Iskelderon

Sr Member

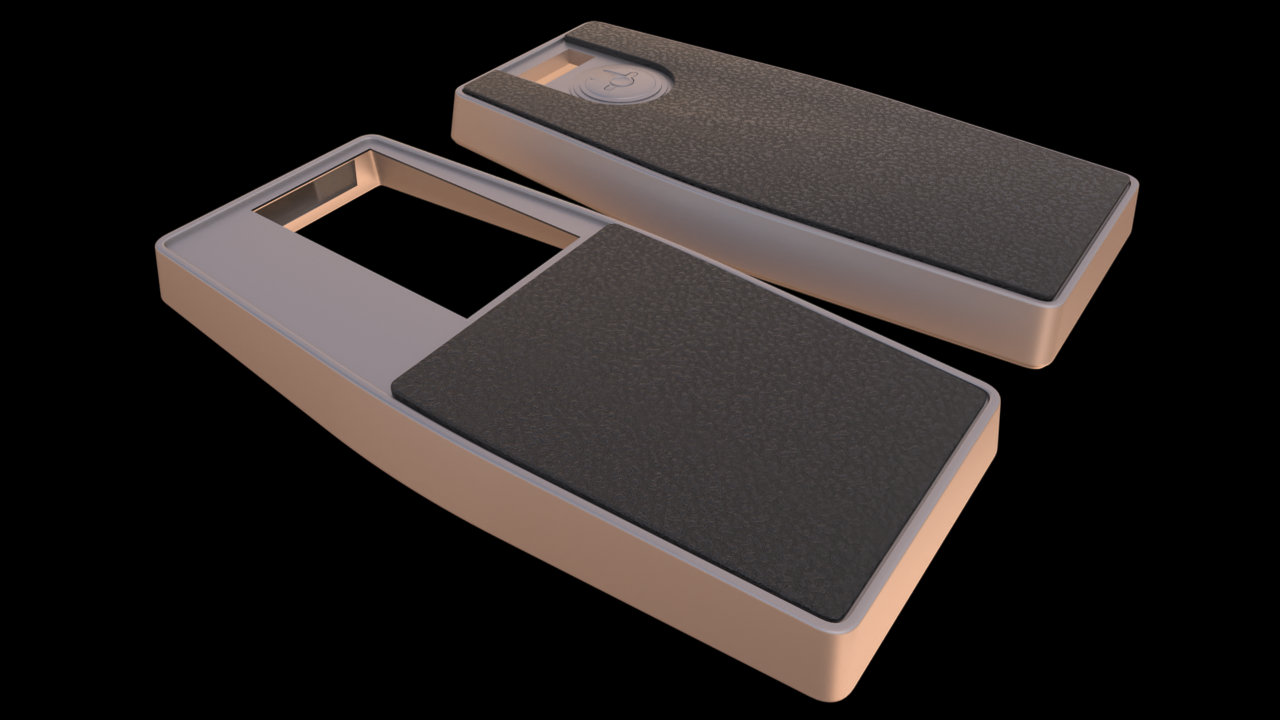

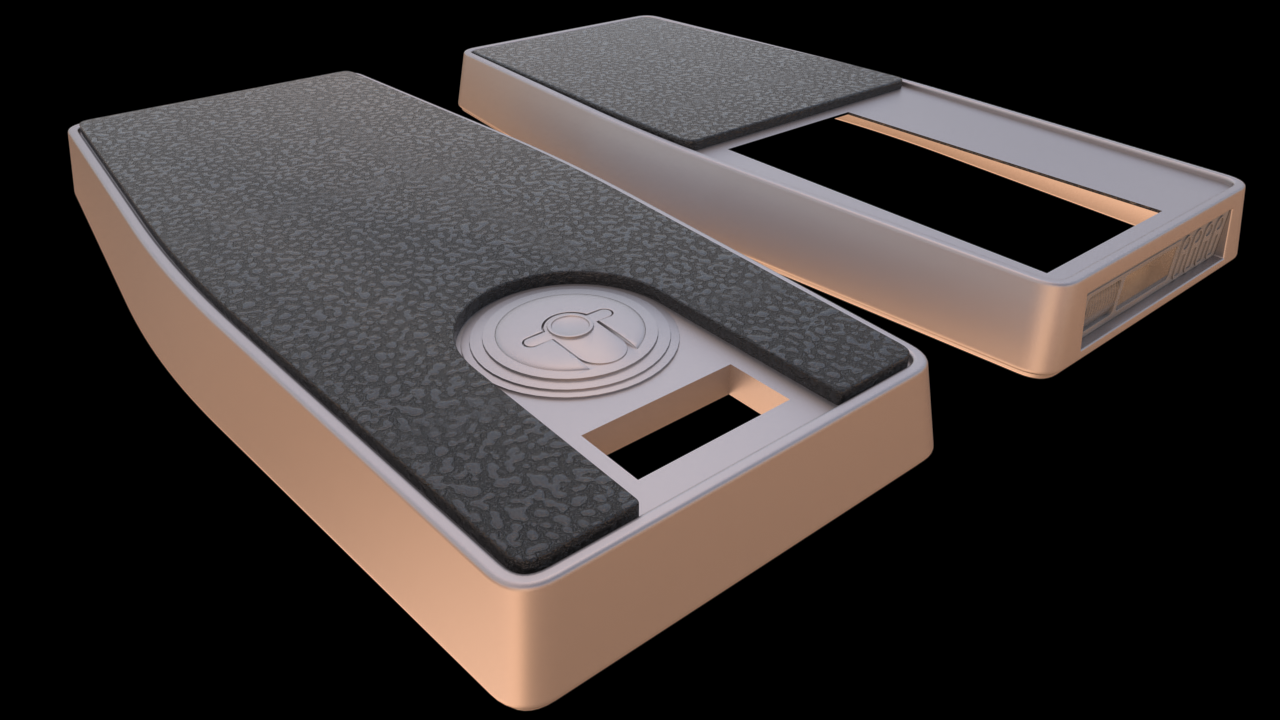

We never got to see one in the movie and since I've always had a fascination with this unexplored era between Kirk's movies and TNG I'm designing my own one, based on an old 70s era walkie talkie.

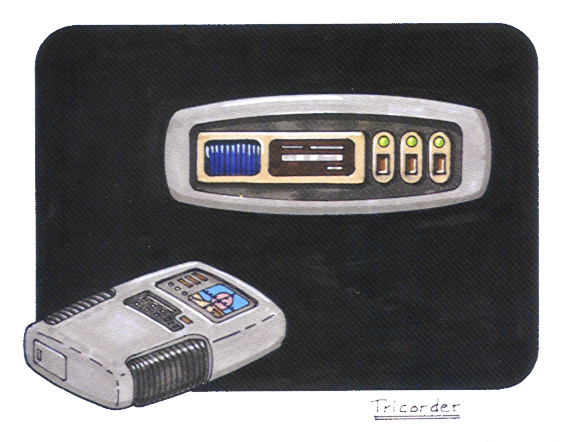

The idea is to have something that bridges the gap between the mostly simplistic greebled movie tricorders Kirk's crew carried during the later movies and TNG's button & LED heavy tricorders with a sprinkle of some of Rick Sternbach's initial concept sketches before he progressed to the clamshell design we're all familiar with.

I've also attached some of the references I'm working from to show where this is heading.

The idea is to have something that bridges the gap between the mostly simplistic greebled movie tricorders Kirk's crew carried during the later movies and TNG's button & LED heavy tricorders with a sprinkle of some of Rick Sternbach's initial concept sketches before he progressed to the clamshell design we're all familiar with.

I've also attached some of the references I'm working from to show where this is heading.