After purchasing one of the Diamond Select Tricorders with science scanner a few years back, I thought it would be fun to try and machine a full-scale scanner. It turns out the Diamond Select version is slightly smaller than the original and it uses a standard RGB (Red/Green/Blue) color changing LED. The original scanner used a small motor with a color wheel that provides six different colors, but I think it's a little overkill for this project, so I'm opting for a standard, color changing LED, instead.

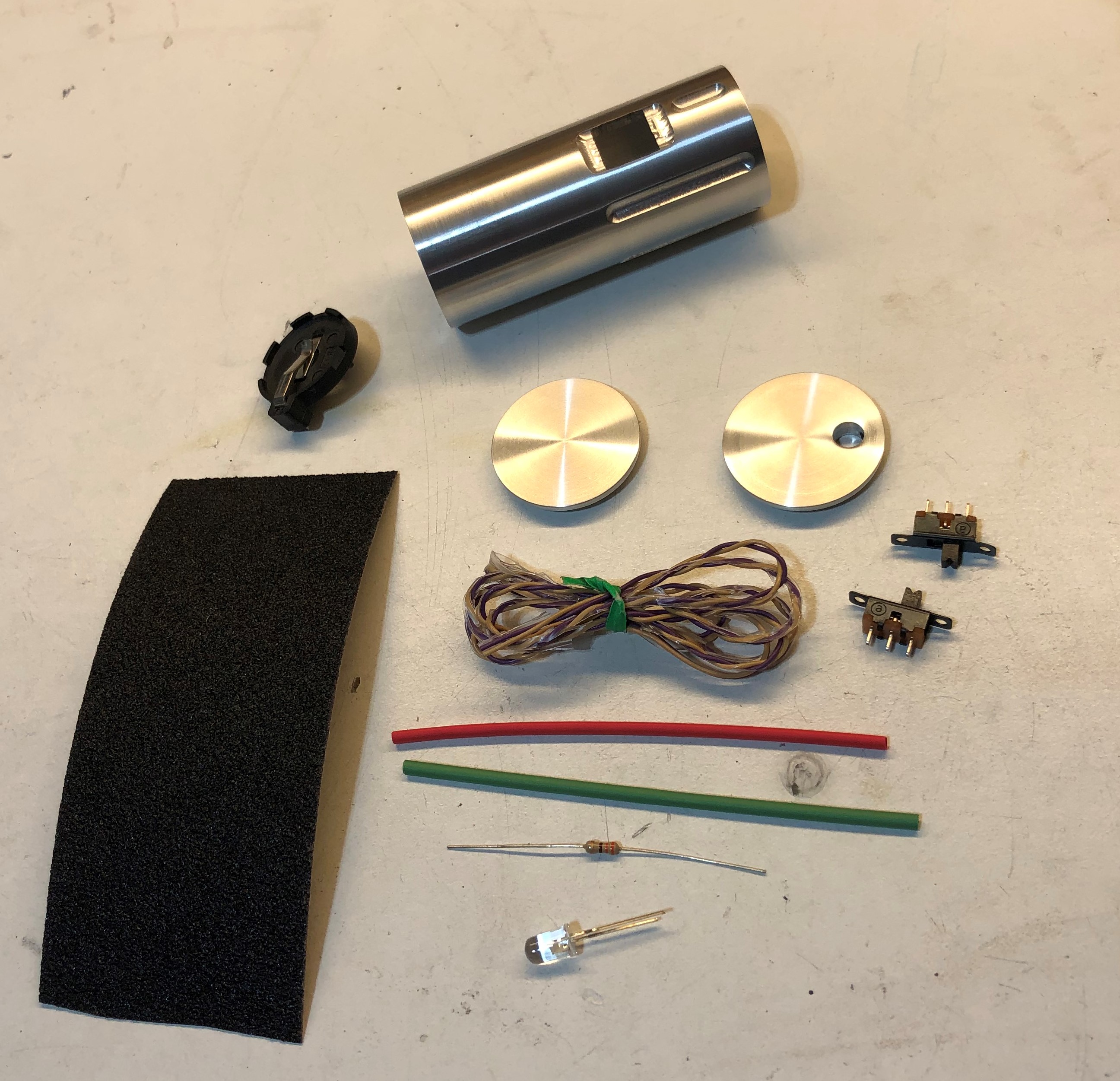

Here's all of the parts (sans the bolts) laid out. Most of the electronics can be found at any surplus store. The black tape is actually "floor" tape I found at a local hardware store:

Here's all of the parts (sans the bolts) laid out. Most of the electronics can be found at any surplus store. The black tape is actually "floor" tape I found at a local hardware store:

Last edited: