All updates completed and I believe the bottom assembly (and some other findings) have finally been uncovered!

So based on new photographs and first hand feedback from

roygilsing, I was able to formulate a theory about how the bottom was assembled. I drew up a quick model to visualize and was off to search for a Plastruct disc or ring (based on the photo evidence I knew I was looking for a Plastruct Part).

I scoured every single part offered by Plastruct and then checked my work against their catalog, but the effort was hallow; so I contacted Plastruct and some distributors to assist. I received confirmation that the disc(s) I was searching for did not exist in the sizes I needed. So I returned to the real prop images to see what else I could see.

On thing is that the disc we are looking for sits in the inner skirt lip, not flush with it… so the disc/plate in question had to be thinner than the ledge of the skirt… and there it was! Plastruct has generic ABS sheets that would have been used, I imagine, across studio models etc and would have been plentiful… the discs we are looking for may have already been cut and been “scrap” from other models… while this was anticlimactic, I decided to give it a try and ordered some.

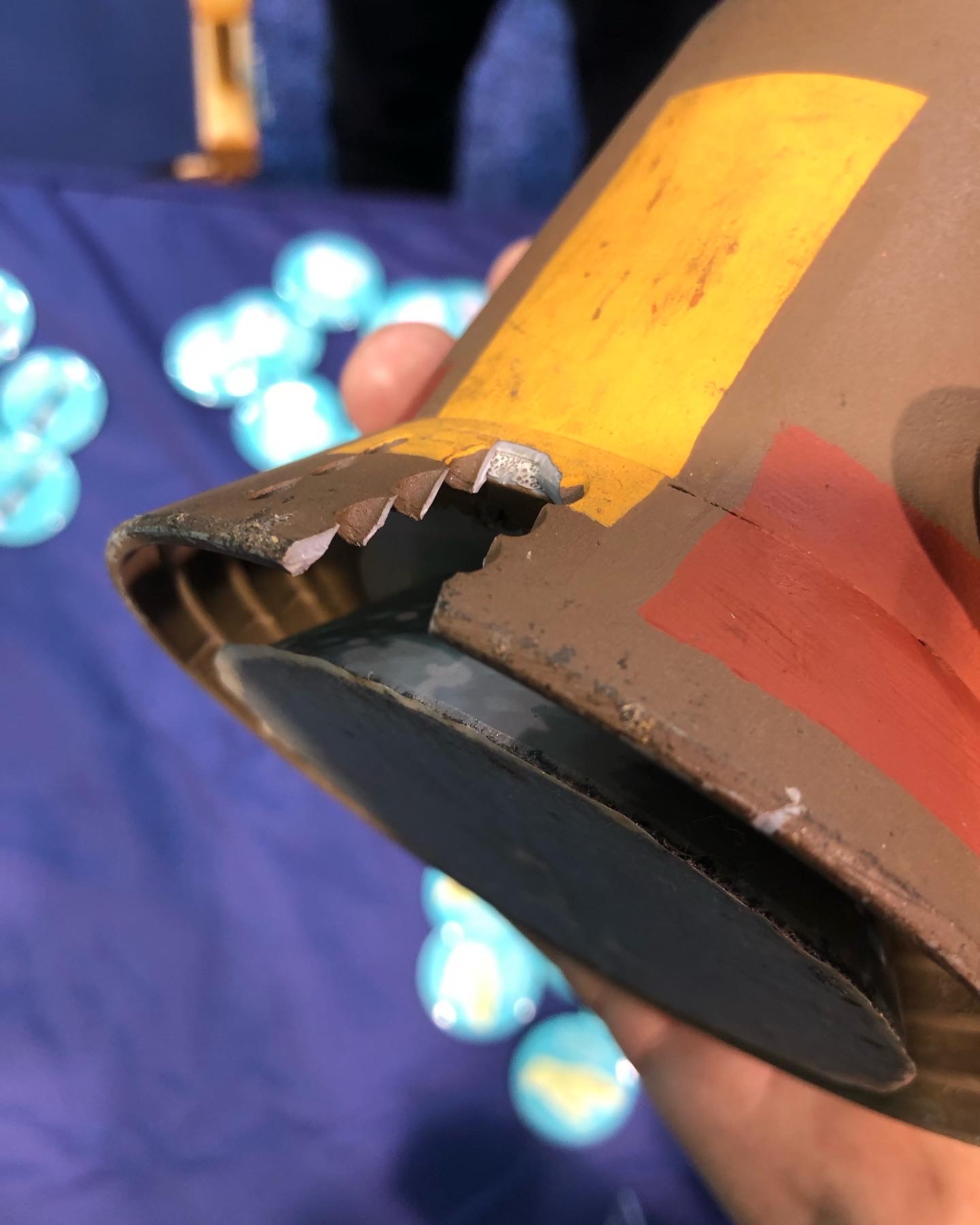

While waiting for the new sheets to arrive, we started to examine the inner cone. To me, it appeared that the base of the inner cone was immediately cut from the top of the skirt.

roygilsing did some overlays to the screen used prop and found that it was approx 2mm smaller than the real part??? We couldn’t cut back one more step in the cone or it would be too small… did they use a different cone for the inner assembly - didn’t make a lot of sense as the discarded top cone would have already been available. Then a lightbulb… just like the upper plate, the lower plate would be thinner than the inner step. If the cone was sanded back in order to make the disc flush, this would reduce the OD ~2mm matching what Roys overlays were telling us.

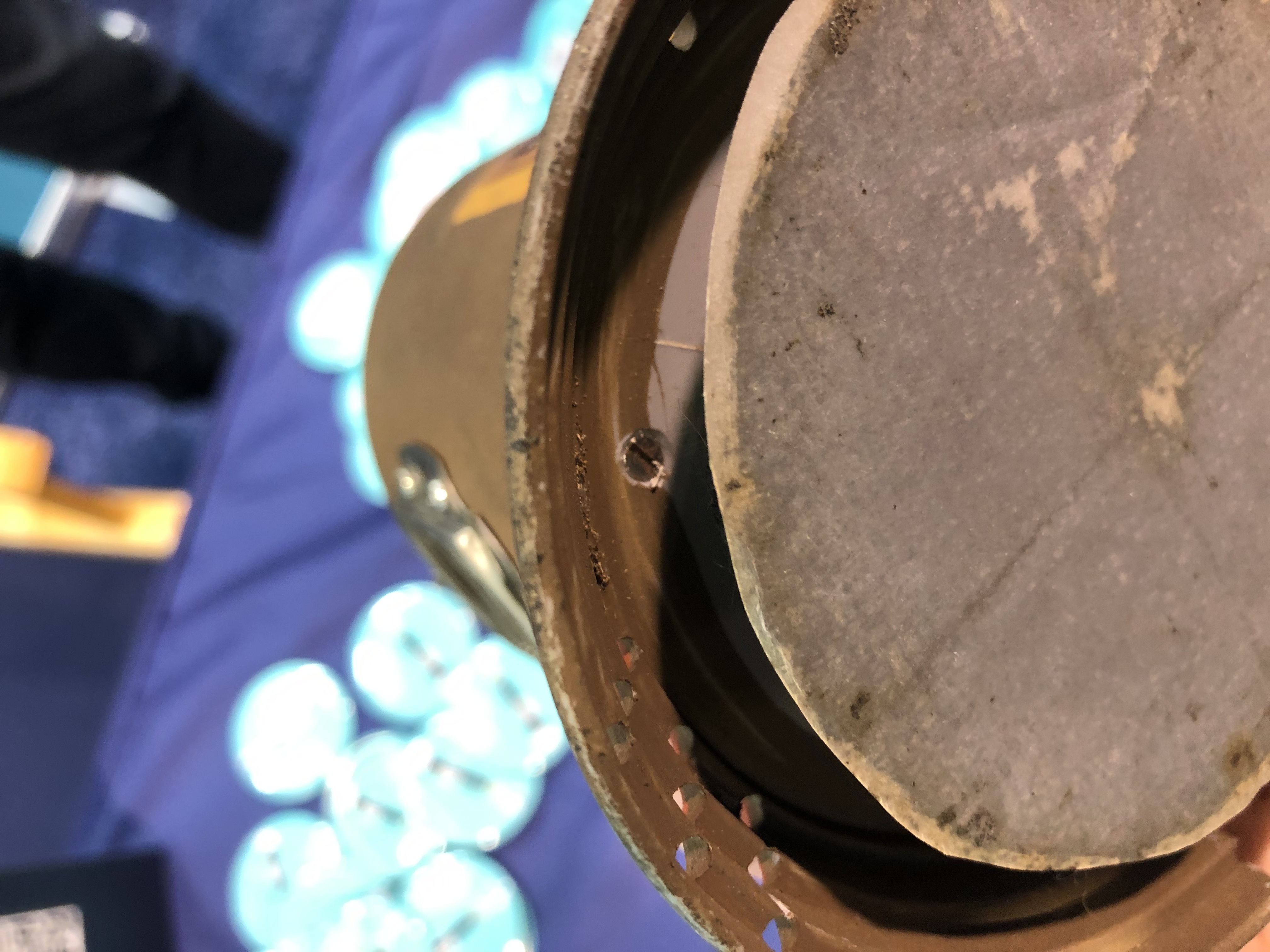

The Plastruct Sheets arrived and were what appeared to be a match. I cut the top disc (about 88.9mm) and the lower disc (about 76.3mm) and then sanded back the ledge of the inner cone to allow the lower disc to sit flush, making the total height of the cone around 19.6mm. Holes will drilled in the center of each disc to allow for an M4 screw to pass in order to lock the assembly together and here were the initial results… I was now convinced we were on the right path!!!

roygilsing took all this and created a cleaner model based on the real parts and then cross checked them against the overlays to confirm everything was a match!

4 screws, about 90 degrees apart, were added to the upper disc to allow it to screw into the bottom of the reduced Kango Body. While working through the finishing touches on the bottom, I began thinking about

roygilsing ’s description of the very top plate that holds the greeblies; “its covered in foil”. Well since 2 discs were already created for the bottom, it seemed very plausible that a 3rd was made for the top, so I did just this, added foil tape, and then drilled the required holes for the pot switch and LEDs. A side note on the LEDs, those were also upgraded after

kurtyboy reached out to me. I was informed that Camdonboss LEDs were used for both Vaders Belt and the Carbonite Panels… this seemed enough evidence to me to give them a try on the Bunker and I think the results are just perfect!

Hope this wasn’t too long and it helps other in their builds!