You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

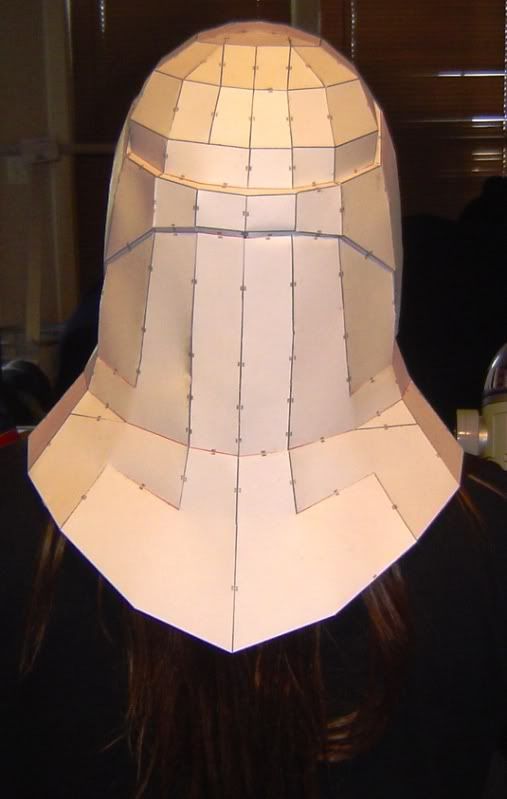

Royal Guard Pep

- Thread starter ctx32

- Start date

rg_helmet_unfold_by_Lando.pdo - 4shared.com - online file sharing and storage - download

This is where I got the file. It is a great Pep file to work with and very well done.

Thanks for the info about the glue, I saw it in a video.

I can't wait to fiberglass now.

Calvin

This is where I got the file. It is a great Pep file to work with and very well done.

Thanks for the info about the glue, I saw it in a video.

I can't wait to fiberglass now.

Calvin

Fierfek, Thank you for the file.

It was a real joy to build and it was very clear on the layout.

I'm also working on a Biker Scout helmet that was done by Nintendo dude.

I think that was the name.

My wife is trying to join the 501st.

I can't wait till the Pit Droid file is complete, hint hint.

Thanks for the info on glassing guys, ill post pics this weekend.

I hope it all goes good.

Calvin

It was a real joy to build and it was very clear on the layout.

I'm also working on a Biker Scout helmet that was done by Nintendo dude.

I think that was the name.

My wife is trying to join the 501st.

I can't wait till the Pit Droid file is complete, hint hint.

Thanks for the info on glassing guys, ill post pics this weekend.

I hope it all goes good.

Calvin

Tigerblood

Well-Known Member

Great pep work... I also use 2 outside coats of resin and 1 to 2 inside coats before I fiberglass... It's always worked well for me

you're just wasting the effort of coating outside and the inside. Just brush the inside with "rondo".

KaanE

Sr Member

you're just wasting the effort of coating outside and the inside. Just brush the inside with "rondo".

If you do a coat of poly resin on the outside it will cover the holes, so you'll have a better rondo work on the inside, and it will also give you a better surface for the bondo (it will stick better to the helmet) plus a harder surface to work.

Tigerblood

Well-Known Member

the resin isn't a better substrate to put bondo on. Using rondo in the inside fills the corners and beveled areas hence it's better to do this alone before the filler. This is the most cost effective way to do it.If you do a coat of poly resin on the outside it will cover the holes, so you'll have a better rondo work on the inside, and it will also give you a better surface for the bondo (it will stick better to the helmet) plus a harder surface to work.

I applied 2 coats of fiber Resin on the outside, 2 on the inside, followed by Fiberglass Cloth. I know it's sloppy work with the cloth but its my 1st time. Its as hard as a rock.

I need to clean the edges and give it a sand to prepare the outside for Evercoat Bondo.

Hope it works out.

Calvin

I need to clean the edges and give it a sand to prepare the outside for Evercoat Bondo.

Hope it works out.

Calvin

Similar threads

- Replies

- 3

- Views

- 444

- Replies

- 2

- Views

- 1,701

- Replies

- 13

- Views

- 1,693