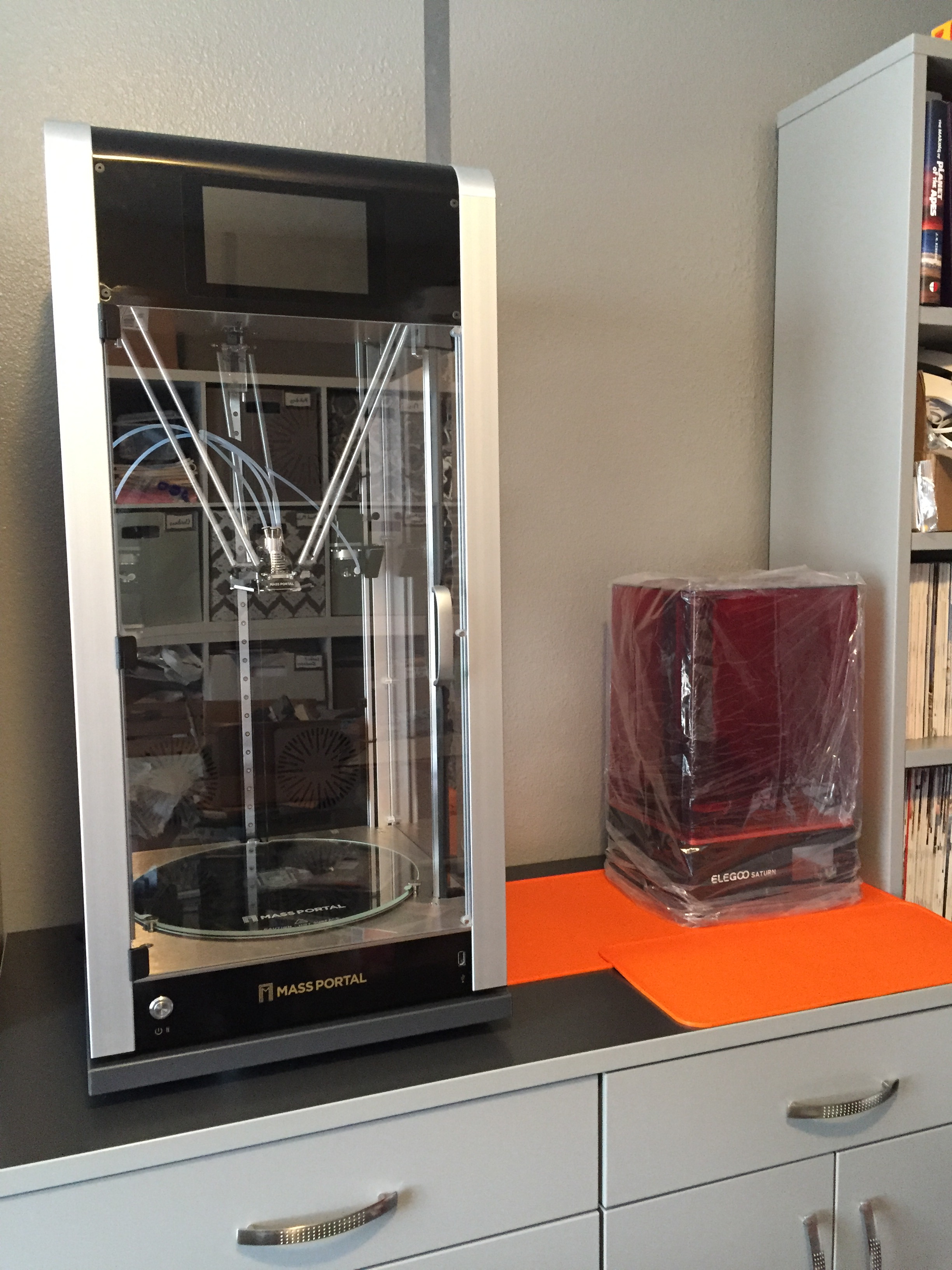

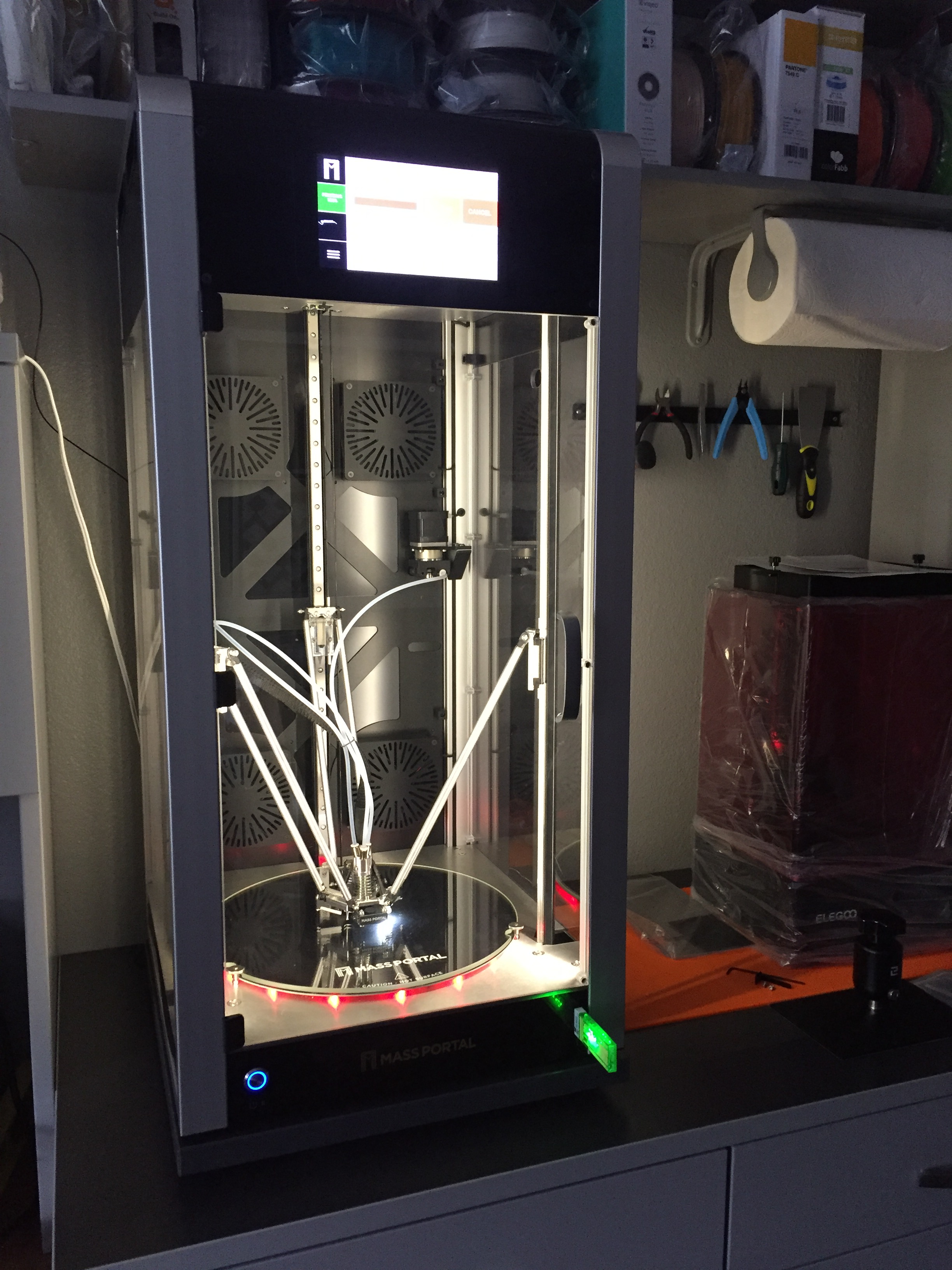

Starting to set up the new workbench, and my oh my the Saturn looks so tiny compared to the Pharaoh (and this is Elegoo's "large" printer):

I love the easy access now to the Pharaoh's backside for loading/unloading filament:

It turns out I sacrificed vertical space for shelving in exchange for under-counter storage (drawers and cabinets) but I don't mind - it's a much cleaner front than the previous cube organizer with custom countertop that I was using previously. It looks like there will be space above for only one shelf with the taller workbench top:

That one shelf and its brackets are already painted gray and ready to install (one of the not-so-showy things I've been working on while waiting for items to arrive in the mail).

I love the easy access now to the Pharaoh's backside for loading/unloading filament:

It turns out I sacrificed vertical space for shelving in exchange for under-counter storage (drawers and cabinets) but I don't mind - it's a much cleaner front than the previous cube organizer with custom countertop that I was using previously. It looks like there will be space above for only one shelf with the taller workbench top:

That one shelf and its brackets are already painted gray and ready to install (one of the not-so-showy things I've been working on while waiting for items to arrive in the mail).

Last edited:

Starbase101

Sr Member

Two steps backwards before another step forward again. Like repainting the walls with a different gray which was a real bummer but I'm glad I did it, I'm realizing the workbench electrical will have issues and now is the time to fix it rather than later. Had I known how the drawers would be set up (as in, not the full depth of the cabinet) I would have not done the 4" overhang in the back and just run power cords behind the drawers inside the cabinet. Having cords behind the cabinet is not so smart when later deciding to switch things around. The Pharaoh isn't going anywhere with its custom turntable, but the Saturn might get a different home in the garage depending on how smelly the resin is. (I've heard very smelly.) Granted, I can wear a respirator, but the cats can't. (Well, technically they could, but then we're causing grudges against humanity....) I've also decided it would be good to have a power outlet between the printers for miscellaneous temporary items like the ultrasonic cleaner and a UV curing cabinet I'll be building. So, this weekend I'm pulling the furniture out from the wall for more modifications (which means emptying the workbench and bookcase again).

It also turns out there is space above the printers for two shelves instead of just one, so I've been busy with more painting.

(And procrastination continues with the red alert electronics.)

It also turns out there is space above the printers for two shelves instead of just one, so I've been busy with more painting.

(And procrastination continues with the red alert electronics.)

Last edited:

Starbase101

Sr Member

Well this weekend was a lot of work without a lot to show for it. The printer filament shelves are done and I'm giving them some cure-time before loading them up.

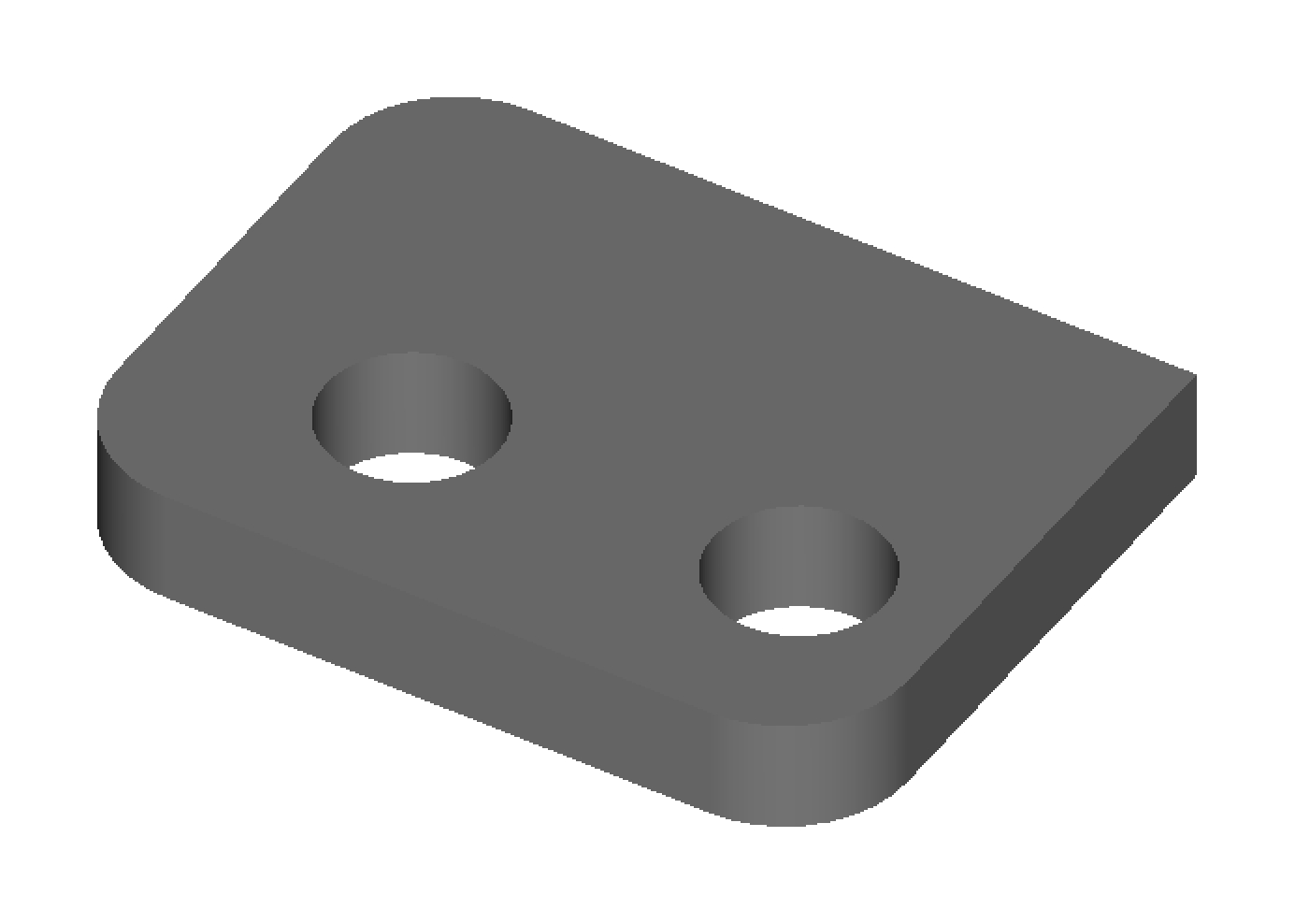

I also got a little more of the resin side set up, but a Wham Bam flexible magnetic build surface is to be installed before the first Saturn test print. The accessory adds 2.3mm thickness to the build plate and can damage the printer if not accounted for. Some people simply attach the plate and re-level the printer (which may work, but Elegoo doesn't recommend this). Some people use a Z-stop extender which can be found on Thingiverse, but after consulting with Elegoo they've recommended to me the optimal way to modify the printer. I'll need to design a part for printing on the Pharaoh to implement Elegoo's suggestion.

The big news for me is there's now "auxiliary power" on the workbench for other devices:

Next on the agenda is getting both printers set up and calibrated, which means designing that custom part for the Saturn.

I also got a little more of the resin side set up, but a Wham Bam flexible magnetic build surface is to be installed before the first Saturn test print. The accessory adds 2.3mm thickness to the build plate and can damage the printer if not accounted for. Some people simply attach the plate and re-level the printer (which may work, but Elegoo doesn't recommend this). Some people use a Z-stop extender which can be found on Thingiverse, but after consulting with Elegoo they've recommended to me the optimal way to modify the printer. I'll need to design a part for printing on the Pharaoh to implement Elegoo's suggestion.

The big news for me is there's now "auxiliary power" on the workbench for other devices:

Next on the agenda is getting both printers set up and calibrated, which means designing that custom part for the Saturn.

Last edited:

Starbase101

Sr Member

Which of the filament colors linked below do you think might be the best color match for:

www.matterhackers.com

www.matterhackers.com

www.matterhackers.com

www.matterhackers.com

www.matterhackers.com

www.matterhackers.com

www.matterhackers.com

www.matterhackers.com

It's hard to gauge from online photos what the actual color is of the physical product, and I'd rather not be buying 4 or more spools of filament just to see them in person. I can already rule out many of the colors at Product Search | MatterHackers for being not even close (like Blonde, Banana, Lemon, Neon, Translucent, etc). It also needs to be a rigid material, so NinjaFlex and other "rubbery" materials are excluded. I'd like to get the yellow (and a red) filament ordered in preparation for making conduit junction boxes.

(I'm leaning towards the Kodak product.)

Kodak Yellow PLA+ Filament - 1.75mm (0.75kg)

The bread and butter of 3D printing, but with that gorgeous Kodak approach that improves the material in every way, PLA+ is the ultimate 3D printing filament when you want an incredibly smooth, easy printing experience, with very little warping, and vastly improved impact resistance. You can...

Protopasta Yellow Matte Fiber HTPLA Filament - 1.75mm (0.5kg)

Protopasta HTPLA combines the ease of PLA 3D printing with the ability to heat-treat your parts post-printing to increase their stiffness at higher temperatures. This makes the PLA a more universal use filament, and this specific blend also features a matte finish. The natural matte finish of...

Raise3D Yellow Premium PLA Filament - 1.75mm (1kg)

The Raise3D premium PLA filament is the perfect solution for 3D printing enthusiasts who want to ensure quality prints by staying entirely within the Raise3D eco-system. This easy-to-print, premium PLA filament ensures great prints, both in quality and aesthetics. It utilizes jam-free...

Fillamentum Extrafill Melon Yellow PLA Filament - 1.75mm (0.75kg)

The Extrafill PLA series from Fillamentum is premium PLA with a vast selection of useful, gorgeous colors, and features very unique finish which makes layer lines less visible. Top Fillamentum Extrafill PLA features include: Dependable, High Quality PLA Easy Printability for Any Application...

It's hard to gauge from online photos what the actual color is of the physical product, and I'd rather not be buying 4 or more spools of filament just to see them in person. I can already rule out many of the colors at Product Search | MatterHackers for being not even close (like Blonde, Banana, Lemon, Neon, Translucent, etc). It also needs to be a rigid material, so NinjaFlex and other "rubbery" materials are excluded. I'd like to get the yellow (and a red) filament ordered in preparation for making conduit junction boxes.

(I'm leaning towards the Kodak product.)

Starbase101

Sr Member

I decided to try ABS filament for the first time and ordered a few colors. The ABS overall seems to be a good color compared to the PLA choices, and should be more durable:

Starbase101

Sr Member

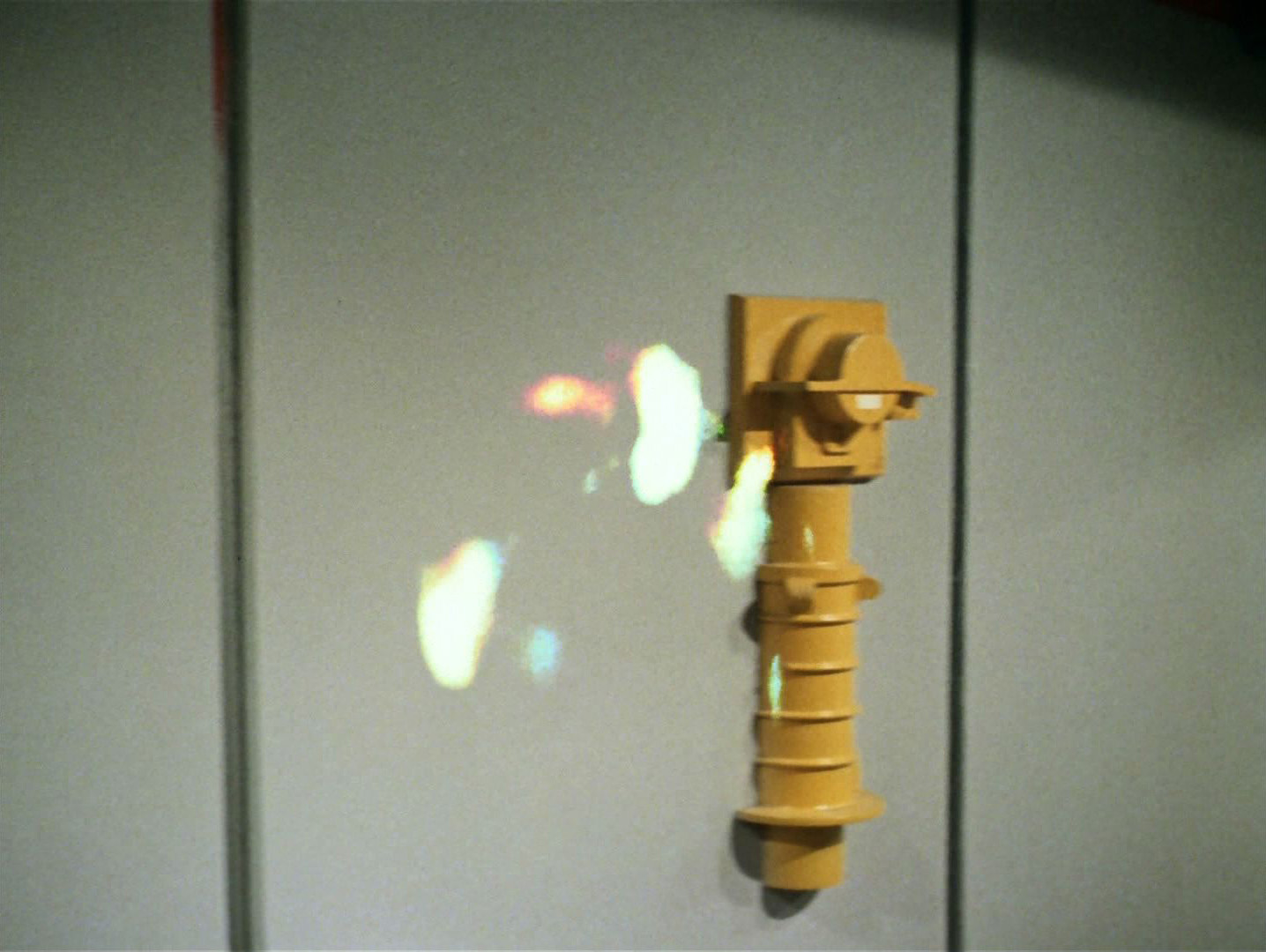

Saturn Z-stop spacer to compensate for increased build platform thickness added by a Wham Bam plate:

Pharaoh printing the part (so much easier loading filament now that the printer can be rotated):

(Yes, the data is stored on an isolinear chip plugged into the printer.) Another "what were they thinking" design decision with this printer is filament spools hanging on the back of the machine. The printer has 3 extruders, but only 1 spool fits on the provided holder rod. Besides, with my machine placement against a wall, even 1 spool doesn't fit (although it probably would have if I installed the turntable further from the wall, but I prefer having it as far back as the rotating allows). Since some filament types such as nylon need to be kept dry (they absorb humidity faster than other filaments like PLA) there was already a plan in place - filament feeds from a dryer beside the printer:

This is still a work-in-progress, as I plan to install conduit for the white power cord and order a 3rd tier for the dryer so 3 spools can be loaded at the same time.

With the spacer printed I can now finish setting up the Saturn, which will be used to print the room's intercom shells:

This Z-stop adjustment is a much better solution for the magnetic build plate installation than the options provided on Thingiverse. However, resin printing won't be happening until the weekend when I can cure a test print outside in sunlight (since I haven't built a UV curing station yet and I work during the daytime on weekdays).

Pharaoh printing the part (so much easier loading filament now that the printer can be rotated):

(Yes, the data is stored on an isolinear chip plugged into the printer.) Another "what were they thinking" design decision with this printer is filament spools hanging on the back of the machine. The printer has 3 extruders, but only 1 spool fits on the provided holder rod. Besides, with my machine placement against a wall, even 1 spool doesn't fit (although it probably would have if I installed the turntable further from the wall, but I prefer having it as far back as the rotating allows). Since some filament types such as nylon need to be kept dry (they absorb humidity faster than other filaments like PLA) there was already a plan in place - filament feeds from a dryer beside the printer:

This is still a work-in-progress, as I plan to install conduit for the white power cord and order a 3rd tier for the dryer so 3 spools can be loaded at the same time.

With the spacer printed I can now finish setting up the Saturn, which will be used to print the room's intercom shells:

This Z-stop adjustment is a much better solution for the magnetic build plate installation than the options provided on Thingiverse. However, resin printing won't be happening until the weekend when I can cure a test print outside in sunlight (since I haven't built a UV curing station yet and I work during the daytime on weekdays).

Last edited:

Starbase101

Sr Member

ABS spools arrived today. The colors are brighter than pictured online, but I'm going to just use them anyway. It will be my first time printing with ABS....

Starbase101

Sr Member

I've been busy lately with other things but did get a couple other yellow filament colors because I've read about too many issues regarding ABS that I just don't want to deal with. As you can see, "Yellow" is not the same color across different manufacturers:

I easily ruled out some brands because their online photos were clearly a bright lemon yellow which is not the color I'm going for. Using the yellow electrical tape as a loose POR (since it will be the yellow striping on nearby gray pipes), it's looking like the Kodak brand might be good a color to use. It's been cold and rainy here the last several days so my next priority is building a Trek-themed UV curing chamber.

I easily ruled out some brands because their online photos were clearly a bright lemon yellow which is not the color I'm going for. Using the yellow electrical tape as a loose POR (since it will be the yellow striping on nearby gray pipes), it's looking like the Kodak brand might be good a color to use. It's been cold and rainy here the last several days so my next priority is building a Trek-themed UV curing chamber.

Starbase101

Sr Member

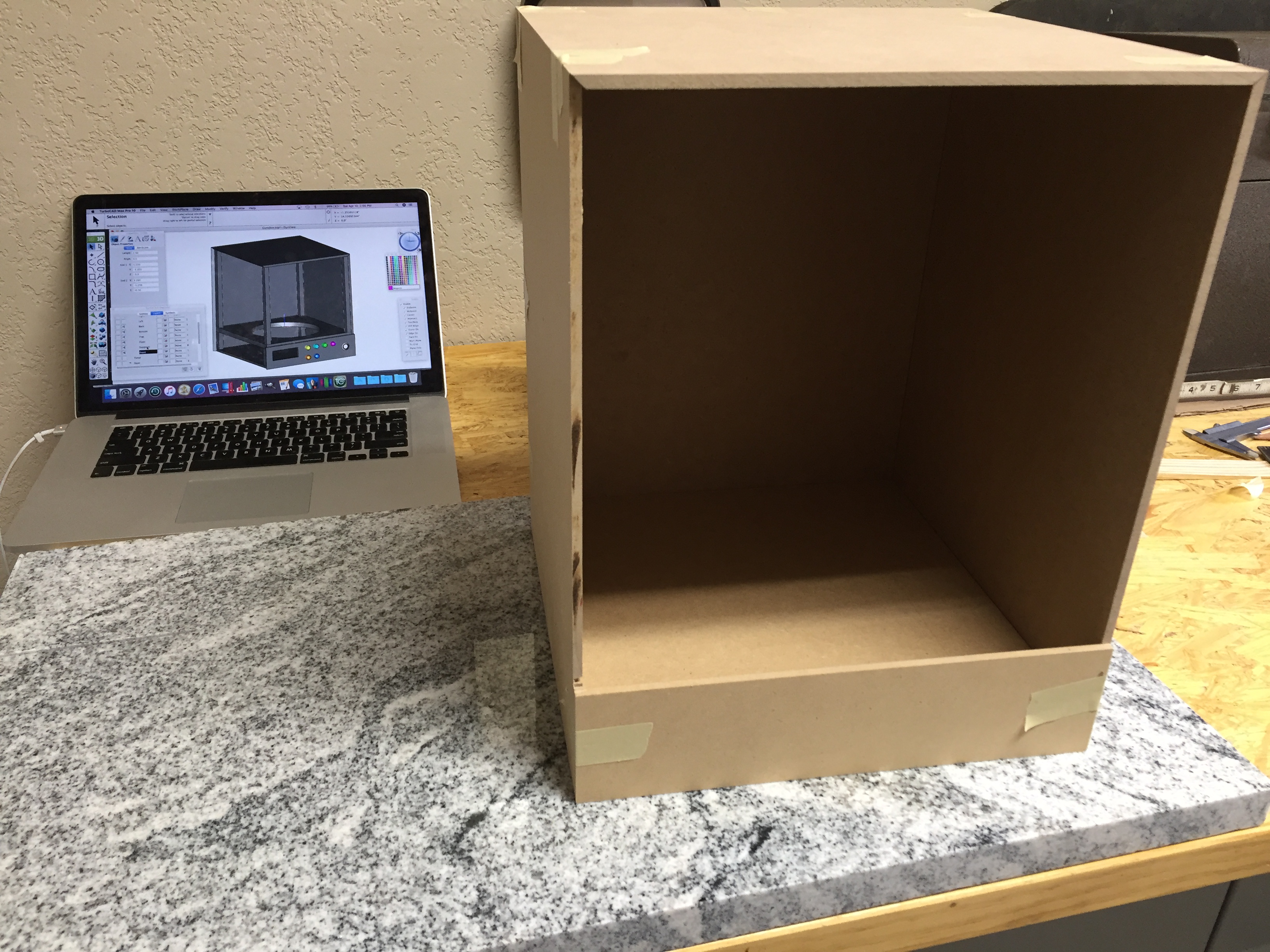

It's been busy here lately, taking time away from this project but I thought somebody might be curious to see one of the items I've been working on. I'm almost done designing a UV curing box for resin prints and it starts construction on the weekend:

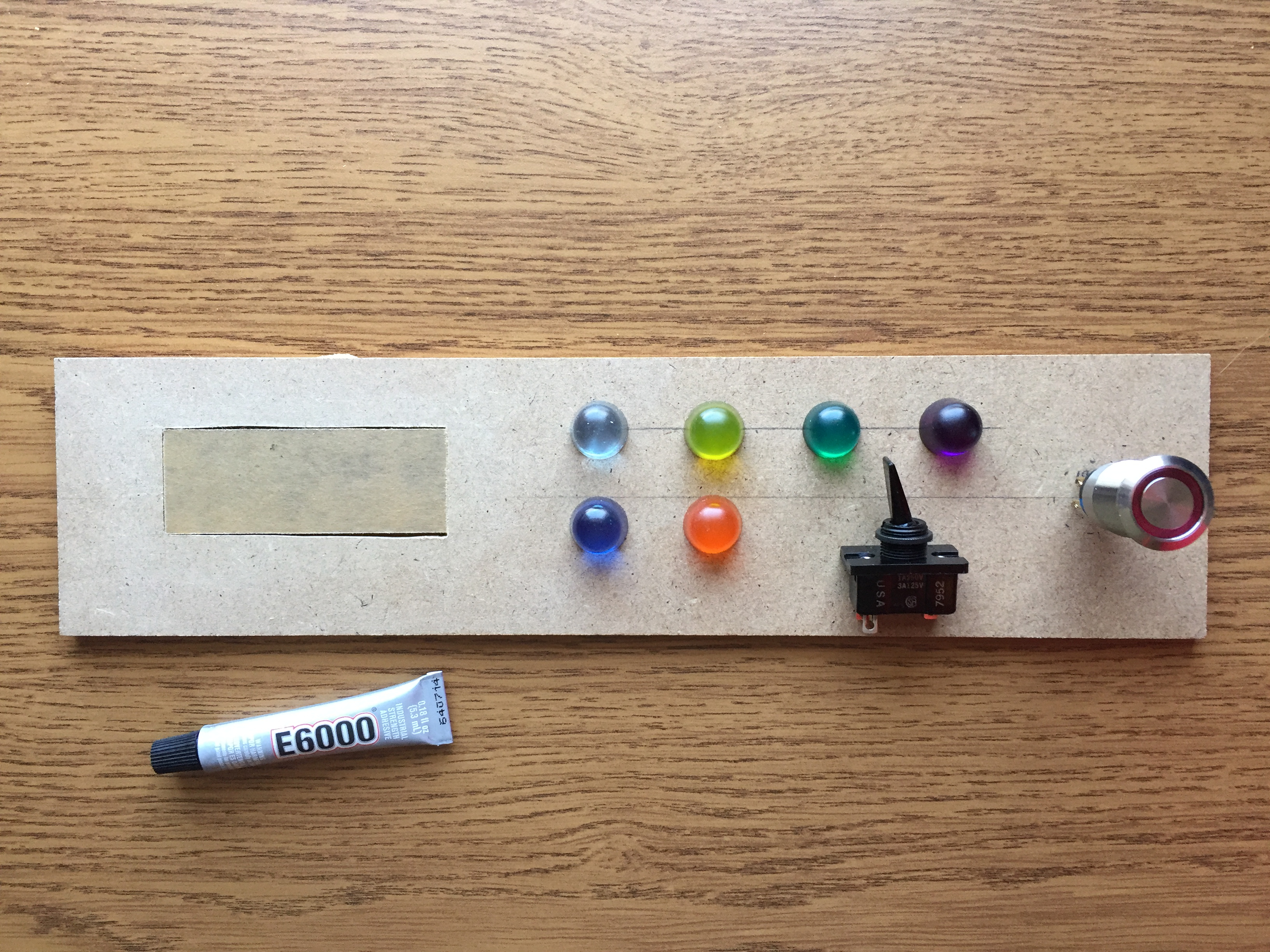

All of the interior will be lined with mirrored chrome and six hundred 405nm UV LEDs, and there's a dual-speed turntable on the bottom. The front has a digital timer and all the LED-lit buttons will be functional (and with sound effects). Not pictured (because it hasn't arrived yet for me to model) will be a black toggle switch beneath the green and purple buttons. There are other components ordered as well but have not arrived yet.

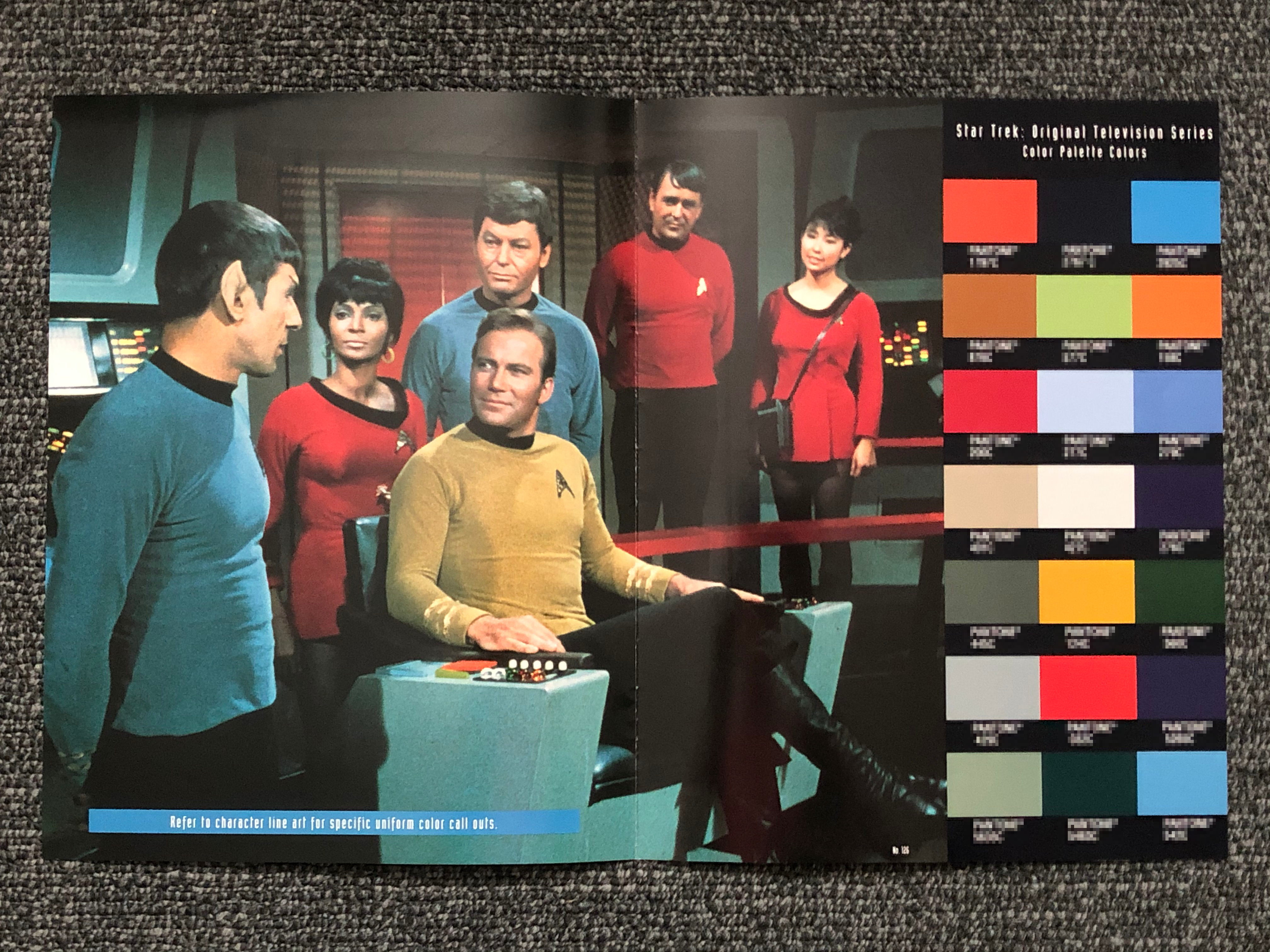

Another item I've acquired is an official Paramount Pictures Star Trek Style Guide:

What will be most useful from this is a Pantone color palette for choosing the proper colors for each of the props I'll be building:

Mostly I've simply been at the mercy of slow shipments for component orders, and springtime tasks around the house and yard.

All of the interior will be lined with mirrored chrome and six hundred 405nm UV LEDs, and there's a dual-speed turntable on the bottom. The front has a digital timer and all the LED-lit buttons will be functional (and with sound effects). Not pictured (because it hasn't arrived yet for me to model) will be a black toggle switch beneath the green and purple buttons. There are other components ordered as well but have not arrived yet.

Another item I've acquired is an official Paramount Pictures Star Trek Style Guide:

What will be most useful from this is a Pantone color palette for choosing the proper colors for each of the props I'll be building:

Mostly I've simply been at the mercy of slow shipments for component orders, and springtime tasks around the house and yard.

Last edited:

Starbase101

Sr Member

UV curing box parts were cut today from 1/4" and 1/2" MDF board. Tomorrow I'll start the panel cutouts, and also begin gluing together parts not having cutouts. The initial design was 10" x 10" x 12" but that was looking smallish so I increased the size to 12" x 12" x 15" for more "elbow room".

Starbase101

Sr Member

The door's "window" is cut. Mounted behind it will be a piece of red-tinted acrylic, the same material used for some UV safety glasses. Box assembly has begun:

Starbase101

Sr Member

Is anybody interested in following along with the UV curing box construction? Should I refrain from pics of the construction and just show the result when it's done? Should it have its own thread or just continue posting updates here?

Lightning

Master Member

You should go ahead and keep everything here. Do you intend for the oven to be like an "in universe" piece of lab equipment? I ask because I don't think 2260s Starfleet designers would make a Delta shaped window. However if you aren't going for "in universe", it looks really cool.

Starbase101

Sr Member

It's a sort of mash-up with in-universe and non. I wanted to include a monitoring window like all the ready-made units, but a rectangular viewport is boring so I thought it would be fun having the delta shape. This now essentially screams "Star Trek" in the box's design. The control panel is inspired by the TOS computers and lab equipment. If I had the workbench space it would have been fun to build this styled as the lab analyzer, but in this circumstance it needs to be function over form and fit within my limited workspace. I'm still waiting for LED tactile switches, a black toggle switch, and a 5v regulator to arrive and then I'll have all the components ready for a photo and placement planning.

Last edited:

Starbase101

Sr Member

Box construction continues, sorry for the backlit washout - that's what you get with daytime photos on a window-facing desk. Great for project lighting, not so great for photos.

Starbase101

Sr Member

I'm still waiting for LED tactile switches and sound boards to arrive, so prep work for the UV box's control panel is started. The saber saw left a few gaps around the red acrylic lens (I don't have a laser cutter), but I suppose that's actually desirable because it provides a place to spatula glue into. I expect the brown paper tape protecting the acrylic will withstand primer and paint, right? My thought was to leave the tape attached until a clear topcoat has dried and then remove it.

Last edited:

Please keep everything in this thread. Enjoying your journey.Is anybody interested in following along with the UV curing box construction? Should I refrain from pics of the construction and just show the result when it's done? Should it have its own thread or just continue posting updates here?

Similar threads

- Replies

- 10

- Views

- 1,176