lewiscondrey

New Member

Heres a look at the finished product

EDIT:

-----------------------------------------------------------------------------------------------------------------

As the title says I'm making a moving lense spider-man cosplay maskI'm actually in the final few stages.

I only have to 3d print my parts and wait for my pcb to arrive so that I can assemble the final product.

using the sensor eliminates the need for a second switch to change "modes" as the mask does what I do

It has been a fun little challenge, but from the lack of info, I intend on releasing a tutorial once I have completed it

I'm using the Arduino nano and an obstacle avoidance sensor close to my eyes being treated like button presses to move 2 rotary servo's

first I had to see if i could get this to react to my eye closing so here's a quick test of that

[removed]

with this working in theory I knew i had to get 2 servos moving independently with virtually no lag if this was going to work

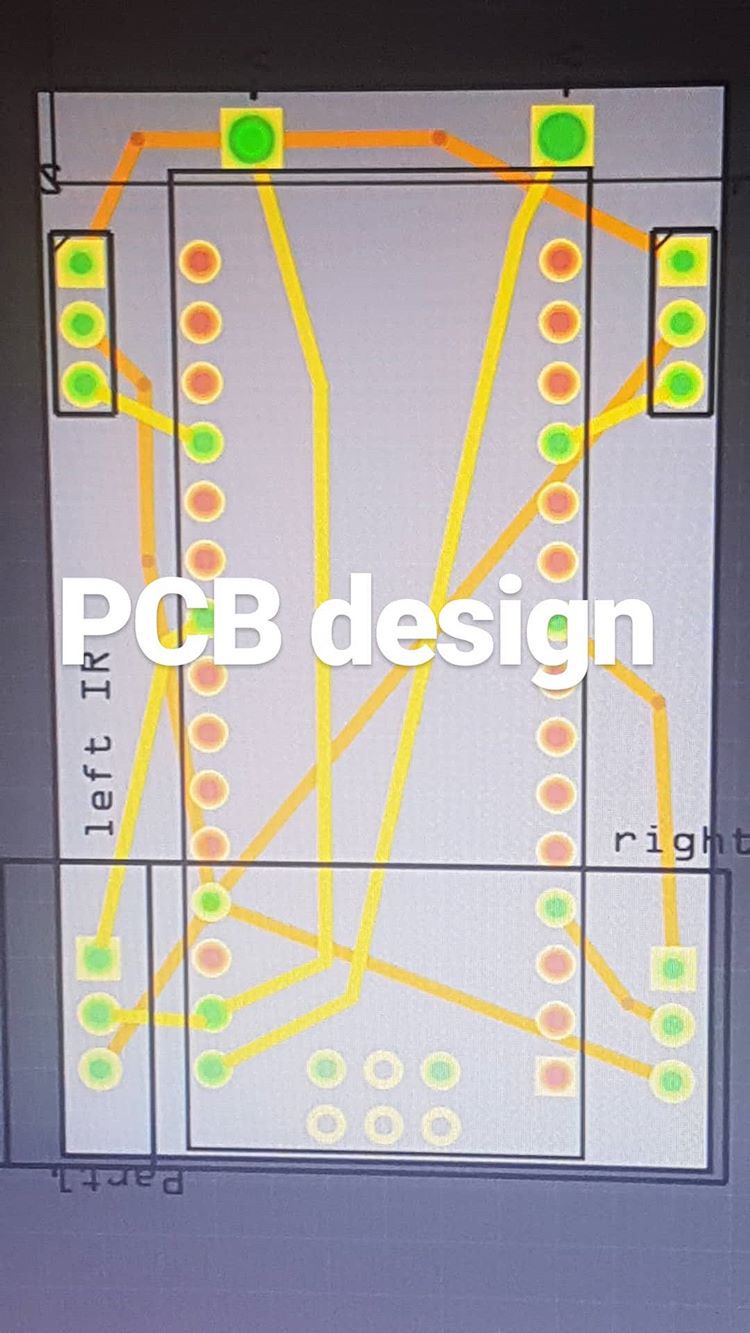

with my circuit built I designed a pcb and got it ordered (currently waiting for arrival)

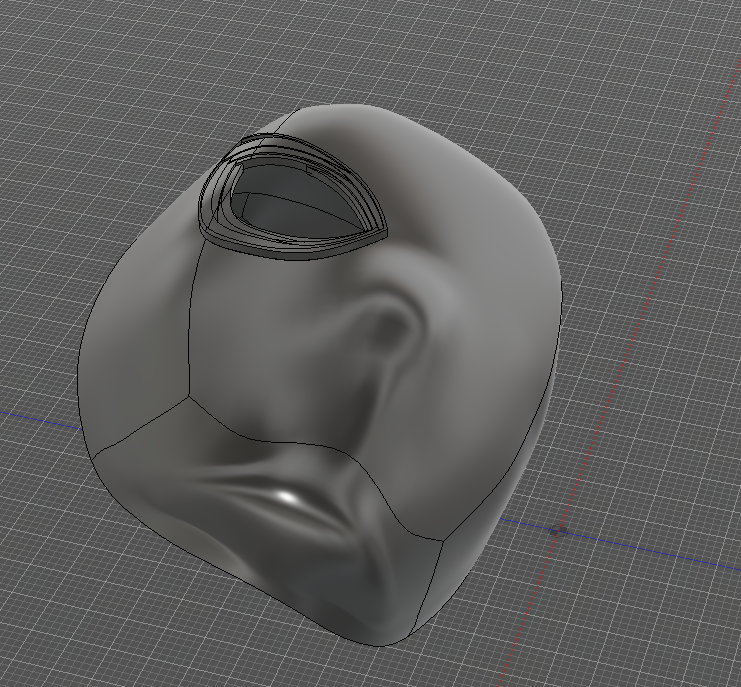

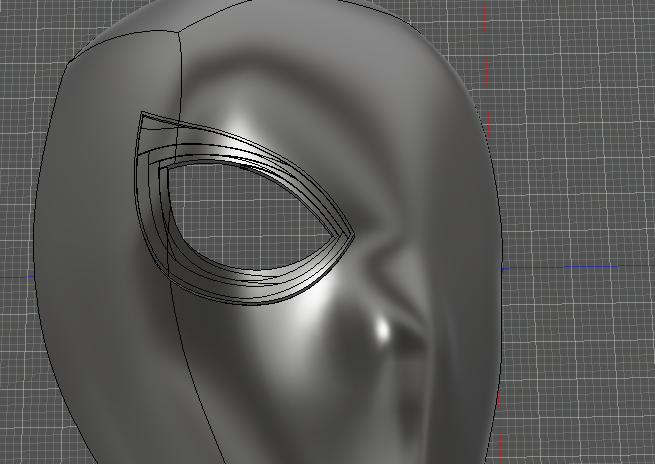

next its time for a faceshell and the lenses themselves, so I began using this reference for the headshape

and began modelling

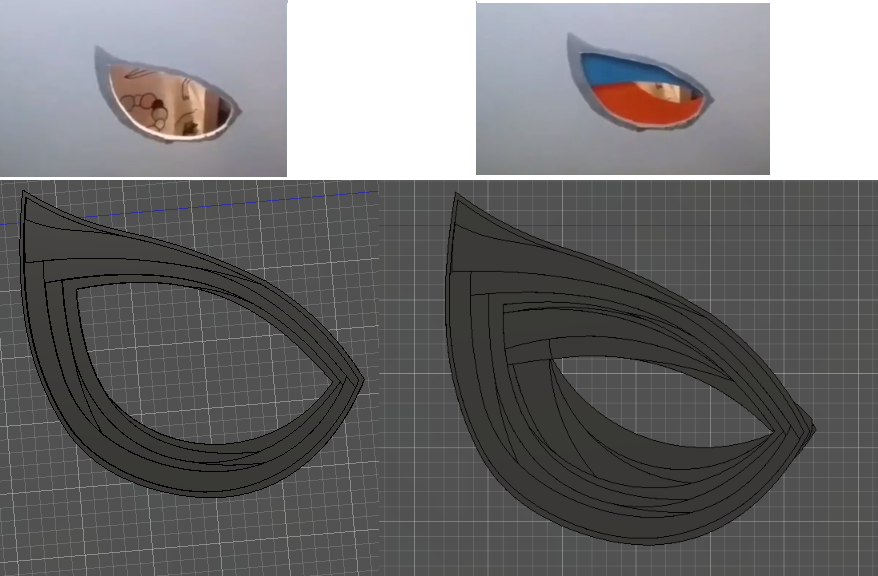

next for the lenses I used this reference but I didn't like how unsmooth the hole was or the way they closed towards the center instead of around where your eyes would sit

So I modelled the outside lens and off the widest/most open in the reference and when designing the inner moving pieces I just repeated the pattern but making the space smaller and smaller to gimmick a camera lens and made it so they close towards the nose

and as of writing this I have curved the lenses to fit the faceshell and just need to add holes for pivots, holes for elastic and holes for breathing

So like I said the project is nearly finished and I can't wait to wear it to mcm london next month

let me know what you all think! if you have any suggestion for other things I can try implement to the mask or smarter ways I could be doing this.

EDIT:

-----------------------------------------------------------------------------------------------------------------

As the title says I'm making a moving lense spider-man cosplay maskI'm actually in the final few stages.

I only have to 3d print my parts and wait for my pcb to arrive so that I can assemble the final product.

using the sensor eliminates the need for a second switch to change "modes" as the mask does what I do

It has been a fun little challenge, but from the lack of info, I intend on releasing a tutorial once I have completed it

I'm using the Arduino nano and an obstacle avoidance sensor close to my eyes being treated like button presses to move 2 rotary servo's

first I had to see if i could get this to react to my eye closing so here's a quick test of that

[removed]

with this working in theory I knew i had to get 2 servos moving independently with virtually no lag if this was going to work

with my circuit built I designed a pcb and got it ordered (currently waiting for arrival)

next its time for a faceshell and the lenses themselves, so I began using this reference for the headshape

and began modelling

next for the lenses I used this reference but I didn't like how unsmooth the hole was or the way they closed towards the center instead of around where your eyes would sit

So I modelled the outside lens and off the widest/most open in the reference and when designing the inner moving pieces I just repeated the pattern but making the space smaller and smaller to gimmick a camera lens and made it so they close towards the nose

and as of writing this I have curved the lenses to fit the faceshell and just need to add holes for pivots, holes for elastic and holes for breathing

So like I said the project is nearly finished and I can't wait to wear it to mcm london next month

let me know what you all think! if you have any suggestion for other things I can try implement to the mask or smarter ways I could be doing this.

Attachments

Last edited: